I don't mean to share a story that you're going to be bored reading, nor am I trying to picture myself as an "inspiring youth inventor". I am an ordinary maker just like anyone else. I hope that this can help other young makers realize their potentials, if anyone reading this is young.

The Beginning

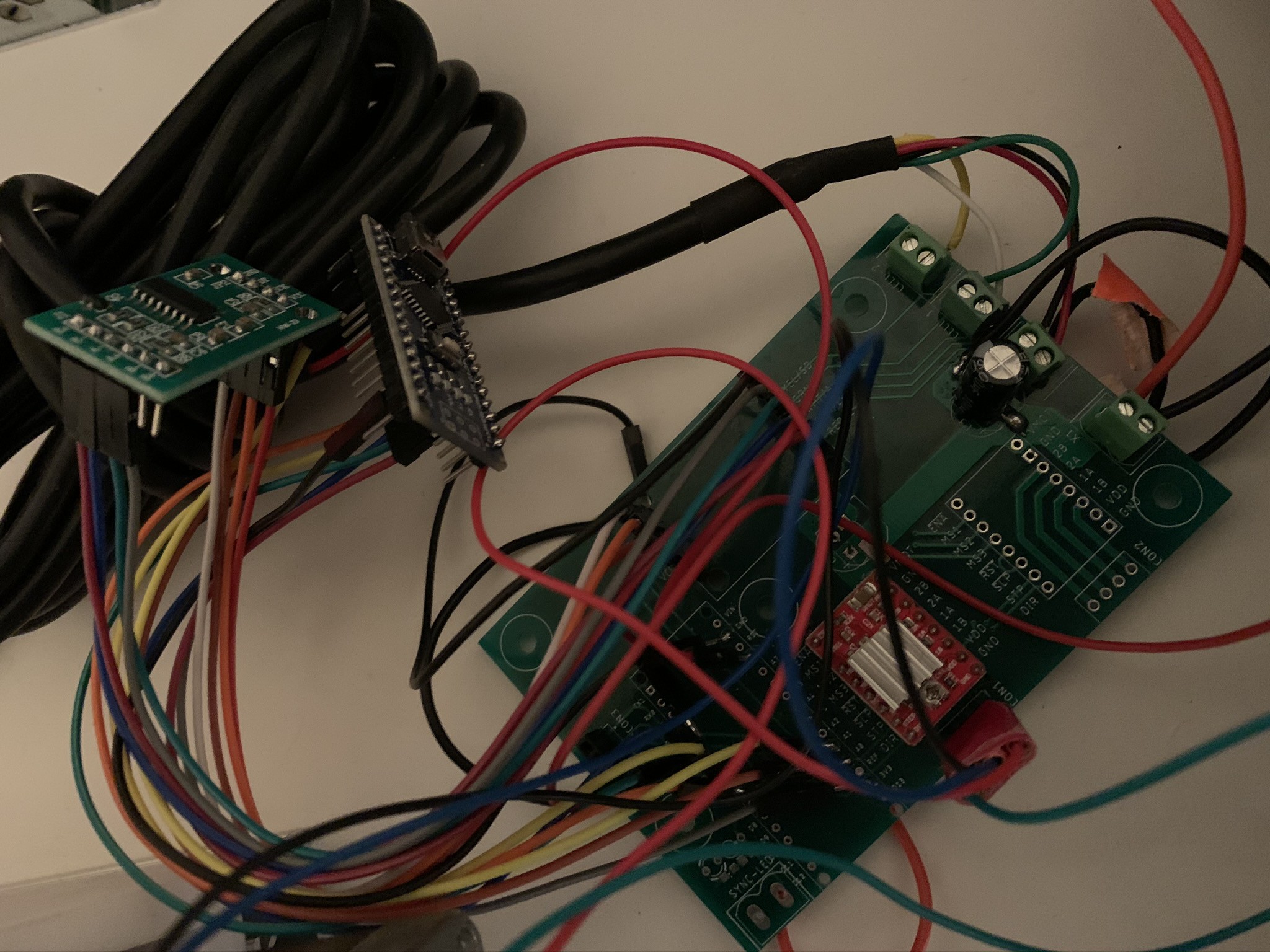

This is the first version of the machine:

The idea was born when I was an 8th grade student at Arizona College Prep Oakland Campus looking for inspiration for Science Fair. A YouTuber I watched, CNC Kitchen, tested the tensile strengths of 3D printed specimen on his videos, and I decided to replicate his experiments for my own Science Fair project.

The idea was born when I was an 8th grade student at Arizona College Prep Oakland Campus looking for inspiration for Science Fair. A YouTuber I watched, CNC Kitchen, tested the tensile strengths of 3D printed specimen on his videos, and I decided to replicate his experiments for my own Science Fair project.With some previous knowledge building hobby projects, including a 3D printer designed entirely in Tinkercad (yes, Tinkercad...I know...). I decided to design a tensile testing machine along with my friend, again in Tinkercad. It took us a few months to do so.

Check out the design on Tinkercad.

Unlike this version presented today, I decided to use CNC Kitchen's tensile testing machine PCB, which ended up being a horrible idea, resulting in this:

The person who designed this PCB did not realize that through-hole pads need pins to GO THROUGH the holes.

That's not all. I don't have a picture for it, but I ended up blowing everything up because I plugged the stepper motor driver in the wrong way.

Here is another lovely picture, featuring my also eighth grade art project.

This version of the machine had many problems, including but not limited to: large flexing/deflection, coupler slipping, specimen slipping, and fixture screw threads stripping. Some of them were "solved" by temporary patches such as this "dogbone" specimen.

It ironically resembles dog bone more than most standard dogbone shaped specimen.

Either way, the machine worked.

The process didn't go without a hitch, but I managed to finish it. My friend and I used the design for our Science Fair projects, where I tested the effect of layer height on tensile strength, while my friend tested the effect of infill type on tensile strength (we completed it on the day Science Fair was due). My friend went to Broadcom MASTERS, but we decided to co-publish a paper on our findings.

I later submitted to the Tinkercad Student Design Challenge on Instructables and won First Prize. I promised to make a second version and publish it on Instructables.

The design and assembly processes for my first tensile testing machine are featured on my Instructable. The project was featured on Hackaday.com and Hackster.

Here is a video of it in action:

Xieshi Zhang

Xieshi Zhang

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.