[18:55] NOOOOOOOOO!!!

Guh! Of course at 6-7pm I think of a new solution that has more of the benefits and less of the drawbacks.

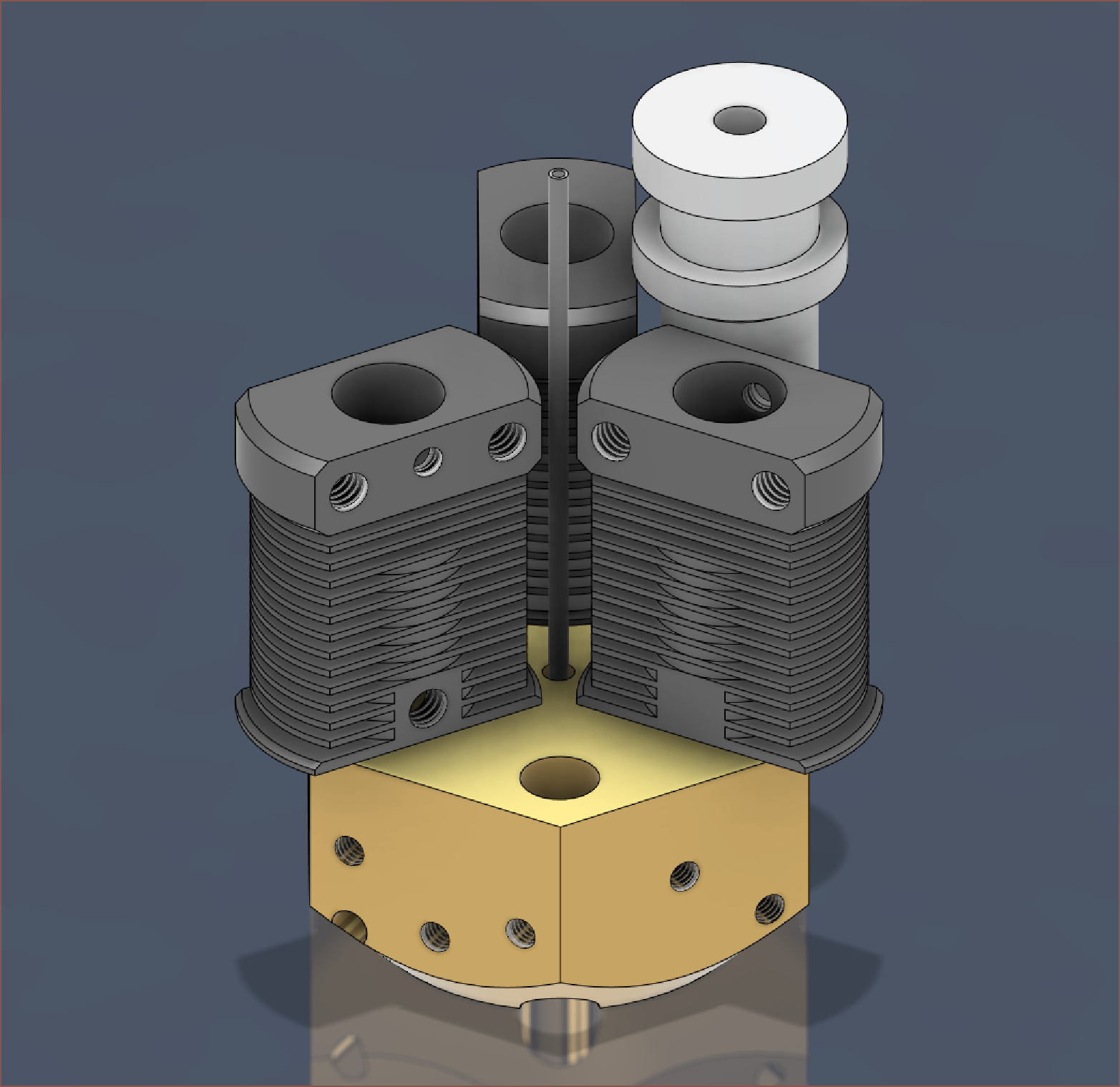

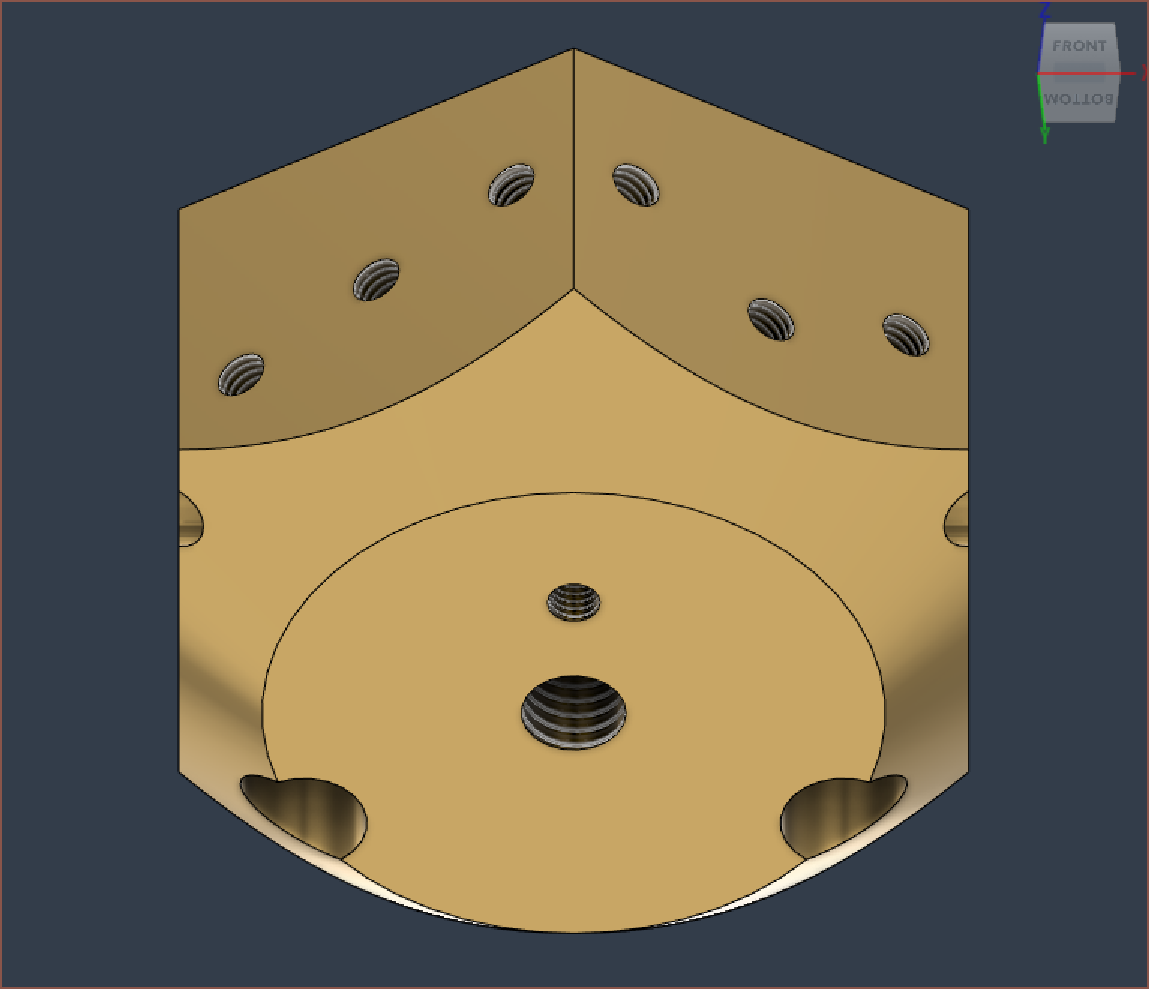

I was looking at AMTEx, thinking how overhangs like the above are pure hacks, and writing about how I'd need to swap out the middle heatsink if I wanted to switch between WCMY printing, tube printing or continuous fiber/wire printing.

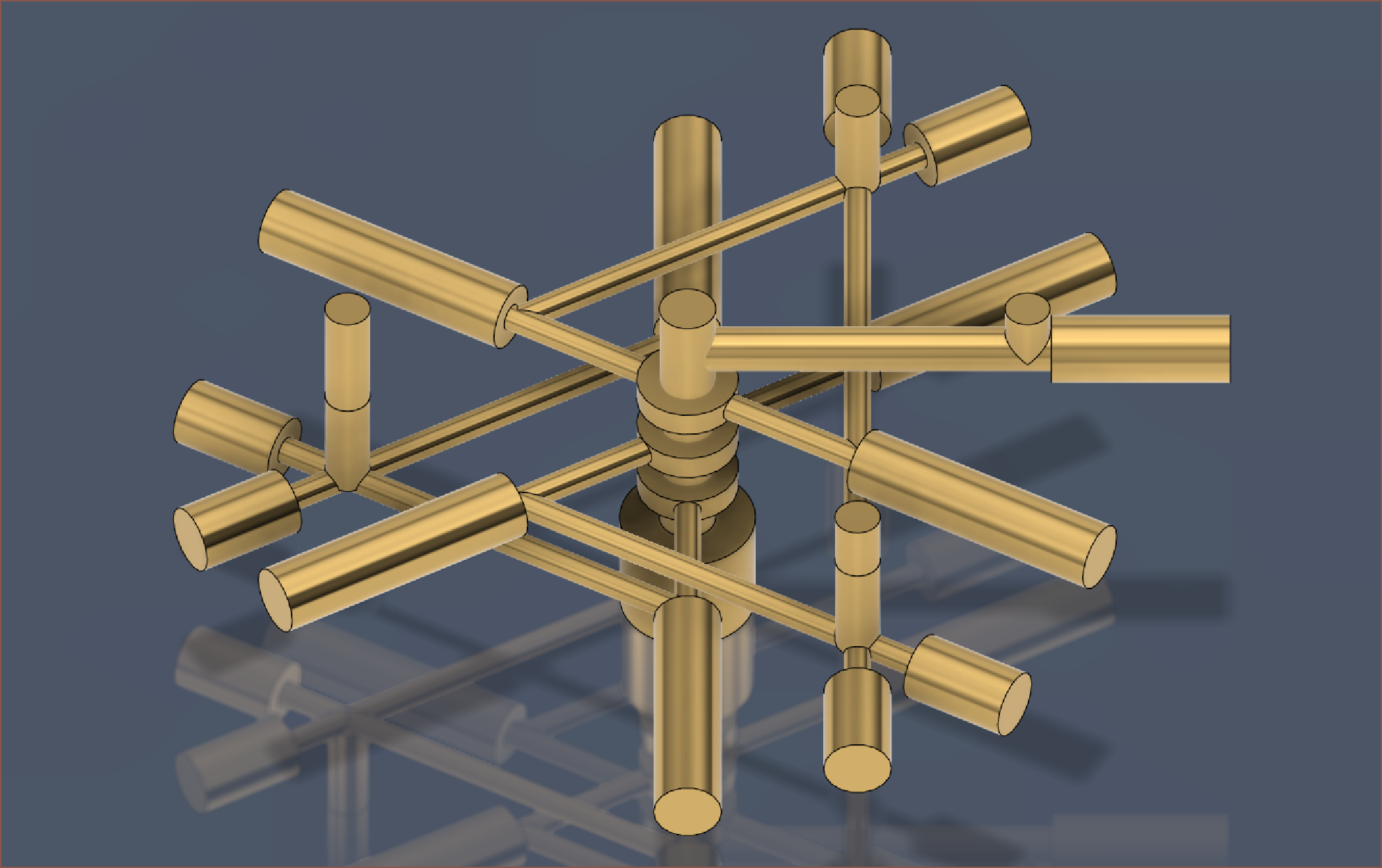

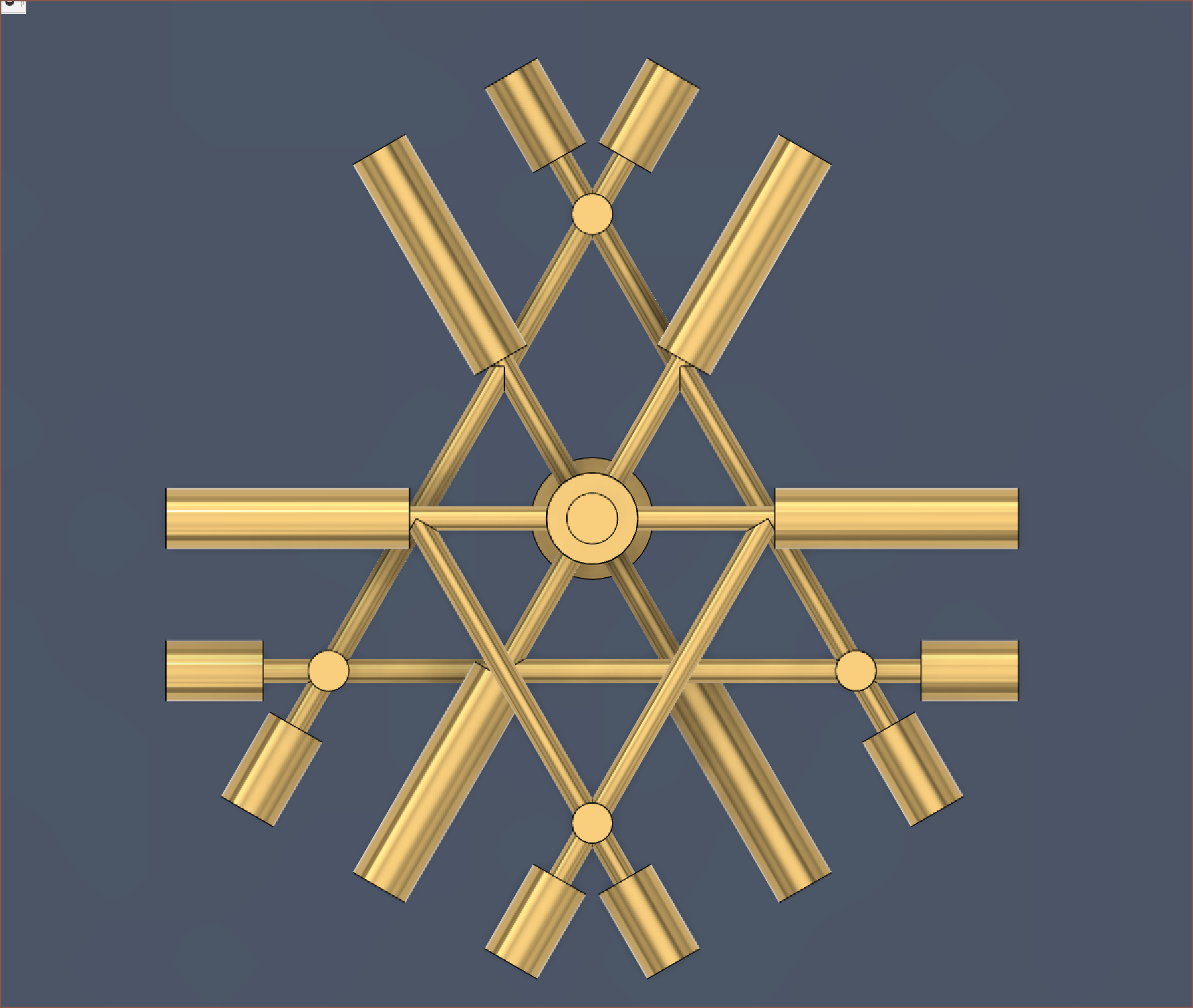

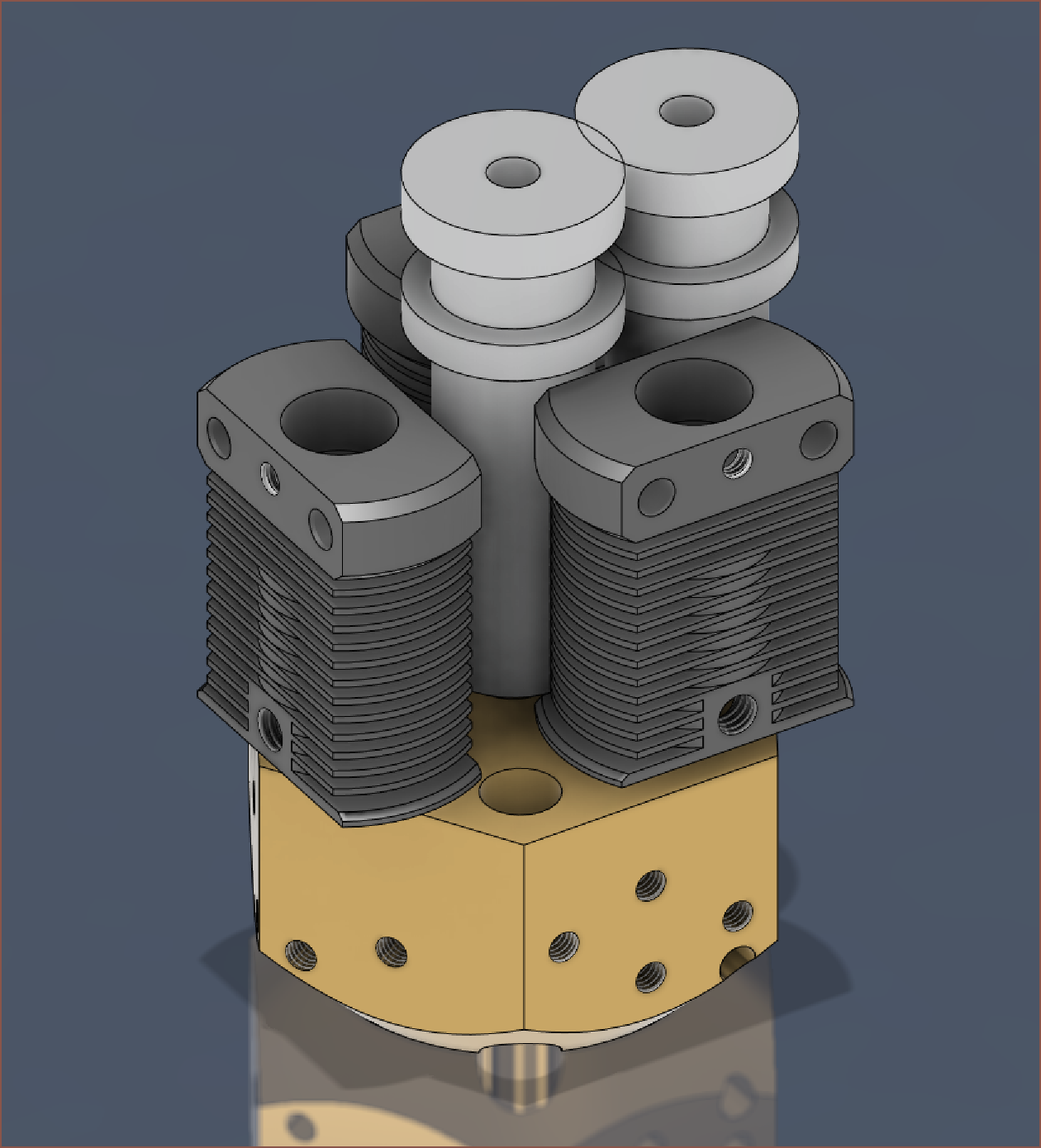

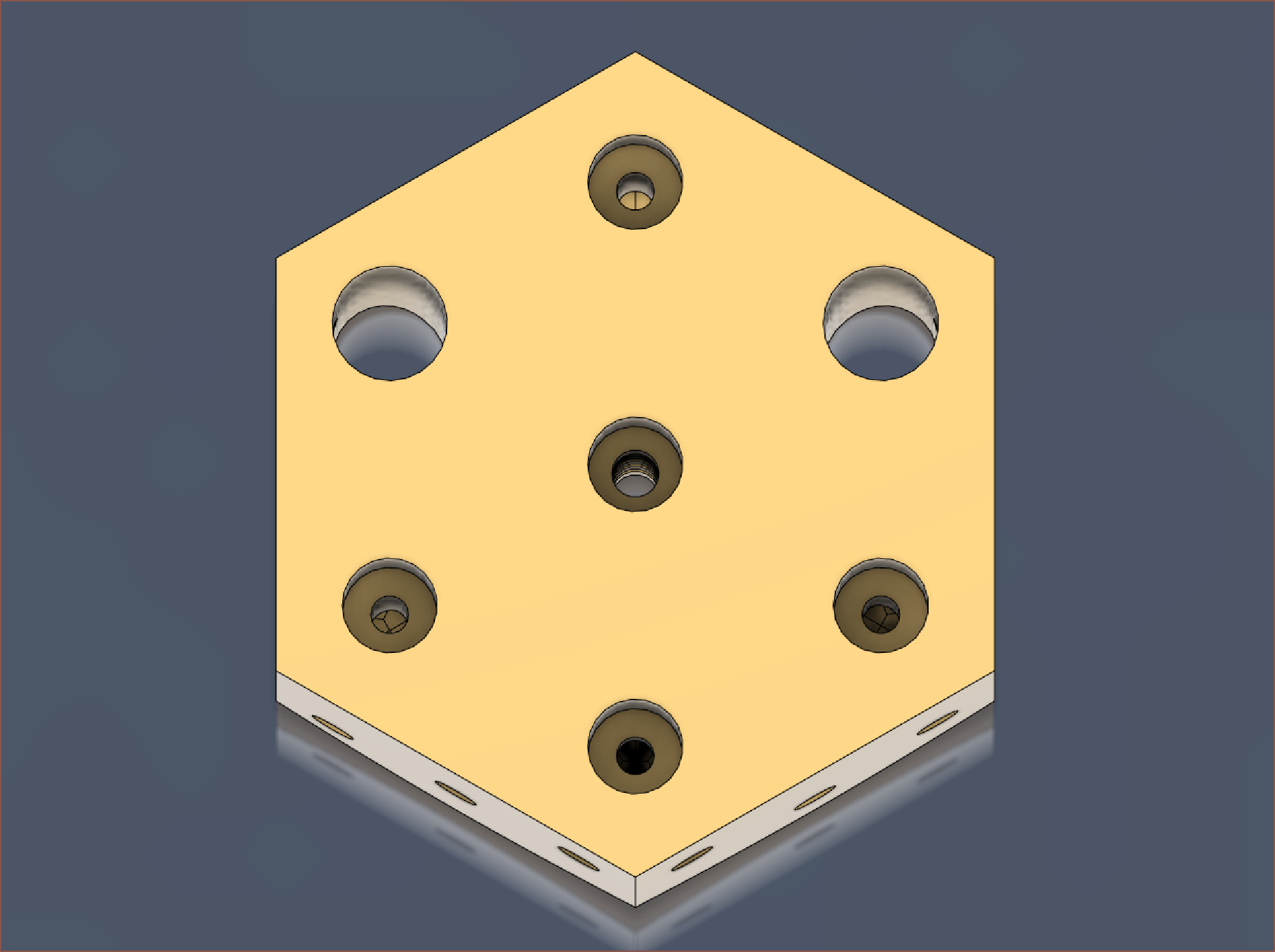

A Pimaxian voice was like "why not all?". Not all features will be active at the same time, but it might've been possible to support them with the design concept above and a nozzle change. This would be the internal path:

I might have to use an M4 grub screw for the main inlet though. And I don't like the idea of starting a hole on an edge.

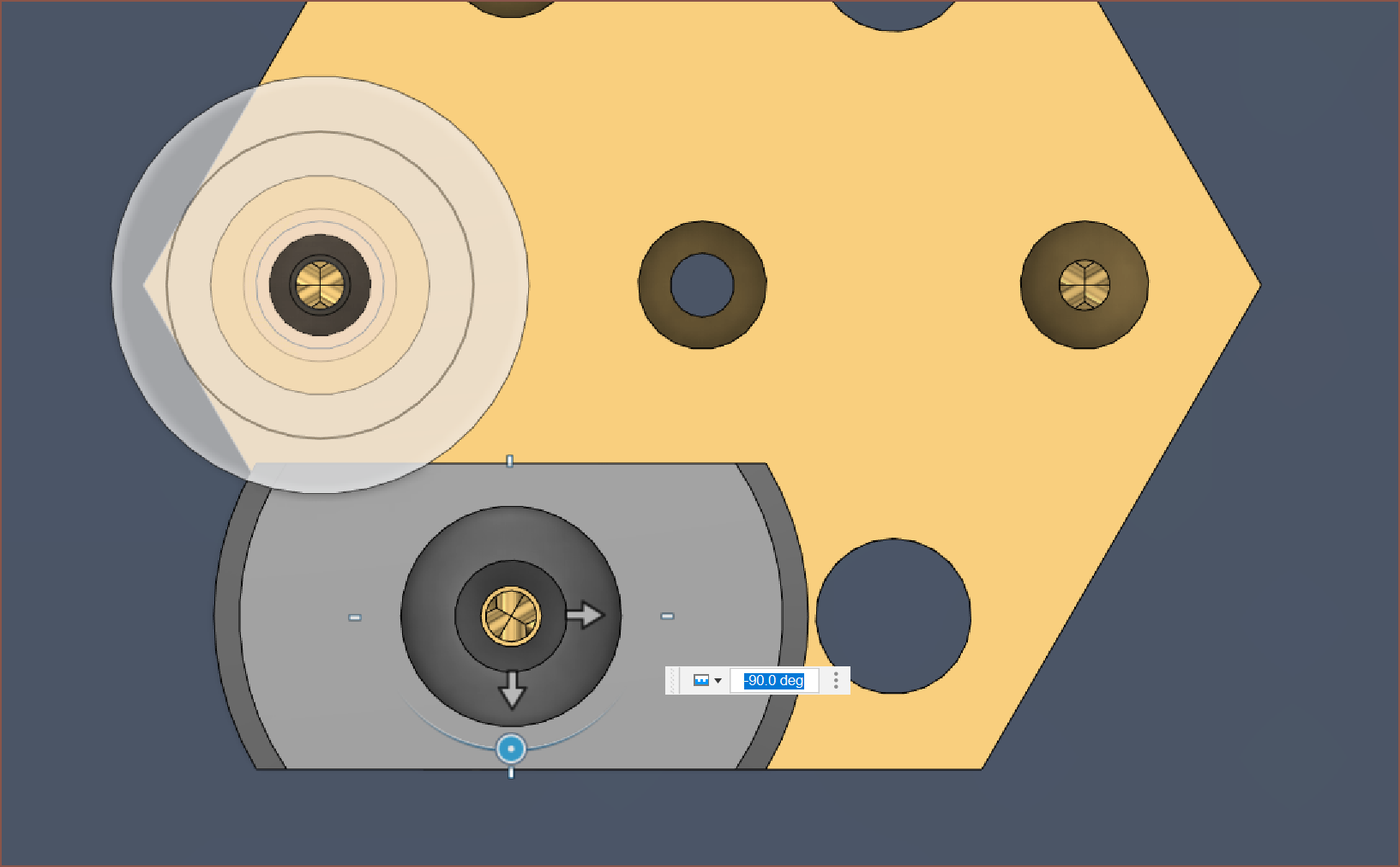

Wait... is it me or am I seeing 0 conflictions with using the same path for all 4 materials?

I thought something would conflict... you're saying nothing conflicts?

Auuuhhhhh I could've had WCMY-KAYYYYY, heatsink no objeeeeeeect!! And it's only 2.3mm longer, weighing in at 208g!!

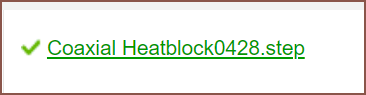

Nouh... and I've already finished designing the entire thing, and fixed some issues in the file. For example, the below camera angle is actually on a main axis instead of some strange 60 degree offshoot.

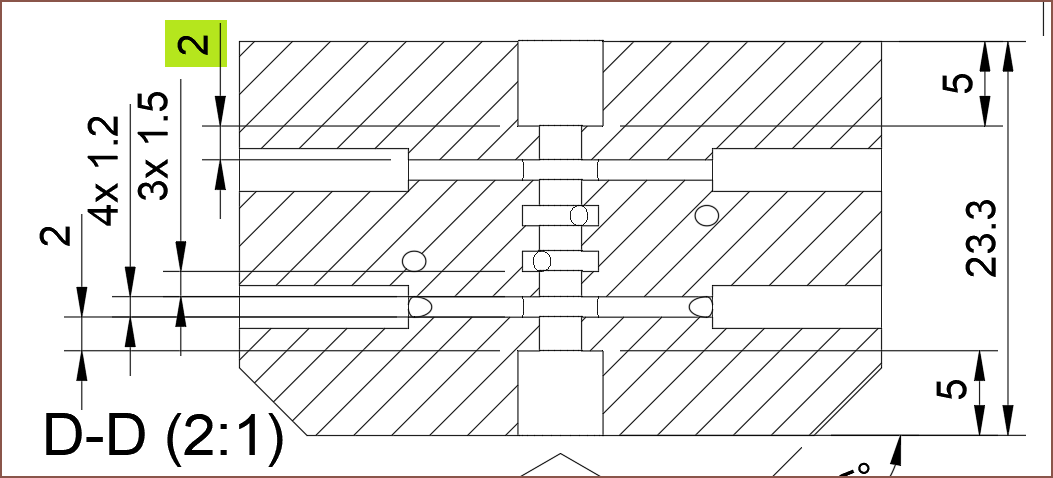

Another thing is changing the highlighed value from 2.4mm to 2mm (so the first version could've been 20.6mm instead of 21mm):

The autoquote is $47.21 so the acutal could be $70.82.

But ah... at least I can feel good that there doesn't exist a heatsink solution to actually take advantage of all 5 inputs at once.

Me, 3 minutes later: Slides Lerge under NF-Smart

Ah.

Well, imagine what could've been:

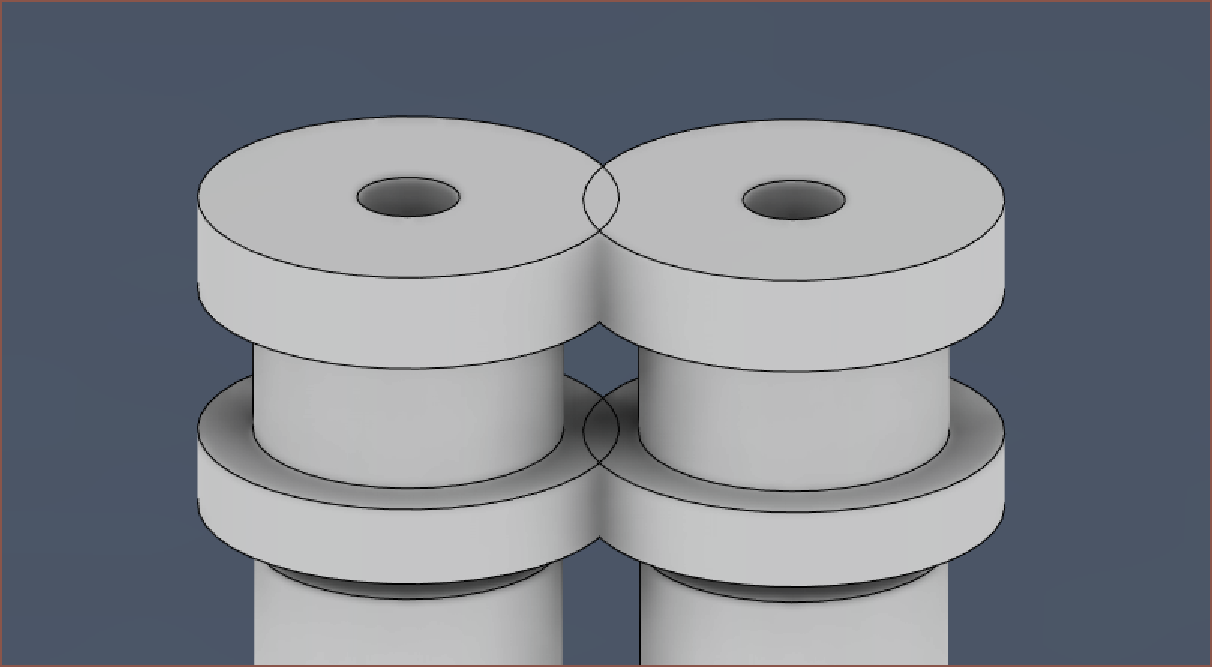

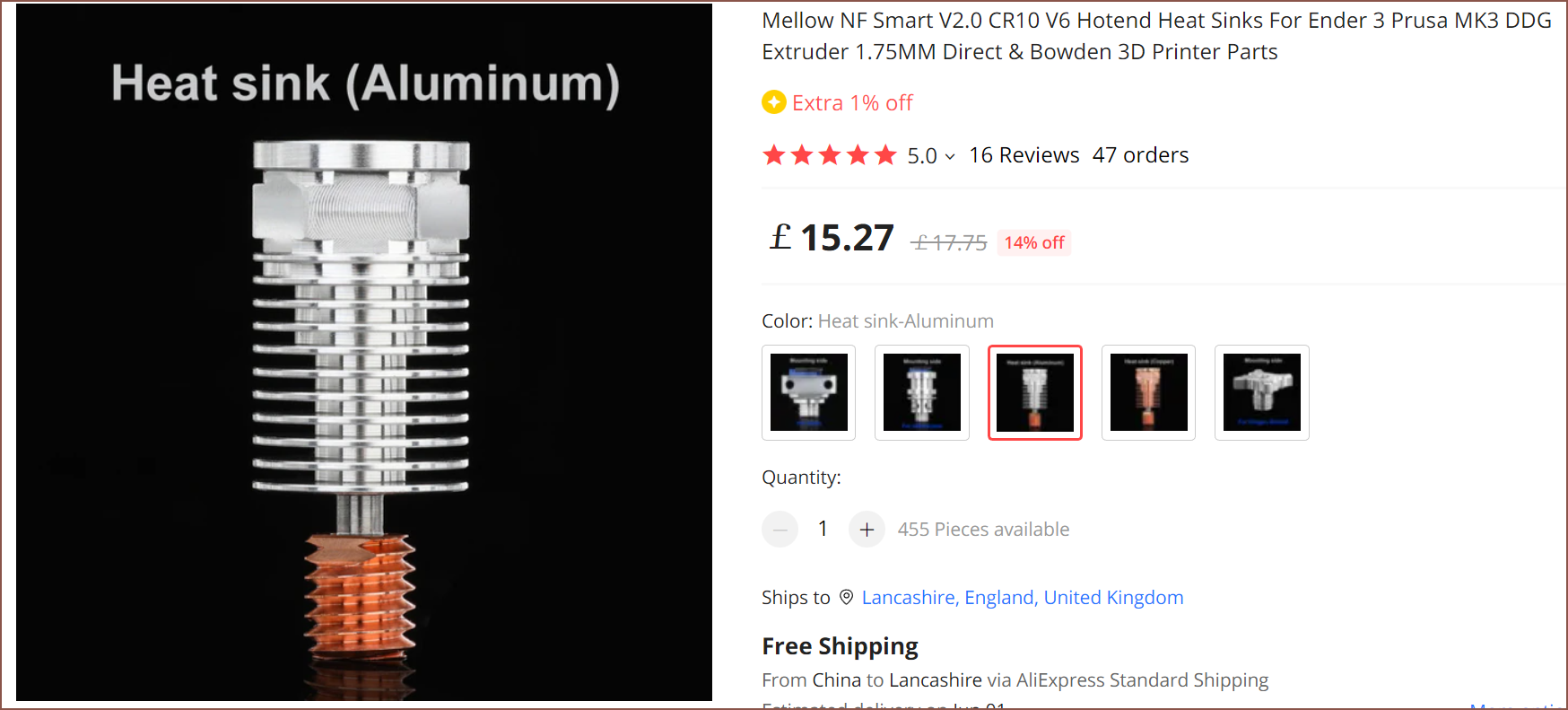

Though, with the NF-Smart V2.0, that costs the same as the first version but is shorter and 12mm diameter, it could become a reality:

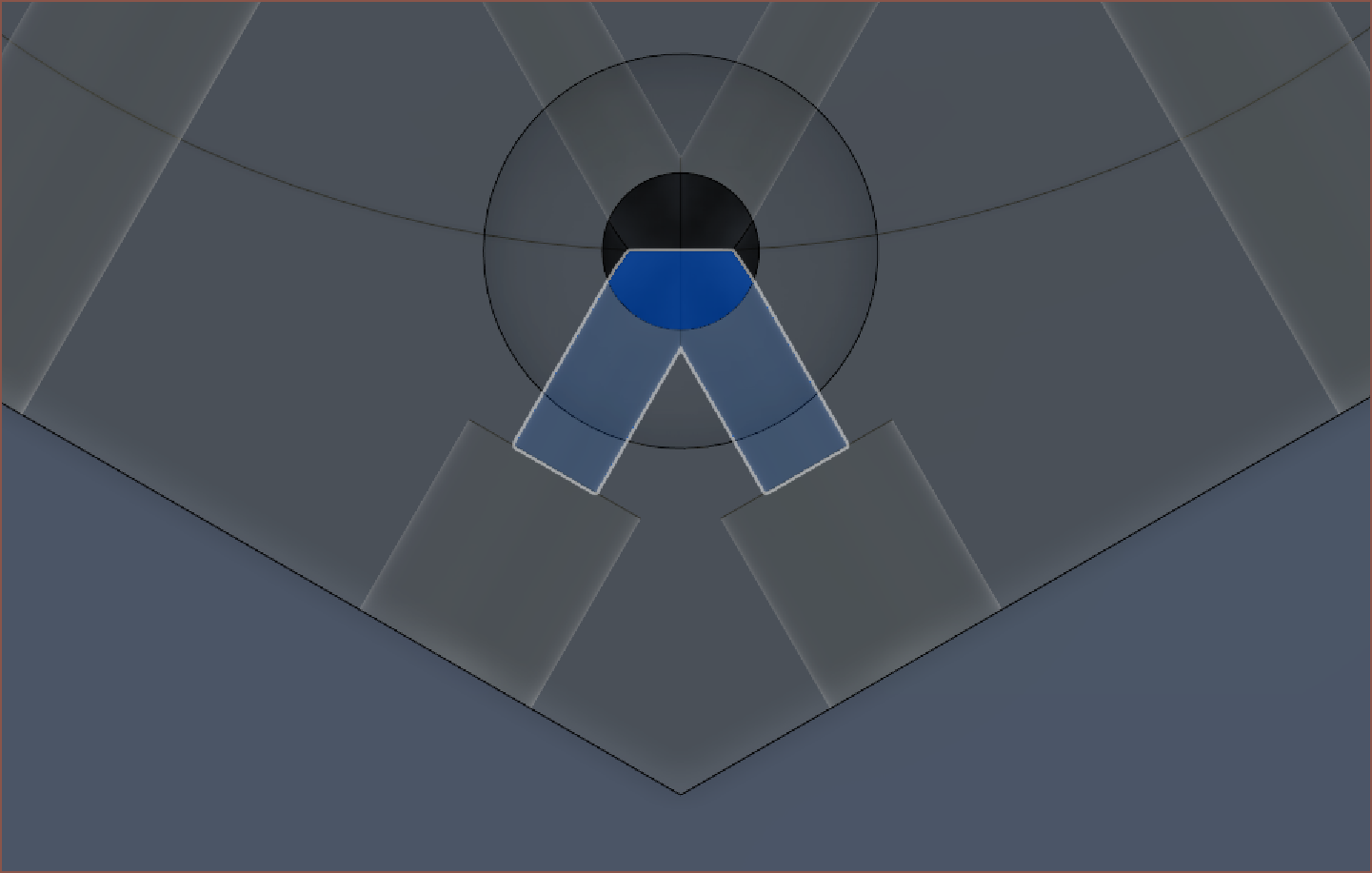

Unfortunately, the thread used is M8. If it was M6 or M10, a bowden coupler could've been connected right to it. It'll be a bit more design work, but one could print something that holds the same couplers as the LERDGE heatsinks (that's what those large holes on the top of them are for):

Ok, can I hit the brakes?

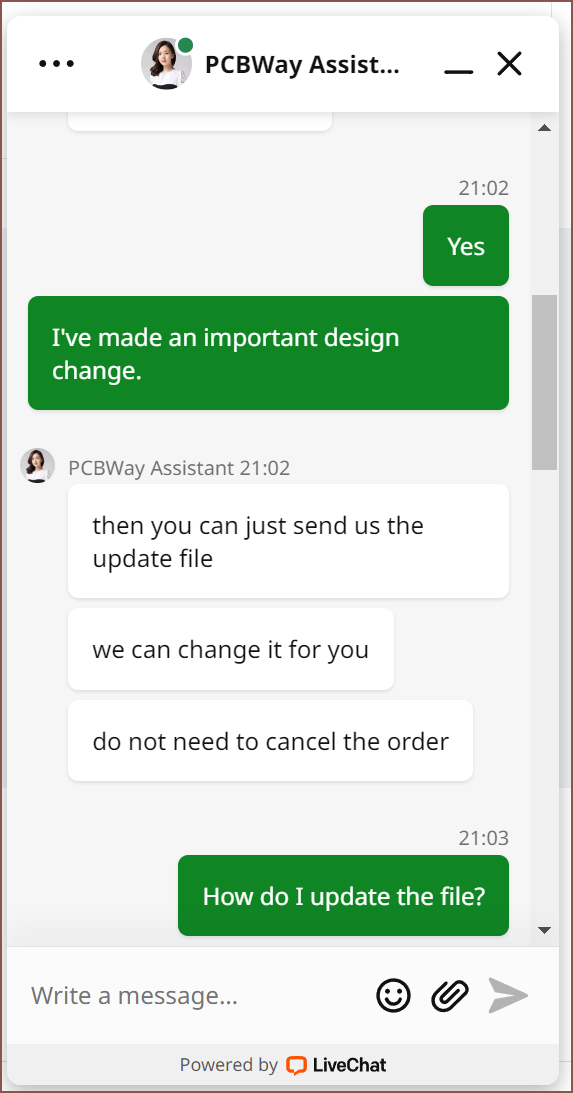

NOH WAY!!! PCBWAY HAS LIVE CHAT AT THIS TIME O' NIGHT! AND SHE SAYS I CAN SAVE THIS RUN!

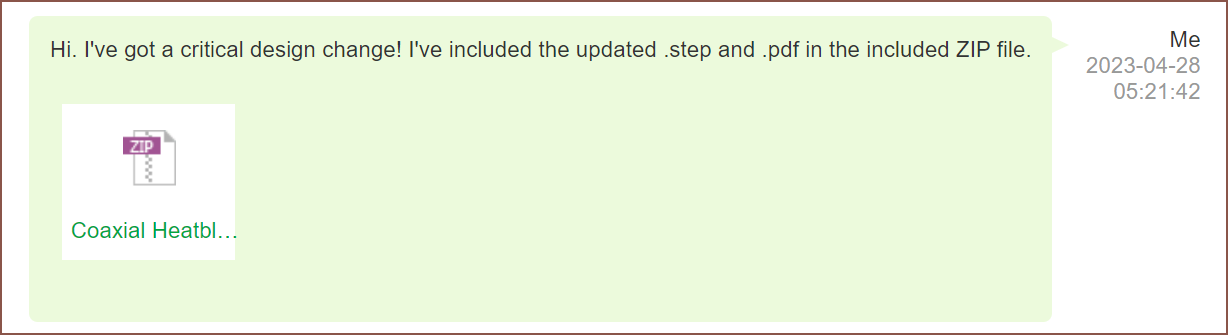

[22:20] Ok... I didn't think so much time had passed but to me it felt like I was running after a train that had started to leave the station. I've got the new design all drawn up and files sent off to my service representative (as per Live Chat instructions).

I'll likely stay up until 3am to make sure this change goes though (essentially, all my designs have been reviewed between the times 02:25 and 03:00).

[April 28, 03:55]

The order's file name... it's different. And I can download it.

Wohoooooo!!! I haven't heard anything tho... do I not have to pay the assumed $4 difference?

In other news, I've got to start looking for some purge material. The hope / idea is that I can send purge material throughout the block so that it fills all the small voids where material is otherwise likely to get stuck.

Oh, found some:

This has a working temperature of 160 - 300C.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.