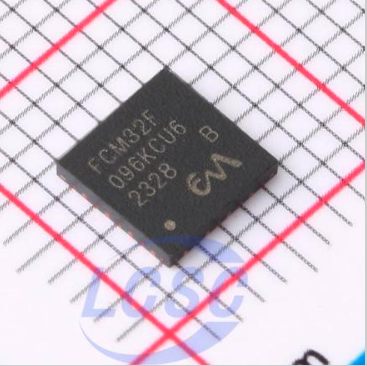

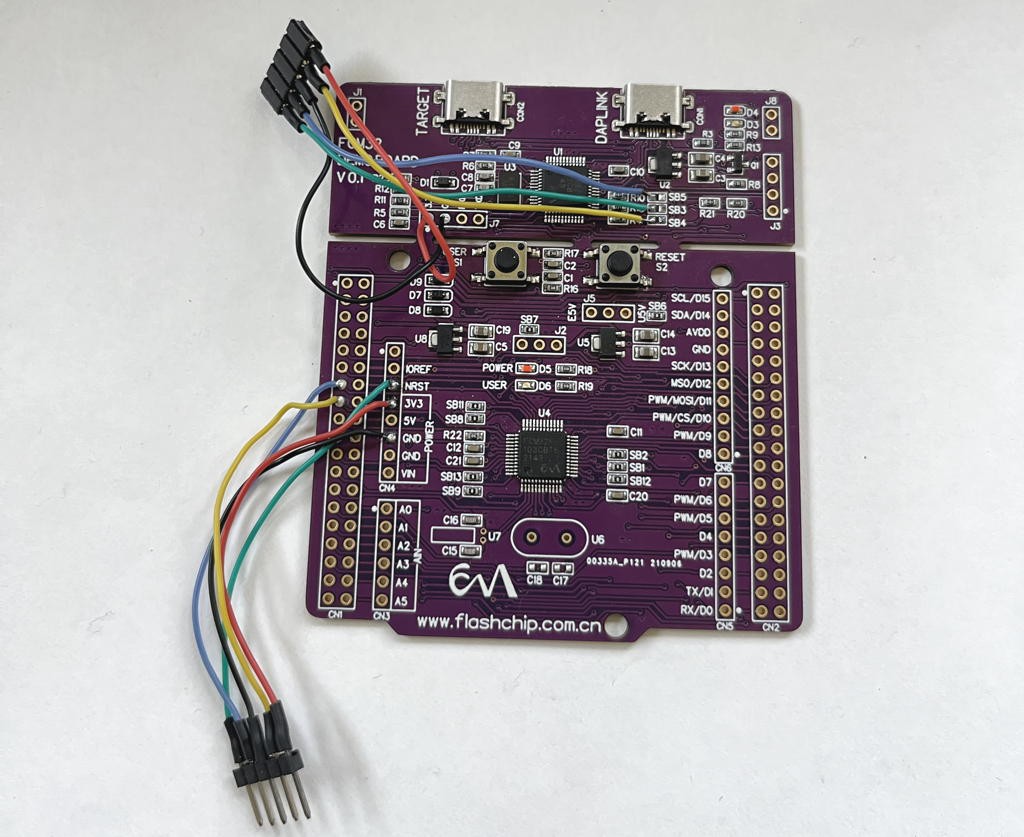

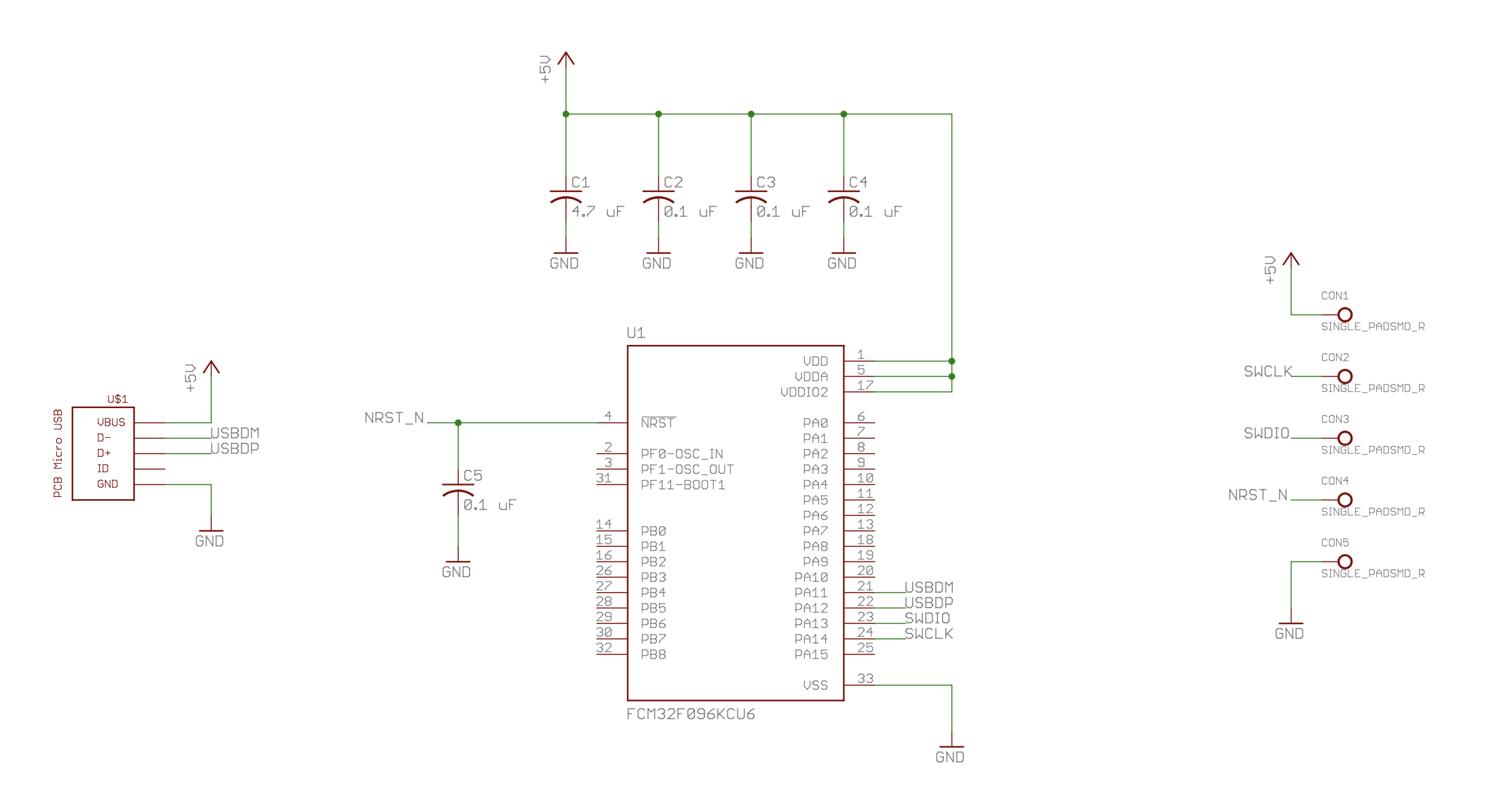

I wasn't planning to enter the contest. However that changed when I stumbled across a cheap STM32 almost-clone chip on LCSC. I had started by looking at clones of STM32 chips for another project and I came across a company called Flashchip. LCSC was selling a FCM32F103 series of chips which clearly were copies of the venerable STM32F103. But interestingly, the Flashchip website no longer listed this chip. I wondered if lawyers had been involved. What they had were some chips that didn't quite match ST's numbering system but had similar features (take that, ST lawyers...). In particular I found the FCM32F096KCU6 that has some intriguing attributes. Specifically it has a USB interface and it can run directly on 5V. Whoa - one could build a single-chip USB doo-hickey with no need for other parts like a 3.3V LDO.

That's when I thought mmm... maybe I could design an interesting business card around this and rise to the glory that is a Digi-Key gift card. That is if I could figure out how to program it (of course - in reality - I quick-fingered in an order for 11 parts before I really thought about the issues I'd run into later).

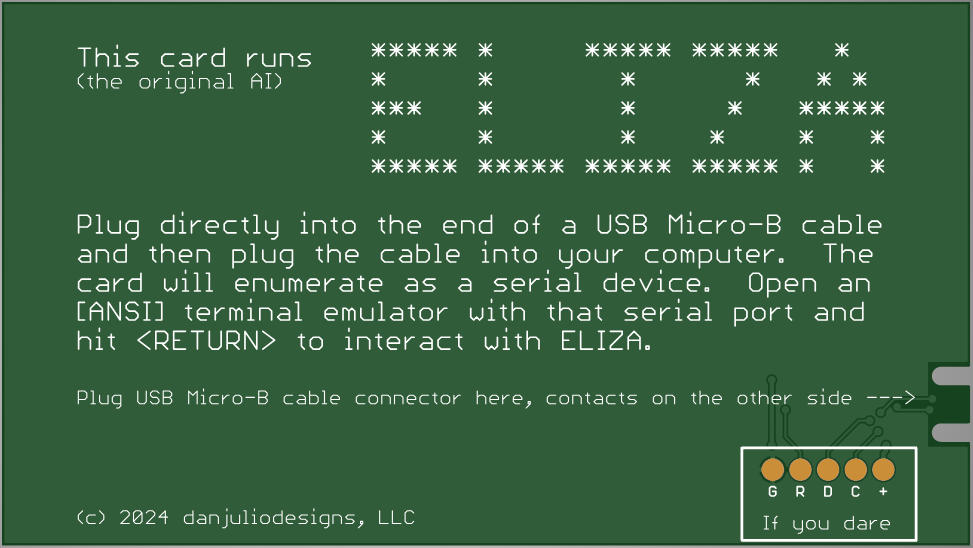

What to run on it was the next question. The hacks necessary to program it weren't yet on the radar.

Dan Julio

Dan Julio

Stephen Holdaway

Stephen Holdaway

mitchell.dokken

mitchell.dokken

deʃhipu

deʃhipu

ajlitt

ajlitt