SPECIAL THANKS:

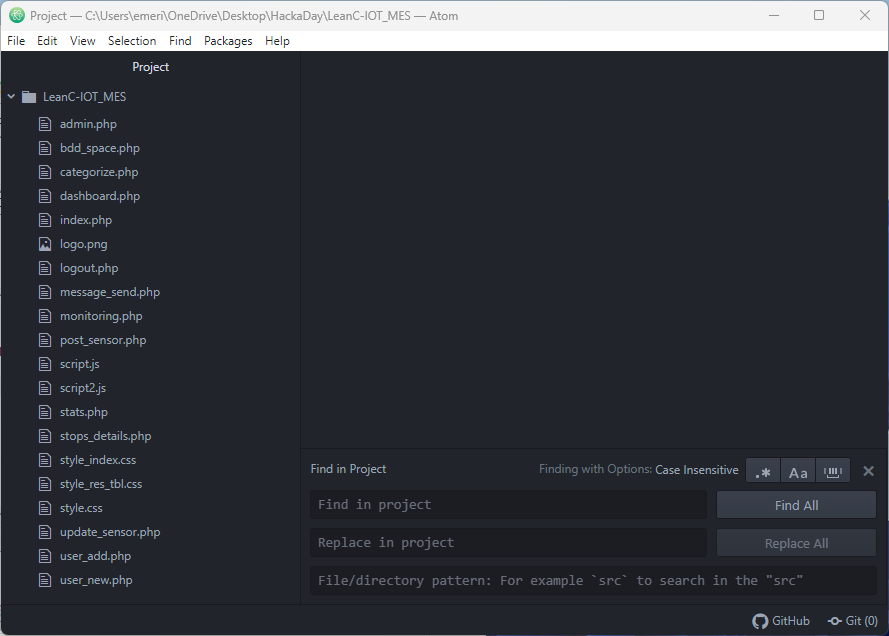

The web management interface of LeanC-IOT MES is developed in Php and utilizes a MySql database.

The interface has been designed responsively to ensure its usability from any device: PC, tablet, or smartphone.

The tables used are based on the work of Matt Smith

https://codepen.io/AllThingsSmitty/pen/MyqmdM

The navigation bar comes from the work of Juan Alberto

https://codepen.io/Juan-Alberto-the-builder/pen/WNPrRNY

Thanks for their code!

LeanC-IOT MES is an open-source system. This means users are free to use, modify, and improve the code under the terms of its license.

By contributing to the development of LeanC-IOT MES, you not only benefit from the collective wisdom of the community but also help in advancing the software's capabilities for everyone.

OVERVIEW OF LEANC-IOT MES FEATURES:

A. LEANC-IOT MES: A TOOL FOR INDUSTRY MANAGERS:

1. Empower Your Decisions with Data:

With LeanC-IOT MES, harness real-time data collection to gain accurate insights into your production performance. Move beyond guesswork and make decisions that are informed, efficient, and productive.

2. Identify and Resolve Issues Swiftly:

Our automated data processing identifies anomalies and failures in your production process fast. This means you can quickly correct problems, significantly reducing downtime and production losses.

3. Maximize Your Resources:

Get precise information on material consumption, machine usage, and labor efficiency. LeanC-IOT MES enables you to optimize resource allocation, cut waste, and boost profitability.

4. Achieve Continuous Improvement:

Analyze your production data to spot trends, bottlenecks, and areas for improvement. LeanC-IOT MES guides you towards ongoing enhancement of your production processes, elevating product quality and enhancing customer satisfaction.

B. USER MANAGEMENT:

In developing this web application, I focused on four main objectives regarding user account management:

1. Enhanced Security:

Implement secure access through a login/password system, use password hashing, and integrate CSRF tokens to achieve a level of security comparable to professional platforms.

2. Multi-User Functionality:

Ensure an efficient multi-user environment to manage user interactions simultaneously without issues.

3. Customized Access Management:

Offer customized access control based on the specific needs of each user type.

4. Session Security:

Enhance security by employing user-specific sessions, making it ideal for terminals shared among multiple users. This approach ensures that each user's session data is isolated, providing a secure and personalized experience on shared devices.

C. DASHBOARD:

The dashboard is designed to display all connected sensors. If you deploy a new sensor, it will automatically appear on your dashboard and will be fully functional without the need for any coding. Each sensor integrates automatically as soon as it's powered on.

The dashboard updates automatically every minute, providing a real-time visualization tool for the status of your hardware fleet.

For each sensor, the dashboard displays:

1. The state of WIFI connectivity:

(CONNECTED or OFFLINE).

2. The status of the production process:

(PRODUCTION or STOPPED)

3. A quick access link to view the production flows for the current day:

(rate in beats per minute, automatic detection of non-production periods).

D. ALLOWING USERS TO EXPLAIN DOWNTIME PERIODS:

The system standardizes data by enabling users to attribute stoppages to specific causes, based on the Ishikawa diagram framework. Additionally, for each downtime event, it offers a chat-like space for users to discuss and gather insights about the malfunction's causes, designed to promote ongoing enhancement.

Noah

Noah

John Costik

John Costik

Pratyush-Mallick

Pratyush-Mallick