Last year I kinda accidentally took the laser cut precursor to this CNC to a day of the Midwest RepRap Festival (MRRF) -- the tenth iteration of the oldest/first of the RepRap Fests. I heard lots of very encourating feedback. Stefan of CNC Kitchen took a close look and gave it a video after he got back home.

MRRF?

A great drone flythrough video can give a quick visual impression of the event.

A more expository 2+ minute local TV news exposition includes a brief interview with Sonny Mounicou.

Going to the Big Show

Earlier this year, after convincing myself that the 3d printed CNC core would work, and getting more stuff working inside the box, and sorting some ideas for doing all that better, and looking at lots of weeks before the event, I started thinking I might have something that would more directly interest 3d printing people than the laser cut thing. So I actually booked a hotel room and made a plan.

Then other stuff happened and I got a lot less done than the motivating aspiration, but still had something coherent to show.

I didn't take a lot of pictures. In fact, at the show I took one picture:

While packing stuff for the show I thought to take my microscope for grins. That turned out to be very helpful for people to get the 'wow' of the project. After fiddling with it for a while, I got the idea of taping out examples in an arc around the vertical pivot in the stand, which made it very simple to swing the scope head across all the things. For example, Ryan of MPCNC fame appreciated the closer look.

The microscope helped in part because I didn't really get to keep the mill itself very busy doing its thing. I did manage to cut one little bevel gear that I didn't have an example of. (because I forgot to pack the little differentials!!)

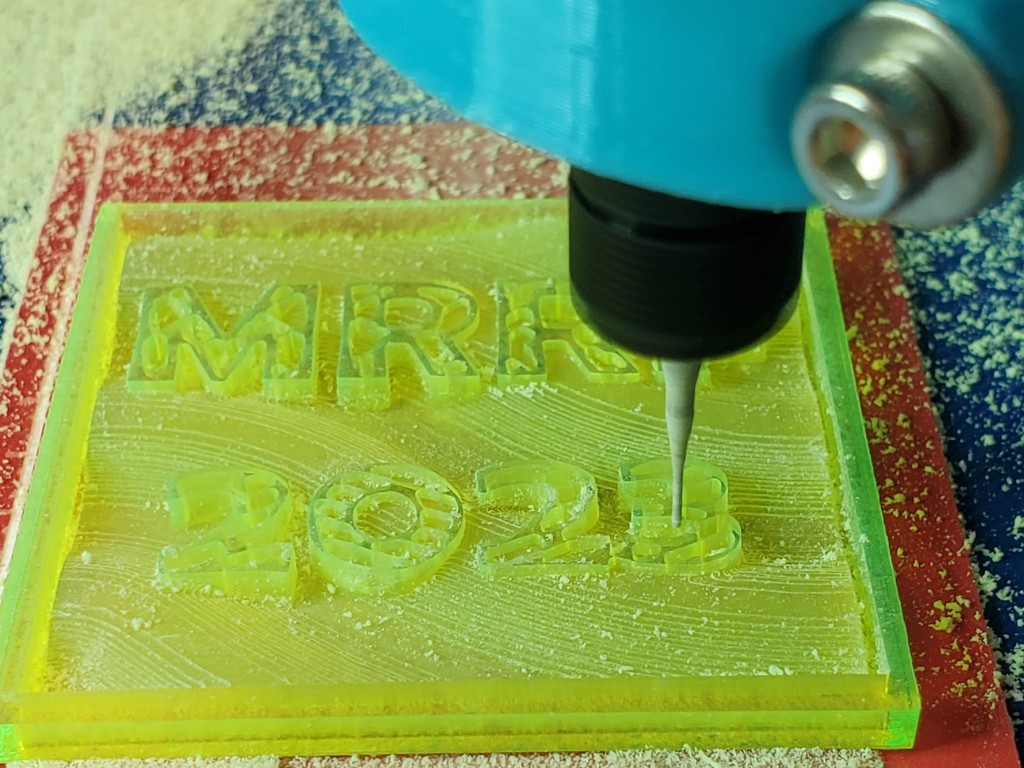

Early on I cooked up the idea of carving the MRRF logo, but by the time I got that idea mashed through CAD to gcode while frequently distracted (the talking-with-people part) it was too late on Sunday to finish, so I just let it run until it was time to pack up and, unsure that I could actually resume the job successfully, took note of where in the gcode I had to pause it.

Later (considerably later, because life) I was able to re-register close enough to perfectly with the incompletely cut workpiece and hack the gcode to gracefully pick up where it left off. It worked pretty well. Here's the end of the resumed-and-completed roughing pass:

The result after a finish pass appears at the top of this page.

Although I was almost continuously at my table and more often than not talking with someone who stopped for a look, I walked away for a bit Sunday morning to collect an offer of free filament. I recall a drone flying overhead as I walked away -- which turned out to be the fly through video that shows my table sadly deserted.

There's the back of a display showing example vids and images (some dated and some current from the new machine), the mill, the blue printed parts for the next rev that I hadn't had a chance to assemble before the show, the microscope and light, my laptop probably with the MRRF logo CAD open, etc.

The filament vendor had already packed up and cleared out, so my absence was for naught.

I enjoyed talking with lots of people, which also helps break up crusty thinking. I didn't do a very good job of retaining who spent time at my table talking about what. Sorry if you're reading this.

Things I learned from talking to people:

- If quicker tool changes matter, multiple rotary tools each set up with one needed bit could help speed up tool changes

- so I'll have to check repeatability of the Z axis tool clamp

- for double-sided parts, using a thicker spoil board could relax how precise holes need to be for locator pins if the holes can be deeper

- While helpful for proof-of-concept, the packing tape hinges really don't count as a durable assembly

- but even with good brainstorming help, we didn't come up with a good upgrade

- but I think maybe I've found something that could work (in hand but not tried yet)

- or maybe UV-resistant tape would actually work?

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.