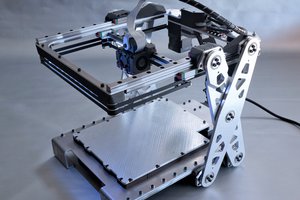

The quest for a perfect 3D printer is a long one. I've had 6 of them now and have spent literally thousands of dollars chasing a printer that I could recommend. Finally, last fall, after hearing all the hype I bought a Prusa i3 MK2. I must say, it was awesome in nearly every way. They nailed the software, they nailed the calibration, they nailed the bed, electronics, etc. It is literally the first and only printer that I can click print and walk away from and know that a successful print will just magically be on the bed when I return.

I'm sure you have read the hype about that machine, and I'm hear to tell you, it's real. BUT.... in an order to keep costs low, some corners were cut. They always are right? For some reason designers always seem to arrive at the crossroads of linear motion and fall prey to the "this will be good enough" trap. They'll run cheap wheels/bearings across cheap extrusions, or buy cheap rods and pair them with cheaper bearings, all held together with zip ties. They’ll then sit an scratch their head wondering why their machine rattles as it moves along its way, lol.

After extensive testing and validation of various linear motion options, from the ultra cheap to the wildly expensive, we have a feel for where you need to go if you require near perfect linear motion. Proper results require proper hardware, there is no substitute. So, we’ve opted for high end authentic HIWIN rails and carriages. The MK2 will never be the same.

anthony.webb

anthony.webb

Sebastian Lenartowicz

Sebastian Lenartowicz

Malte Schrader

Malte Schrader

TTN

TTN

Xo Ne Un

Xo Ne Un

Hello :) can you share parts for laser cut ?