BeagleStamp

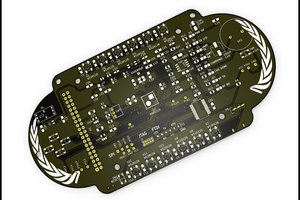

A pocketbeagle in stamp form, for direct SMT soldering to your board

A pocketbeagle in stamp form, for direct SMT soldering to your board

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

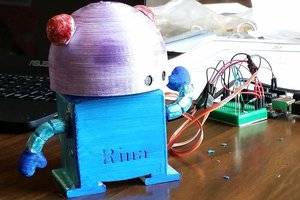

Yesterday I got the new boards in the mail - and they look good!

I actually got the castellations right this time:

Notably, it soldered much better than last time, as expected XD I'm pleased with how the bare PCBs turned out.

This project has been difficult to build. The BGA-packaged OSD3358s aren't cooperative, and they are difficult to obtain. The boards take a long time to fabricate. This is why my project logs are so far apart time-wise. I think the boards I have should work at this point, I don't know of any reason they wouldn't, other than being difficult for me to make at home. I don't have a proper reflow oven or solder stencils (but I'm probably going to get the latter).

If anyone knows of a good, cheap source of OSD3358, or a better way to disassemble pocketbeagles, let me know.

Yesterday I made a failed attempt at recovering an OSD3358 from a PocketBeagle. Whatever solder they use melts at the same temperature, or very near temperature to, the OSD3358's solder ball melting point, probably higher than 225C. The PocketBeagle fell, throwing the OSD3358 inside my oven... and ruining all of the solder balls on the bottom of the package.

I find that it's all too easy to ruin the package like this, this is the third one I've messed up, and they aren't cheap. The chip was already messed up, so I removed all the solder debris from the bottom and soldered it to my board anyway. It's not working yet, we'll see if I can make it work despite it's bad fate over the next several days. In any case, here's what it looks like on a board:

I should be ordering more of the OSD3358s. The reason I tried desoldering from the pocketbeagle is because, for some reason, the pocketbeagles are cheaper than the OSD3358 in USA. Perhaps it is different in China. If anyone knows of a good, cheap source of OSD3358, or a better way to disassemble pocketbeagles, let me know.

I've been trying to get a working stamp in the bits of free time I've had the past week. Although the design is goofed, I figured I could hack the connections to make the system work. I think that approach could work, but instead the soldering was the problem.

Progress (kindof?)

Soldering a 256-pin BGA with a syringe of solder paste and a toaster oven is very error prone. My theory is that, on my first attempt, I did not use enough solder paste on some of the power supply pins. Due to this, the 3.3v line sat at zero (which was my observation). For background, the OSD3358 has on-board regulators and power management. This obviously wasn't working, and since the SoC worked before, and there were no other obvious problems, I must assume one of the pins was not soldered.

The next logical step is to remove the OSD3358 and try again, and for that I needed a heat gun. Then we face a worse issue: the heat is not distributed evenly, so the fragile balls on the SoC melted (but only the ones on the edges). For reference, this is like the legs of a typical IC melting, so it is really bad. Most of the chip seemed salvadgeable, the melted pins weren't needed for my tests, but resoldering the SoC to the stamp did not fix the power supply problem.

Problems Discovered

I think it wasn't for nothing though, I discovered some more problems in the board design, namely that the 5v USB input pin is not connected to any external pin (I had corrected this in my tests), and that the pinout has conflicts. Of course, there is also the issue mentioned in the previous log file.

Planning a Board Rev, and Other Necessities of this Project

I could try making it work again with a new SoC chip, but I don't think it's worth it. There's too high a likelyhood of more things going wrong, and I've identified things I can fix for the next board rev. This design is difficult to get working due to the mentioned issues, it would be a waste of my time to keep trying with the current design.

I will need better and easier ways to test these stamps soon. I'll probably need some sort of test setup to verify these things work, and I also want to make some cool projects with them.

One project I'm thinking of starting is making a digital notebook with wikipedia downloaded, and an EPaper display + pen. Perhaps I'll add other utilities like a GPS and compass. Although things like this exist, I think it would be a nice project, a good way to exercise the BeagleStamp, and it's always nice to have full control of the source code on your devices anyway.

Let me know your thoughts. Advice for making a test aparatus? Ideas for this proposed notebook/tablet project? Advice for soldering BGA packages?

The finished product (so far) looks about as nice as I had hoped!

Now, when I got the boards, I immediately noticed a serious problem. Most of the pins are not plated. See here:

I decided to assemble a board anyway though. I can desolder the components later (The components used here are already desoldered from another board I made XD). I can also correct for the lack of copper manually for now, just to test the boards to know I don't have any other design issues.

I tried to solder wires to these pins, but without metal on the sides, he wires easily pulled up the pads. I'll have a board to test with soon though, so I'm going to wait for that, then I can see if I have any other design flaws.

I expect to make a board rev in the coming week or two.

I can't believe I actually made this a 1in x 1in board. I thought it would have to be bigger.

I've tried to make a beagle in a CM3 form factor before, so I basically copied my design from that, which I had originally based on the PocketBeagle design as a template.

The components are *very* closely packed on this board:

This is the first time I've tried to make a "stamp", hopefully it goes well! If it does it will be much easier to put Linux into my electronics projects.

I left some pins on this board unused so that I can add functionality later if I need it, without changing the layout. I should have my boards in about 2 weeks, so this project will be silent until then.

Create an account to leave a comment. Already have an account? Log In.

that a neat SiP however what about prices \ availability of it? Looked a few distributors and it is sad

by any chance if you figure it out maybe you have tindie store to sell stamps when ready?

This is great! I think this would be perfect for a project that I've been brewing up in my head for quite a while. My electric bike is great but has zero cool features outside cruise control, this would be perfect for controlling a homemade turn signal/taillight setup, and may be exactly what I need to rig up a homebrew "find my bike" system too! How can I get my hands on one of these?

So, you could make one. I have the repository link up if you want the design files. If I'm able to make them though and enough people are interested I could sell them on Tindie.

I'm pretty sure I could make these, but it is yet to be seen what the interest is in the community. I also plan on building a tablet for myself using this, and who knows what else!

I've got several ideas as well, but my undetectable bike security system is the one that I can't stop thinking about. Now to decide whether it's like location services security or booby trap security, though I'm pretty sure I cannot do the latter.. I'd definitely love to buy a unit or two if any become available for sale!

Thieves deserve no mercy. Well, I'm glad to have some interest especially so early, I'll keep you posted!

Very cool. Looking forward to seeing your progress :)

Thank you very much! I hope to have some news on if the circuit itself works next week - really hoping it goes well :fingerscrossed:

Become a member to follow this project and never miss any updates

Chris

Chris

Edward Li

Edward Li

John Adams

John Adams

Jackson Keating

Jackson Keating

Nice project! How many layers in the PCB?