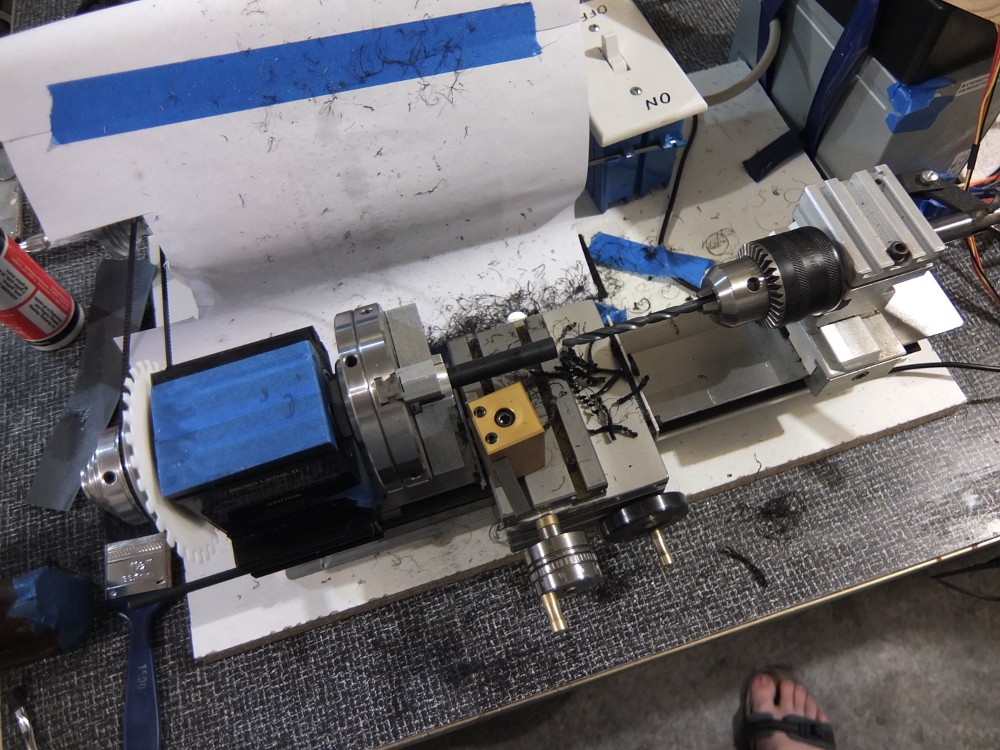

I use my Makerbot Thing-o-matic to create most of my project enclosures. It's simple, easy, and inexpensive. For the NoteOn case, this wasn't an option. Most of the parts have thin walls and require a precise fit. Instead, I machined the parts on my Taig Lathe.

The parts were made of black polycarbonate, delrin (for the ink cartridge sleeve) and clear acrylic (for the button/status indicator).

Most of the parts are tube-shaped. They just need to be turned to size on the outer diameter and drilled. A tip on drilling large holes in polycarbonate: don't use a pilot drill. I don't know why, but a pilot hole causes the larger drill to bind horribly. Also, don't be too aggressive, or the plastic will melt.

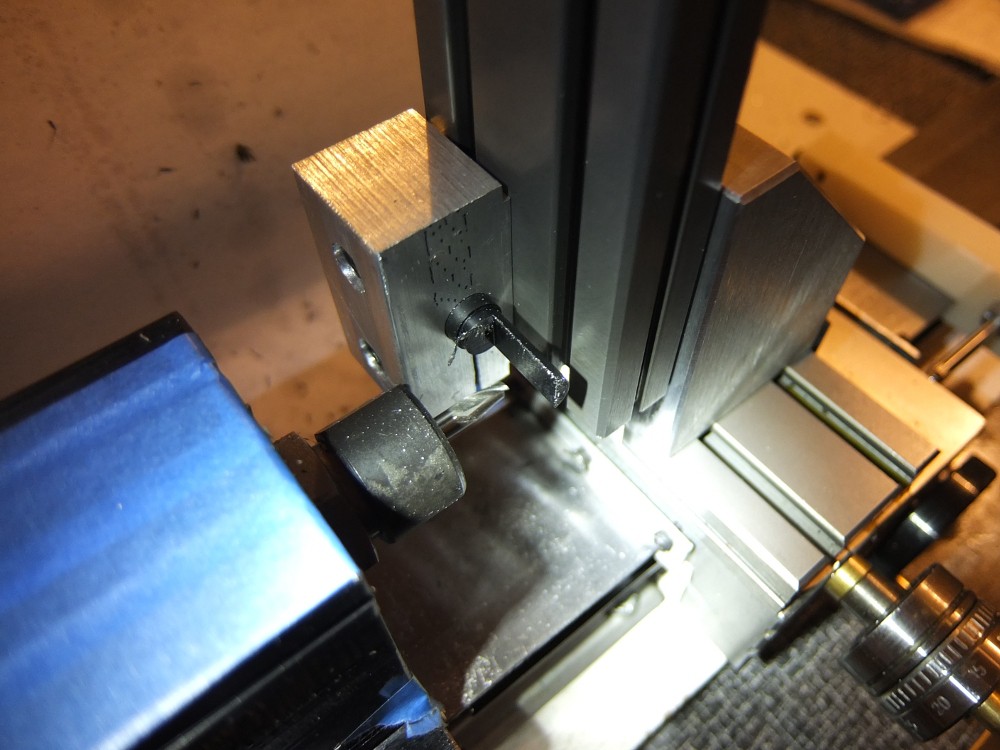

For the PCB shelf, USB slot, and tip switch wire holes, I used my milling attachment with a simple fixture. The fixture is just a 10mm hole with a slot in it that clamps on the OD of the parts.

To get a matte finish on the outside of the pen, I used 380 and 500 grit sandpaper with cutting oil (Cool Tool II). Some hot water and ivory soap afterwards leaves the parts nice and clean.

Nick Ames

Nick Ames

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.