All schematics, CAD models, manufacturing drawings, source code, circuit schematics and PCB designs are linked.

The project's main objectives were:

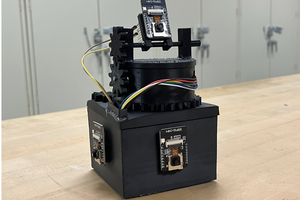

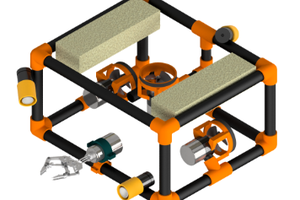

- Build camera turret capable of 2-axis rotation

- Rotation must be continuous

- Speed in either axis must be >6.7 RPM

- Requires position accuracy of < 1 degree

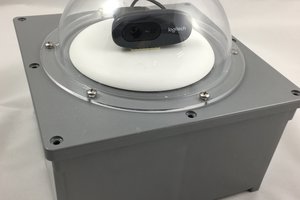

- Full data stream must be received from camera (31MBps Firewire)

These goals were achieved by:

- Making use of Moog slip rings to allow data and power connections

- allowed for continuous rotation

- powered camera and carried data (>31MBps)

- Carried power and clock signal for motor control

- Making use of two 200 step stepper motors in half-step mode

- results in 0.9 degree steps

- achieved drive in excess of 50RPM for both axes

- Used an Arduino

- Communicated with GUI on computer

- Received position data from hall effect sensors

- Sent step motor commands to controllers

Gareth

Gareth

allai5

allai5

John Leeman

John Leeman