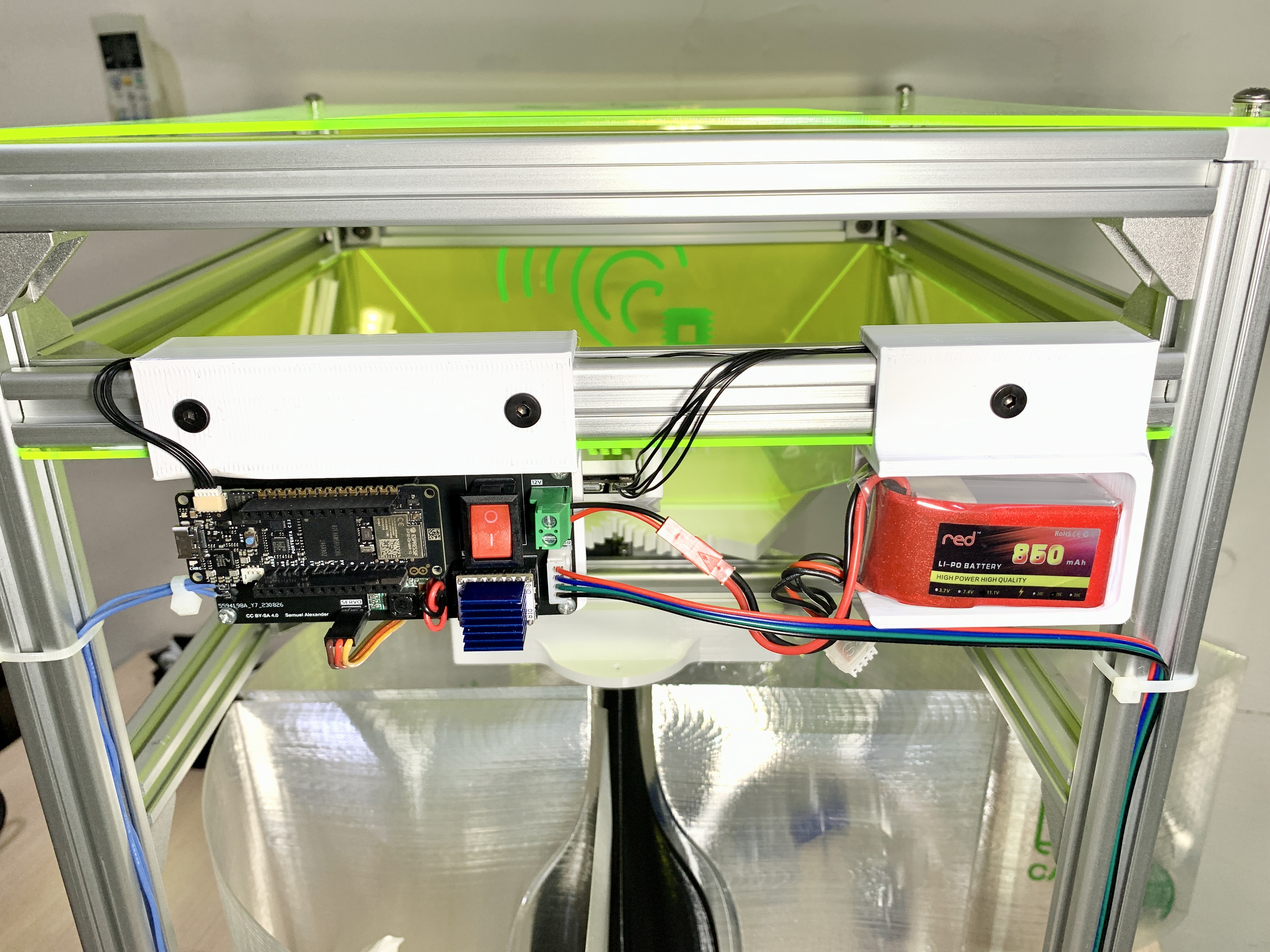

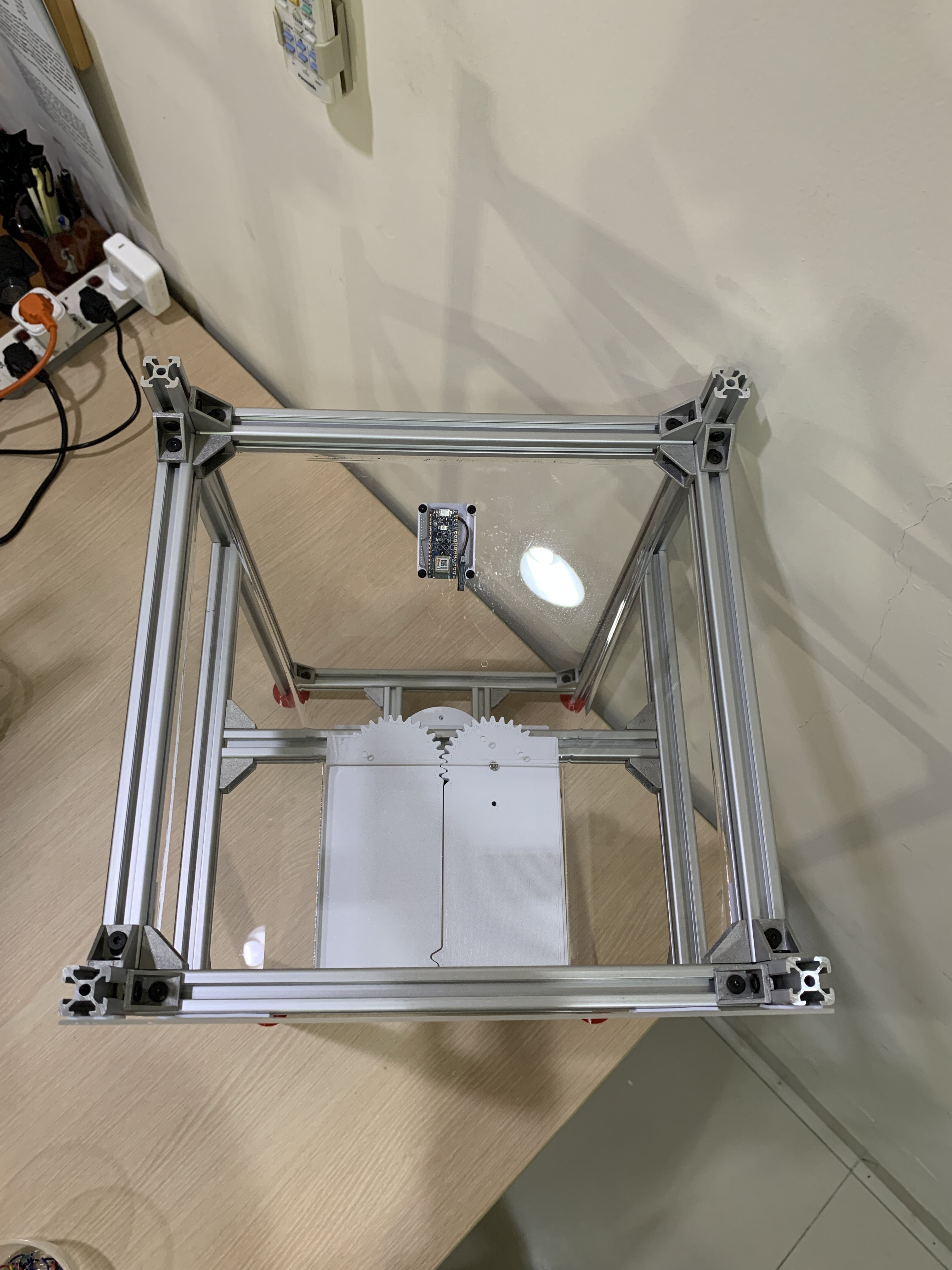

Welcome to the AI Audio Classifier Recycle Bin Hackaday project page. All the parts necessary for this build are detailed in the "Components" section. This project is made to be reproducible, by following the "Instructions" section you should be able to build one for yourself. The Code, Gerber files, STL files, editable, PCB schematic and design are all provided in the "Files" section. All the resources in this project are fully open source so you are free to use it or modify it. I've also added some tips, hardware upgrade options, testing videos, and a case study discussion in the "Logs" section so you can learn more about this project.

Contest Entry Video

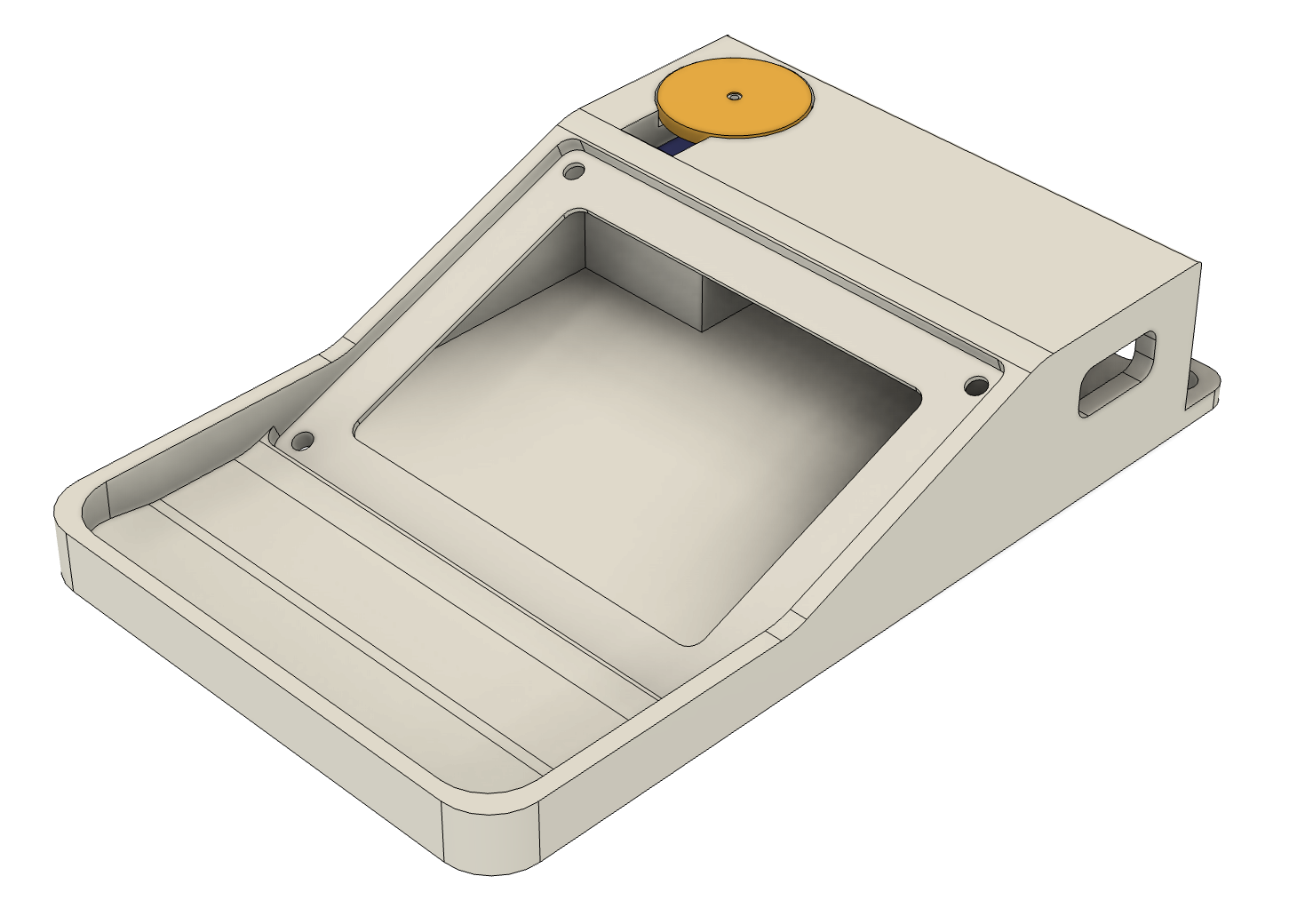

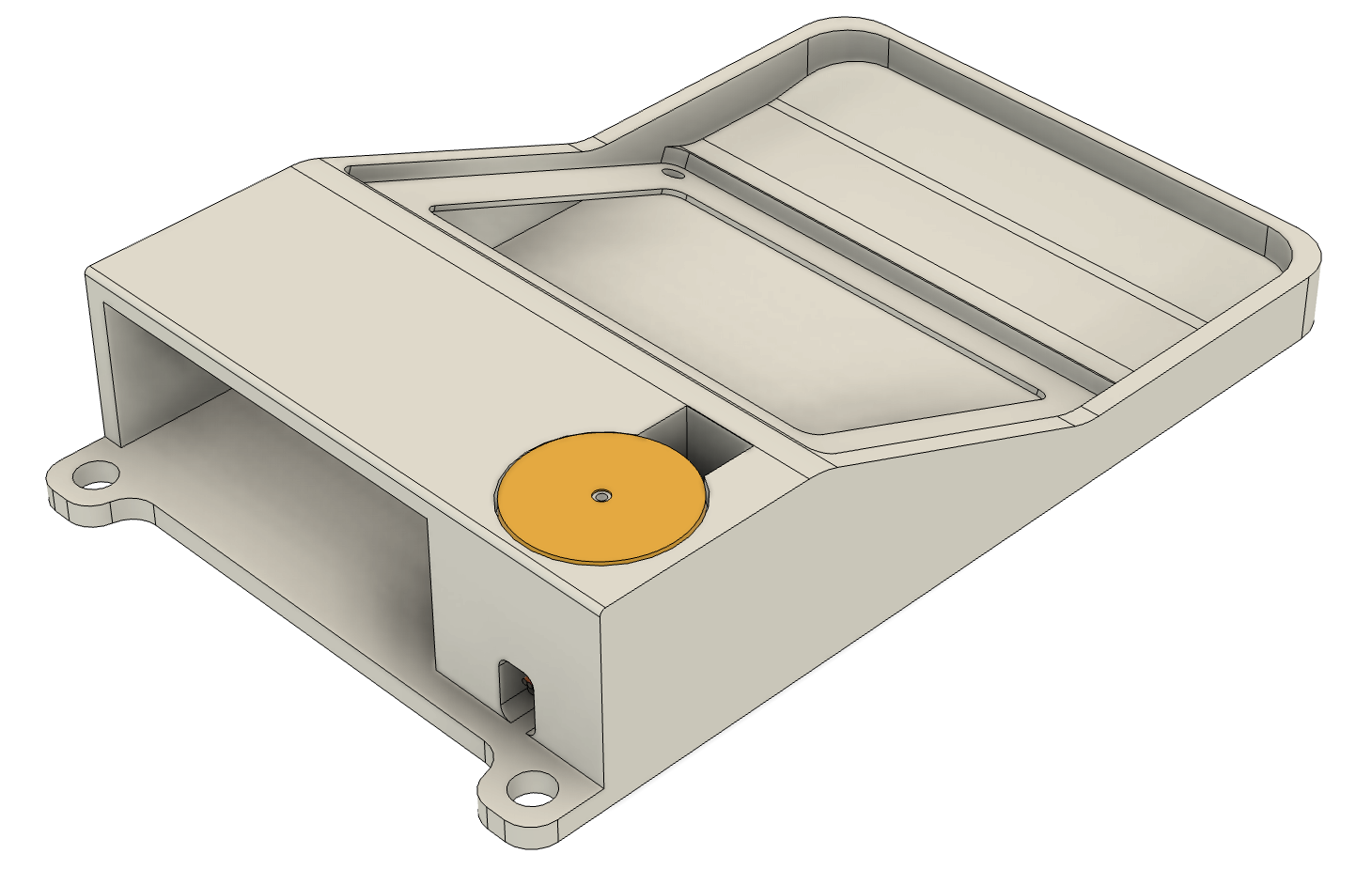

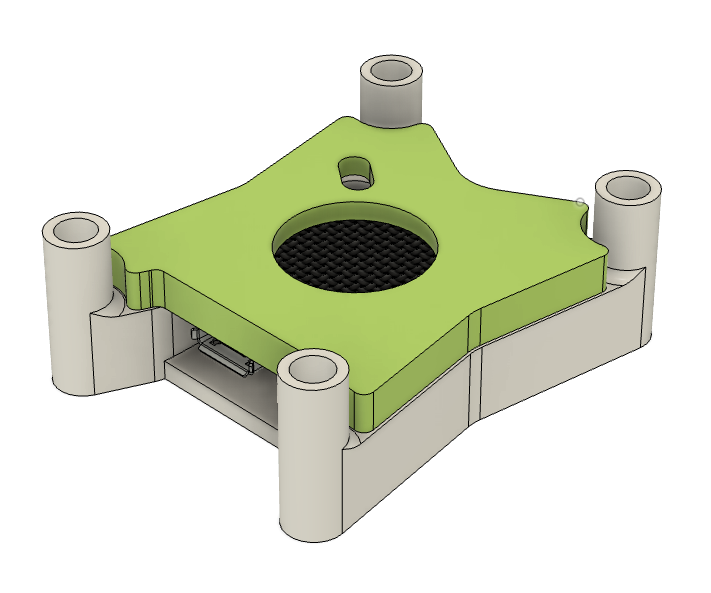

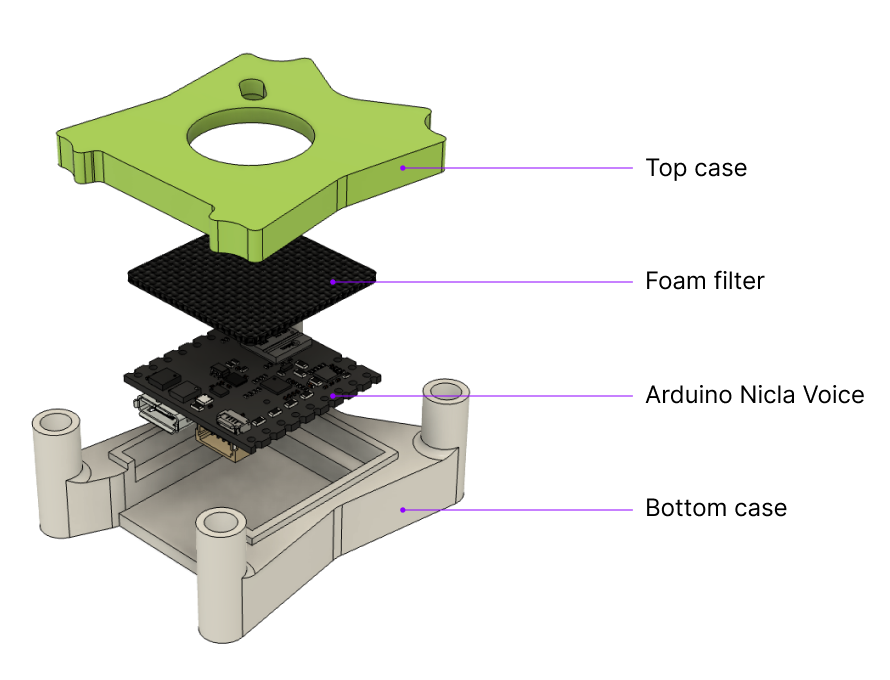

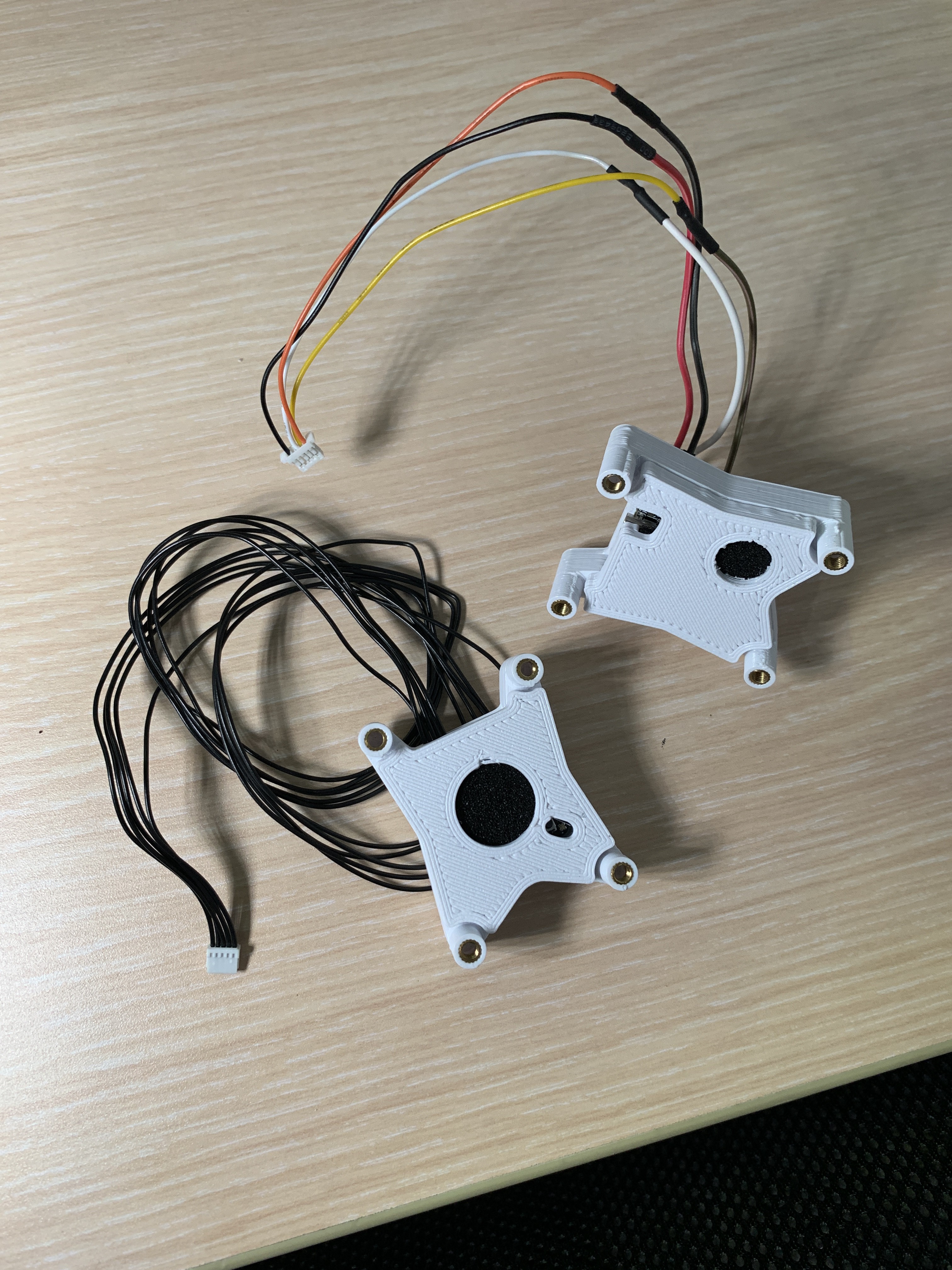

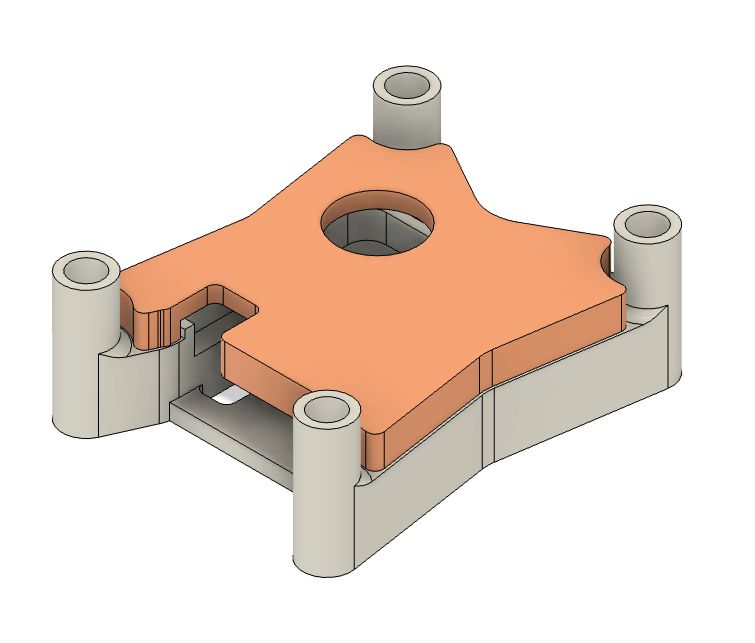

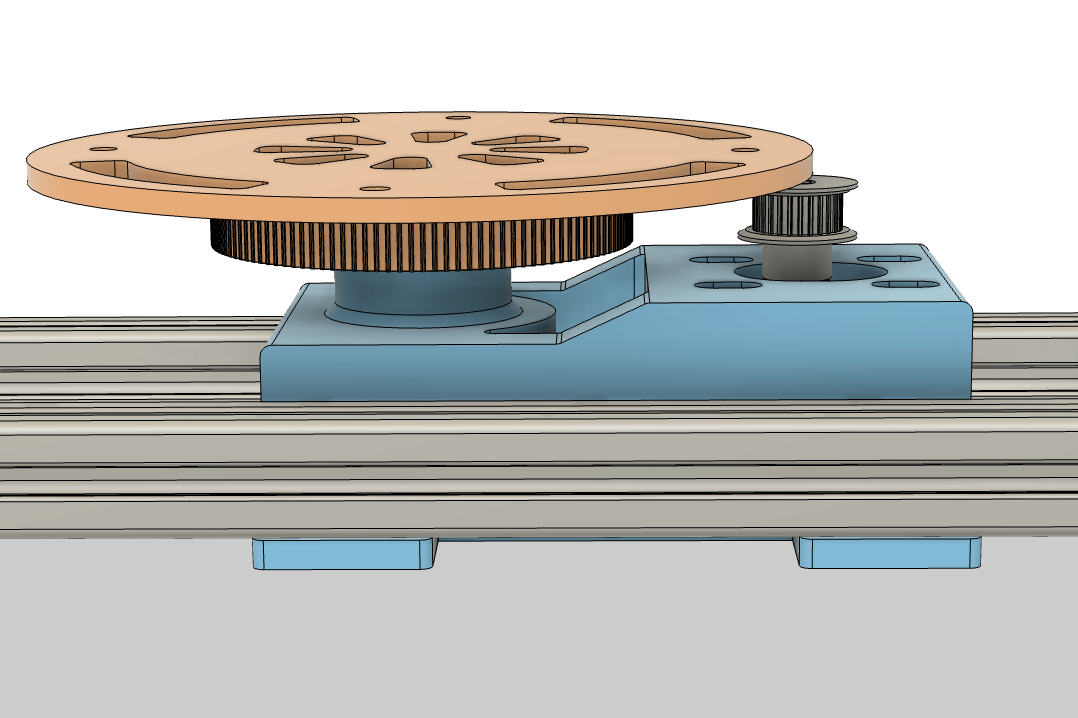

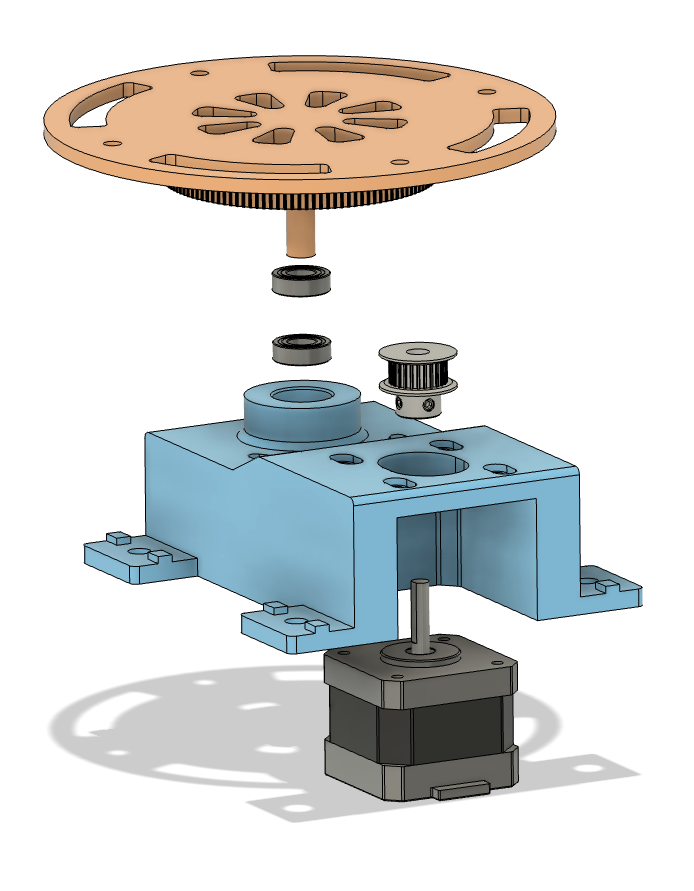

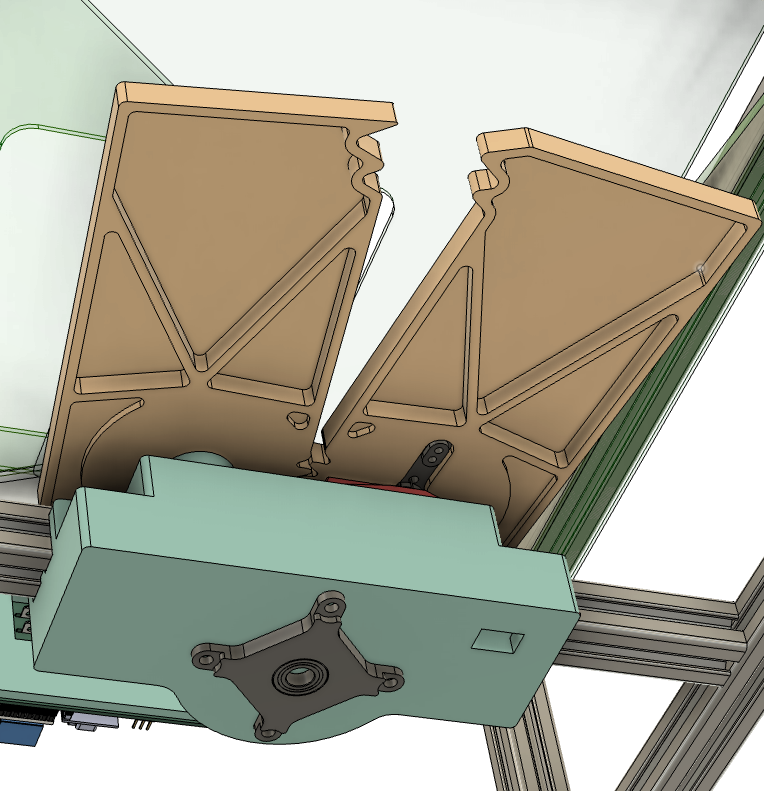

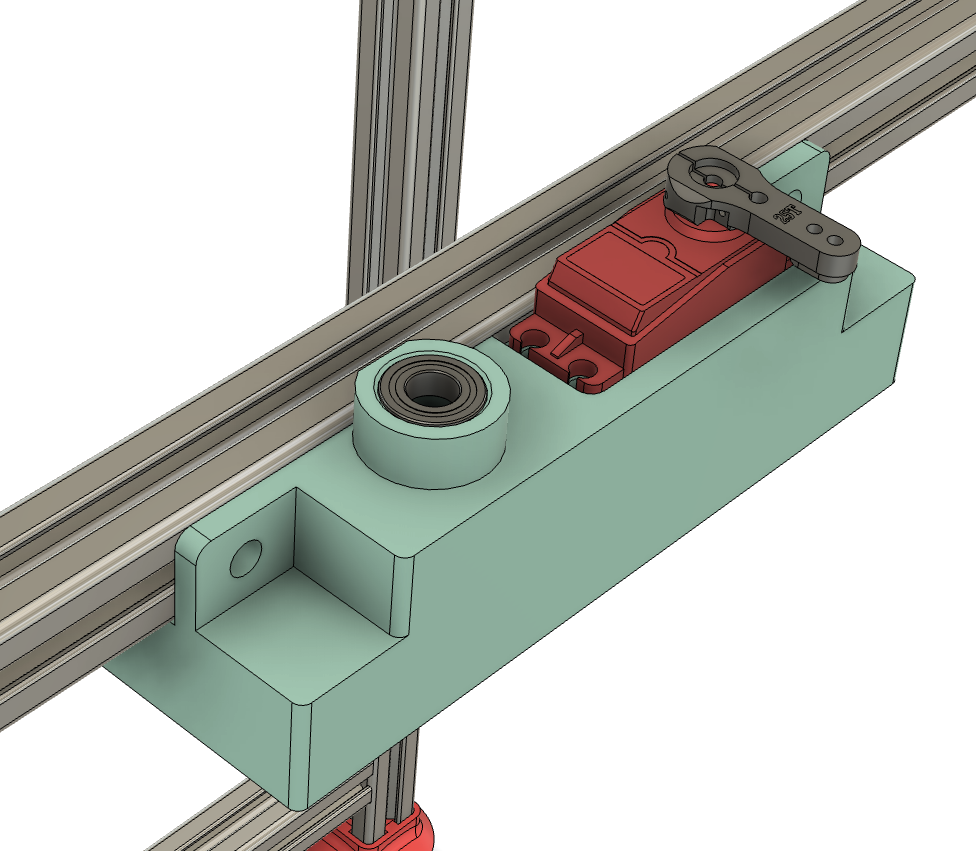

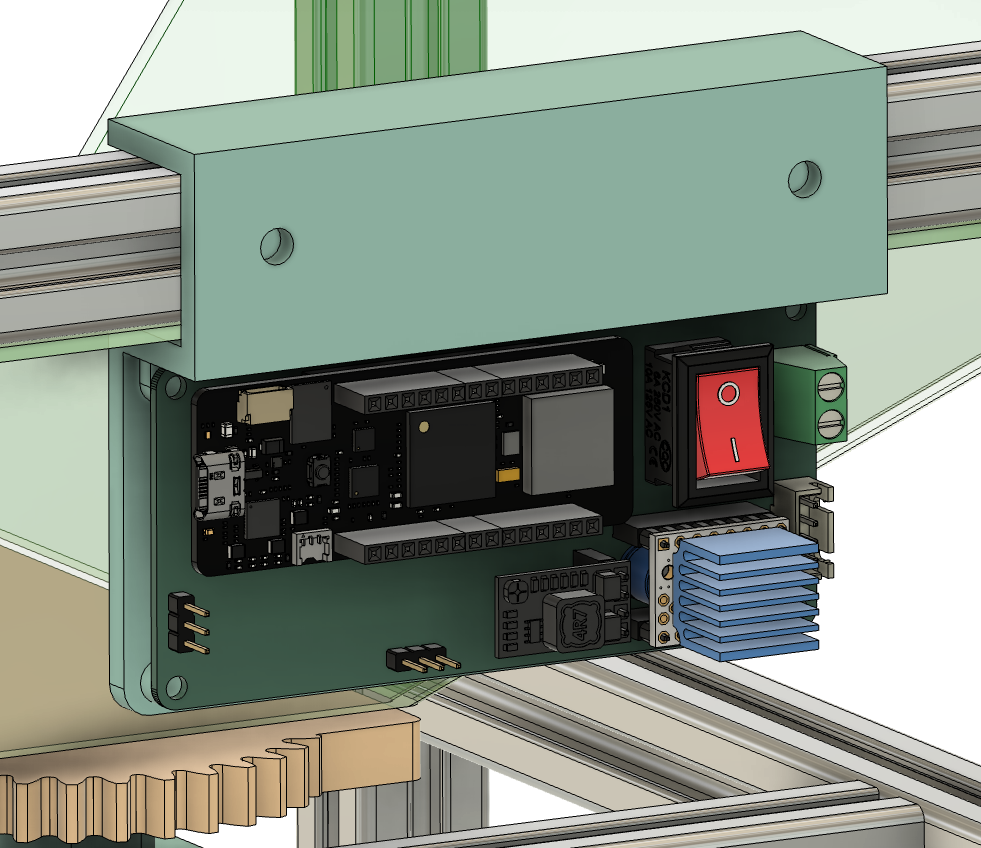

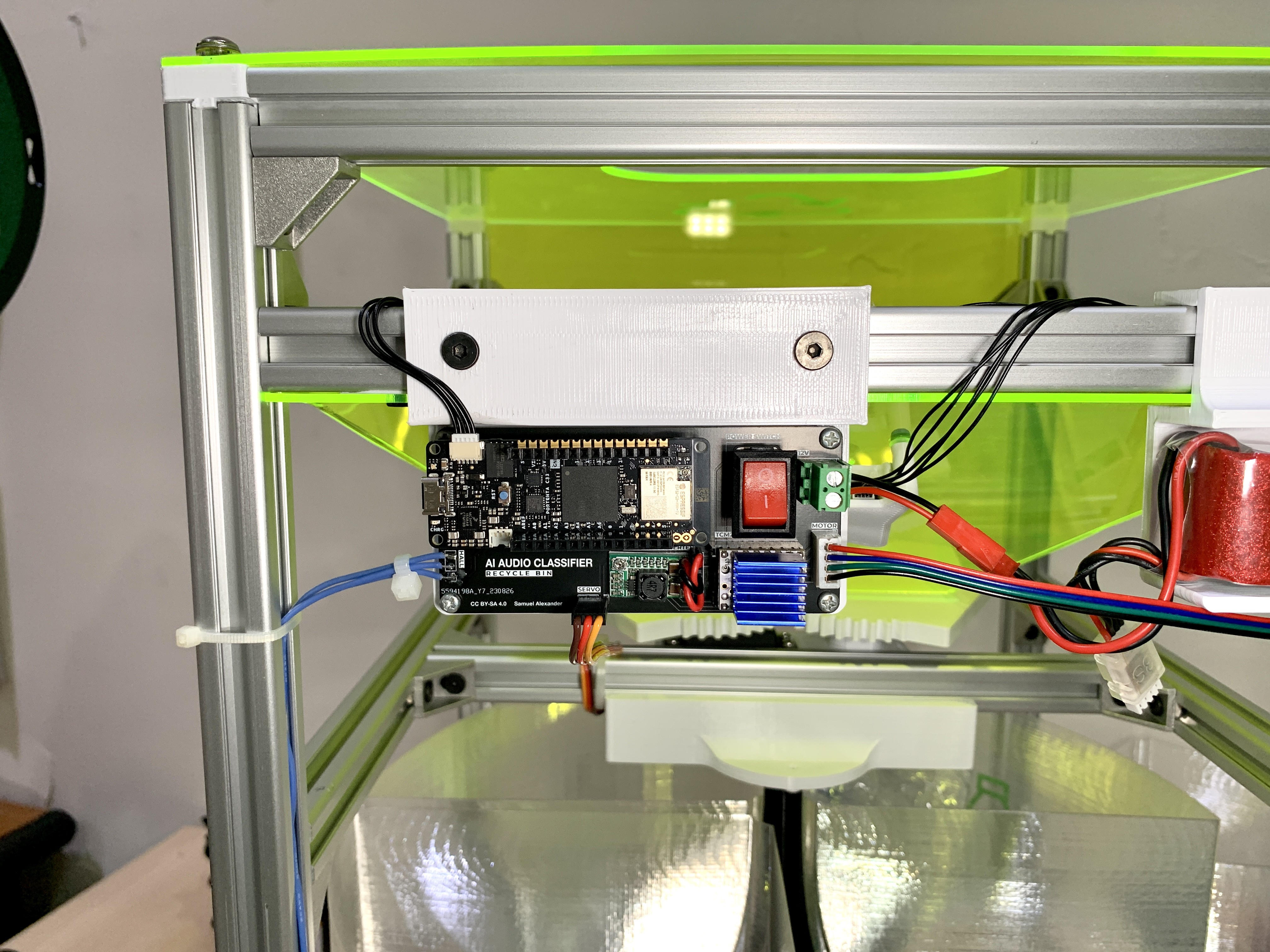

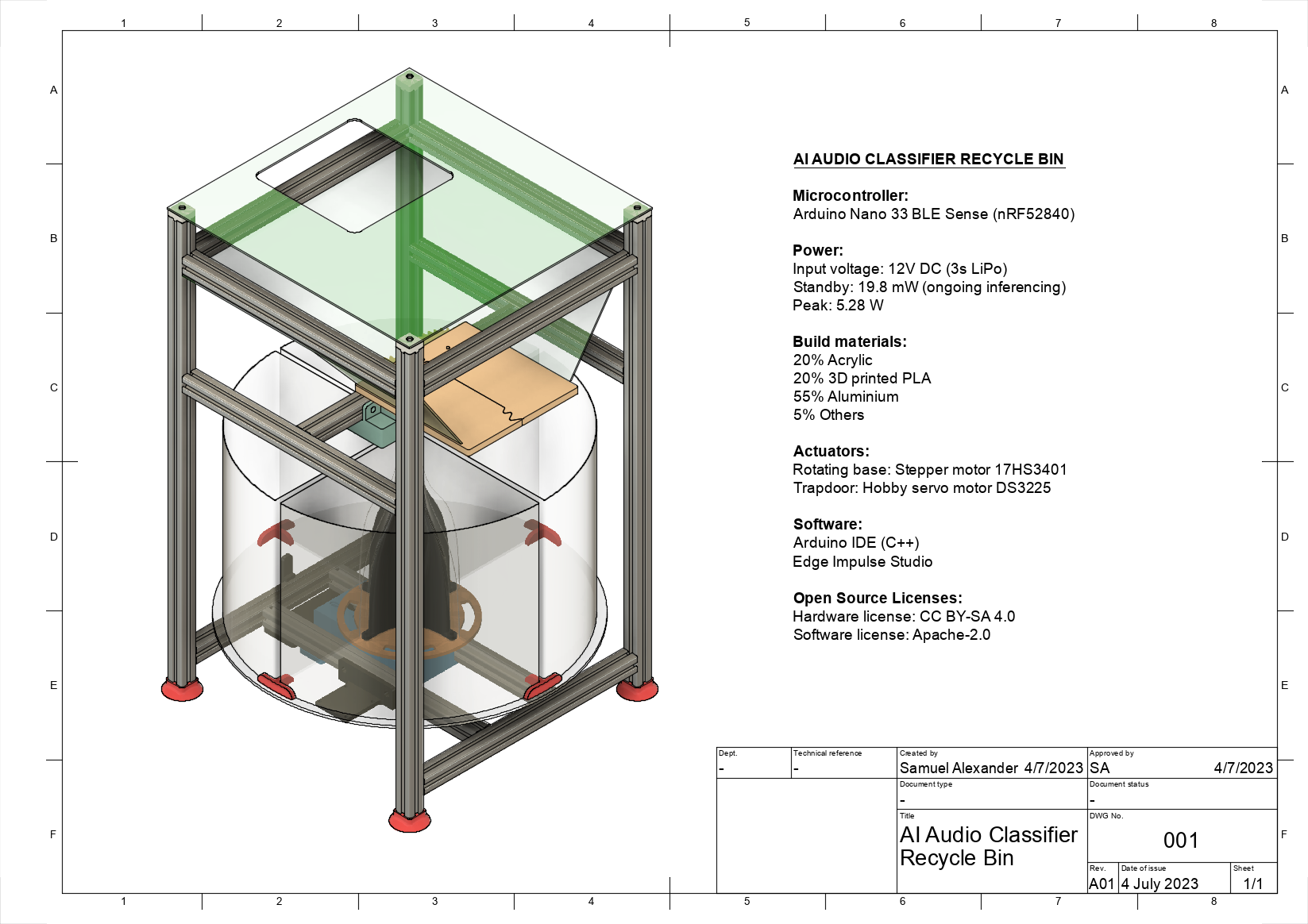

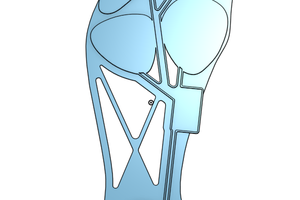

3D CAD hardware model

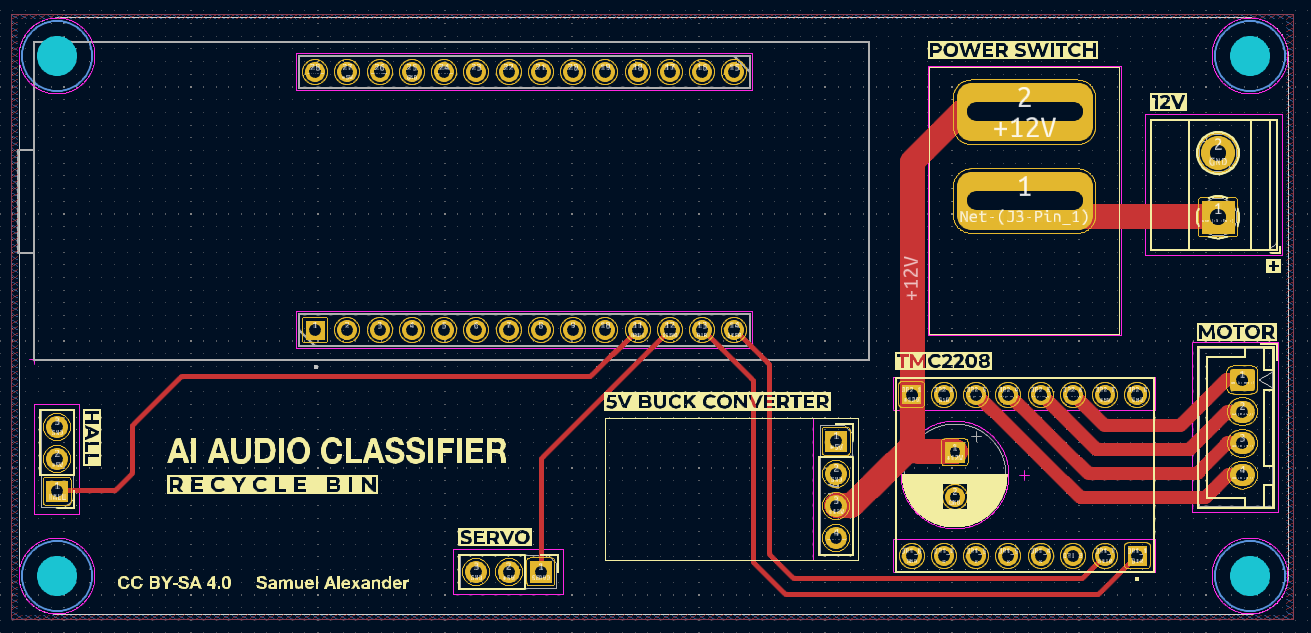

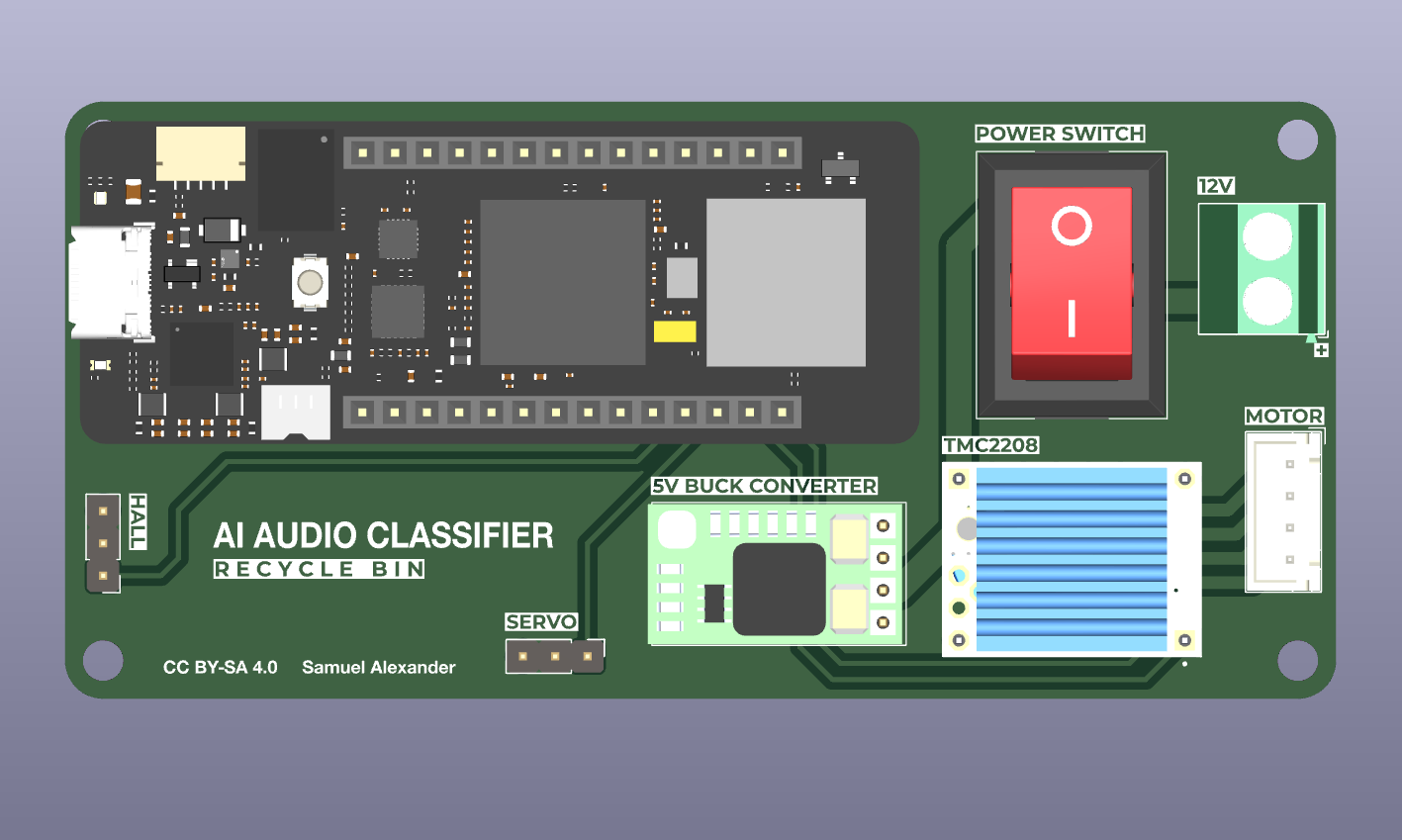

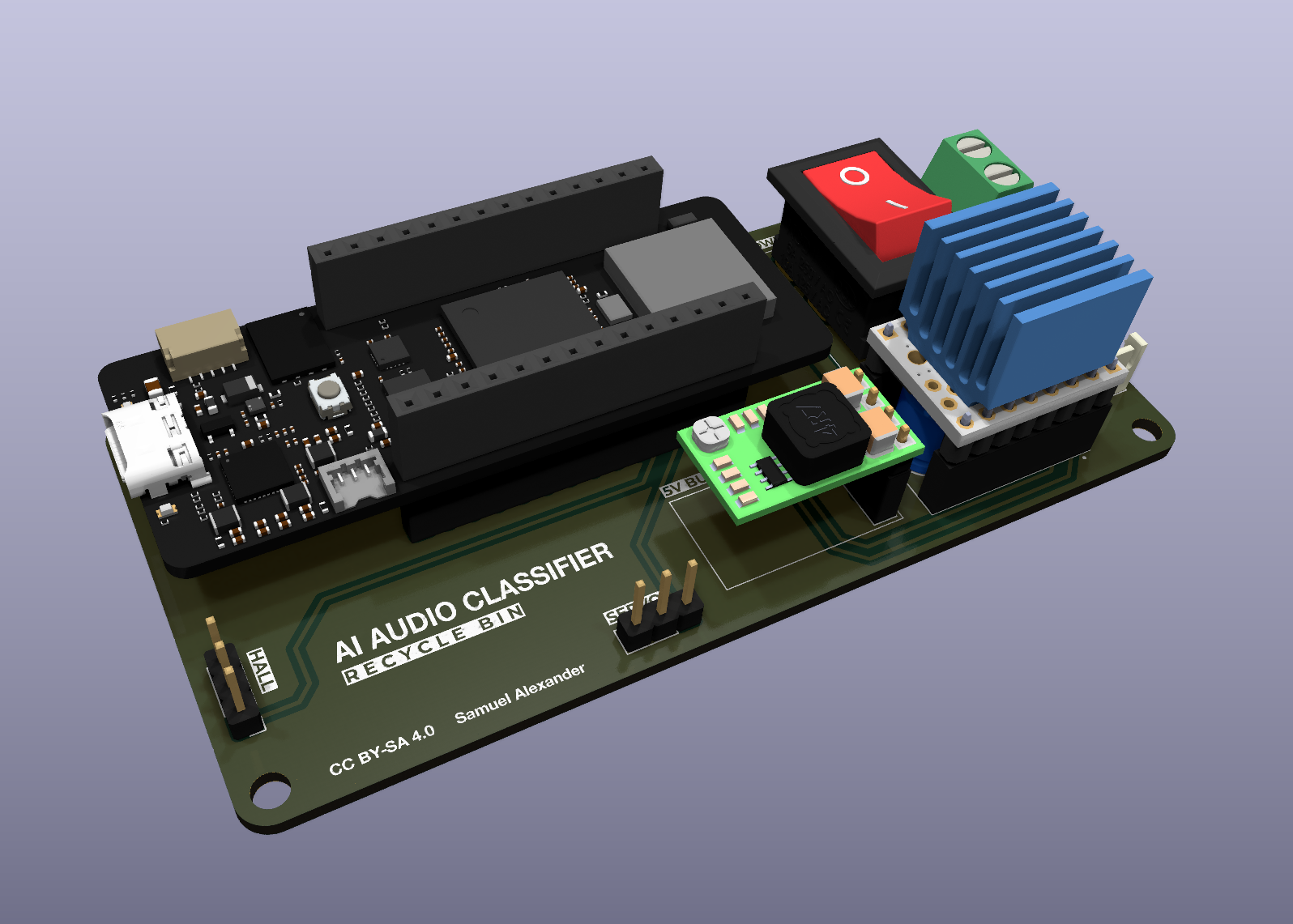

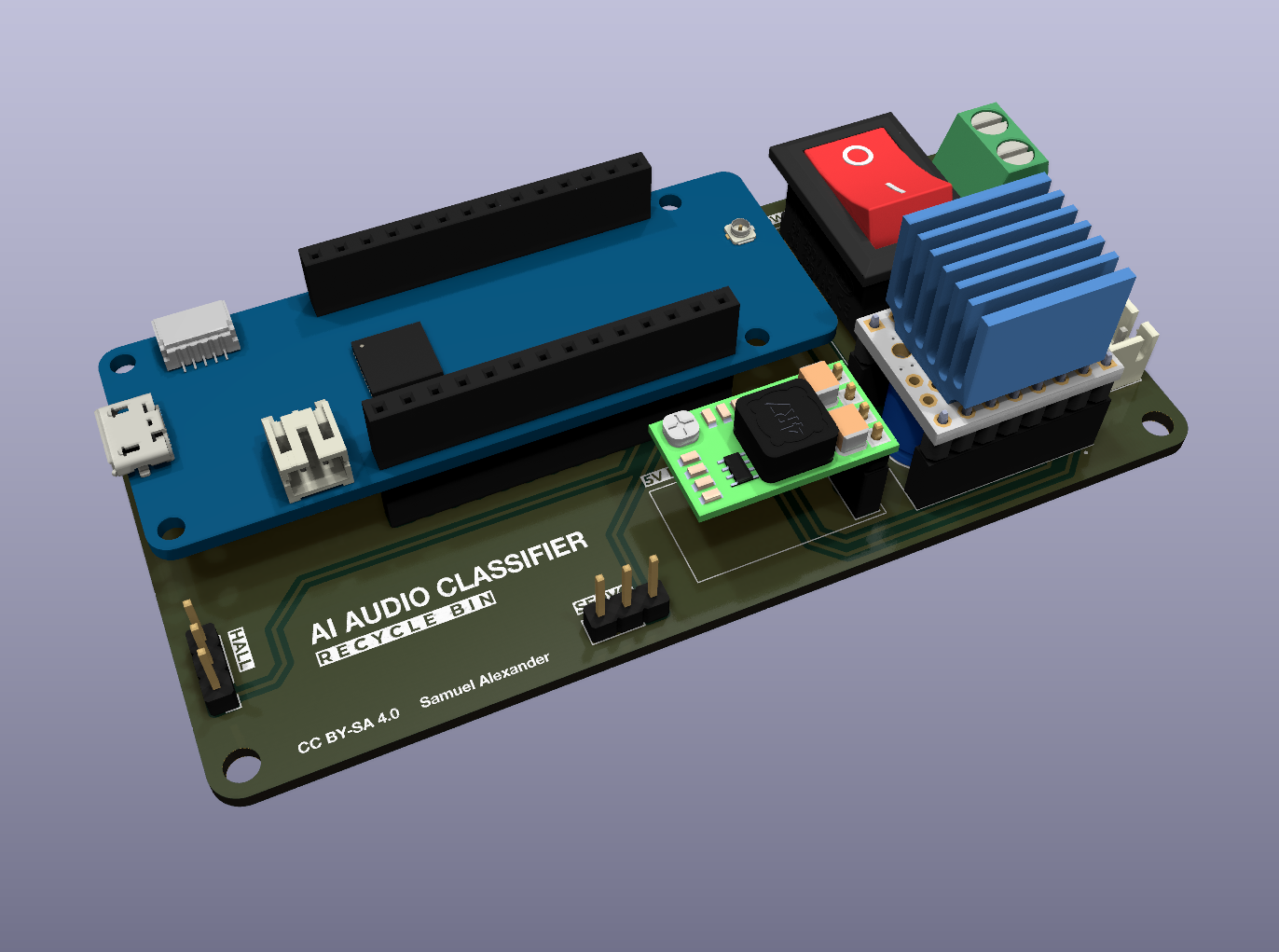

PCB Design (New)

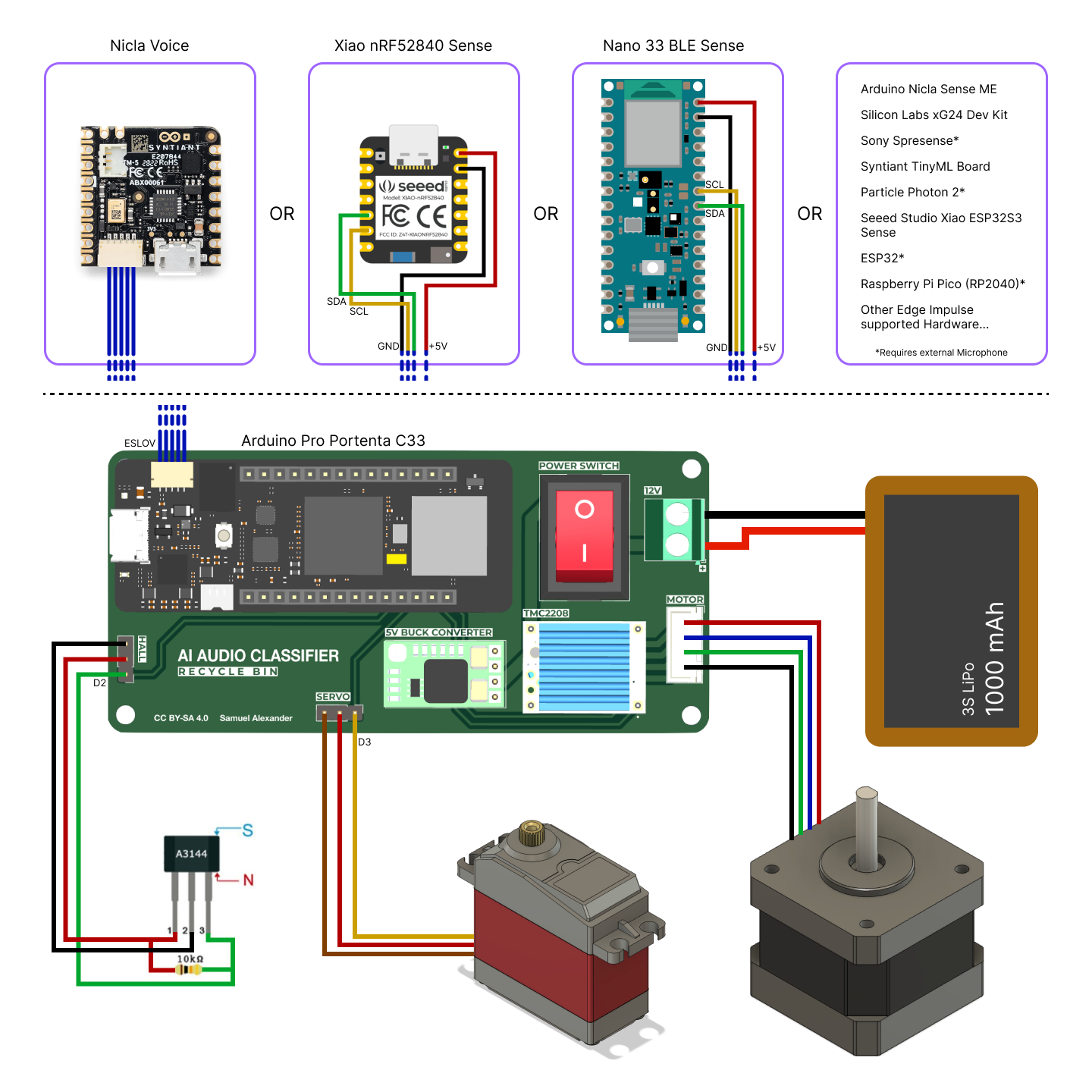

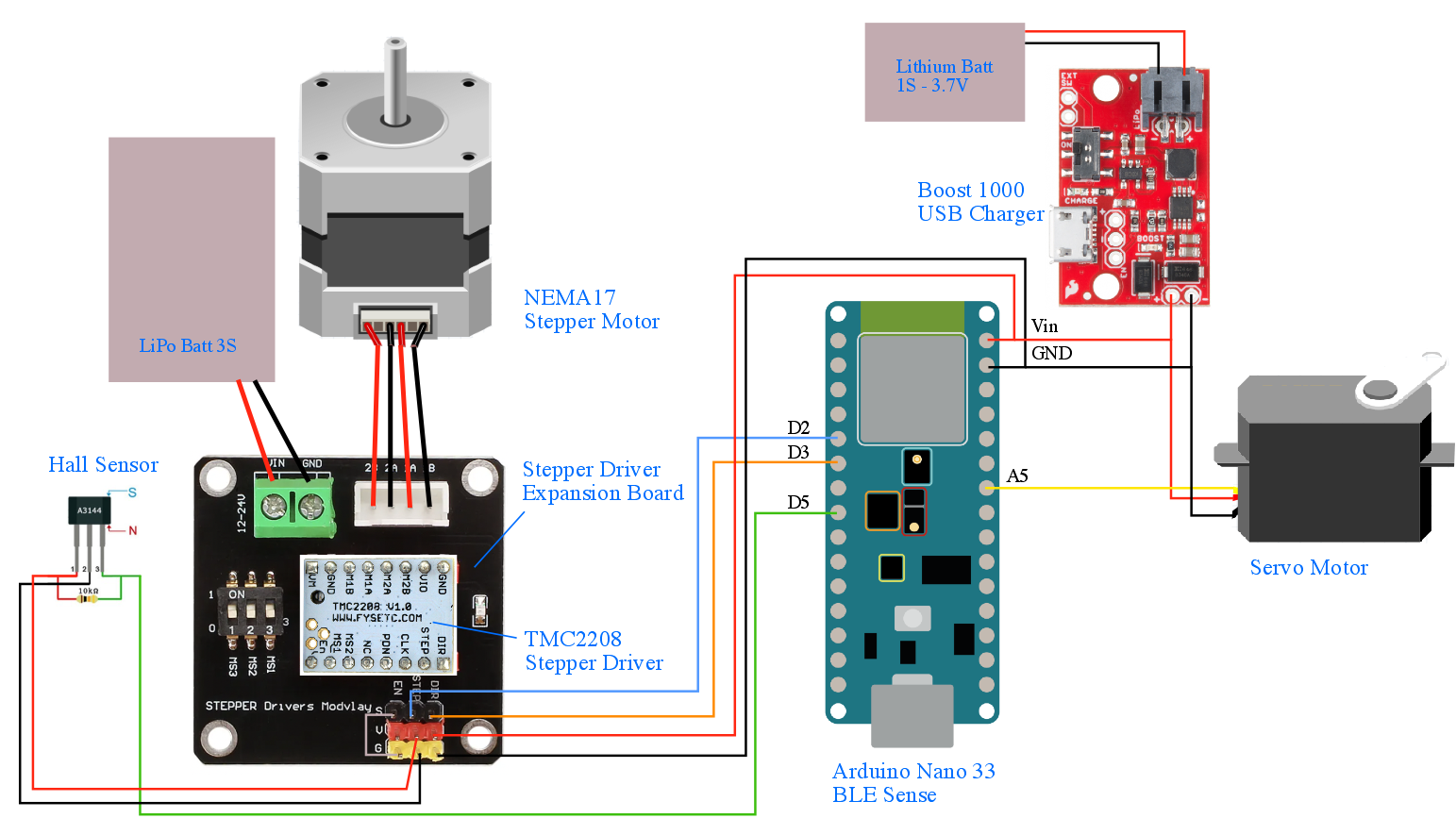

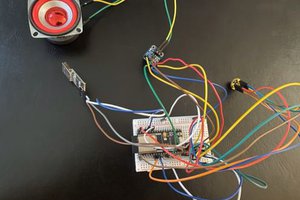

Electronic Connections System Diagram (New version, with upgrades)

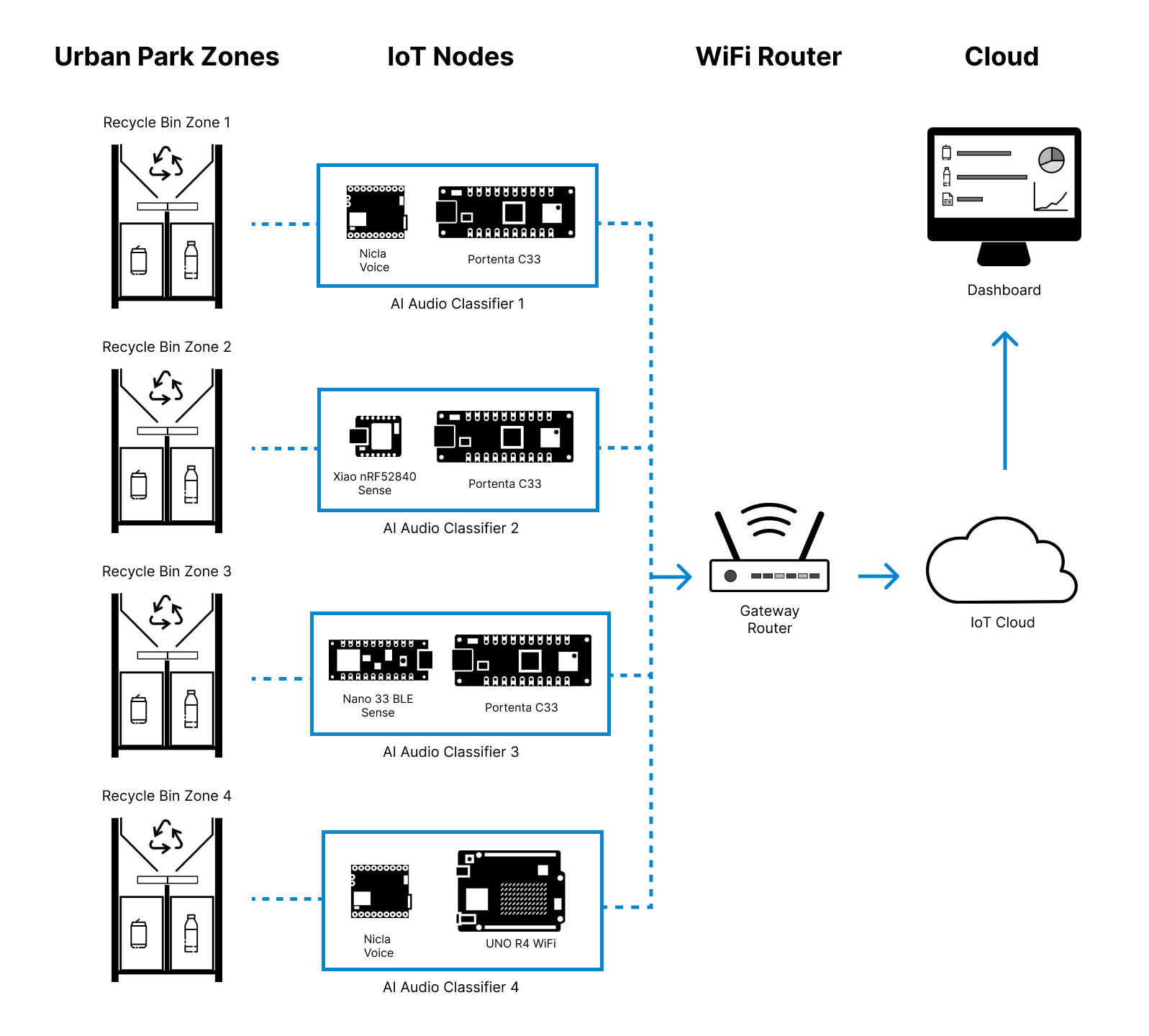

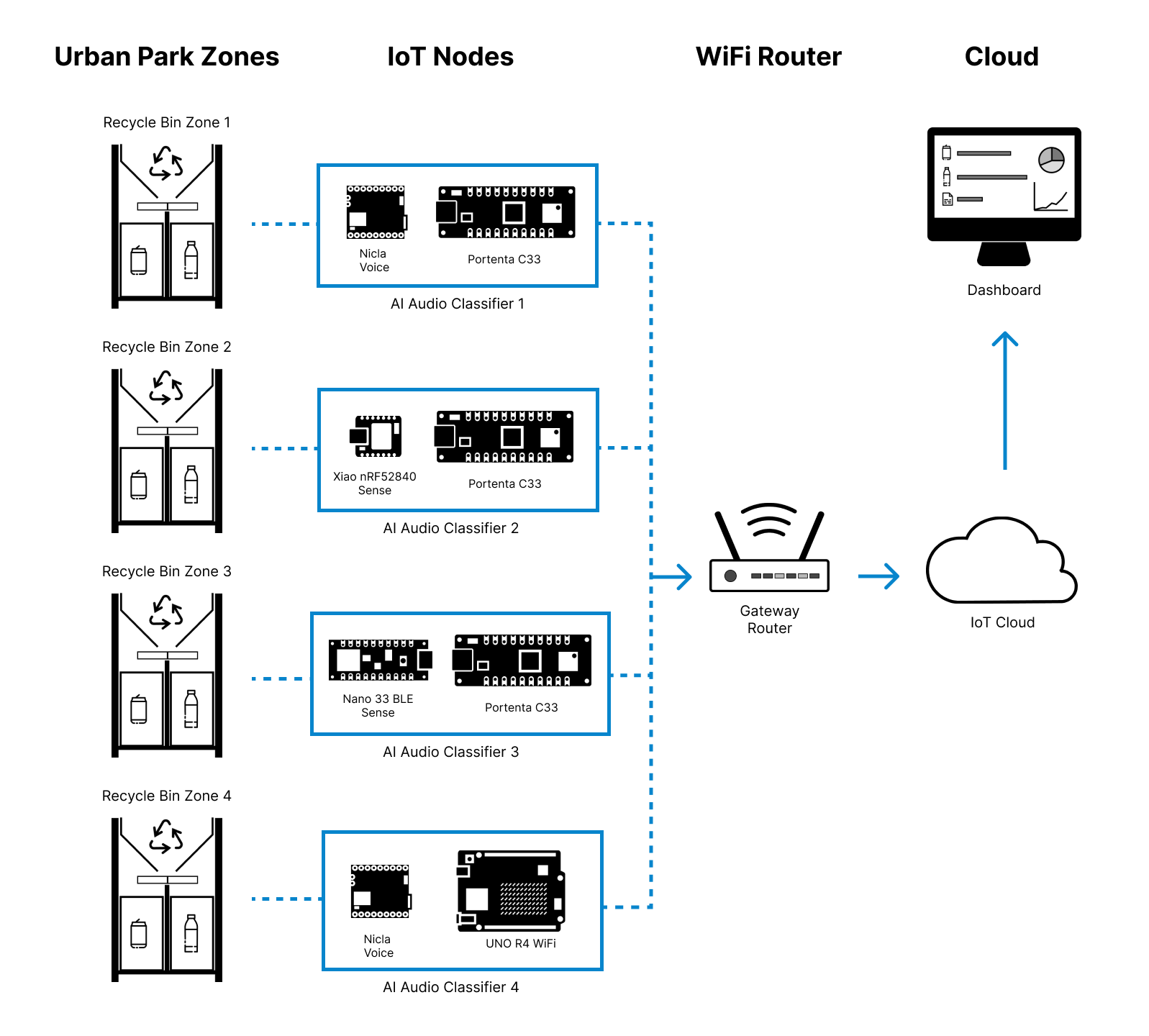

IoT Cloud System Diagram

Electronic Connections System Diagram (Old version, base unit)

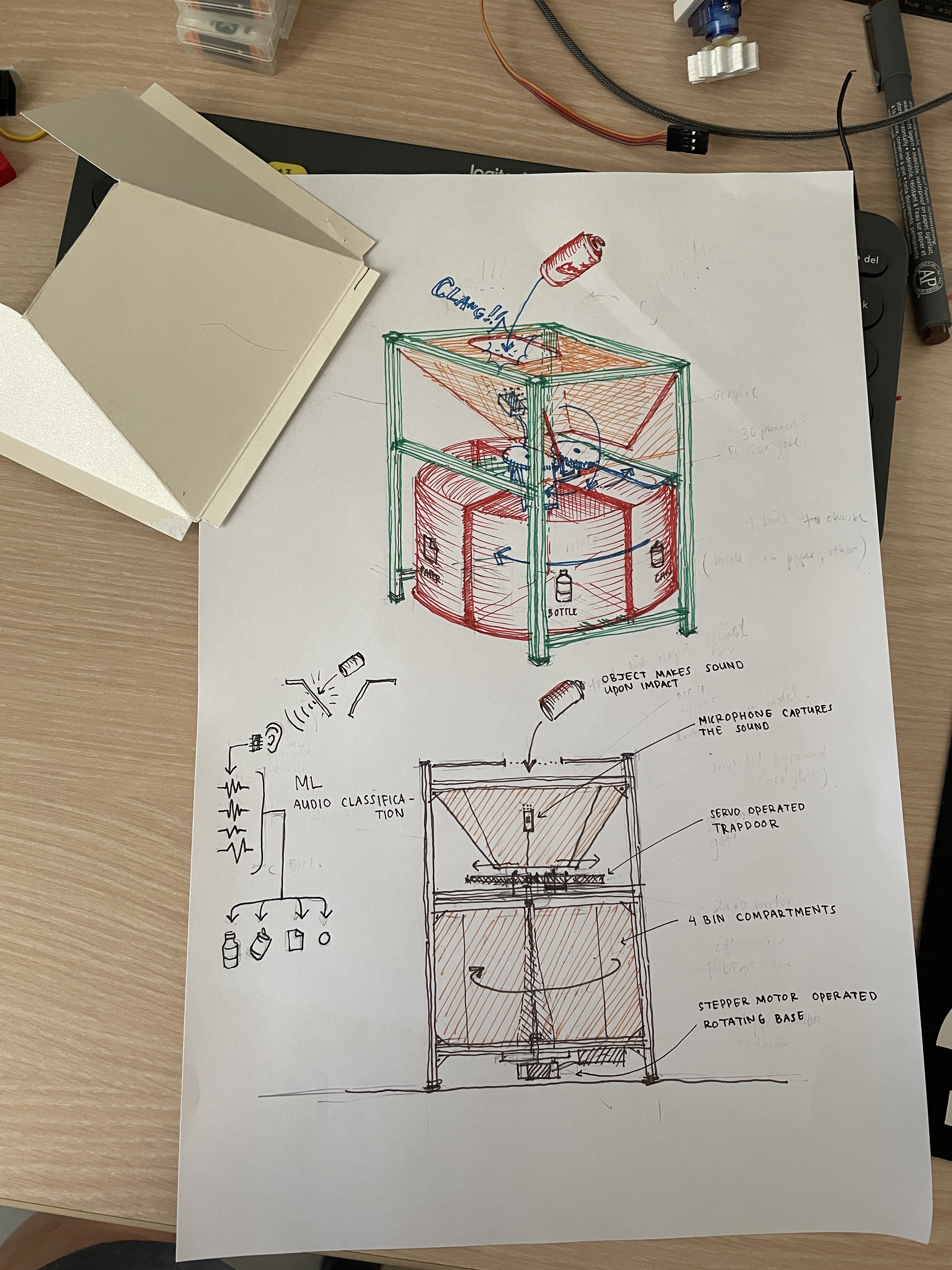

Concept Sketch

Project specifications:

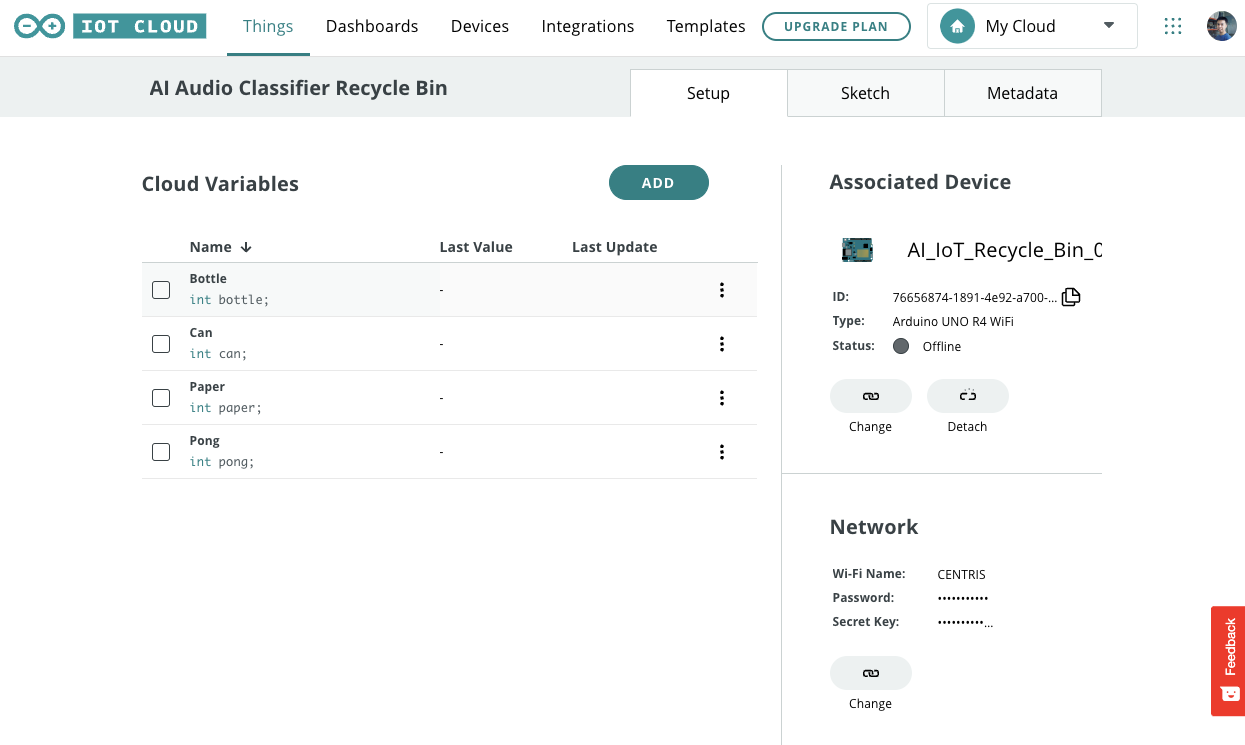

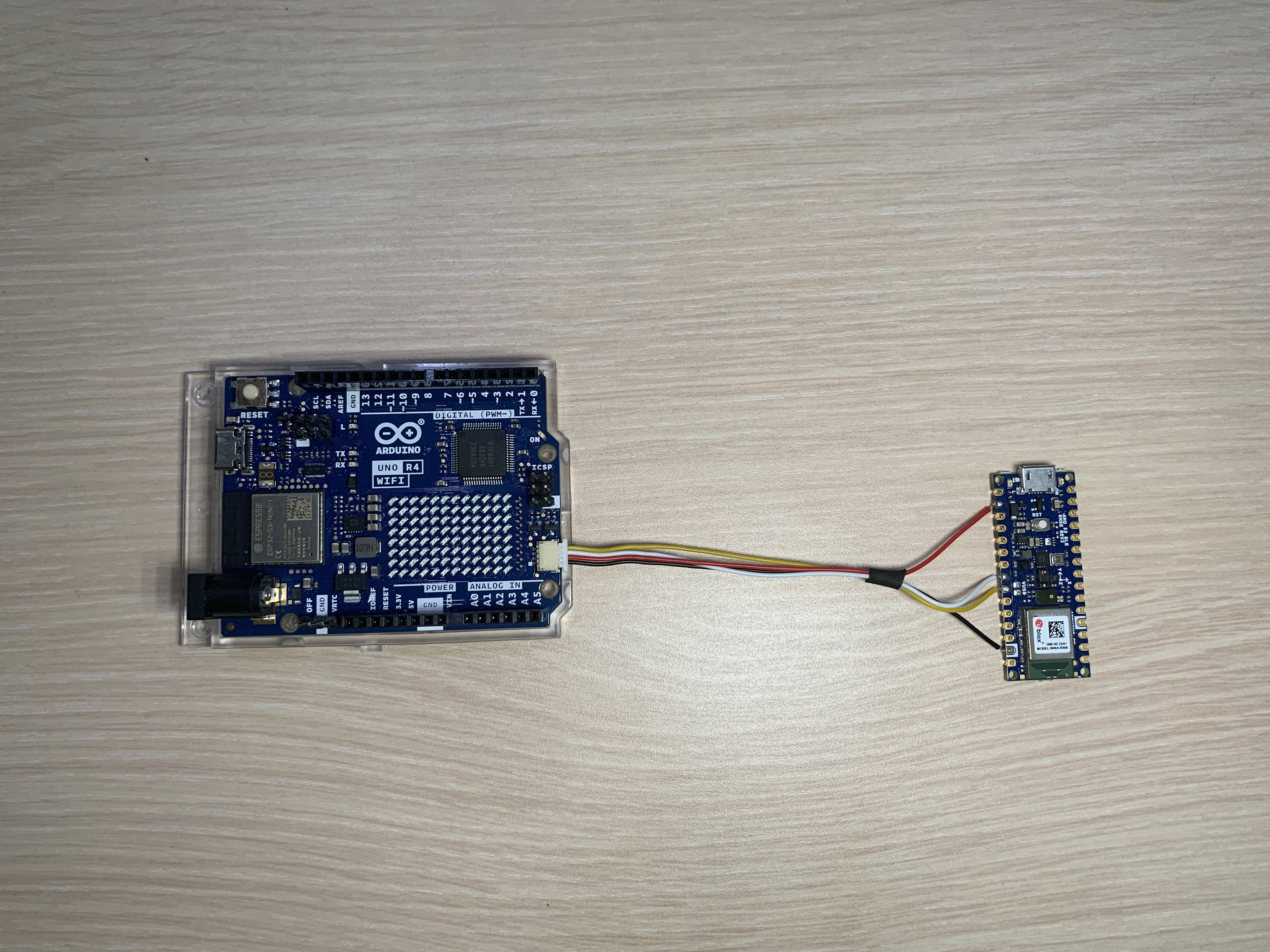

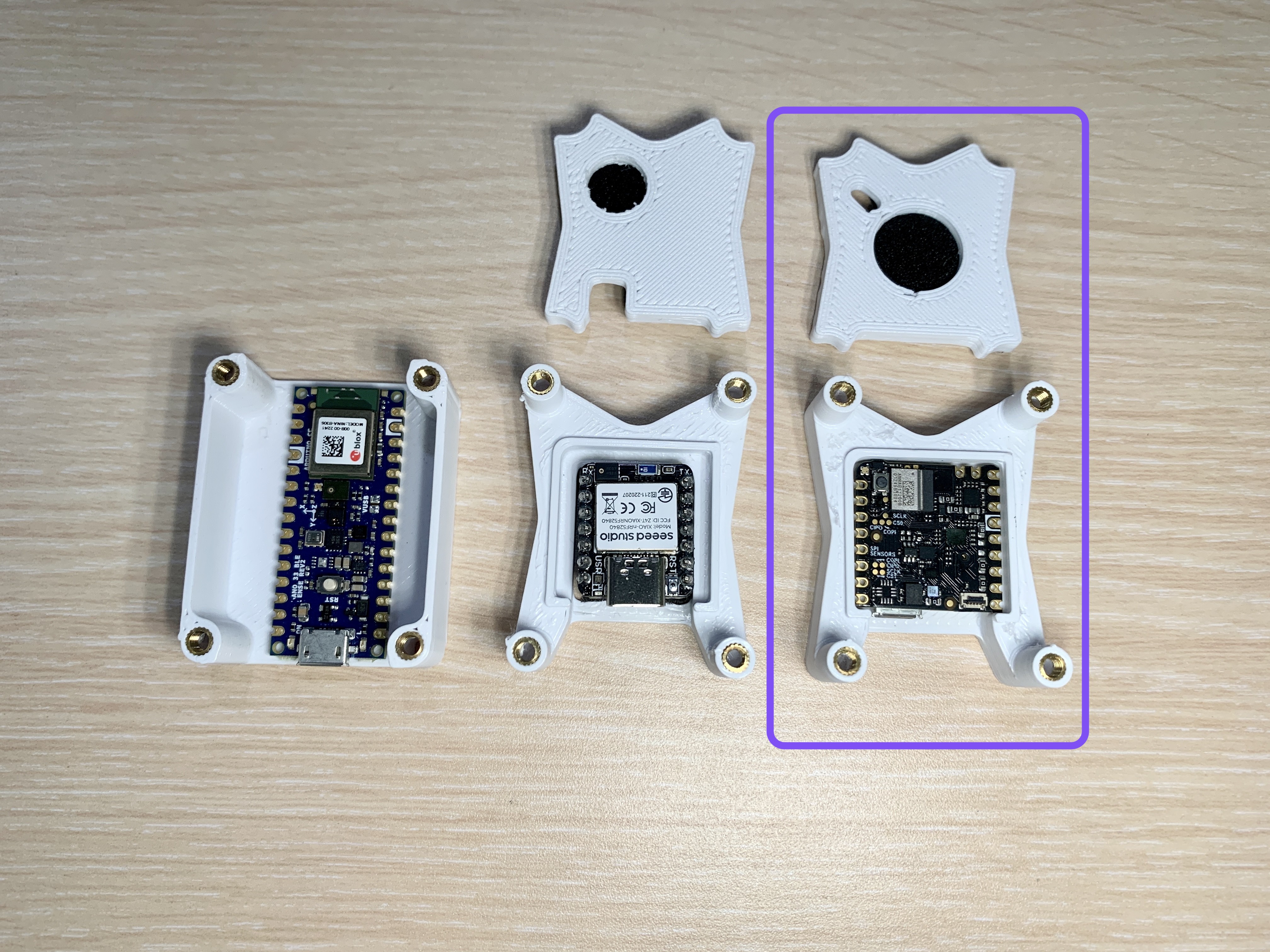

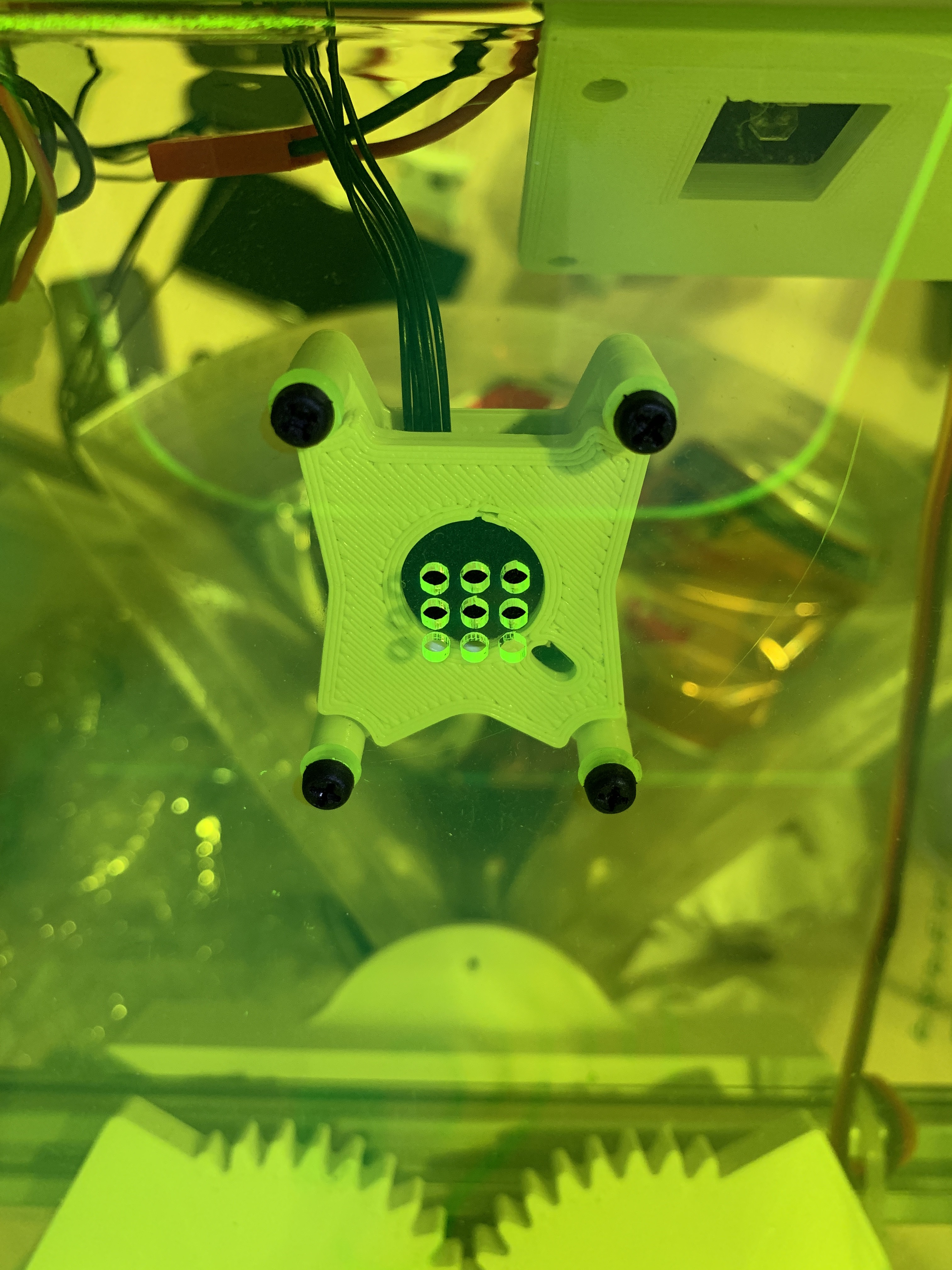

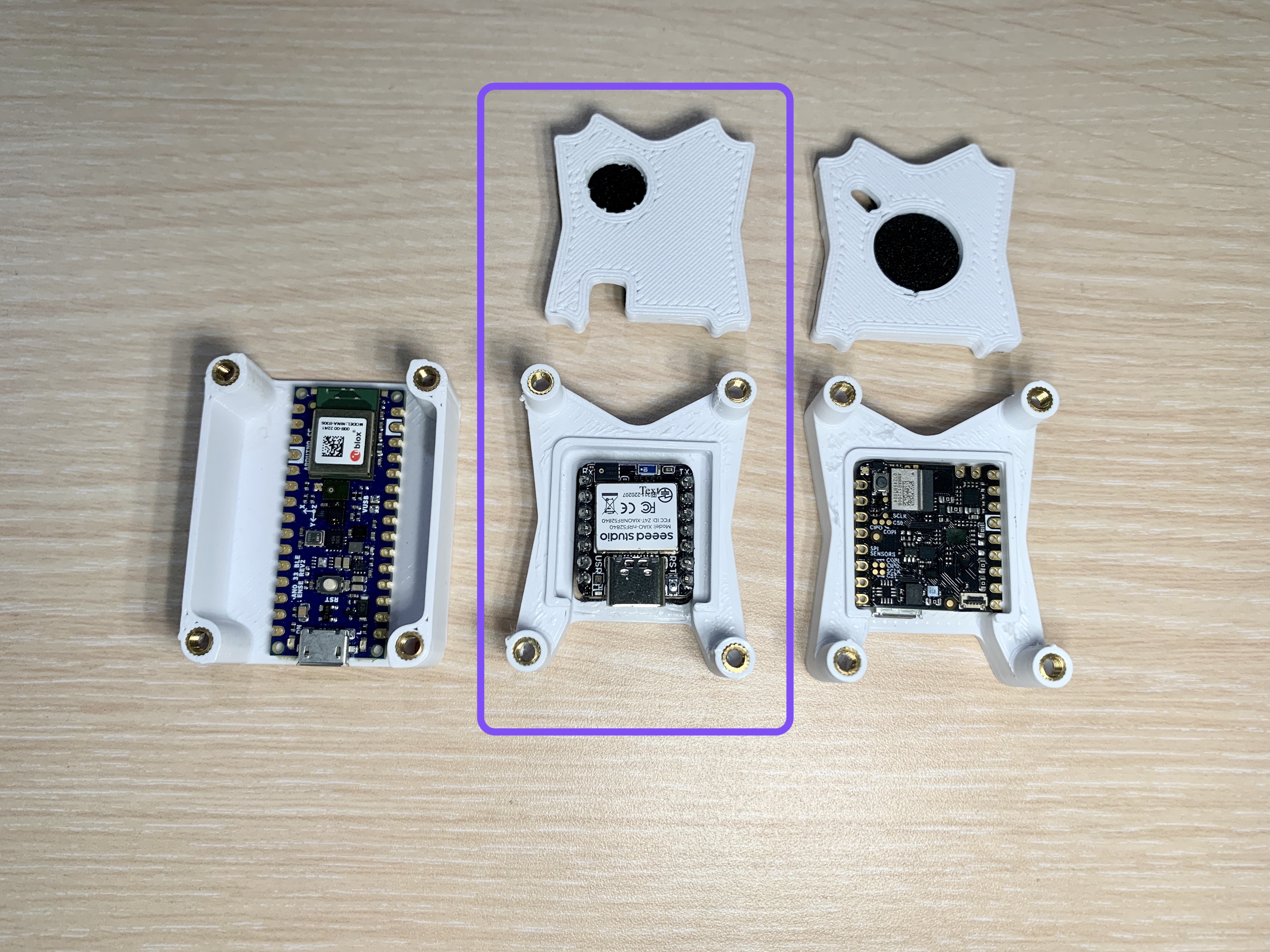

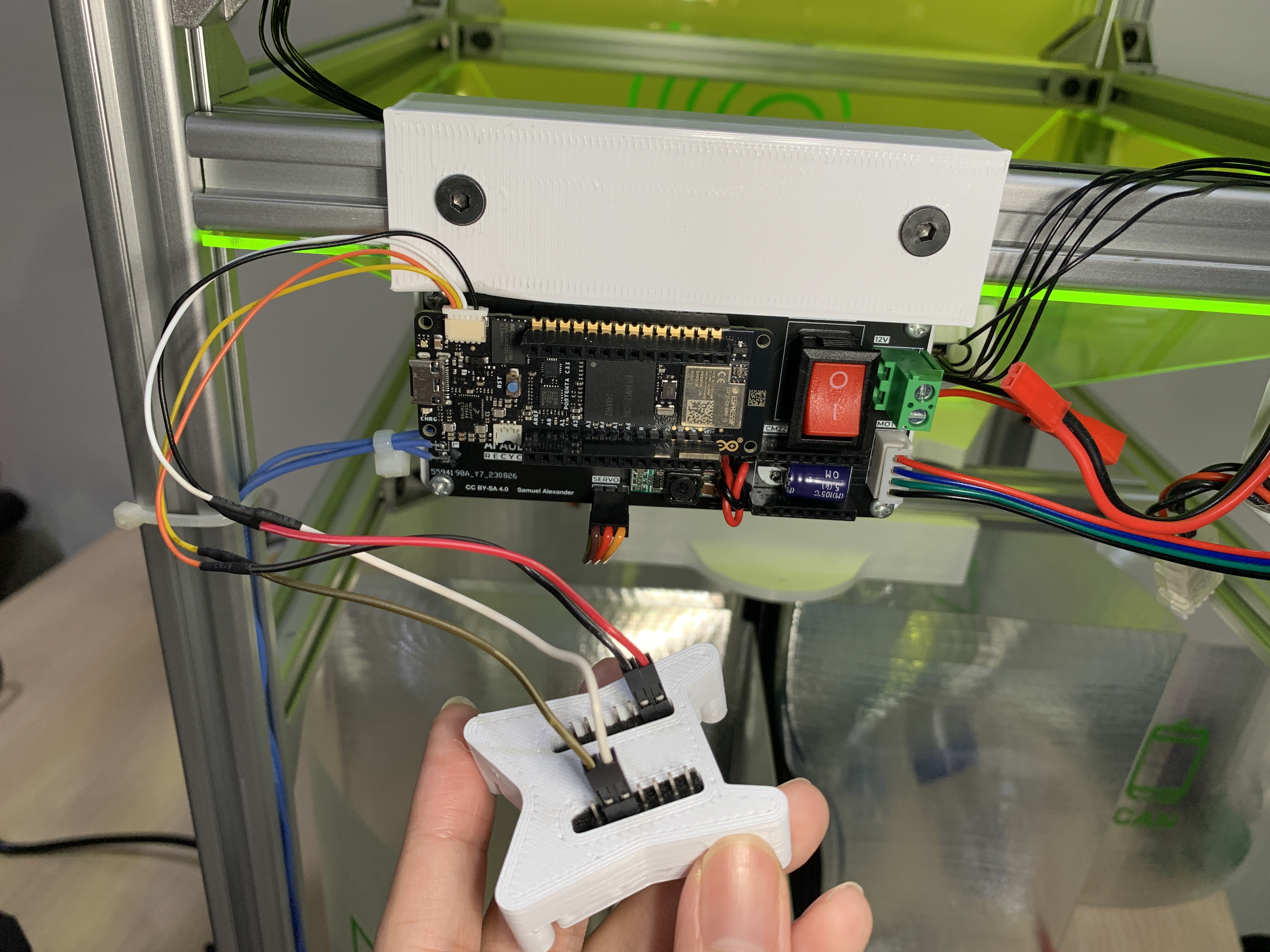

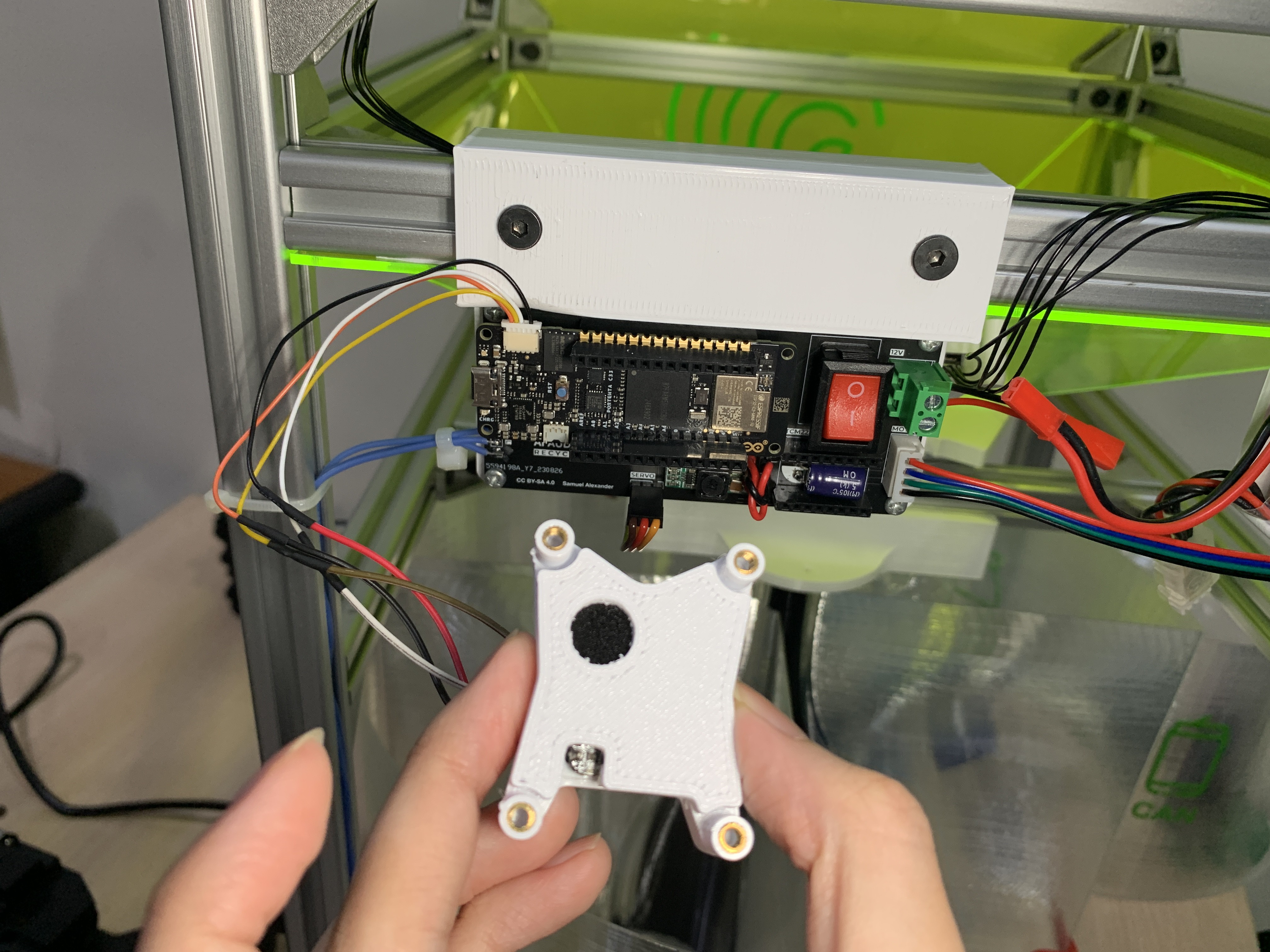

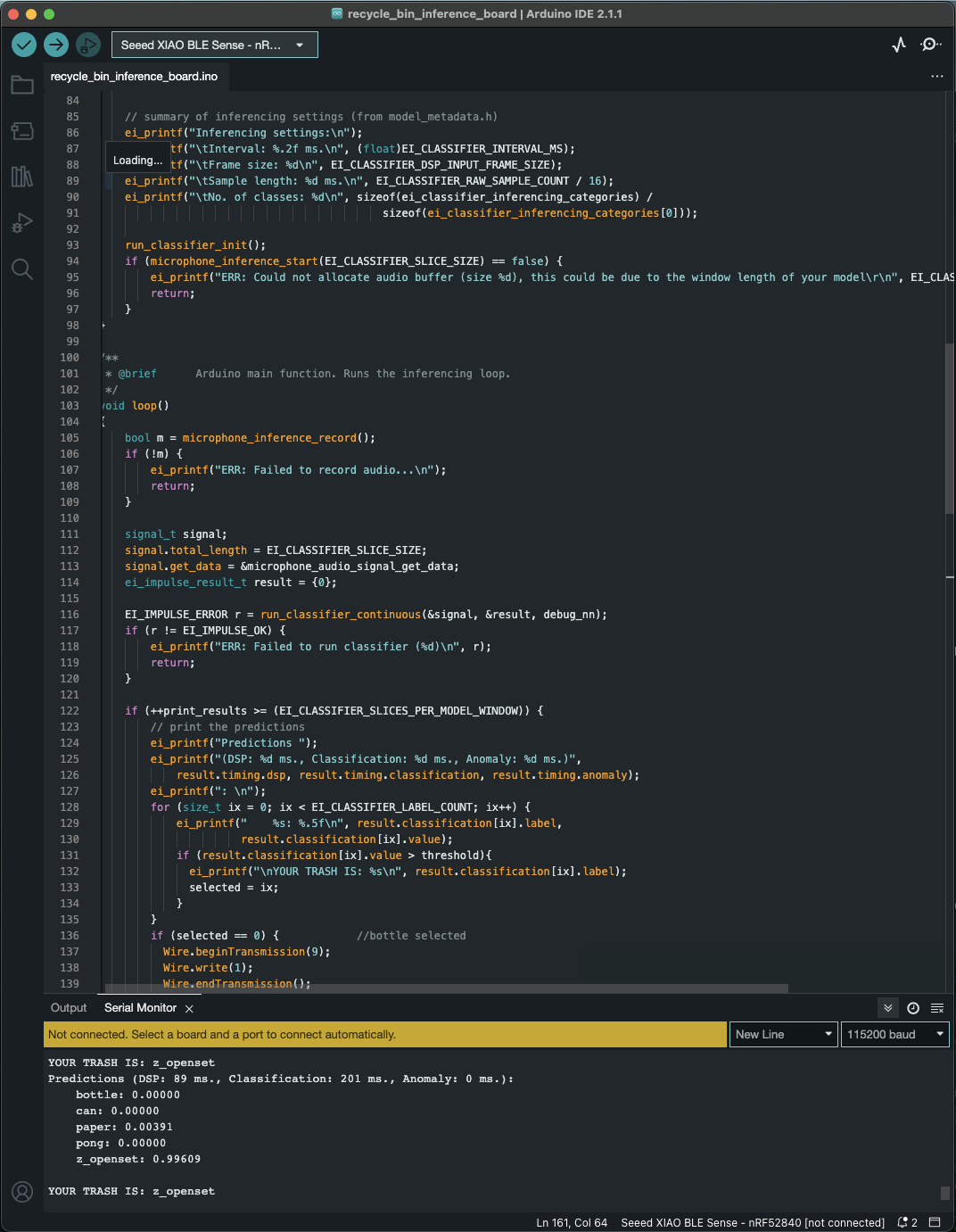

Inference Microcontroller: Arduino Pro Nicla Voice or Seeed Studio Xiao nRF52840 Sense

Actuator Microcontroller: Arduino Pro Portenta C33

Power:

Input voltage: 12V DC (3s LiPo)

Peak: 5.3 W

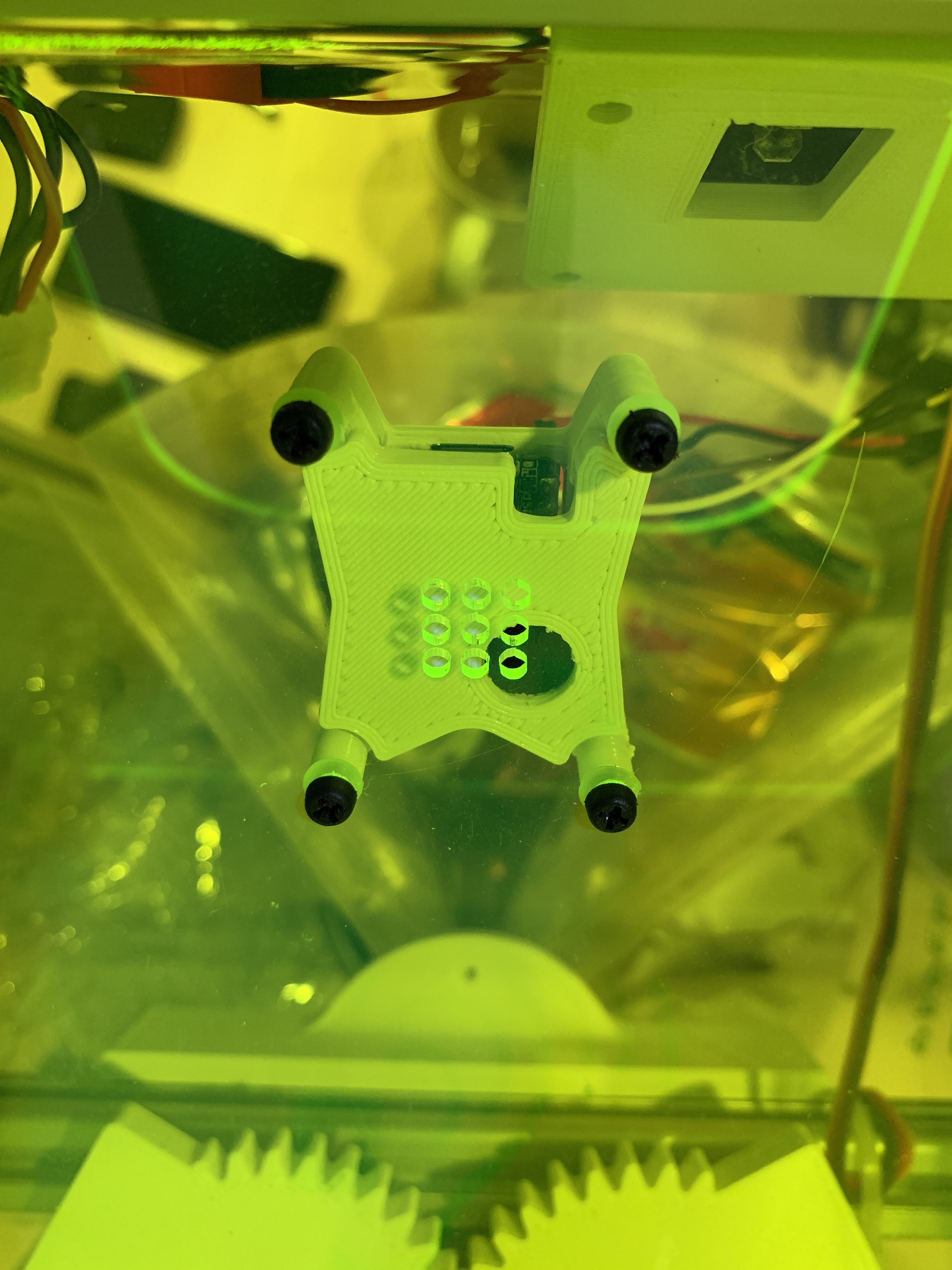

Build materials:

20% Acrylic

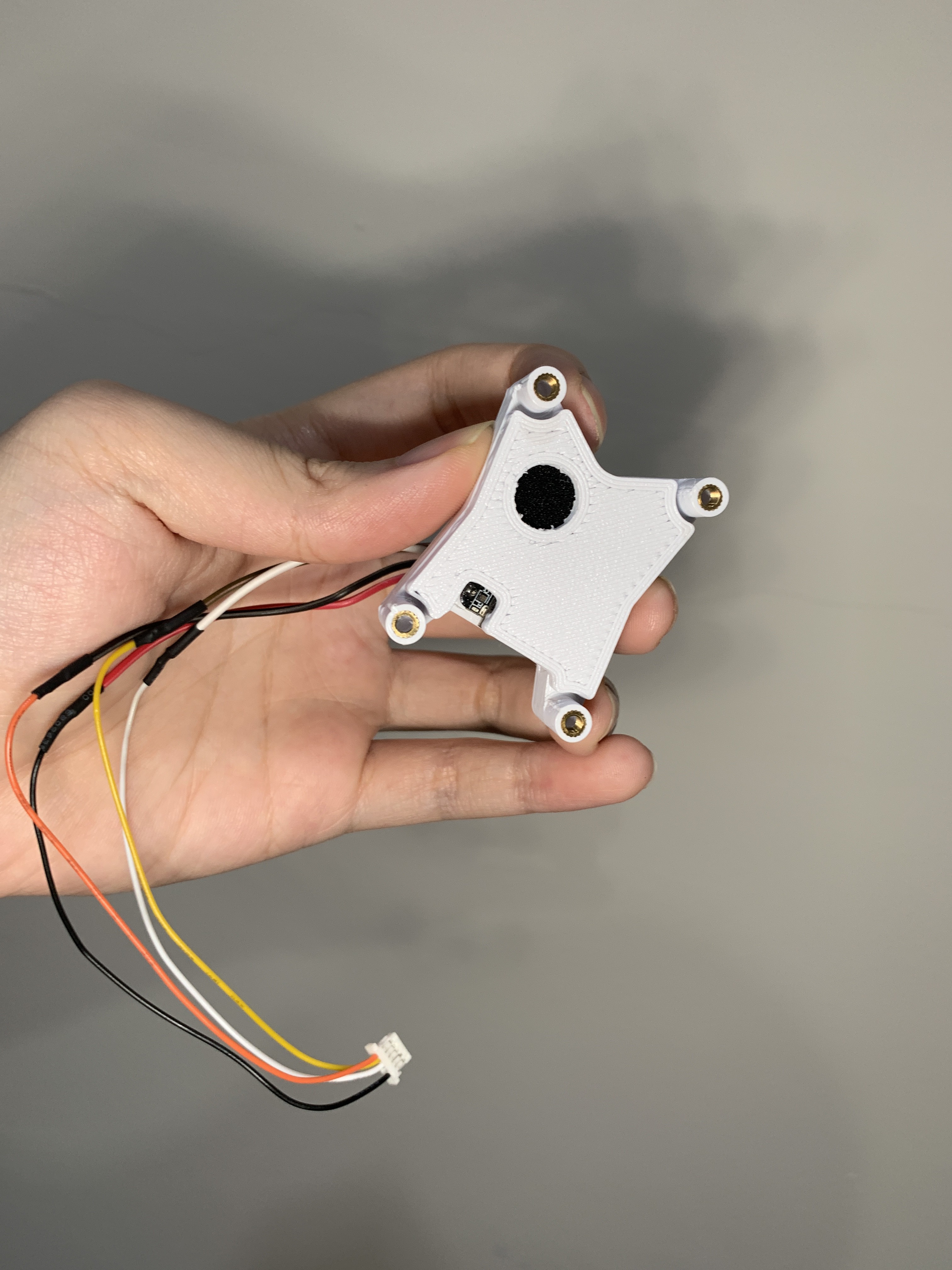

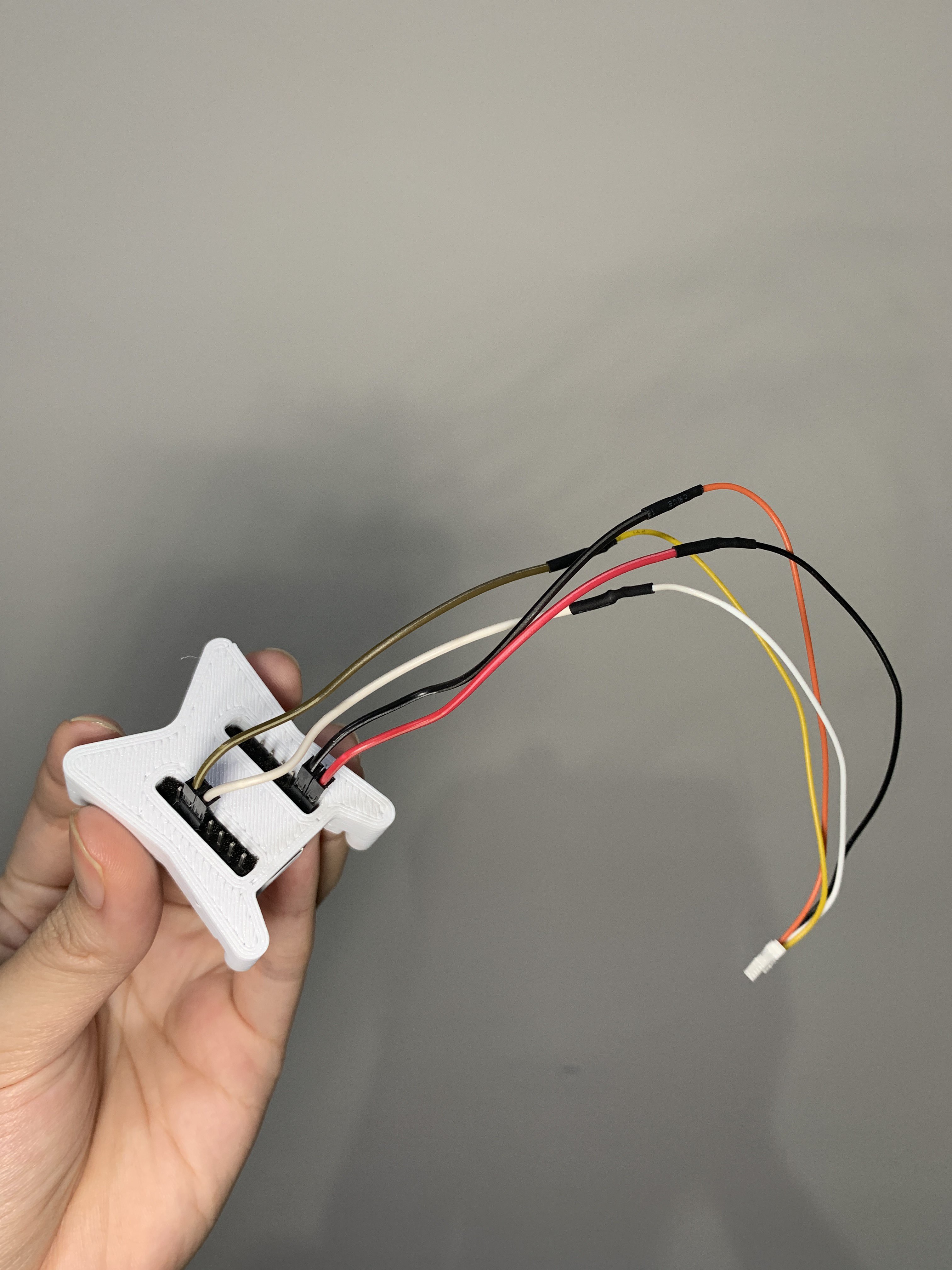

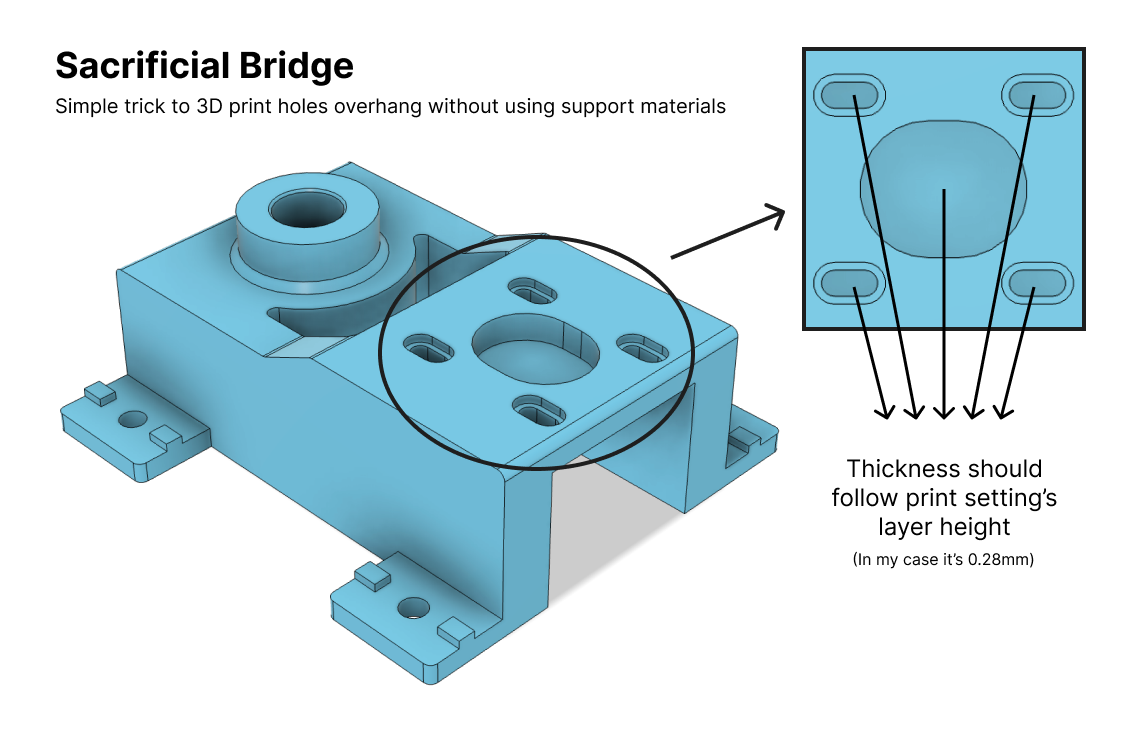

20% 3D printed PLA

55% Aluminium

5% Others

Actuators:

Rotating base: Stepper motor 17HS3401

Trapdoor: Hobby servo motor DS3225

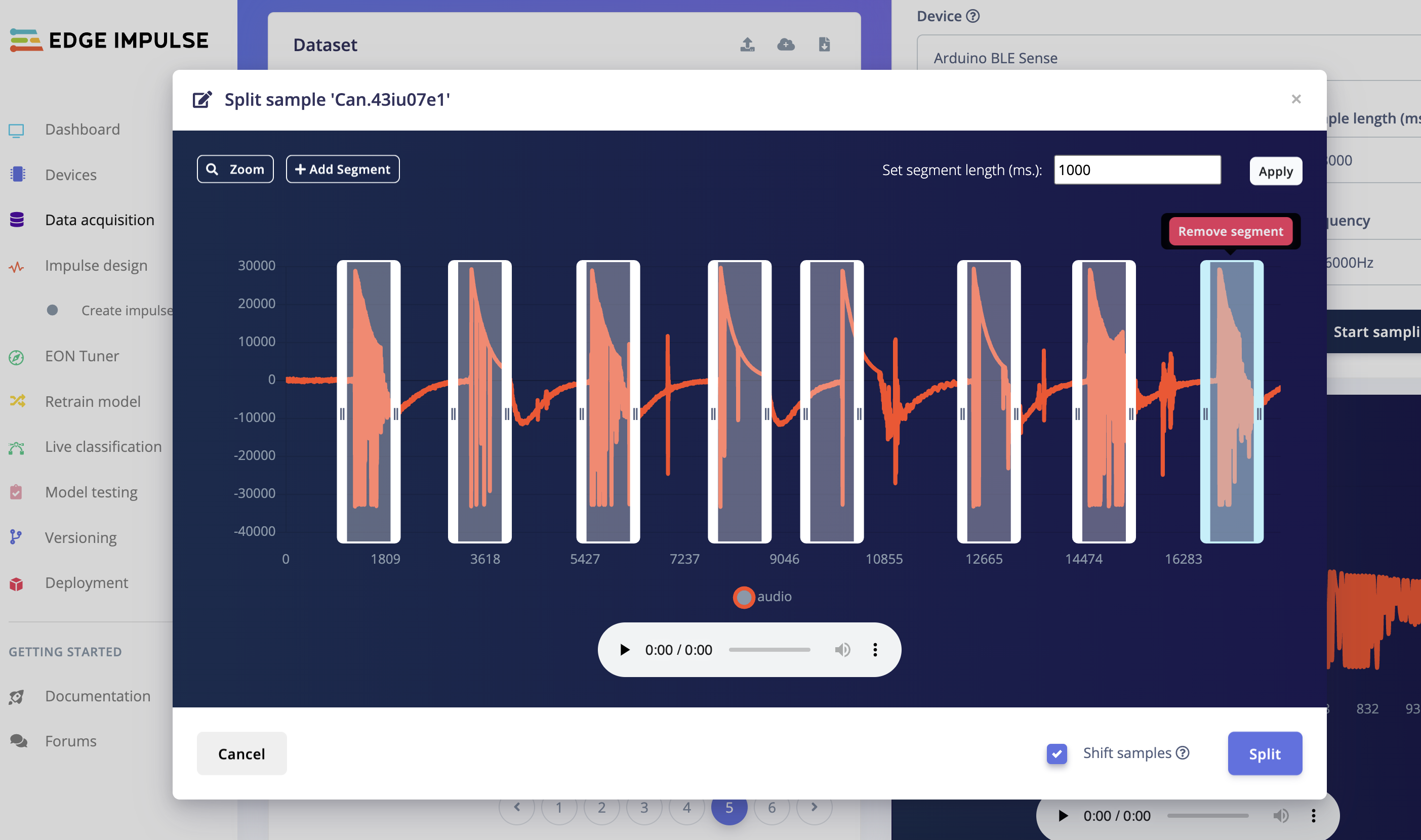

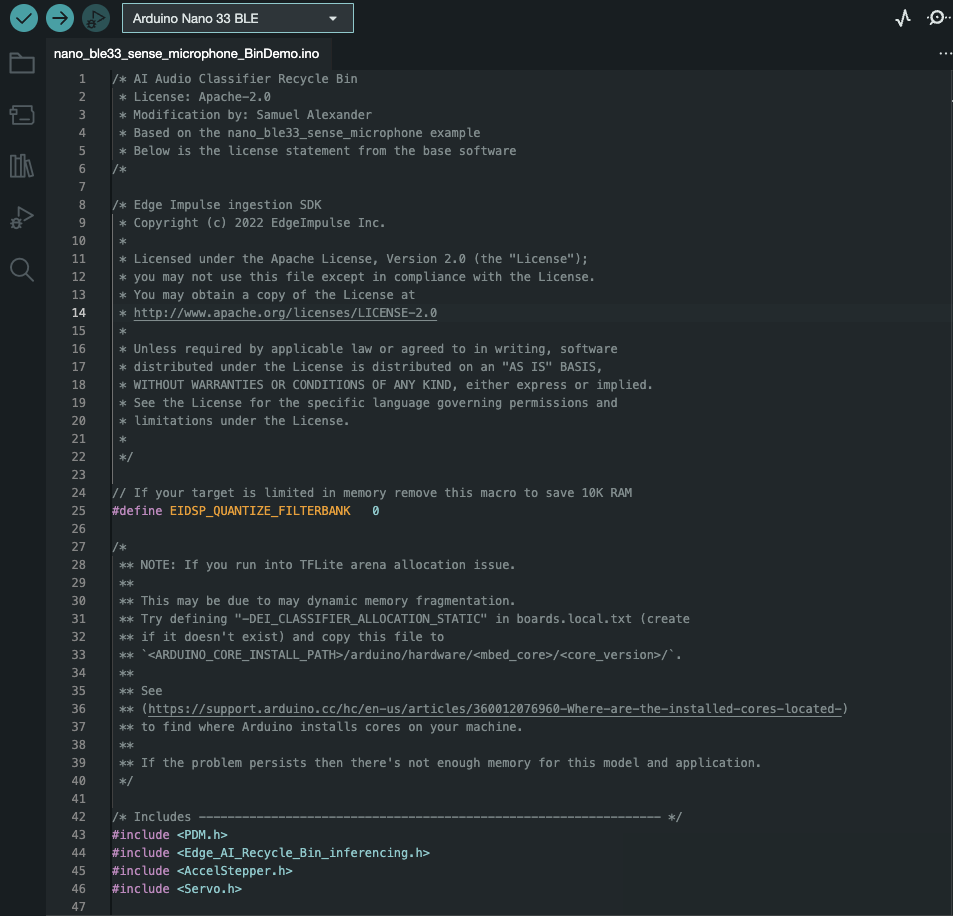

Software:

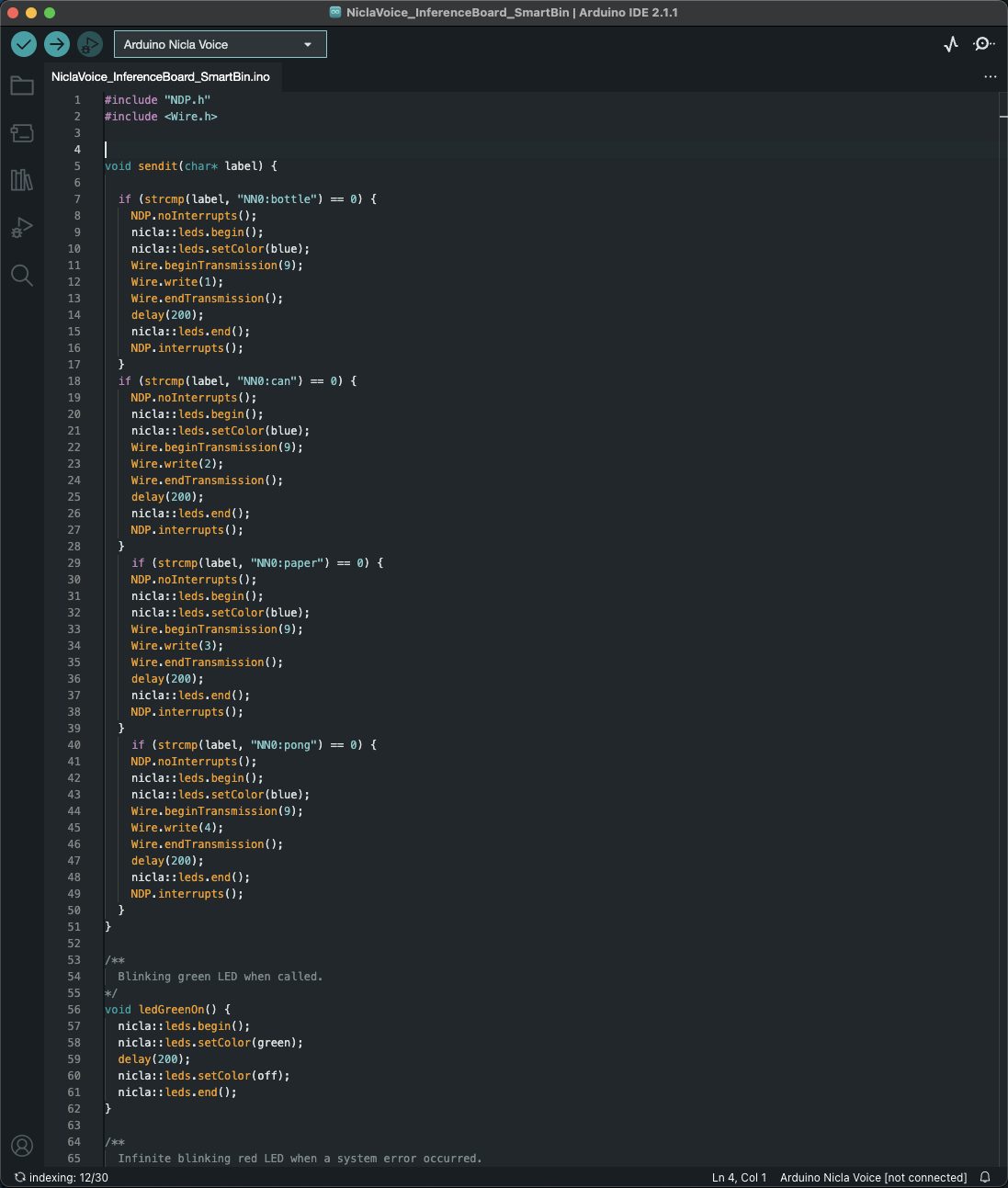

Arduino IDE (C++)

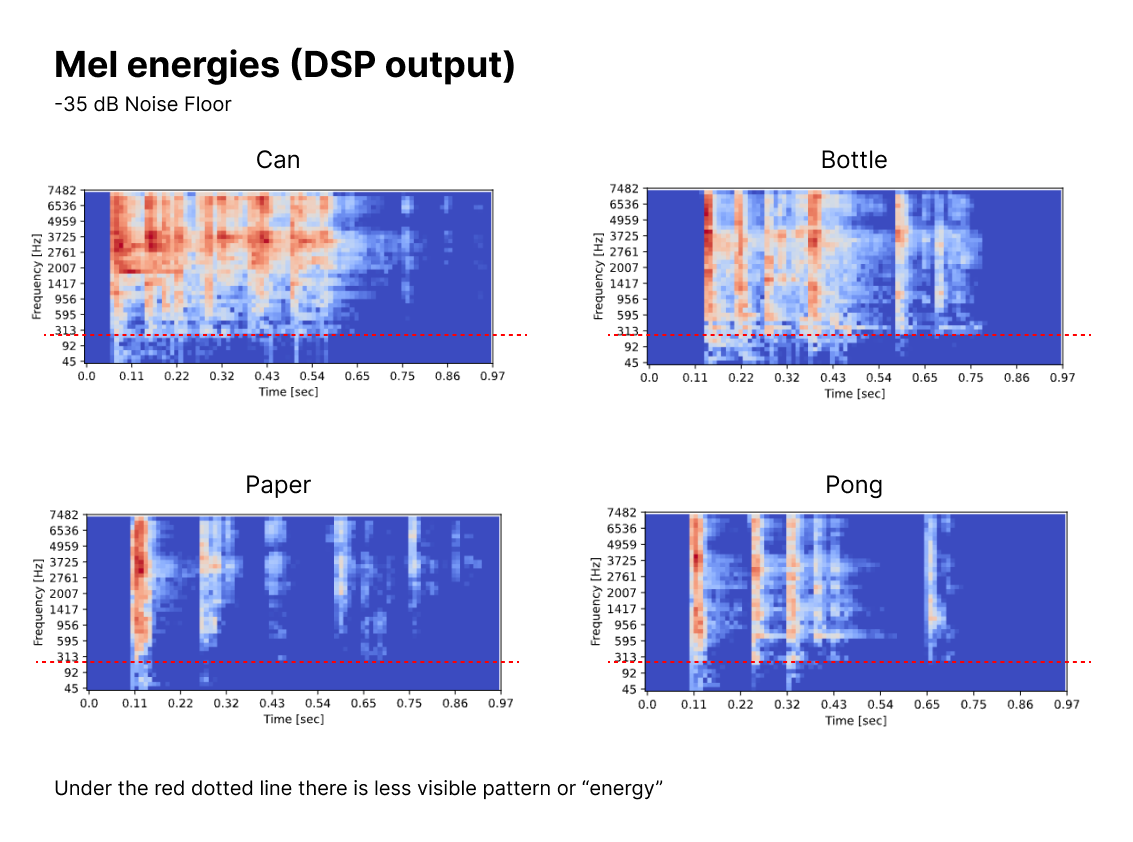

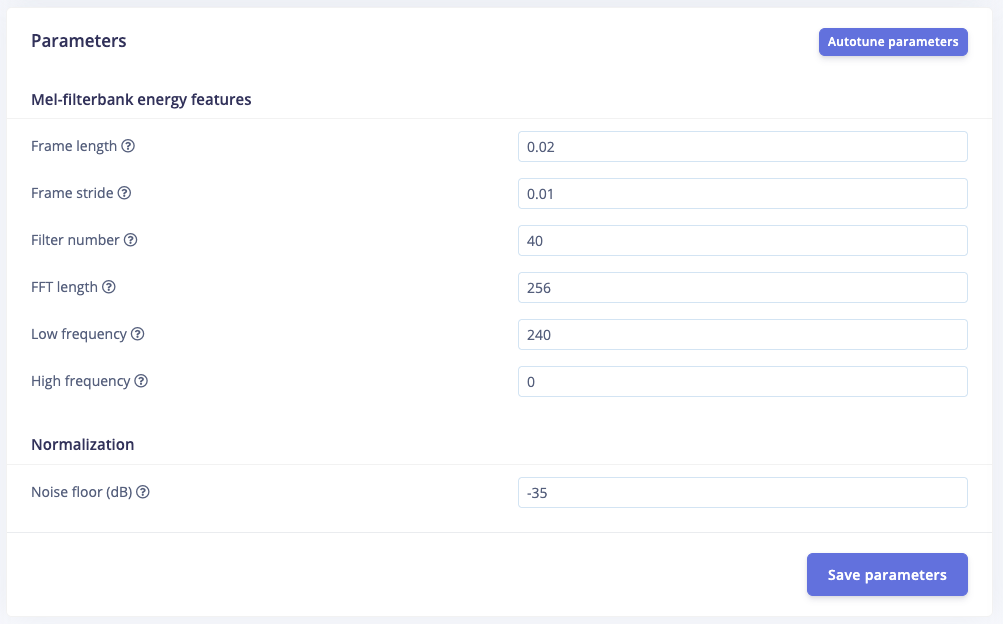

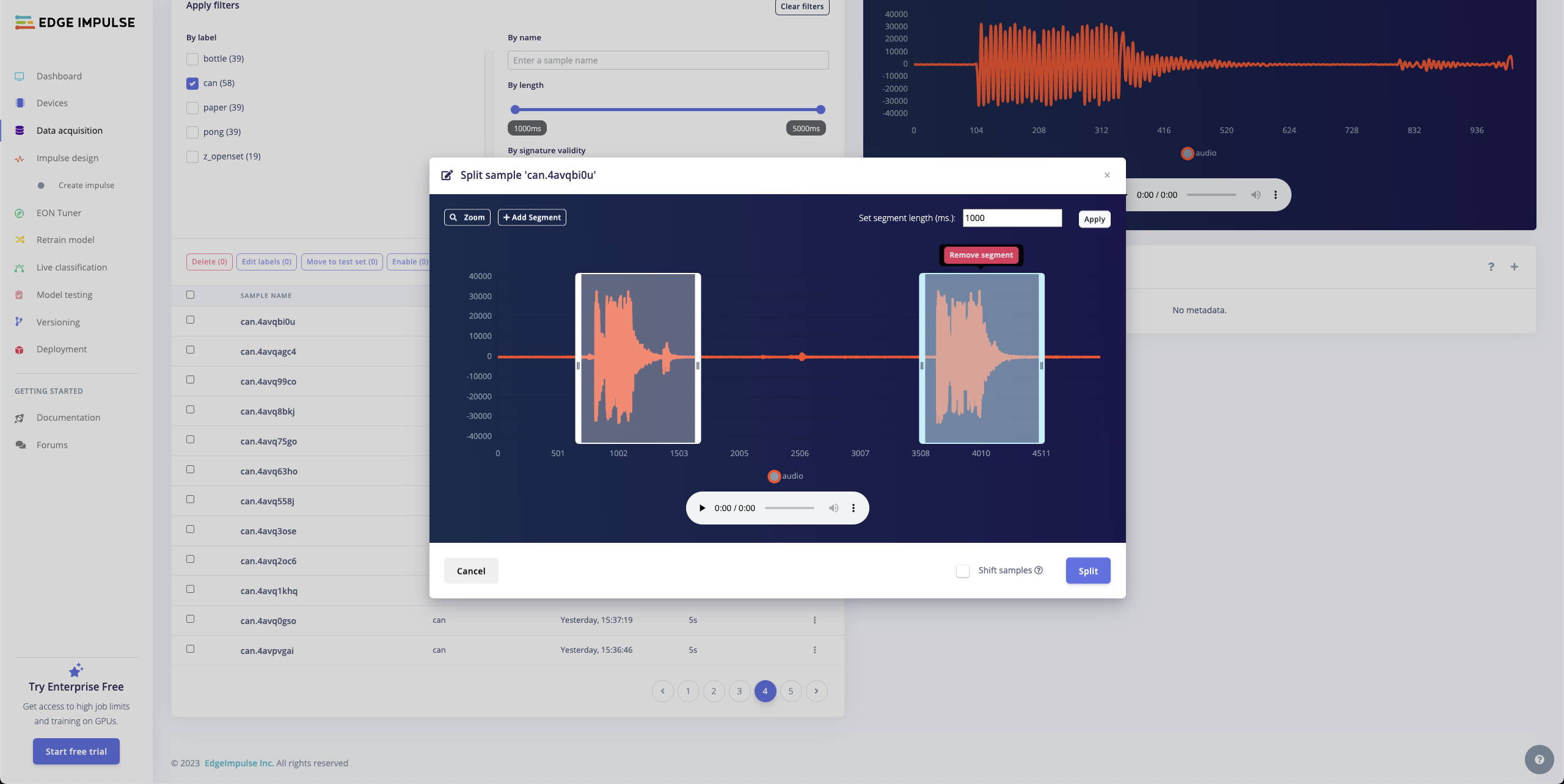

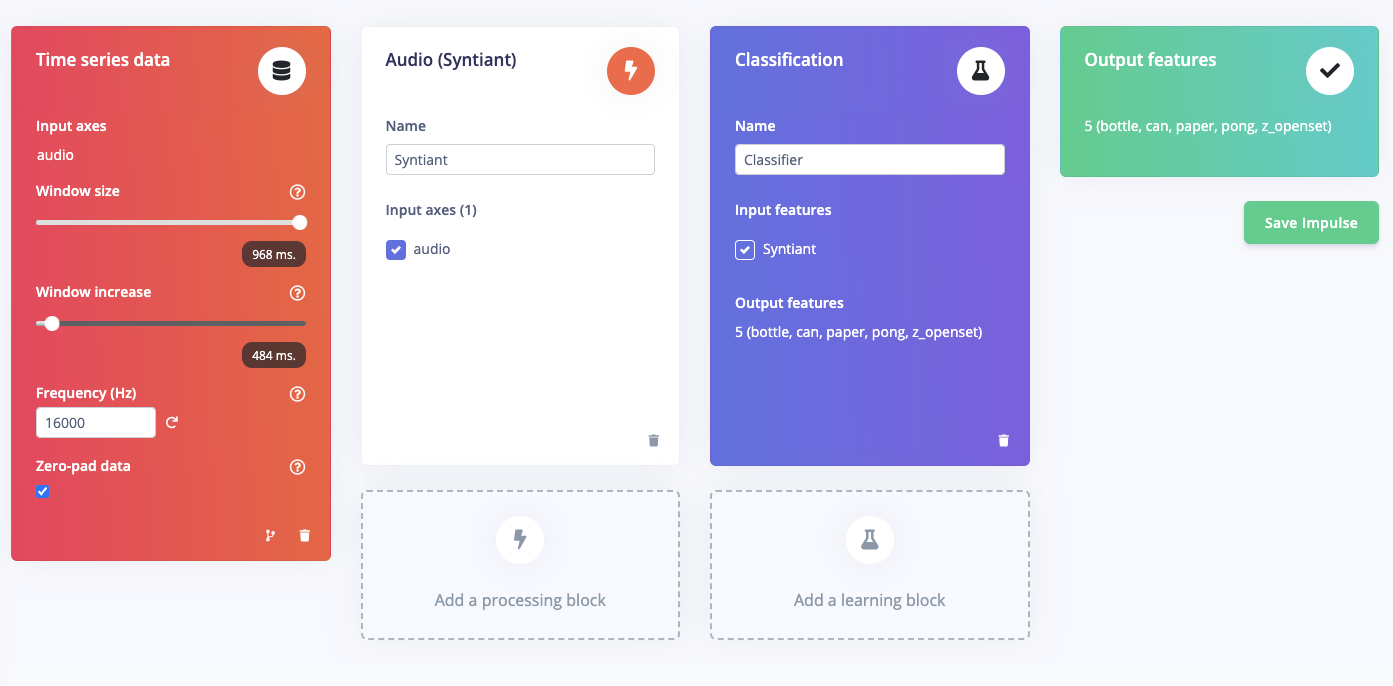

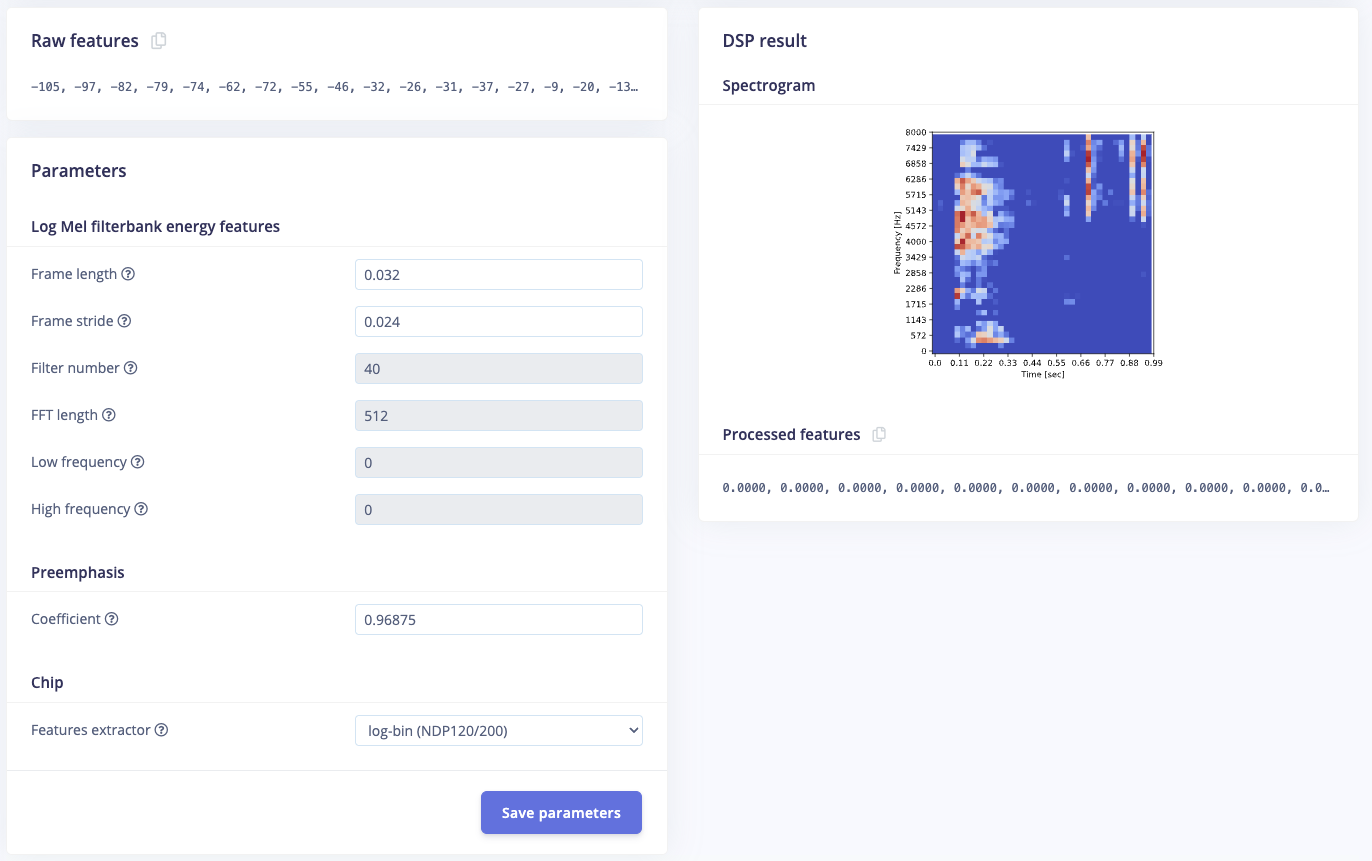

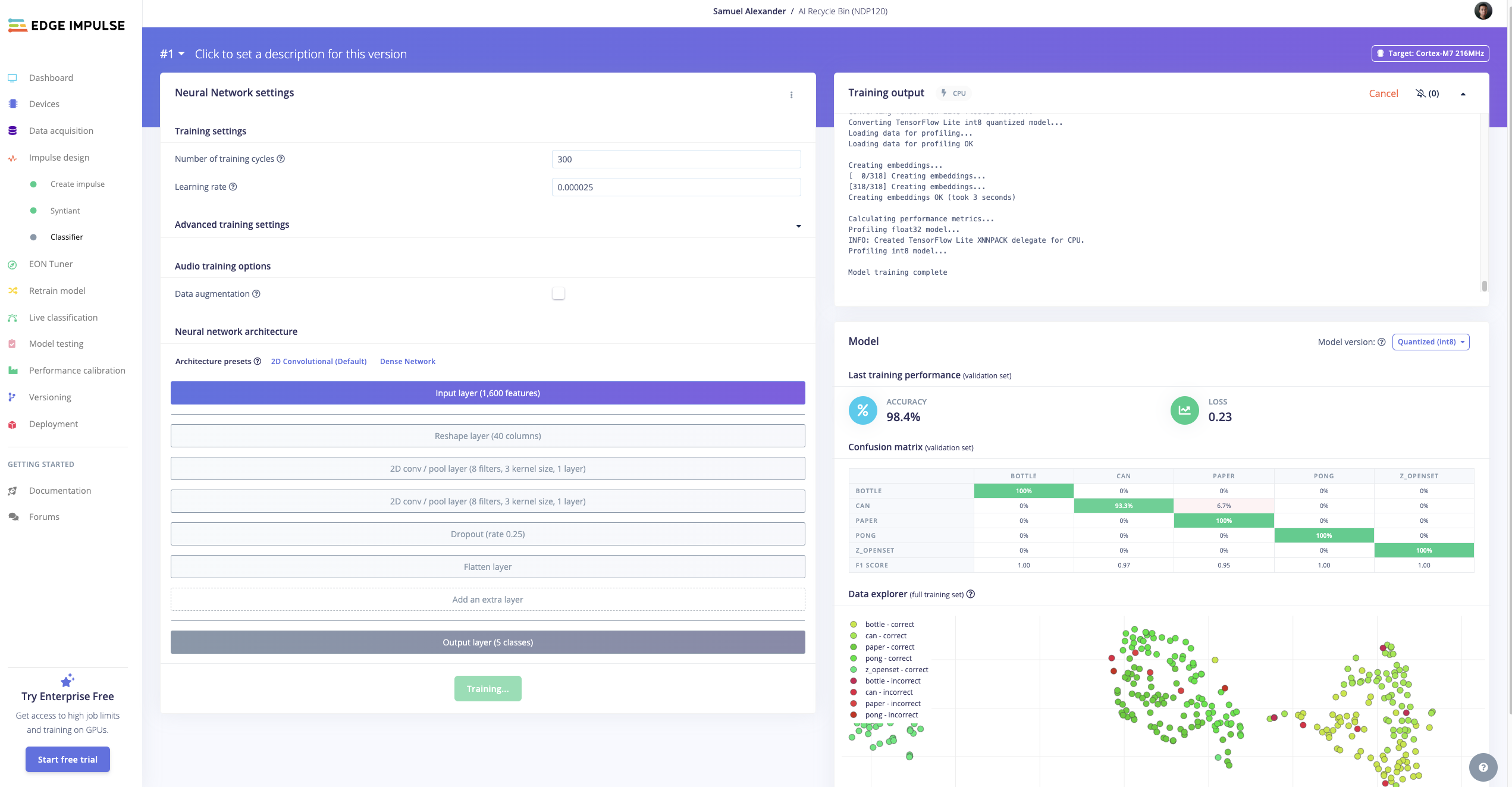

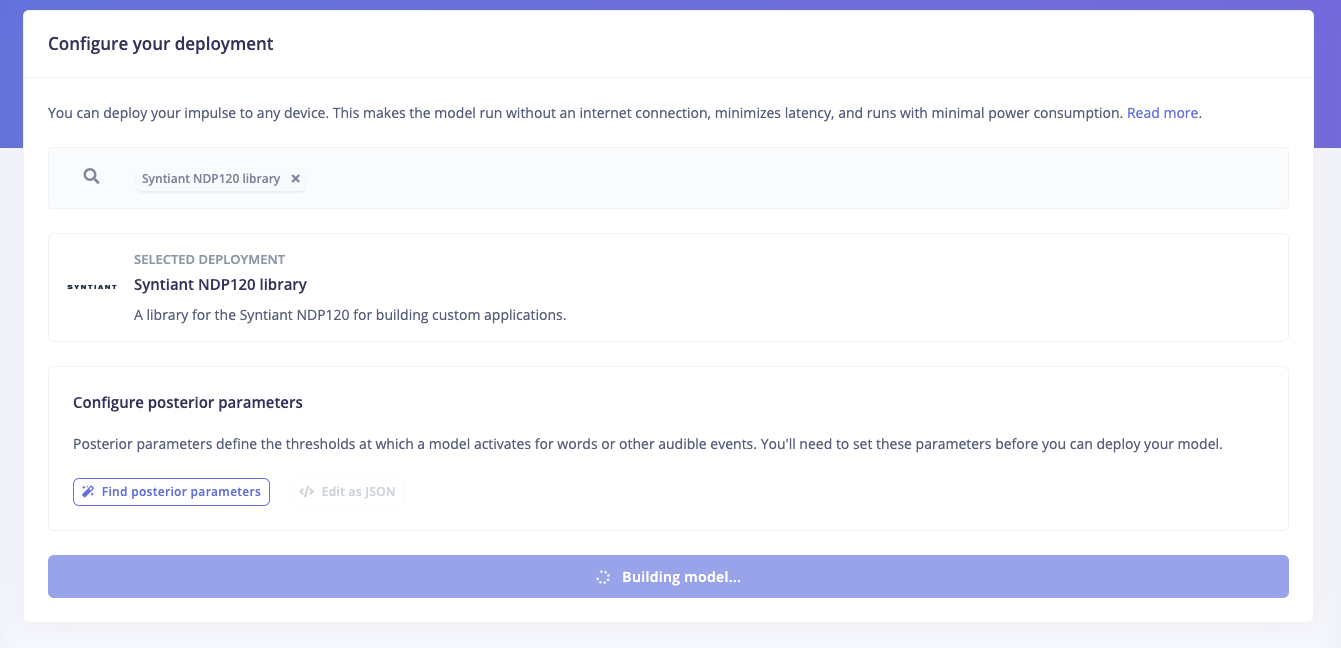

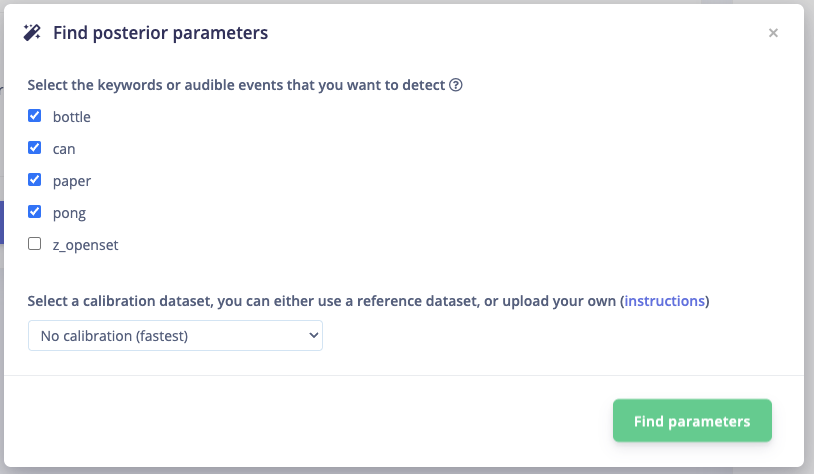

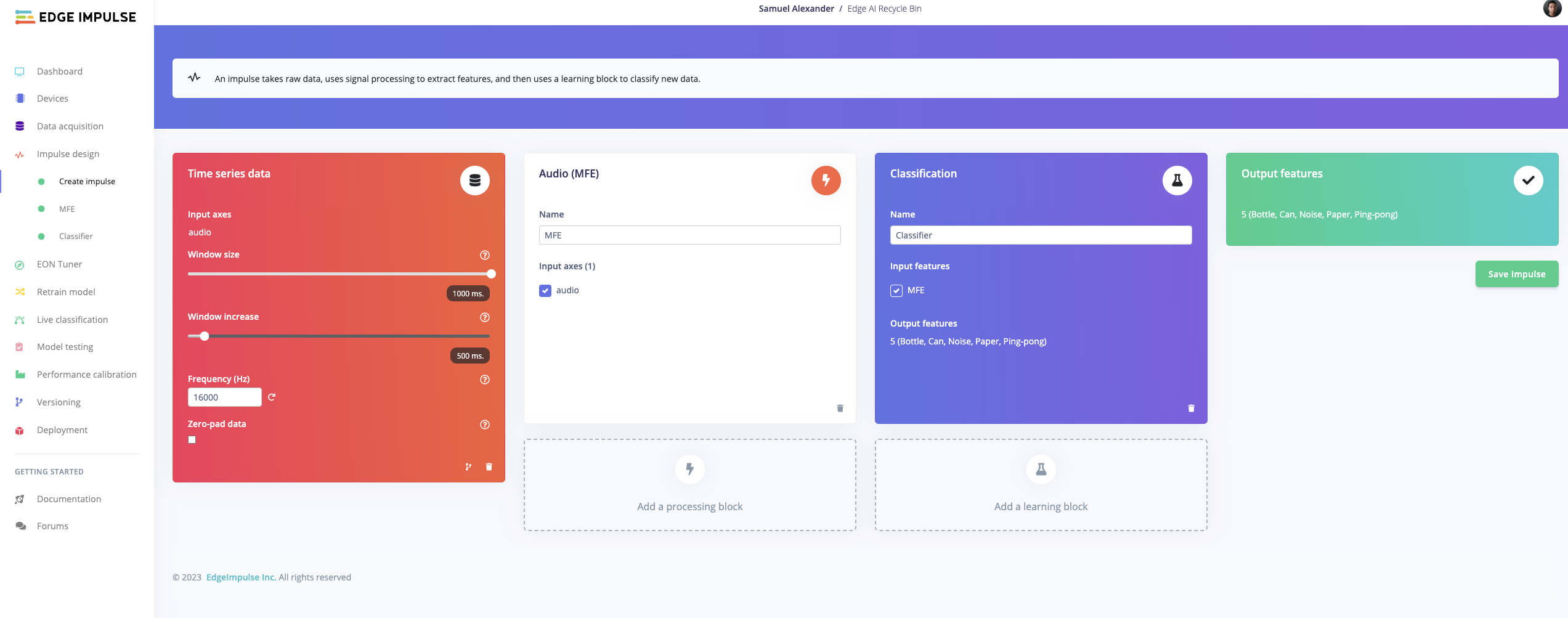

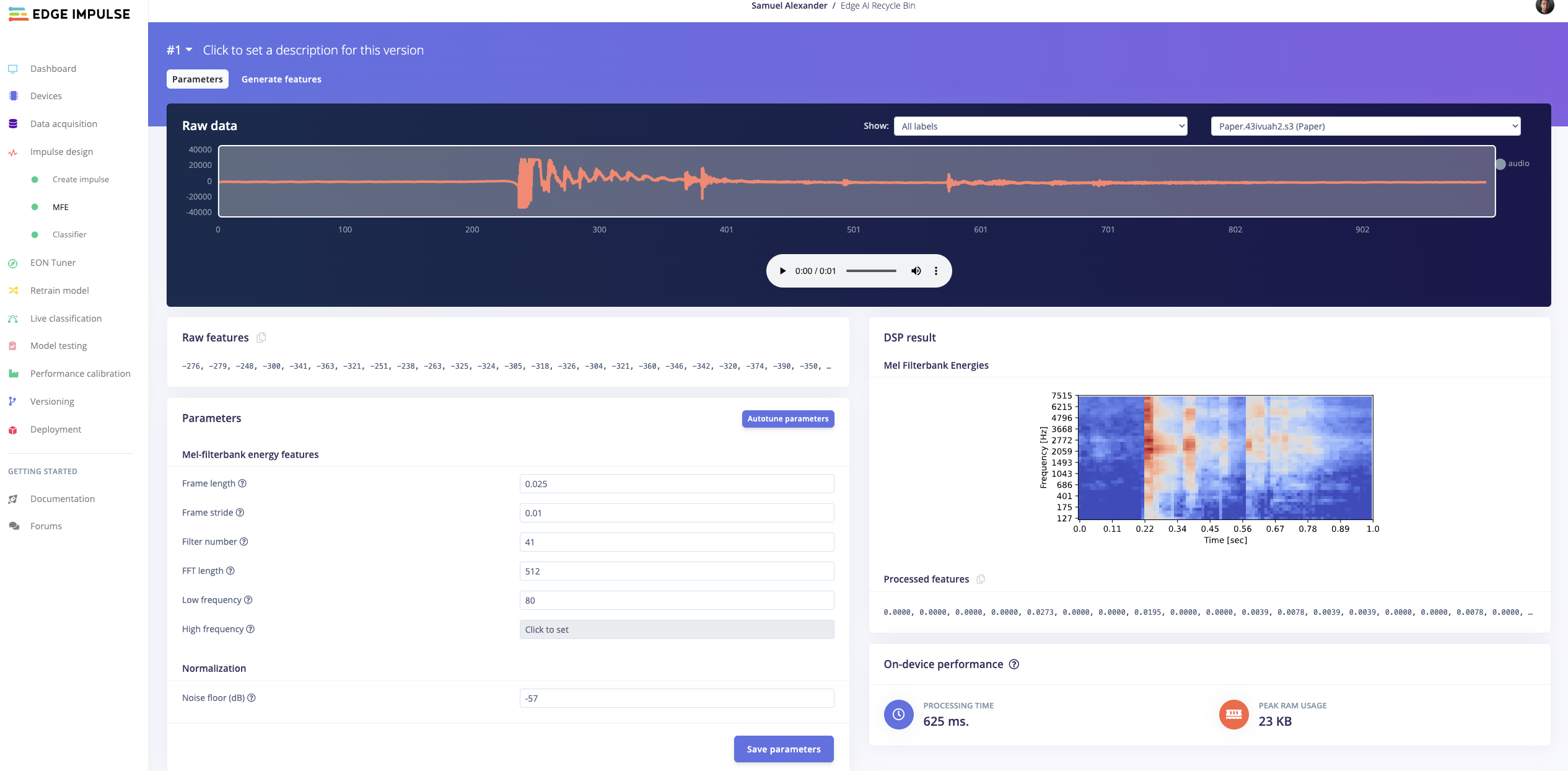

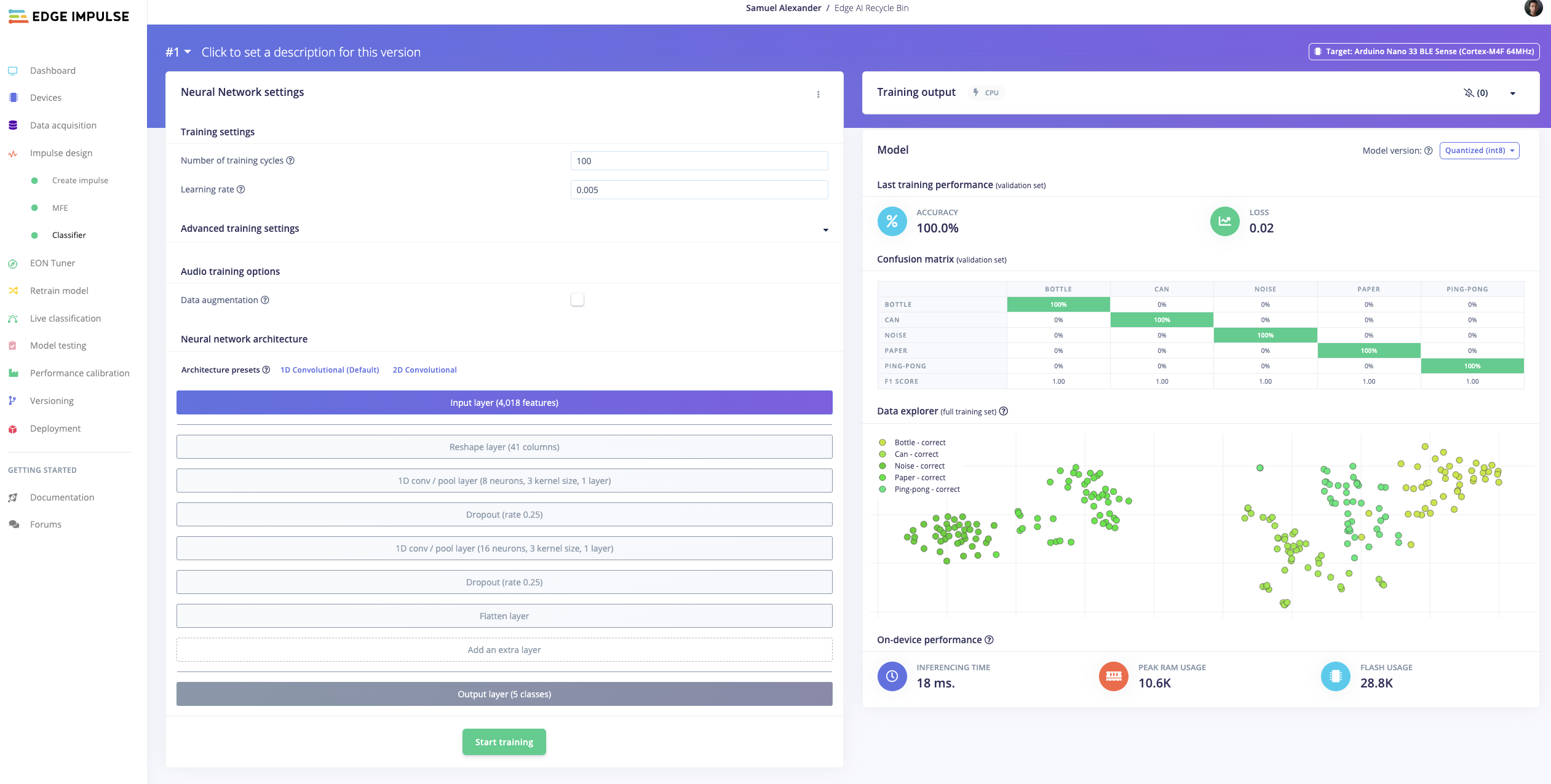

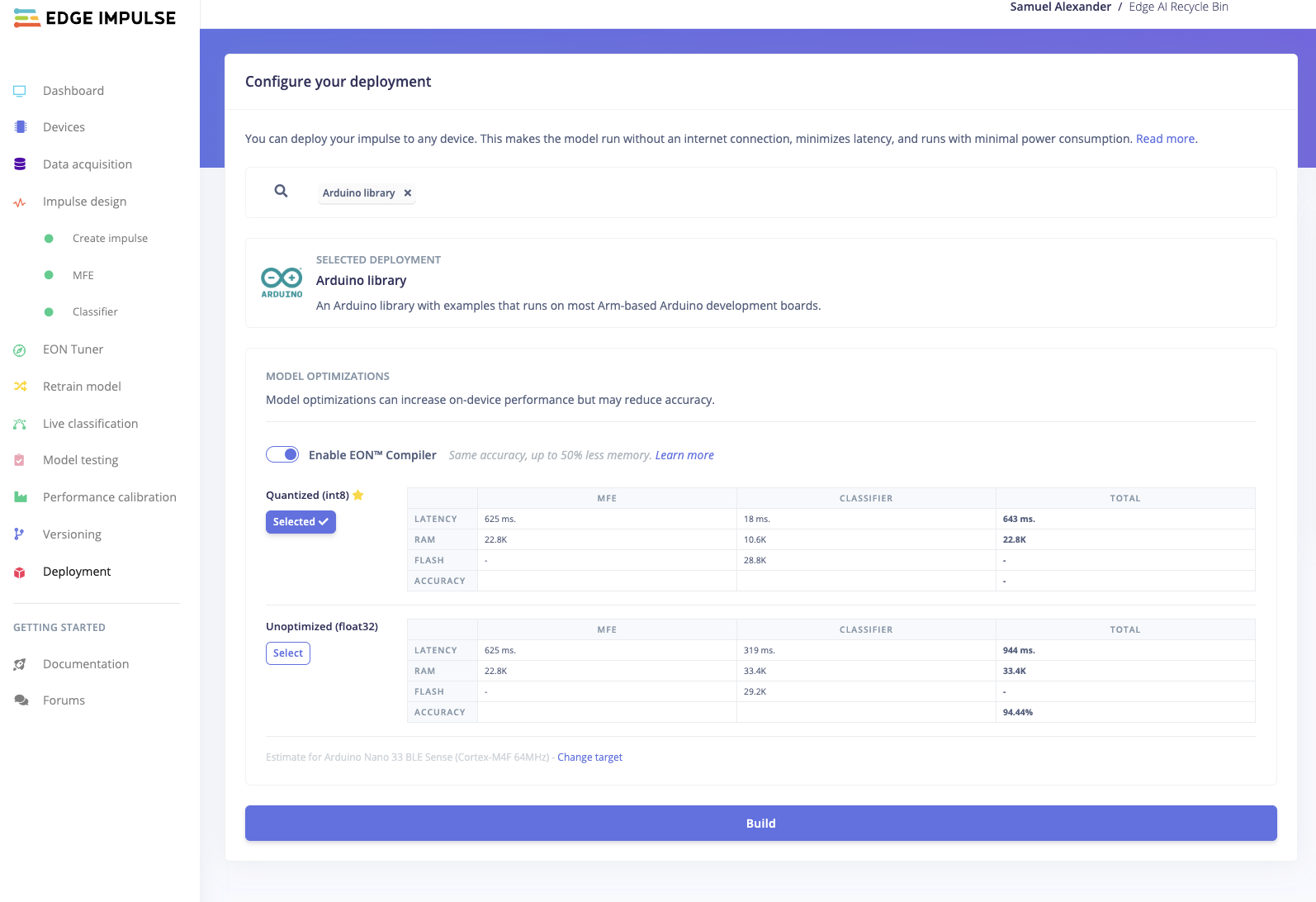

Edge Impulse Studio

Open Source Licenses:

Hardware license: Attribution-ShareAlike 4.0 International (CC BY-SA 4.0)

Software license: Apache-2.0

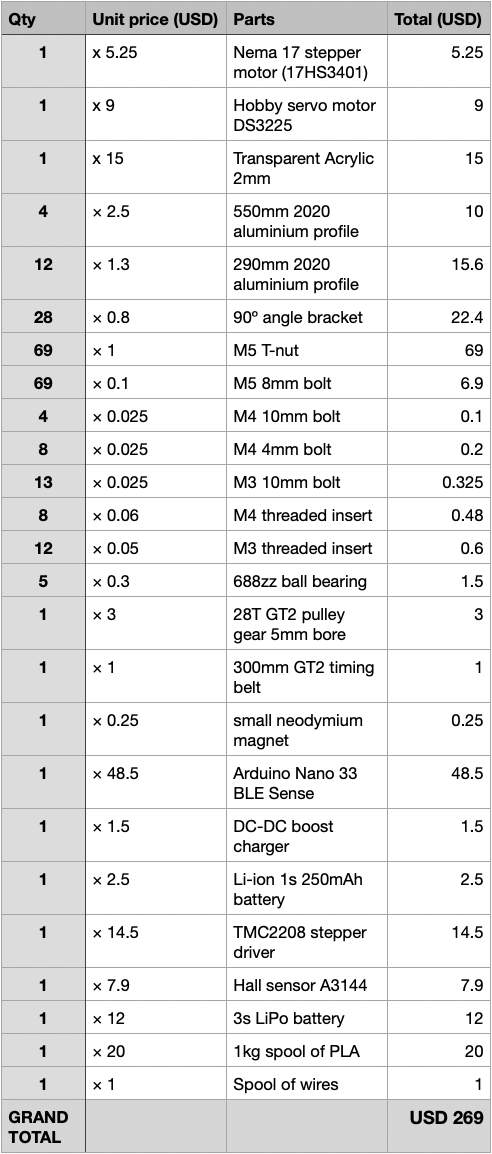

Bill of Materials for 1 unit (base model):

Keep in mind that this does not include customs fee and shipping fees because it will be different depending on where you are located. This Bill of Materials does not include upgrades; with a custom PCB + Portenta C33 + Nicla Voice + other small upgrades, the cost of 1 unit may go up to USD 371.

Samuel Alexander

Samuel Alexander

Mirel Paun

Mirel Paun

Simon Merrett

Simon Merrett

Errol Joshua

Errol Joshua

Hi. I'm interested in purchasing one of your kits. Could you please contact me?