-

2Step 2

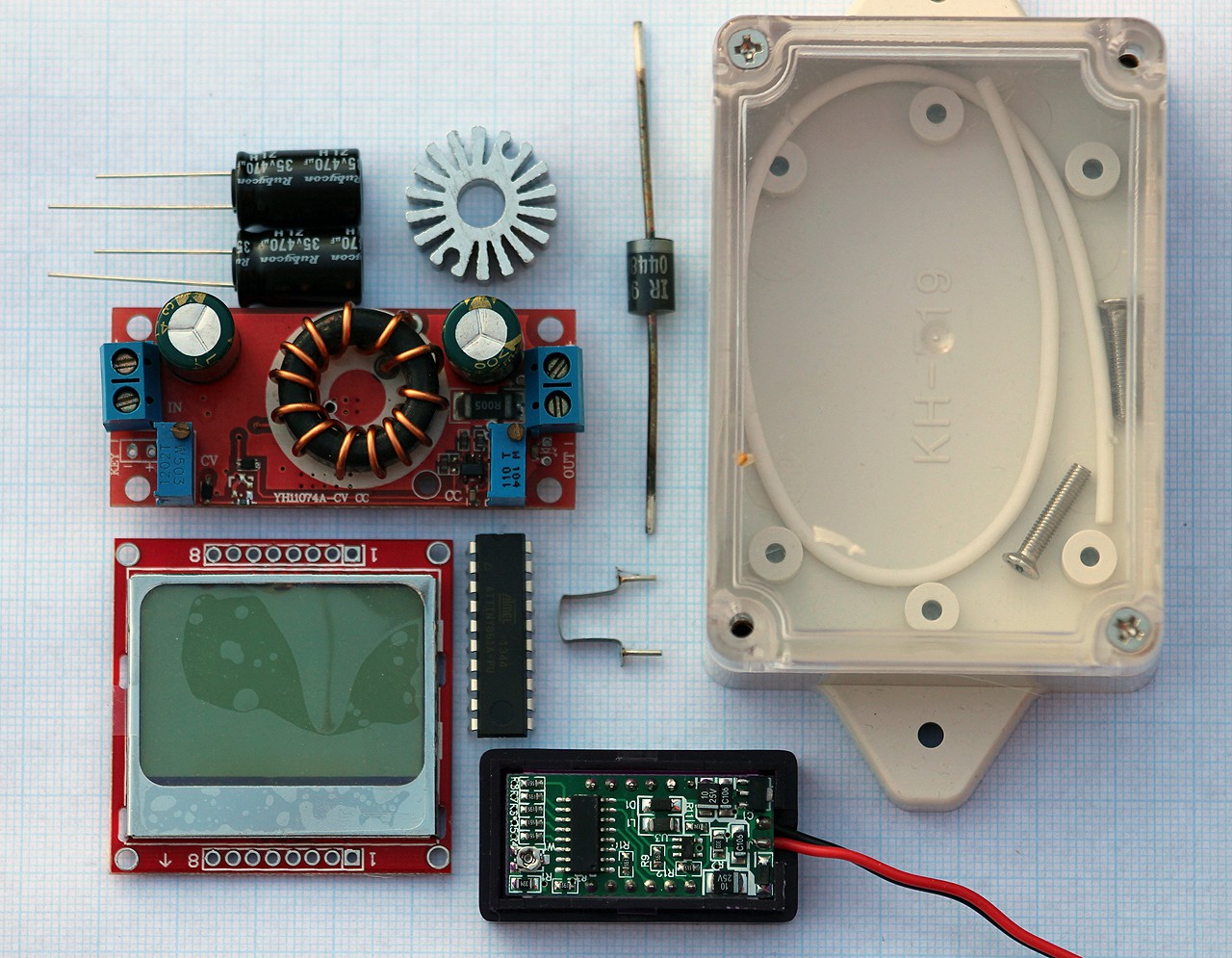

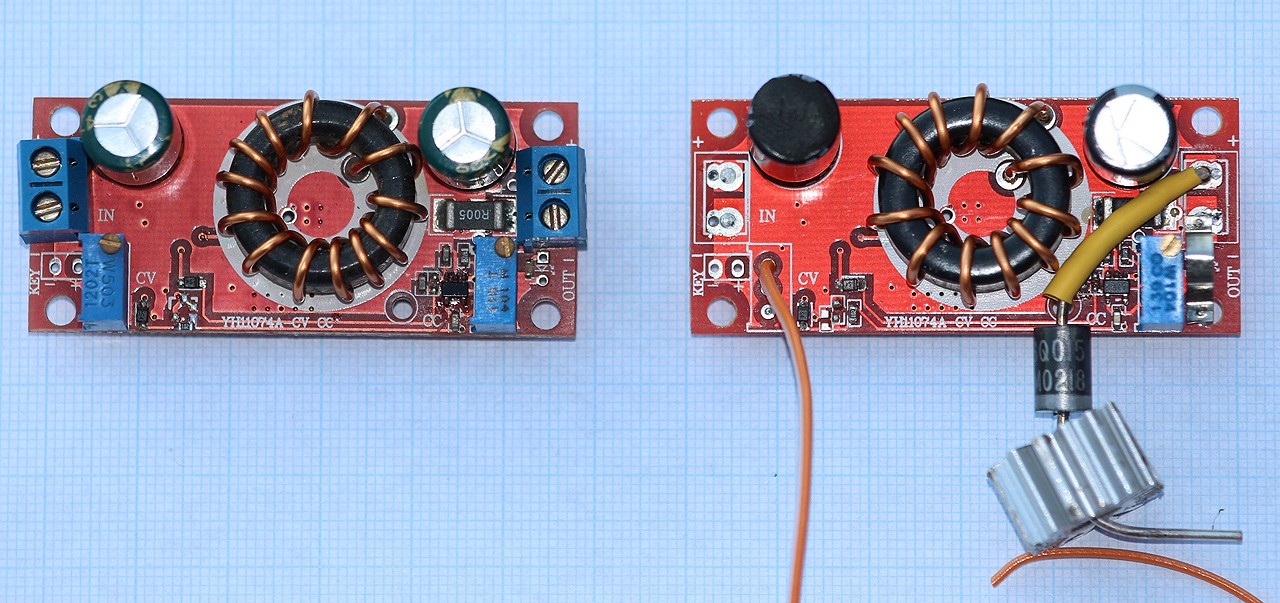

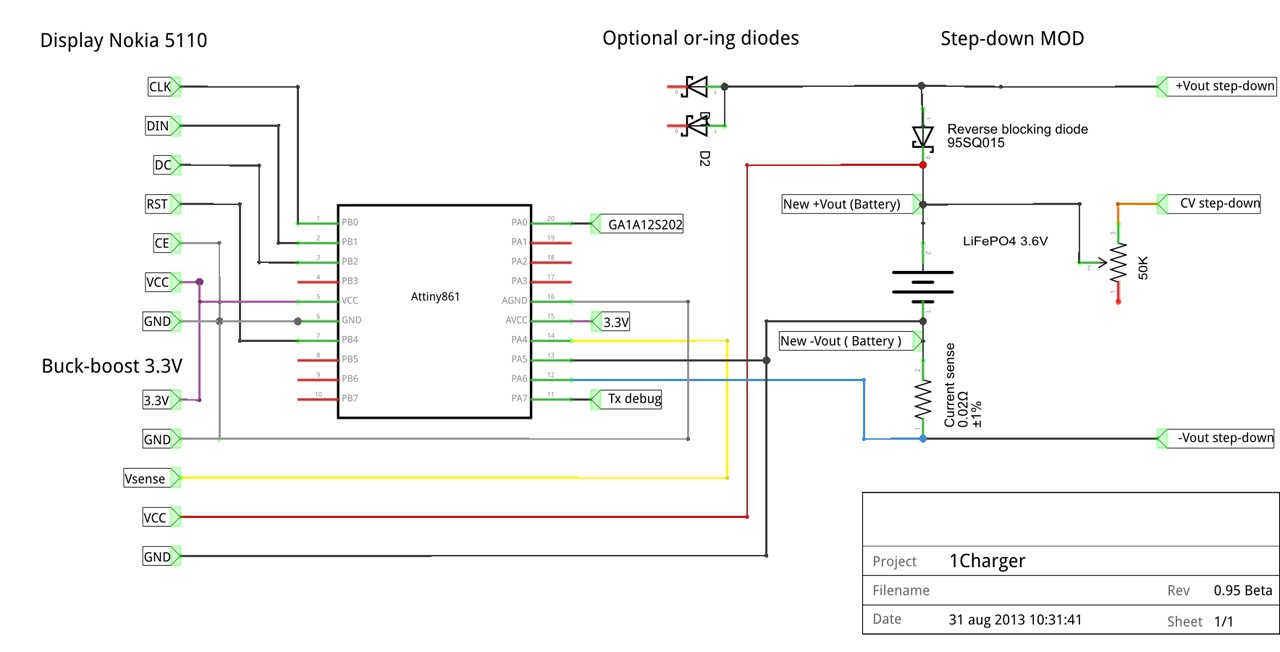

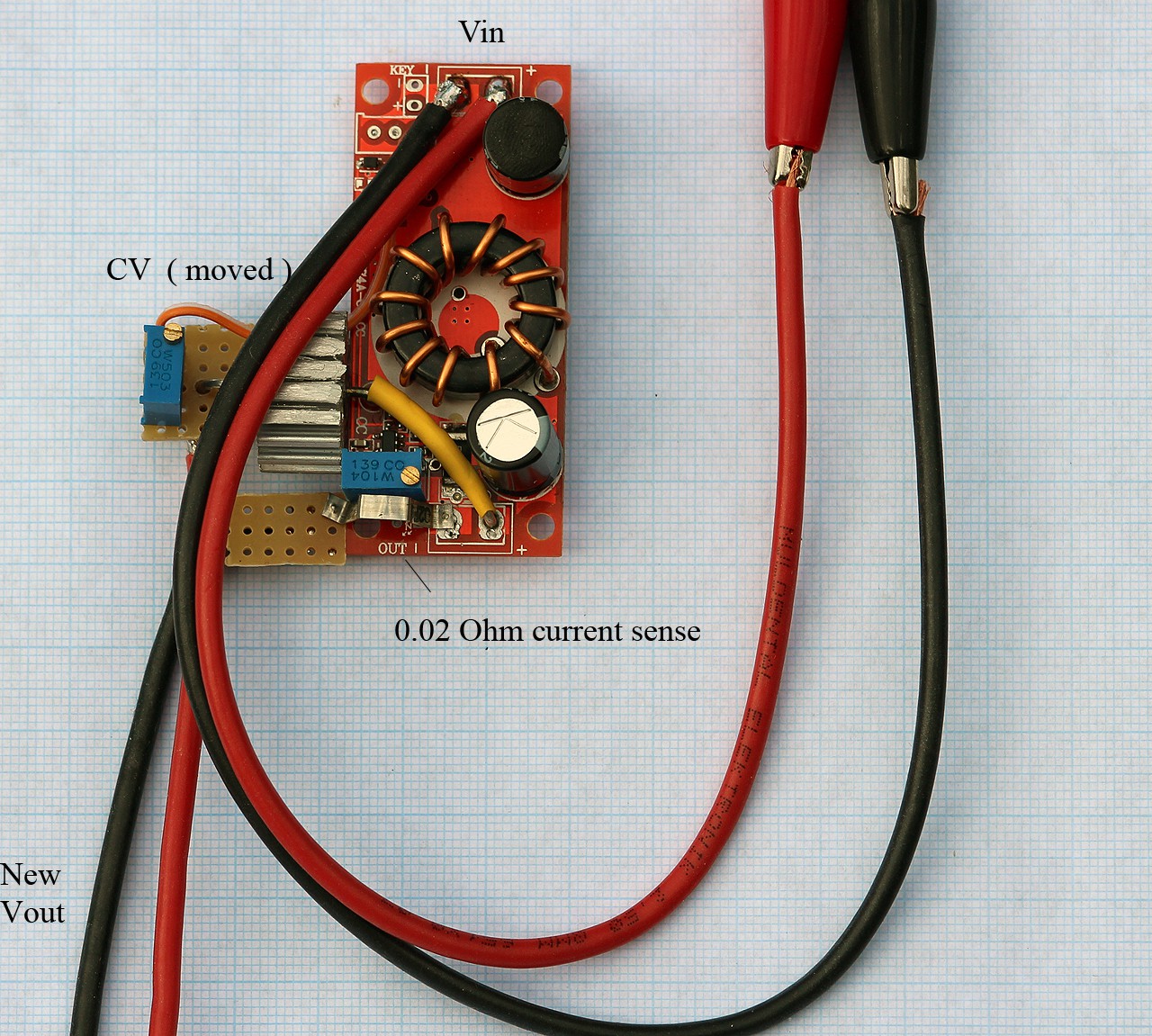

Initial modifications to step-down circuit

* Replace Sanyo capacitors with Rubycon 470µF ( optional )

* Solder reverse blocking diode to Vout+

* Desolder CV sense potentiometer and solder a wire ( orange )

* Solder 0.02 Ω current sense resistor to Vout-

-

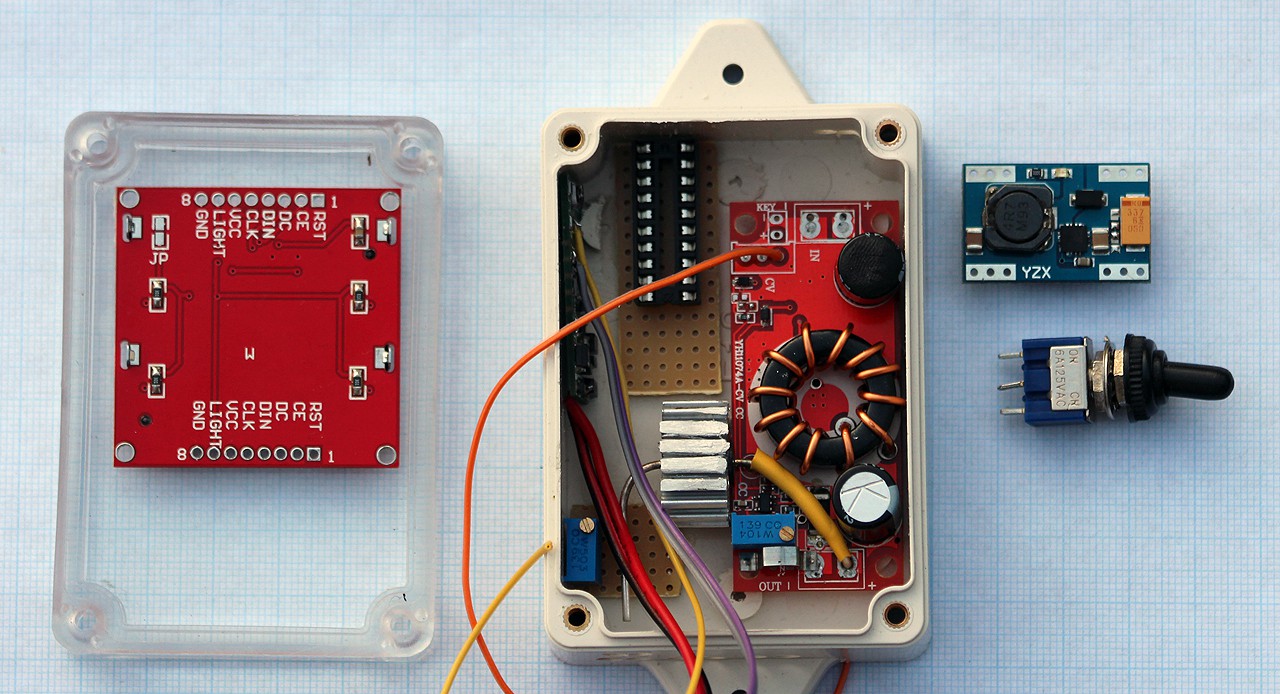

3Step 3

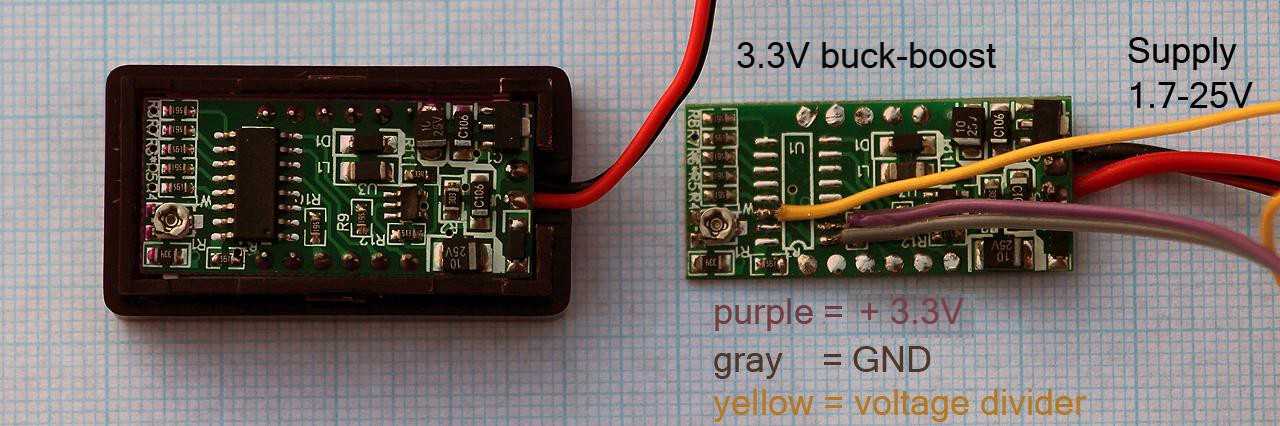

buck-boost (3.2)-3.3V from a gutted ebay voltmeter

( my guess is it's something similar to a Dickson Doubler with a 3.3V regulator )

* Desolder CPU

* Desolder LED ( 7-segment )

* Solder wire to regulated voltage 3.3 V ( purple )

* Solder wire to GND ( gray )

* Solder wire to voltage divider ( yellow )

* Apply voltage and verify you get 3.3V ( grey-purple) when you vary supply voltage 1.7-25V ( black-red ). Voltage sense( yellow) should vary accordingly if soldered correctly

-

4Step 4

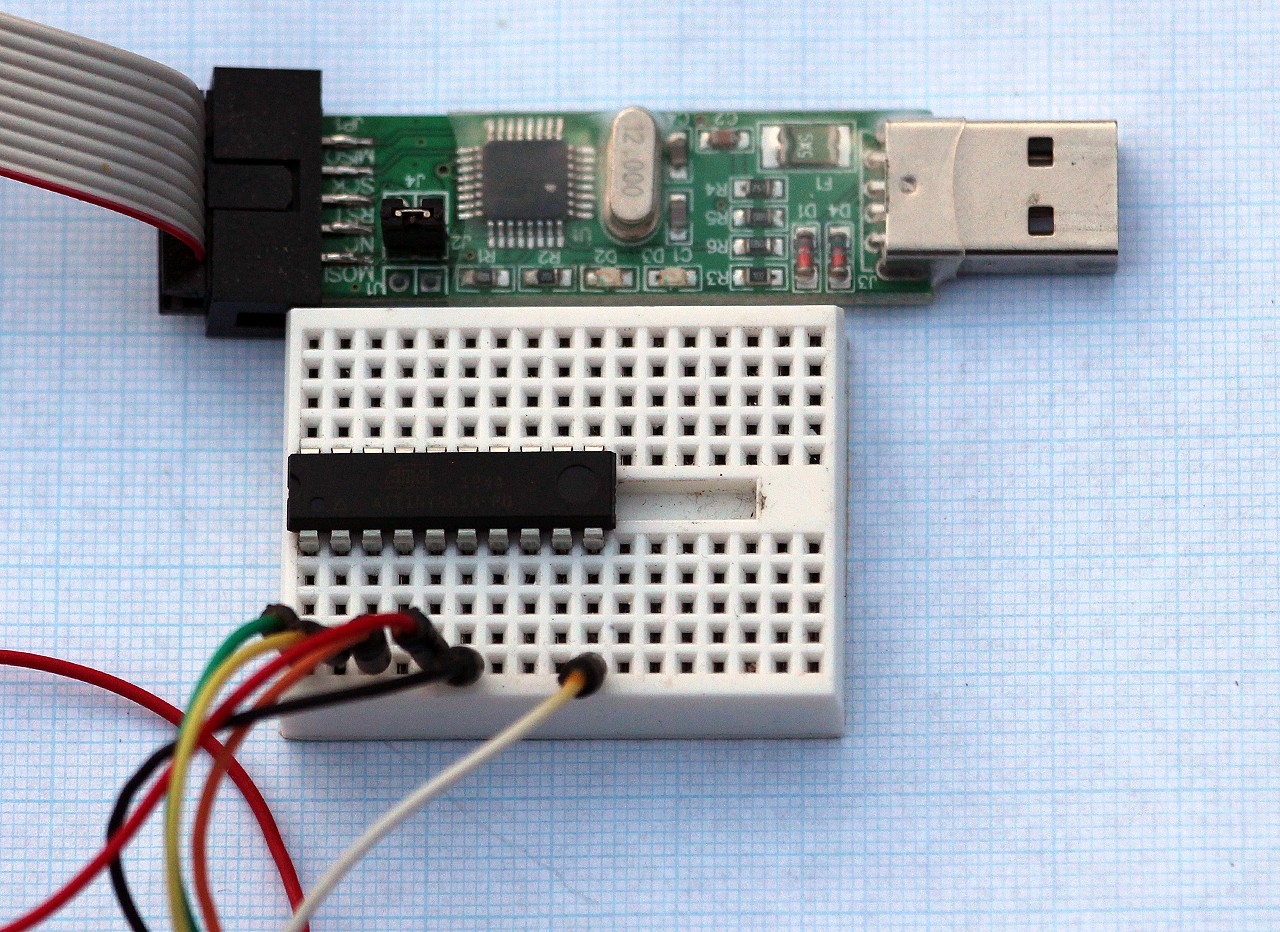

Flash ATtiny861

1. build software 1charger_src ver 0.95 with WinAvr and Code::Blocks

Read this for basic ATtiny development ....

cd C:\1Charger\src

make clean

make2. Flash

avrdude -p t861 -c usbasp -u -Uflash:w:1CHG.hex:a -Ueeprom:w:1CHG.eep:a

pre bulit with CALIBRATION

avrdude -p t861 -c usbasp -u -Uflash:w:1CHG-CALIB.hex:a -Ueeprom:w:1CHG.eep:a -

6Step 6

-

7Step 7

-

8Step 8

Complete modifications to step-down converter ( from step 2 )

* Solder 50k Ω CV resistor ( moved )

* Solder new Vout ( from reverse blocking diode )

* Solder silicone wires to Vin

* Solder silicone wires to the new Vout

* Apply voltage to Vin and verify that the new Vout can be controlled with the 50k Ω CV potentiometer

* Adjust new Vout to 3.55V for LiFePO4 single cell

-

9Step 9

There can be only one

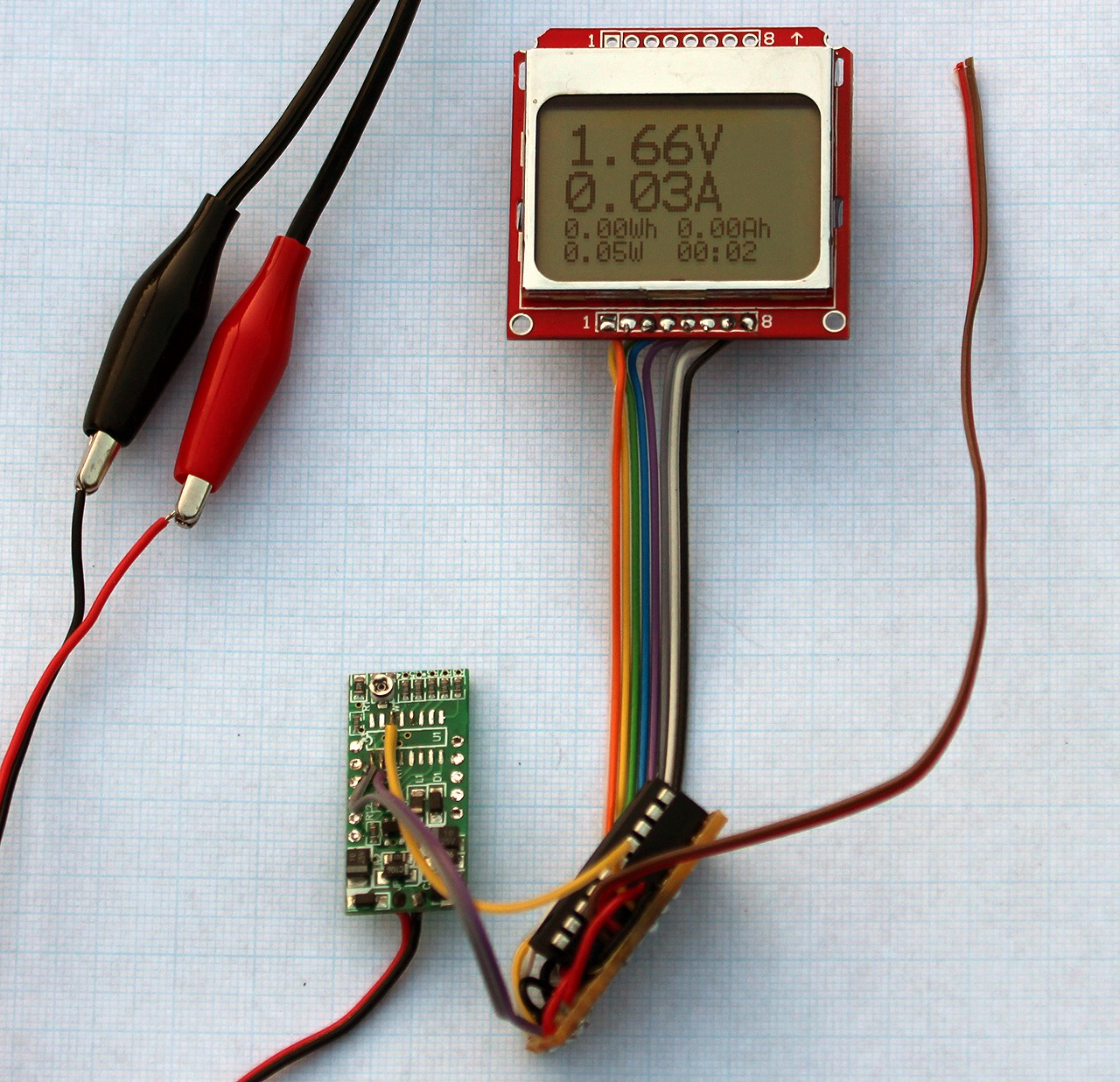

Complete the 1Charger by soldering the two circuits together ( from step 7,8 )

Solder current sense to ATtiny861

* new -Vout to PA5 ( pin13)

* old -Vout to PA6 ( pin12)

Solder 3.3V buck-boost supply to new Vout

* Vcc+ to new +Vout ( from Schottky diode )

* GND to new -VoutTest outside the box, calibrate and test everything before inserting it int the project box.

-

10Step 10

Calibrate connected-ish ( serial port )

The serial port is useful for making charge curves and debug. I use a usb to serial cable that accept 3.3v level.Connect the serial cable to GND and pin PA7

The software UART timer interrupt is also used as a timebase. If you care about serial output this calibration should be completed before time calibration. You probably have to adjust TX_TIMERVALUE =12 (default). The timer prescale is 8. Theoretically the timervalue = F_CPU/(baudrate*prescale) = 1E6/(9600*8)=13. By changing this value between 11-14 you will probably get it right ( recompile flash, test with Tera Term )

mr.jb

mr.jb

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.