When we were creating hRobot we had to face a lot of problems from many different reasons. Now I want to tell about some.

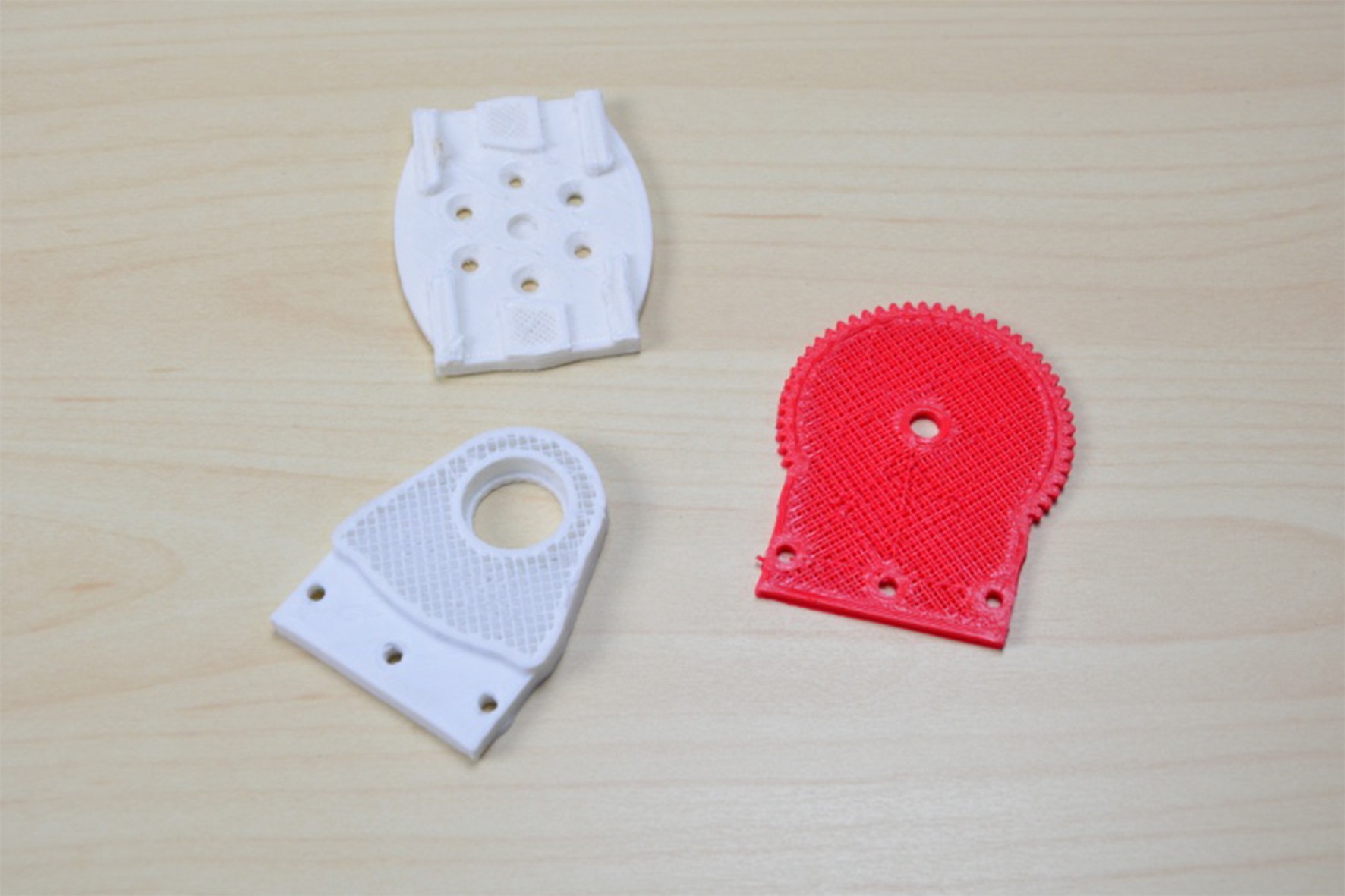

#1. Problems with 3D printer.

If you think about making a big 3D printable project, you have to be sure your device is suitable for it. For example cases with stopped print or problems with extruding filament are completely normal for bad printer. Sometimes it’s better to invest more money in your equipment then wasting your time on repairing old one.

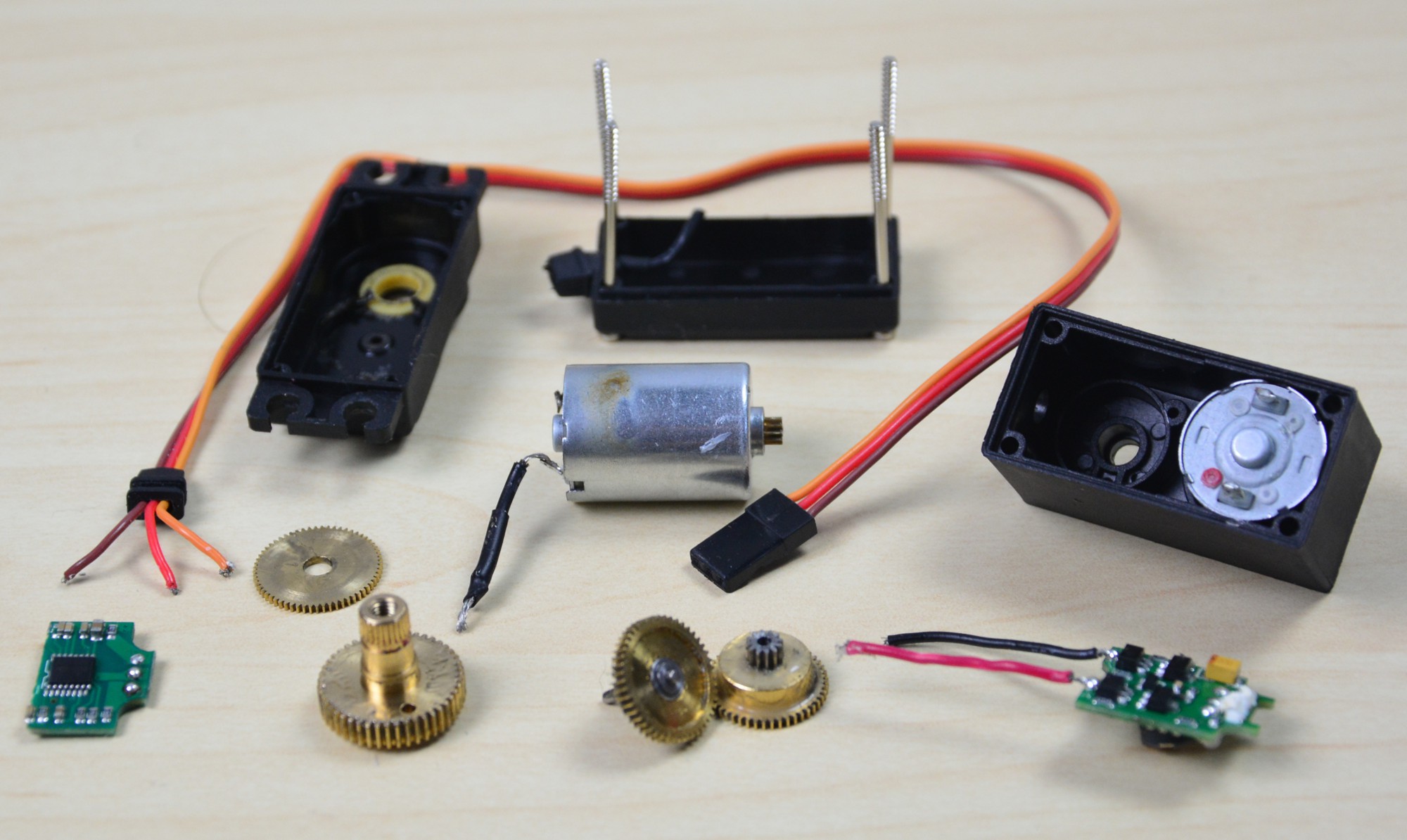

#2. Burned servos and DC motors.

Errors in code, overheating, improper connection - all of it can result in damage of motors. Sometimes it’s not even our fault, it can be just a factory defect, so if you order that things, think about some spare pieces in advance!

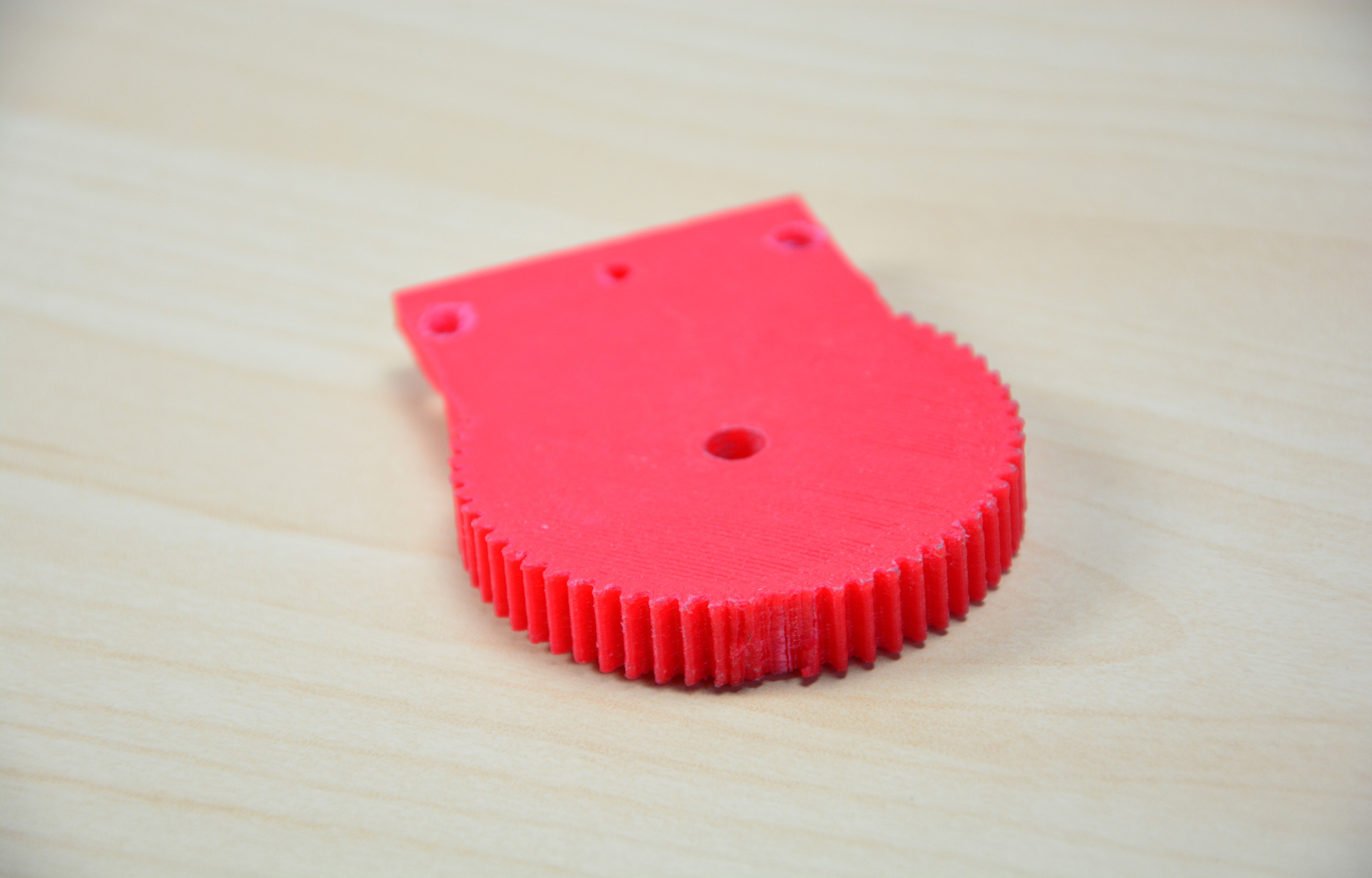

#3. Wrong strength calculations.

When you printing some parts of your robot, not always piece which looks exactly like other one have the same strength properties. Difference can come from another printer settings, time of cooling and few other factors. So you have to adopt bigger margin of error then you used during strength calculation. In other way part can be badly damage.

As you can see creating robot can be little a bit difficult, but it’s really worth all of this efforts and brings so much fun!!!

Next log soon...

Hubert

Hubert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.