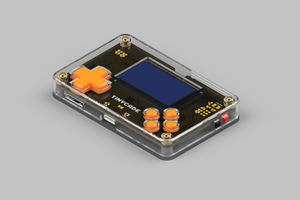

This project integrates an e-ink screen (2.9 inch flex monochrome) with a NFC IC (NT3H2111W0FHKH) and a STM32(L432KCU6) to make a business card that you can update with your phone via the NFC field.

This project is inspired by the plethora of e-ink battery-less phone cases and other battery-less devices that are available on Amazon and elsewhere that have e-ink screens updated and powered over NFC without a battery. This project uses a battery. I would like to one day figure out how to make a reliable device that can change its display without a battery. I write more about this in my opening log entry.

Demo Video

This card also doubles as a standard NDEF compatible tag. In the beginning of this video I demonstrate this by being able to get the "Website NFC Detected" notification when I hover my phone over the card that links me to my website. See more about NDEF and the Compatibility Container mechanism that is used to make this interaction work in this log entry.

Afterwards I transfer a set of different designs over to the cards back and forth and end with a cat. See more images in this log entry.

Hardware

This circuit is electrified with a CR2032 3V coin cell battery that is wired to a TPS610981DSET power management IC. The TPS610981DSET has two different power outputs (VMAIN and VSUB) and one control pin (MODE). VMAIN is always on, and powers the NFC chip. VSUB powers the MCU and the e-ink display, and is only on when MODE is driven HIGH. The MODE pin is wired through some business logic (logic gates) to the NFC "FD" interrupt pin to enable the NFC chip to turn on the VSUB (MCU + E-ink) power line when a NFC field is detected. See more in this log entry.

The MCU for this project is a STM32L432KCU6 picked for its low power features.

A 2.9 inch flexible Waveshare monochrome e-ink screen is used for the display.

The NTAG I2C Plus NT3H2111W0FHKH is used as the NFC chip with a custom made antenna using https://github.com/nideri/nfc_antenna_generator

View the schematic for the design here: https://codeberg.org/wsqnyc/pcb-160-eink-card/src/commit/de1f44bc5fa77c327a22e172a4ca7371b458612f/Schematic.pdf

I explored how much this device costs in this log entry and estimate the cost of components is $25. Cost is hard to estimate, and the most expensive piece is the e-ink display which is $15+ depending on where you get it.

Software

This circuit would not work without the software, and there are two sides: the iPhone app that updates the screen and the software on the board that interacts. I talk about this interaction in this log entry where I link to the code for each side at a high level. Another blog posts talks about the React Native code that processes the image and applies the dithering a bit further in this log entry.

Physical Dimensions

The thickness of this board is mostly contributed by the battery connector. It measures 90mm x 50mm and about 7mm in depth.

The screen is attached to the PCB with double sided scotch tape.

Eddie

Eddie

Andrey Ovcharov

Andrey Ovcharov

Anthony

Anthony