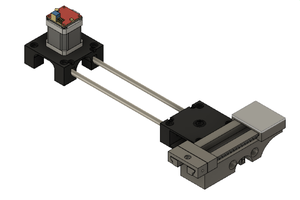

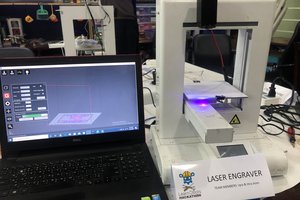

ssembly structure: Gantry structure

Design: full metal modular assembly kit fixed base:

steel plate mechanical holes fixed function realization: 3D

printer(Laser engraving machines, food printer, Smart Brush, etc.)

Printing precision: 0.1mm (100μm) within minimum print layers: 0.05 mm (recommendation> = 0.1mm)

The fastest print speed: 120mm / s (recommendation <= 40mm / s)

nozzle diameter: 0.4mm

Support Supplies: PLA

Supplies Diameter: 1.75mm adapter

Power supply: 110-220V, 50-60HZ

Data Entry: SD card, USB interface supports file formats: Pcode slice

Software: Pango

Print Size: About 110 * 120 * 125mm

Package Size: about 376 * 386 * 196mm

Operating System: Windows7

Housing (value-add): 3D printing and dispensing machine frame, multicolor acrylic bezel

Structure : Mechanical arm

Features : Modularization parts

Filament Diameter : 1.75mm Works With : PLA

Positioning Precision : 0.02(with100mm)

Power: 110-220v

Connect: SD card Compatibility: windows7

Package Size: 376*386*196mm

Software: Pango with independent intellectual property rights

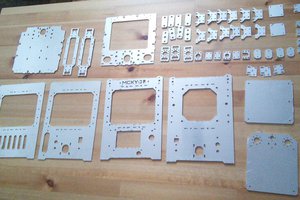

Delivery status: Delivery of spare parts assembled

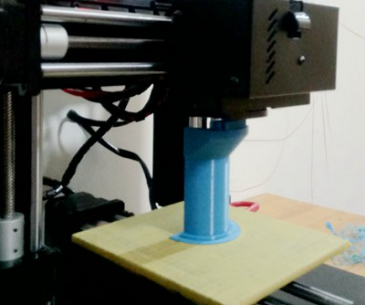

an be a 3D printer or be laser carving by exchanging a head.Is not it cool? When unpacked:

A bunch of modular components, the assembly process is simple

A few screw, follow the instructions on the line. Connect according to the instructions

Installed on the drive, this operating system is very simple. No need to install, directly copy into the computer.

Masking Tapes is neccessary

Then insert card and print

This machine can not be imported directly into the computer's file

print.Need to first copy the file and settings into the SD card.

SD card is inserted into the machine that is automatically printed. The

period can be controlled via the software console. Takes effort, but can

improve safety and stability.I agree with that

The first question that started printing was not attached

This is every printer are inevitable debugging process. Adjust the heating temperature and the first layer distance

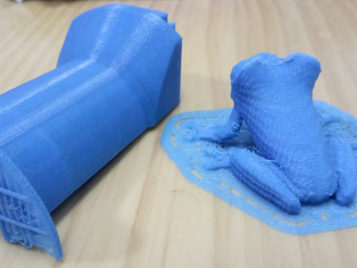

Compare the print effect of the scara arm 3D printer

It is clear that the accuracy is much higher. What to do with a small

part of the use should be competent.One of the shortcomings is to play

too high base easy to Alice off

Increase the temperature of the hot bed with the anti-alice of the print

wire may be resolved

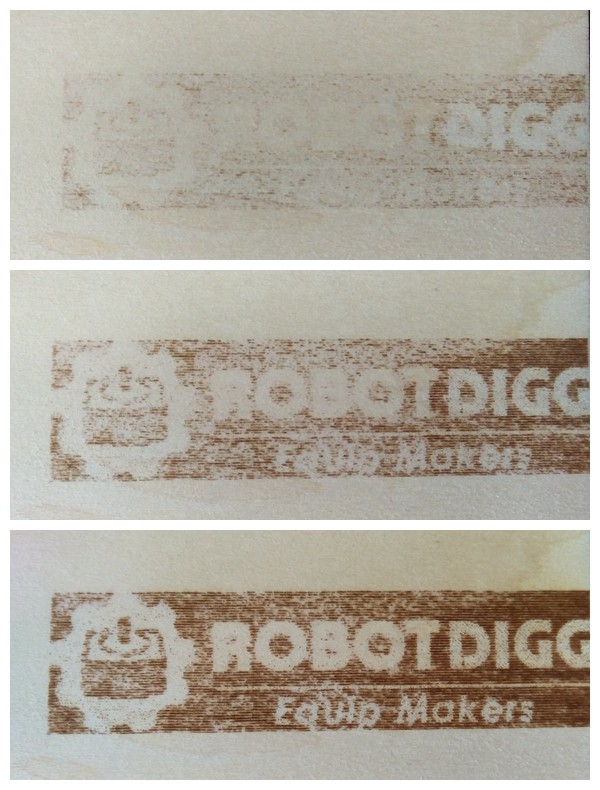

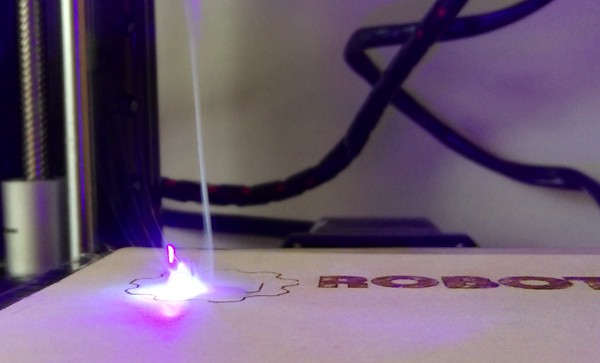

Now let's try the laser.First turn the print head into a laser head.Plug the line

Fixed wood board, wear glasses, same method, import files and settings

into the SD card, Card to play. The laser sweeps wood no response. The

original is the laser head no focus distance.This adjustment can only be

done manually.After all, is the wood can burn the laser. But I was told

that the laser power is not high.

The chopsticks head so thick laser transferred to the toothpick thick.

Or recommend the use of the process more careful!

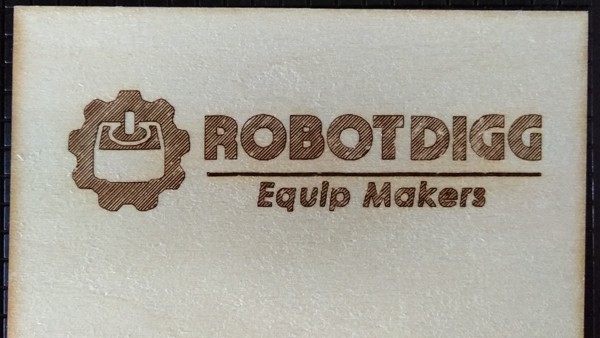

The laser has two modes of engraving and cutting

Engraving mode

Cutting mode

Beacon four corns fragrance

This feeling really a little excited to say

Image reverses 50% fill effect

- See more at: http://www.robotdigg.com/news/130/F1-Modular-DIY-3D-printer-SET-RobotDigg-Presentation#sthash.PLzCsldy.dpuf

RobotDigg ME

RobotDigg ME

Dave

Dave

bobricius

bobricius

A-A-W

A-A-W