The objective of this project was to build a meter that I could simply put on my motorcycle so that I could visit XYZ locations and take temperature readings without having to rely on inaccurate data from my smartphone.

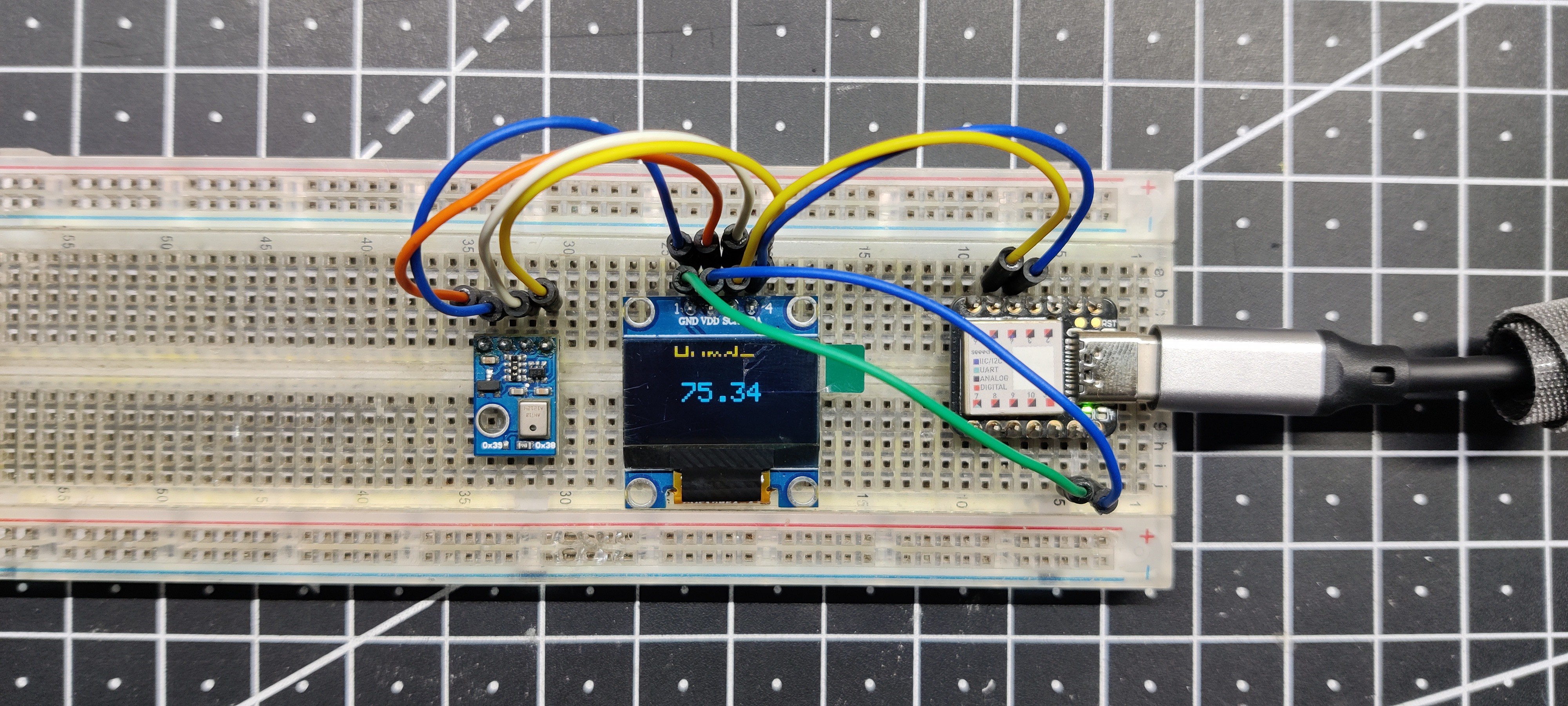

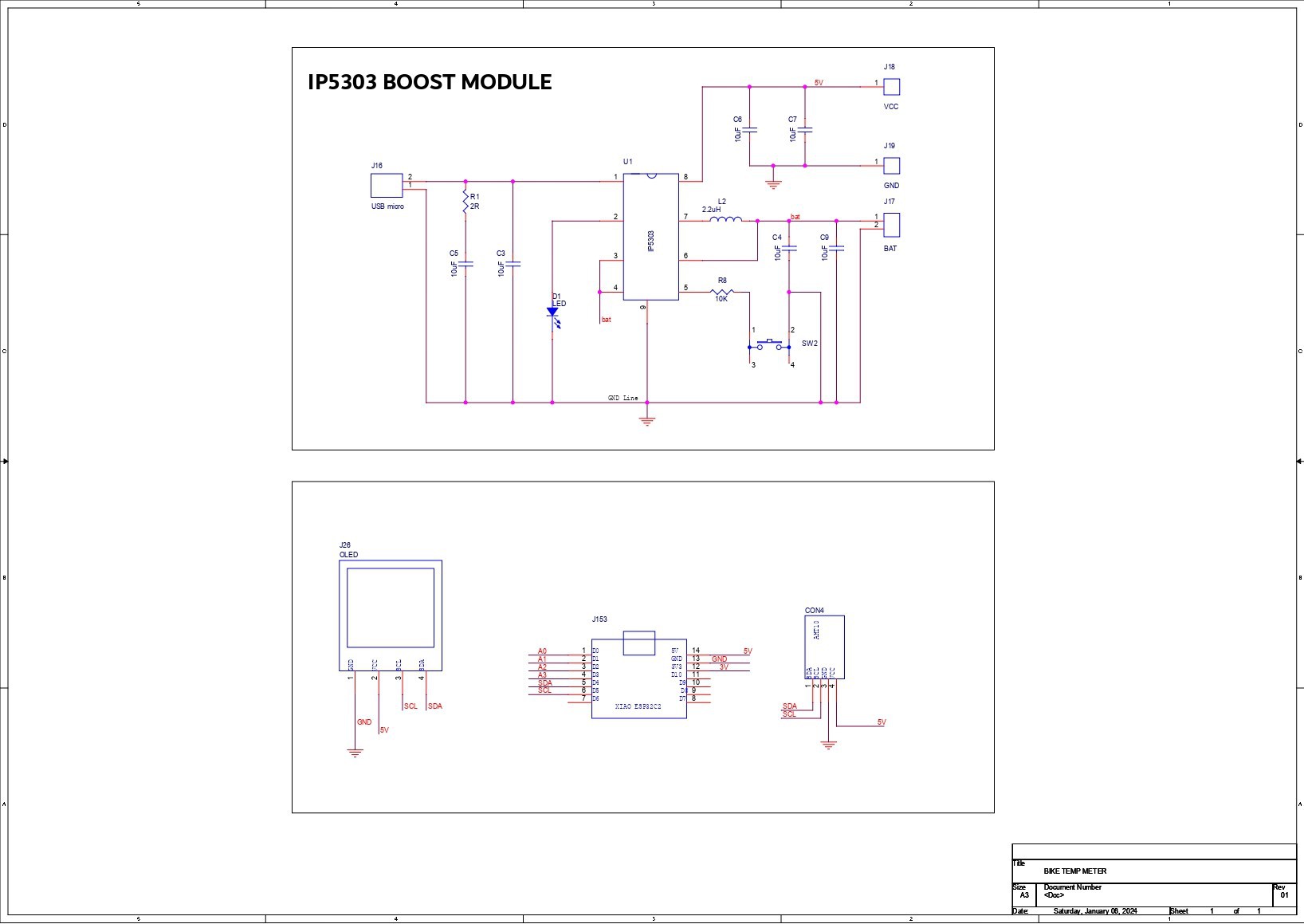

Here, the XIAO MCU is connected to an AHT10 sensor for data collection, and the SSD1306 display is used to show the temperature and humidity measurements.

This circuit was mounted onto the bike's handle using a 3D printed holder, and it has a built-in 3.7V 2600mAh Li-ion battery for power.

Arnov Sharma

Arnov Sharma

Enki

Enki

misha

misha