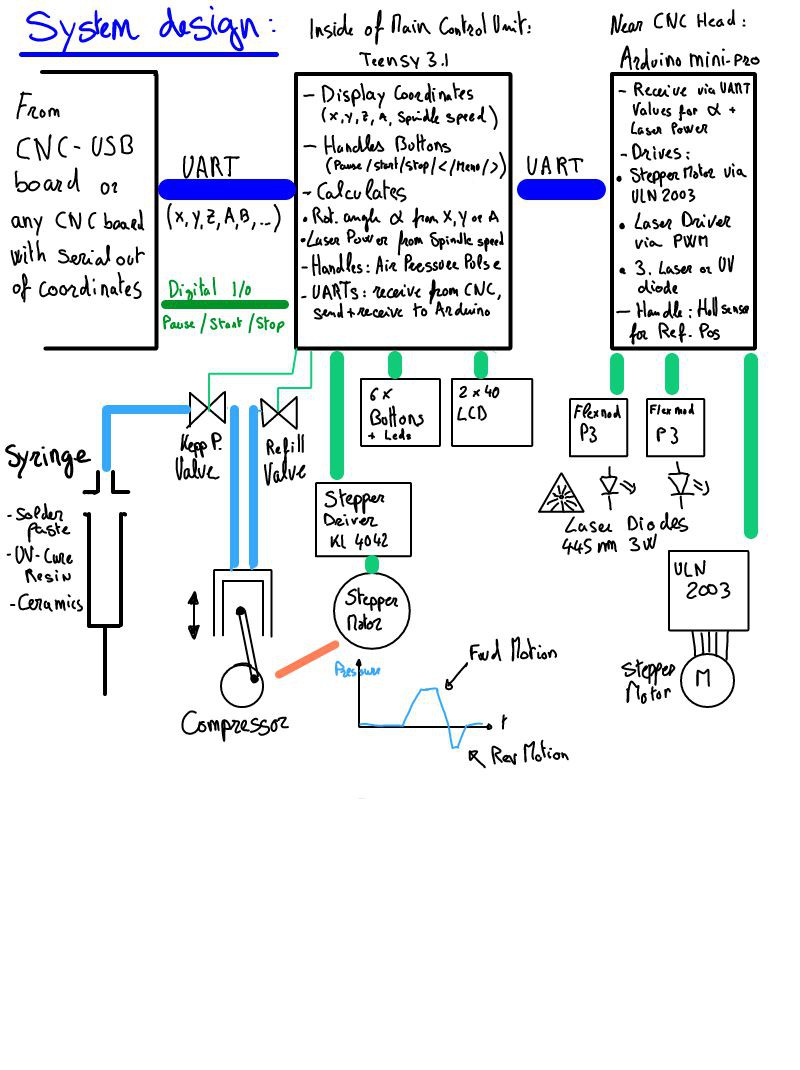

System Design:

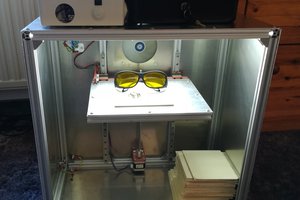

The assembly is built for my mini-cnc-mill (see my other project), it has a mount diameter of 65mm like my Chinese spindle (0.8 & 1KW have the same size) which means to be compatible with other small CNC.

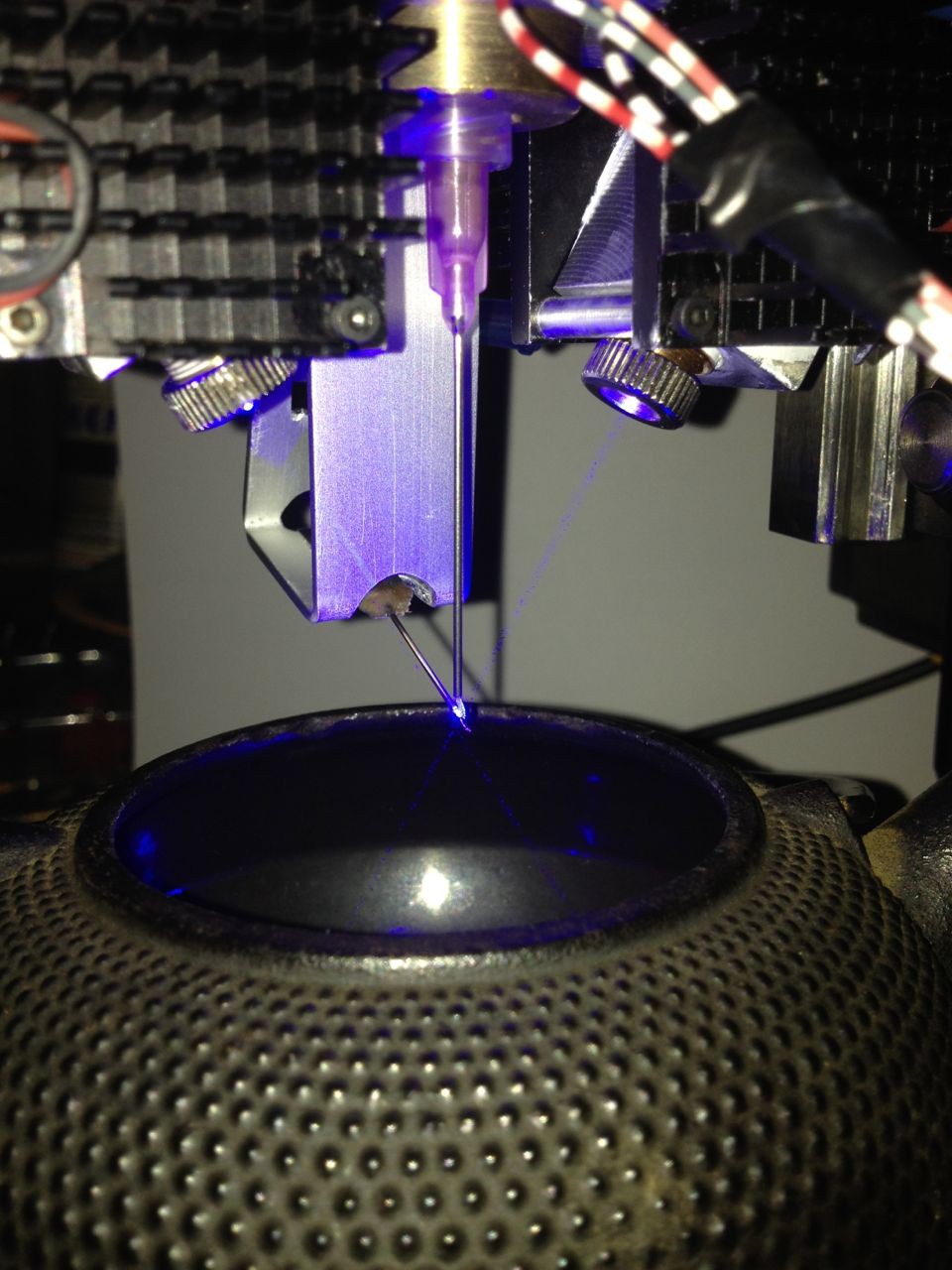

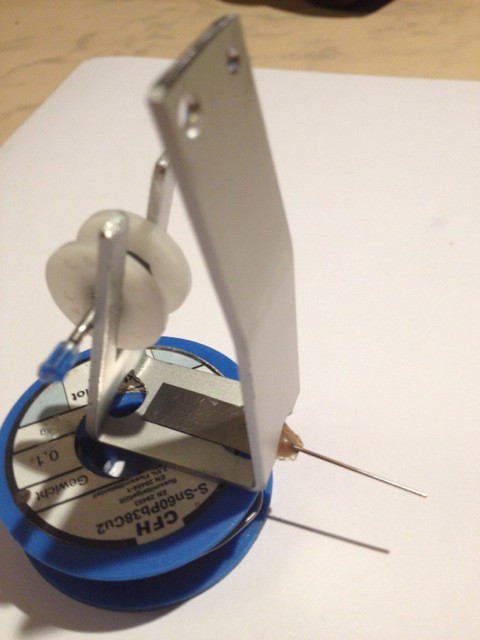

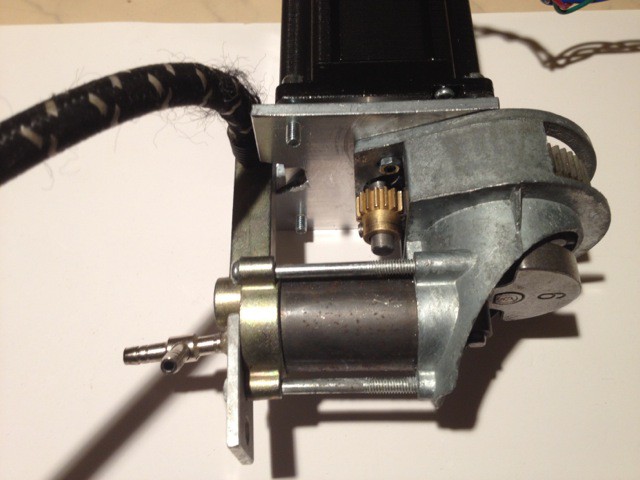

The syringe is 10ccm, mounted in a brass body, 2 bearings 6005 2-RSH O.D. 47mm, are compressed with a M24x1.5 threaded ring on top.

The 2 bearings are mounted in an Alu. part O.D 65mm by 32mm height. A ring OD 47mm ID 40mm keep both outer part of the bearings apart, it permits to put tension on them with the threaded ring and the syringe holding body.

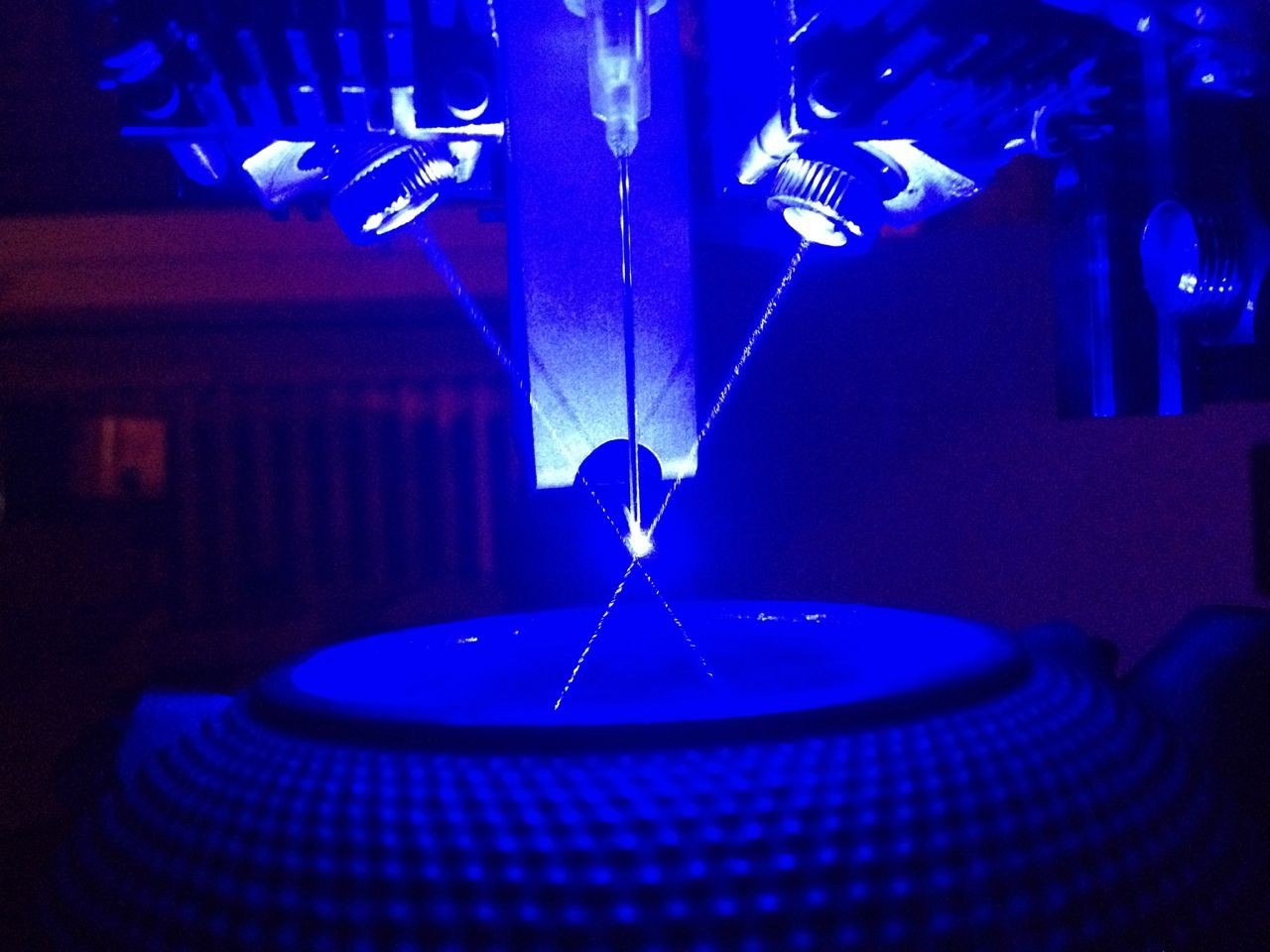

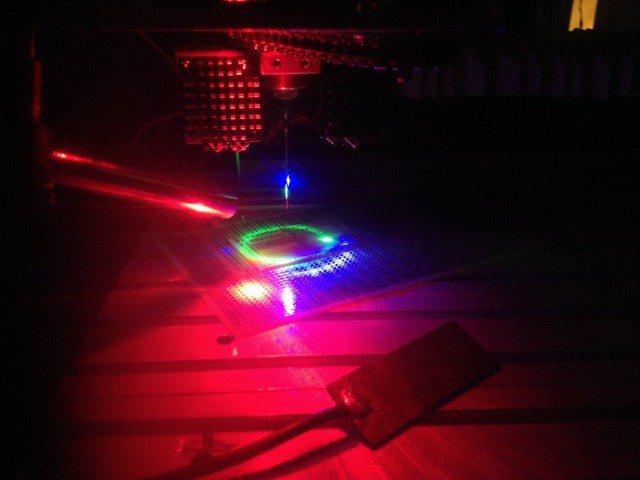

The laser diodes came mounted in 12mm barrels, 2 alu. blocks 20x20x20mm have a 12mm hole with a blocking set screw M3.

These blocks will be pinched between 2 heatsink (30x35mm), on each corner of these heatsink there are 2.5 mm holes.

The horizontal beam have M2 threads where the heatsink get fixed, 4x M3 threads to lock it to the syringe holding body. These M3 are also used to mount the wire feeder and/or a UV led.

Atop of this horizontal beam is a spacer ring and the 24T Alu. Hub Sprocket.

A chain will link this sprocket to another one 13T which is mounted to a Nema 17 stepper motor.

AltMarcxs

AltMarcxs

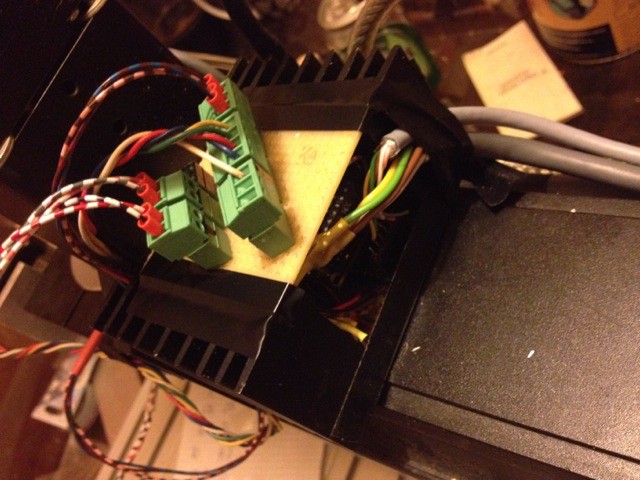

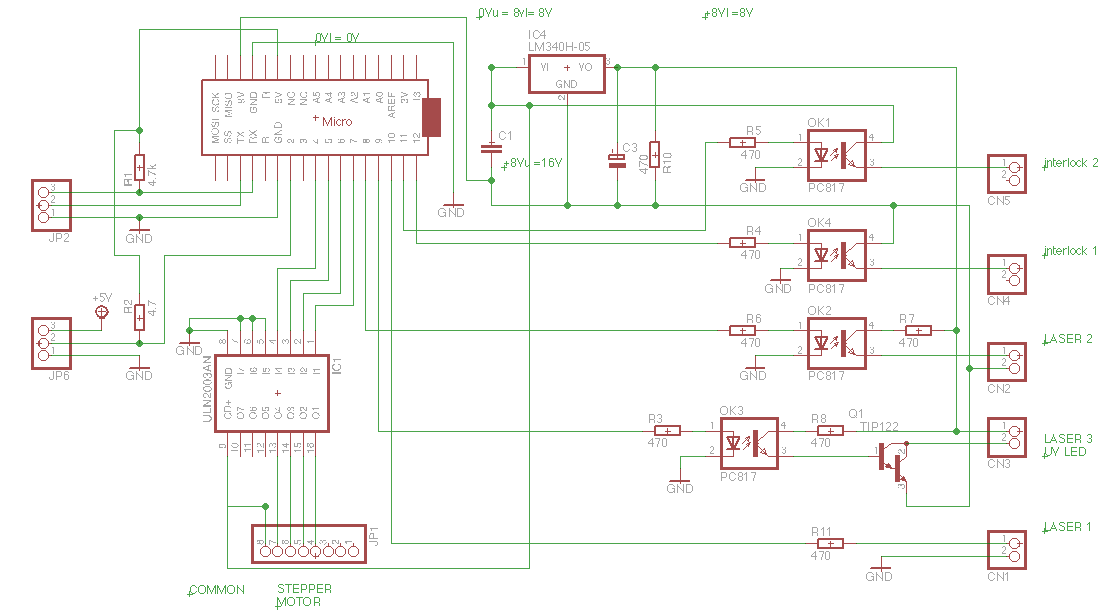

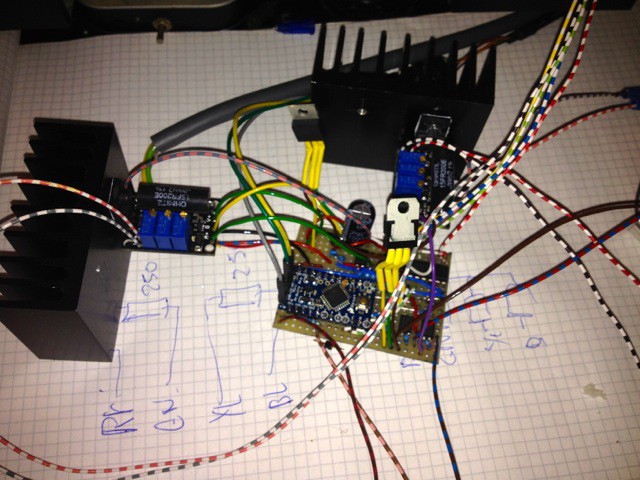

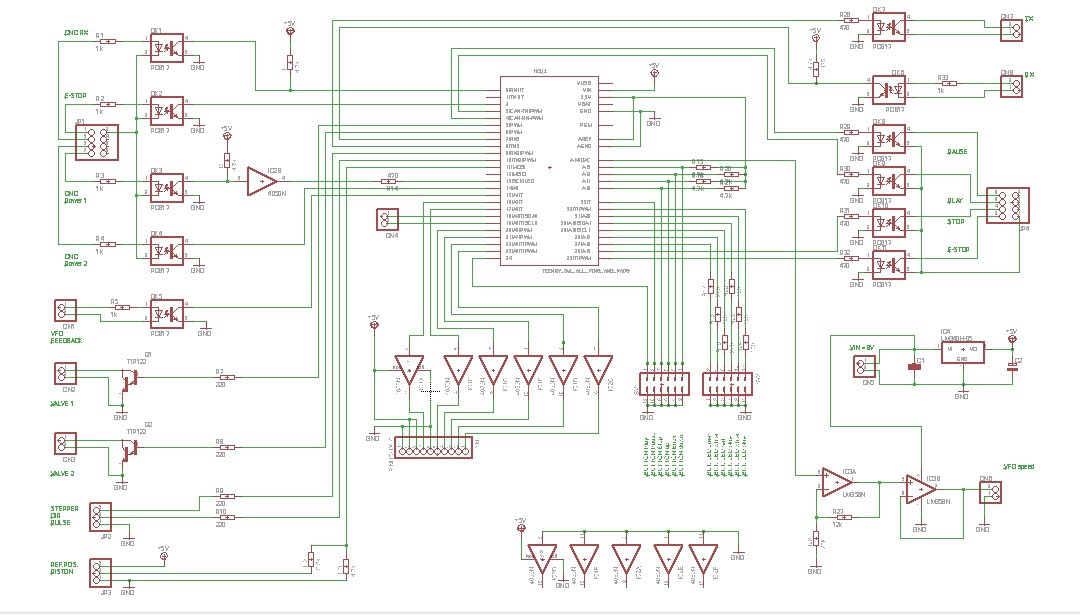

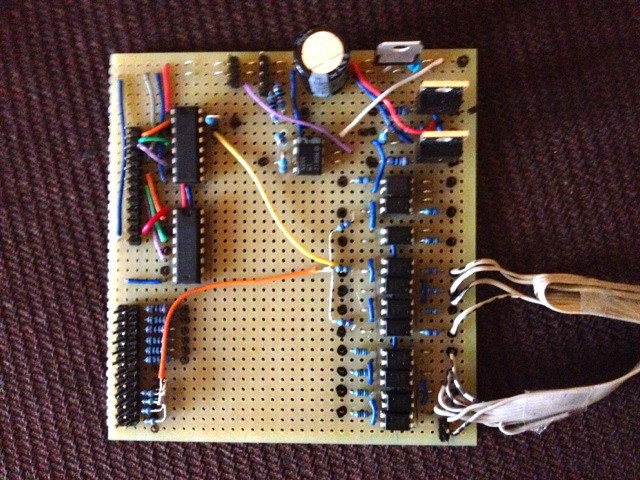

Update: Small modification in the schematics AND building it on perf. board.

Update: Small modification in the schematics AND building it on perf. board. On this it misses the Teenys 3.1 for clarity ;-)

On this it misses the Teenys 3.1 for clarity ;-)

Dominik Meffert

Dominik Meffert

Jonathan Bumstead

Jonathan Bumstead

Christian

Christian