We are ChaBotsMX, an independent student robotics group based in San Luis Potosí, Mexico that has been running since 2014. In the past, we have had the honor of representing our country in international robotics competitions, such as RoboCup Soccer Primary in Hefei, China in 2015 and the World Robot Olympiad (WRO) in Thailand in 2018. This year we hope to once again reach the greatest level of competition at the international stage of RoboCup Soccer Lightweight at Eindhoven, Netherlands.We believe this will help us with our goal of spreading knowledge and inspiring young people from our country to enter the world of STEM.

In RoboCup Soccer Lightweight, teams design and program 2 autonomous omnidirectional robots that are capable of playing soccer matches using an infrared light emitting ball. To do this, robots require many electronic components such as: microcontrollers, motor drivers, infrared light sensors, line sensors, IMU sensors and more. Since having to connect all these components with cables would be impractical and confusing. Most teams resort to making PCBs, as they are space and weight efficient and if made right, also boast very low latency and reduced noise at high speeds of communication.

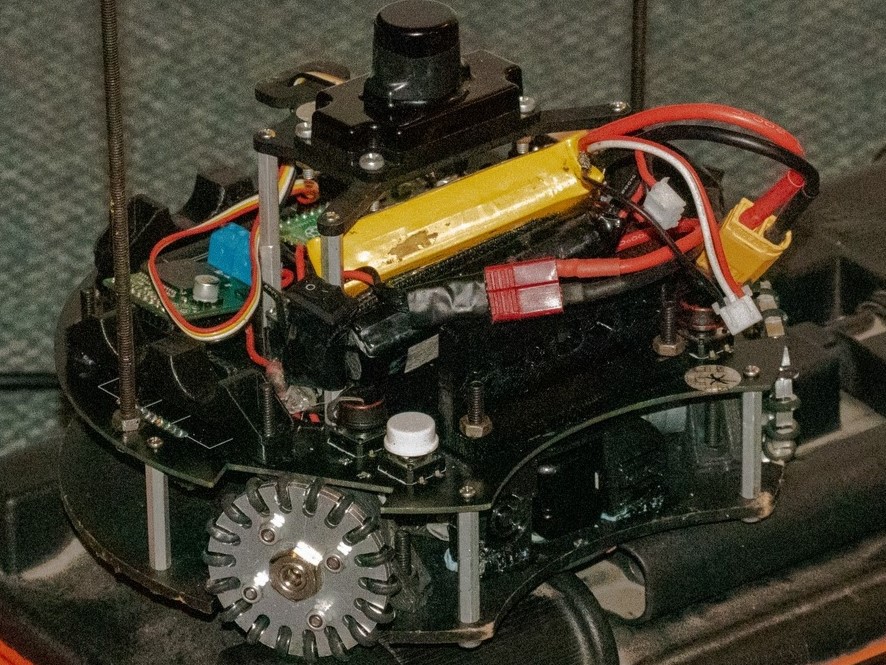

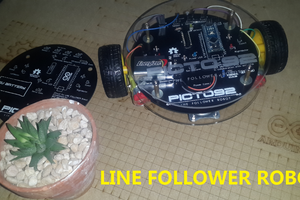

Old robot

Last year was our first time participating in RoboCup Soccer since

2018 so our robot left a lot to be desired. This year, thanks to JLCPCB, we have been able to massively improve our robots design and performance as they provided all of our PCBs. Thanks to that, we believe we will be competitive at the international level this year.

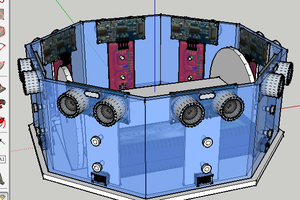

Current robot

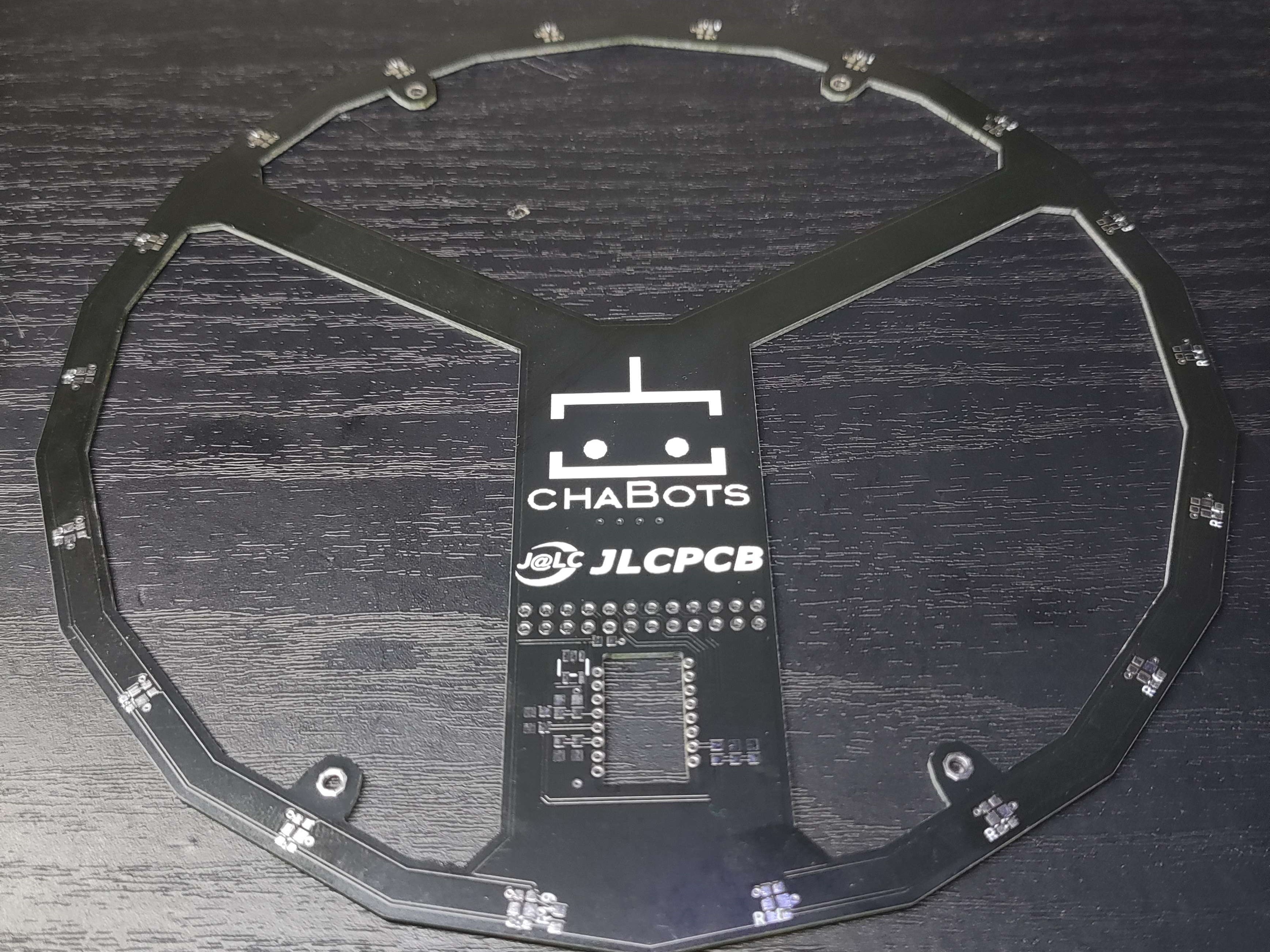

360 IR Sensor (TOP PCB)

We decided to stray away from using market Infrared sensors as they did not have the greatest reliability and resolution. We decided to instead create our own 360° infrared sensor using an array of 18 TSSP4083 IR receptors. This gave us the reliability and resolution we desired. Having a lot of extra space on the PCB we also decided to integrate an IMU sensor and a camera module.

Line and Optic sensor (BOTTOM PCB)

We made an array of 18 als-pt19 light sensors to detect the change of color in the playing field to keep the robot within bounds. This was an upgrade from using through hole photoresistors, as the als-pt19 are much more consistent and precise. We also made the addition of an optic mouse sensor. This sensor allows our robots to know their position much more accurately.

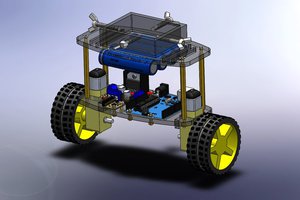

Main control (MAIN PCB)

Lastly, for our main board we upgraded from using a 3 motor drive to a 4 motor drive, and added a “kicker control circuit”. Going from 3 motors to 4 greatly increased our robots torque and speed. This was greatly beneficial since the robots maximum weight was increased from 1100g to 1400g. As for the “kicker control circuit”, it allowed us to deliver a great amount of voltage and current into a push solenoid. Doing this, the solenoid delivers a powerful “kick” to the ball which is very useful for our goalkeeper robot.

This being the first iteration of our robot, there are still things to improve on, but thanks to JLCPCB’s affordable prices, we look forward to making these improvements. Due to their wide variety of services such as PCB manufacturing, PCB assembly, 3D printing and even CNC machining, we are certain JLCPCB will come useful when developing future projects.

JLCPCB empowers flexible manufacturing through the integration of digital technology, a self-built order platform, automated production, and intelligent warehousing. This enables them to meet customer demands for prototypes, small batch production, and the "fast delivery, high quality, customization, one-stop" experience. Get your free quote today at https://jlcpcb.com/HAR, and order for as low as 5PCS for $2.

electronicsworkshops

electronicsworkshops

ZaidPirwani

ZaidPirwani

DIY GUY Chris

DIY GUY Chris

Yerkebulan

Yerkebulan