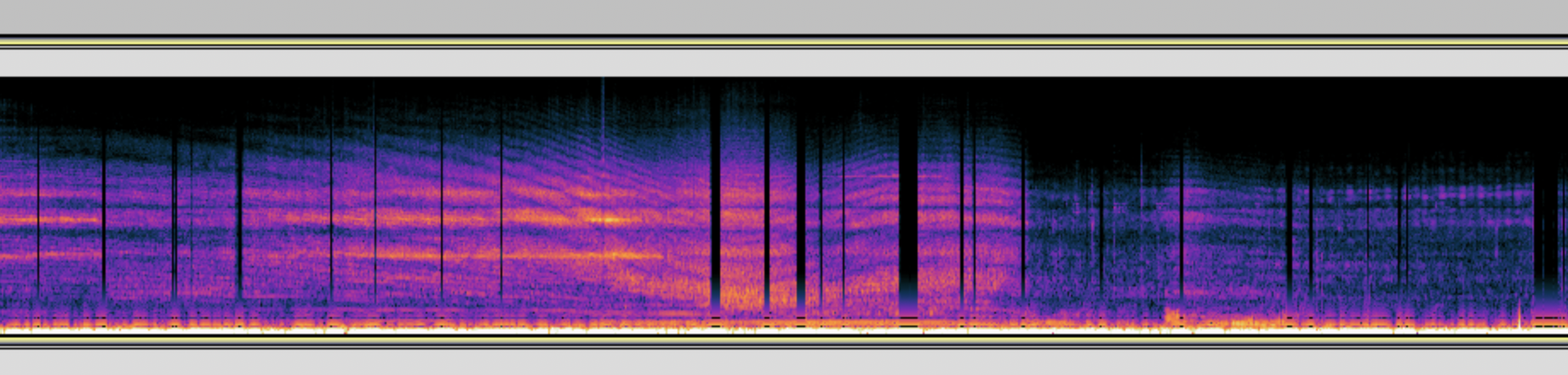

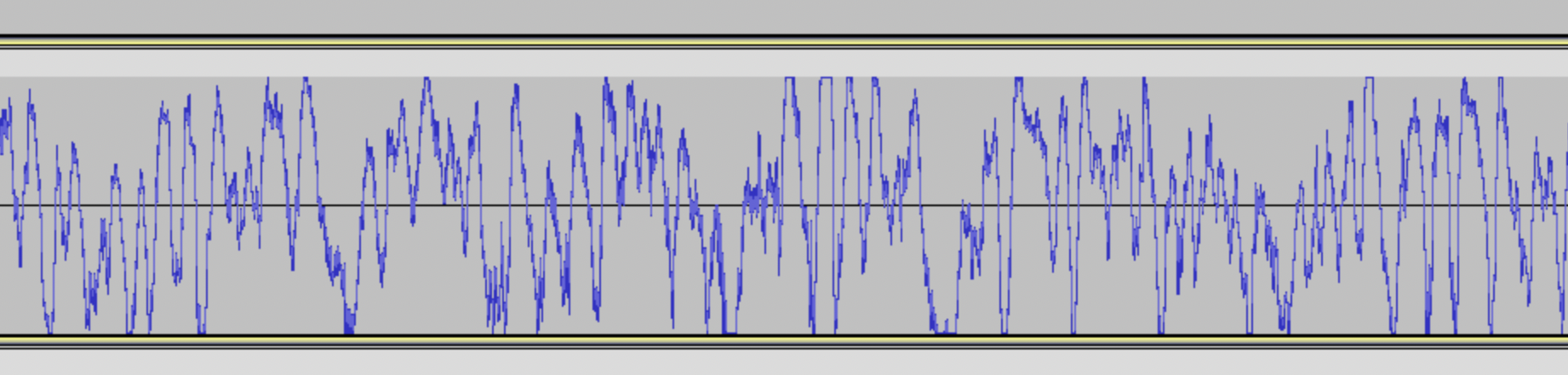

Bottom Unit: Acoustic DAQ: Applied Ocean Science's PAMELA DAQ (Portable Acoustic Monitoring Electronic Logging Apparatus)

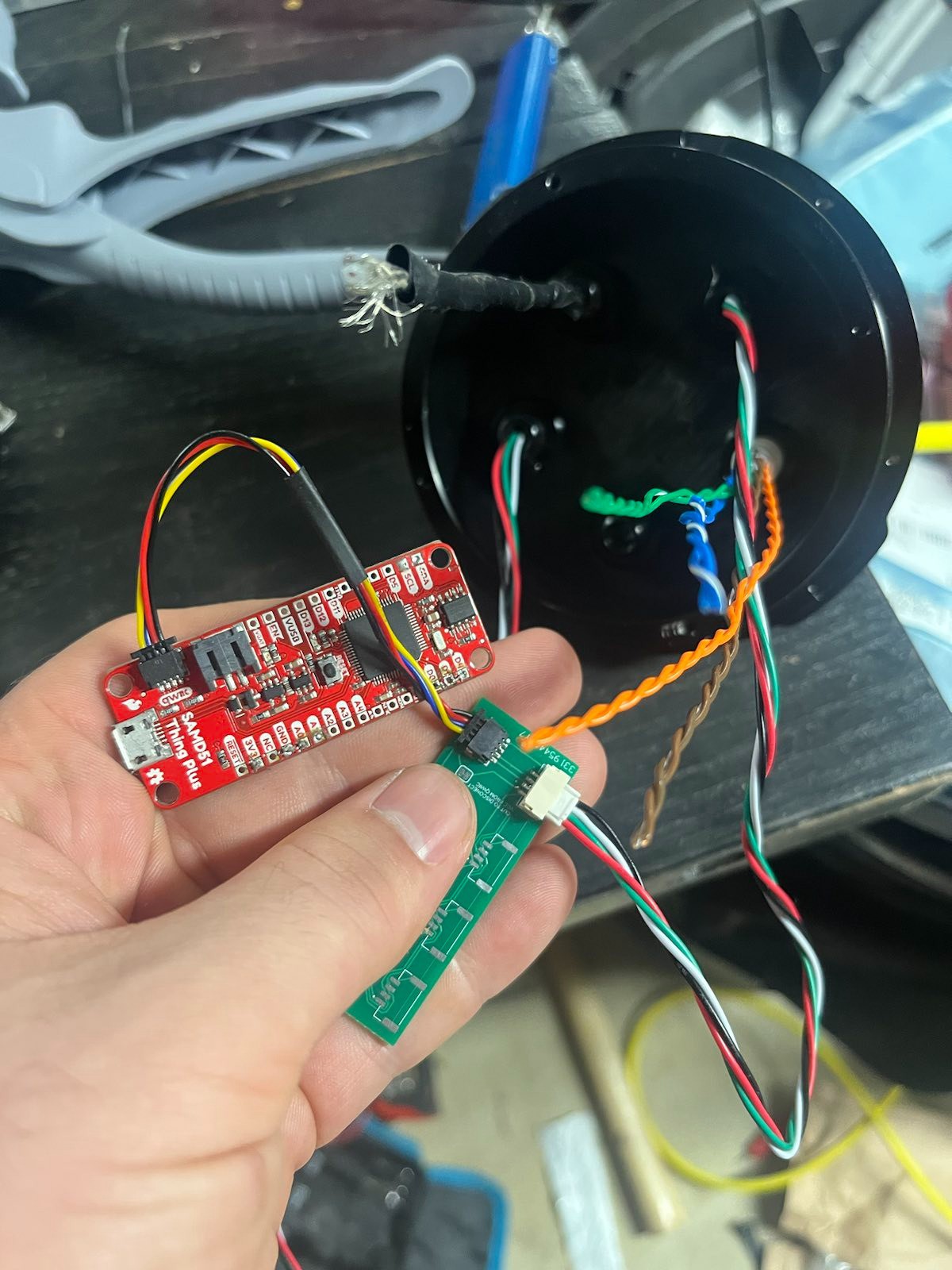

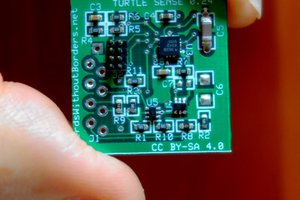

DIY recorder using an SGTL5000 codec and a op-amp based pre amp

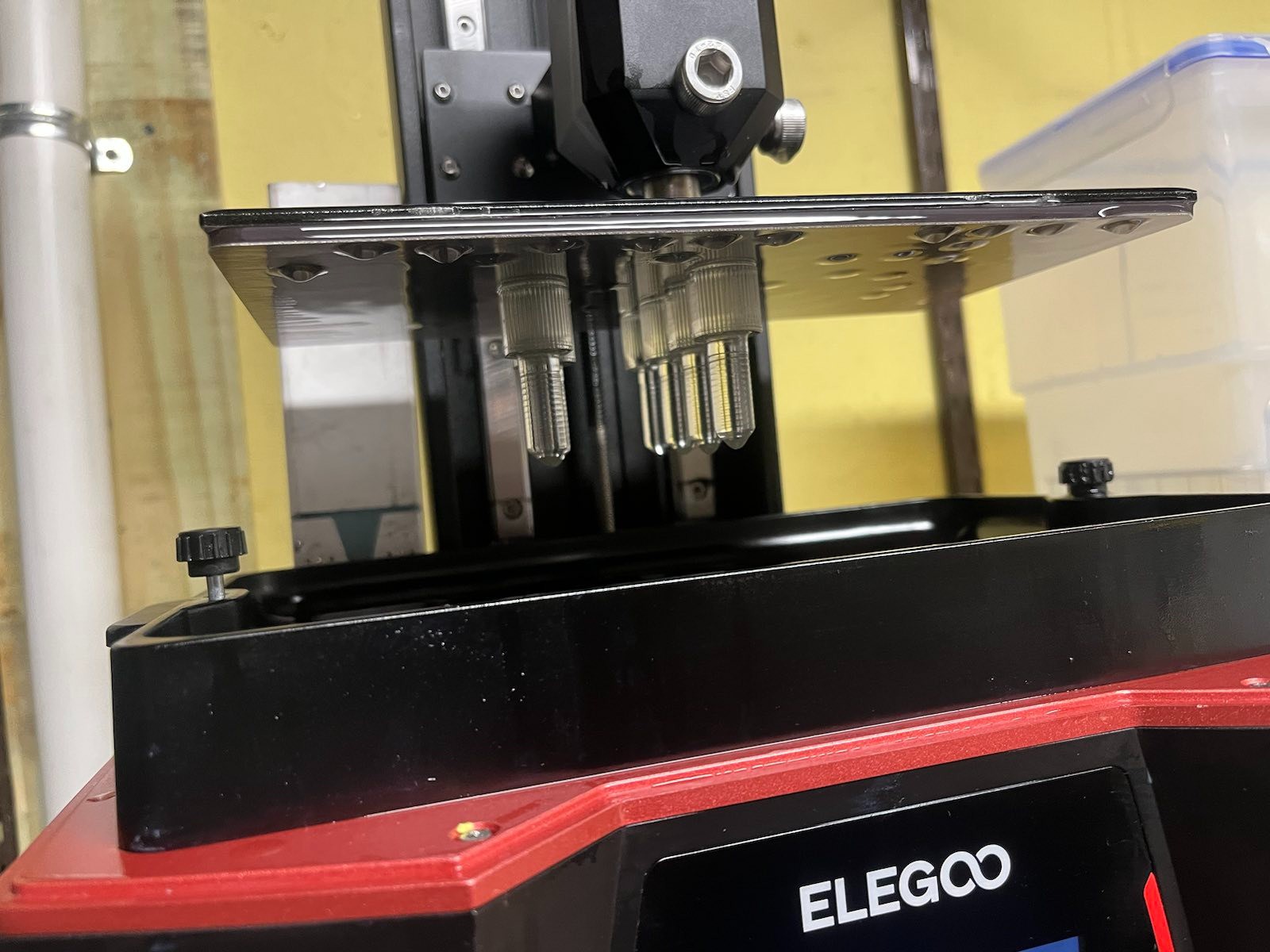

Aquarian AS-1 Scientific hydrophones

Lipo pack: 3s5p 18650s

Blue robotics Pressure Sensor for depth (MS5837-30BA)

Blue robotics Temperature Sensor (TSYS01)

Sparkfun Single Pair Ethernet transciever

Tether: 300 feet of Blue Robotics Fathom ROV tether for 4 twisted pair

Blue Trail 8 pin waterproof connector

Topside:

Radio unit

Spot tracker

Julian Blanco

Julian Blanco

Samuel Wantman

Samuel Wantman

Naveen Sridharan

Naveen Sridharan

pastcompute

pastcompute

Param Aggarwal

Param Aggarwal