I've finished bolting the rails in place, so the next item on the list was to make the spindle holder and the last ball nut mount. But I've gradually come to realize that the machine is becoming very heavy. I've always known what the total mass will be when finished (around 300kg), but I've come to a better understanding of what that means as I'm producing the parts and putting them together. It's going to be very heavy.

Given this new understanding, it is obvious that the machine does not qualify as a desktop machine. standing on a desktop the milling table would also become too high, but standing on the floor it would be too low. So it will need to stand on some sort of custom support.

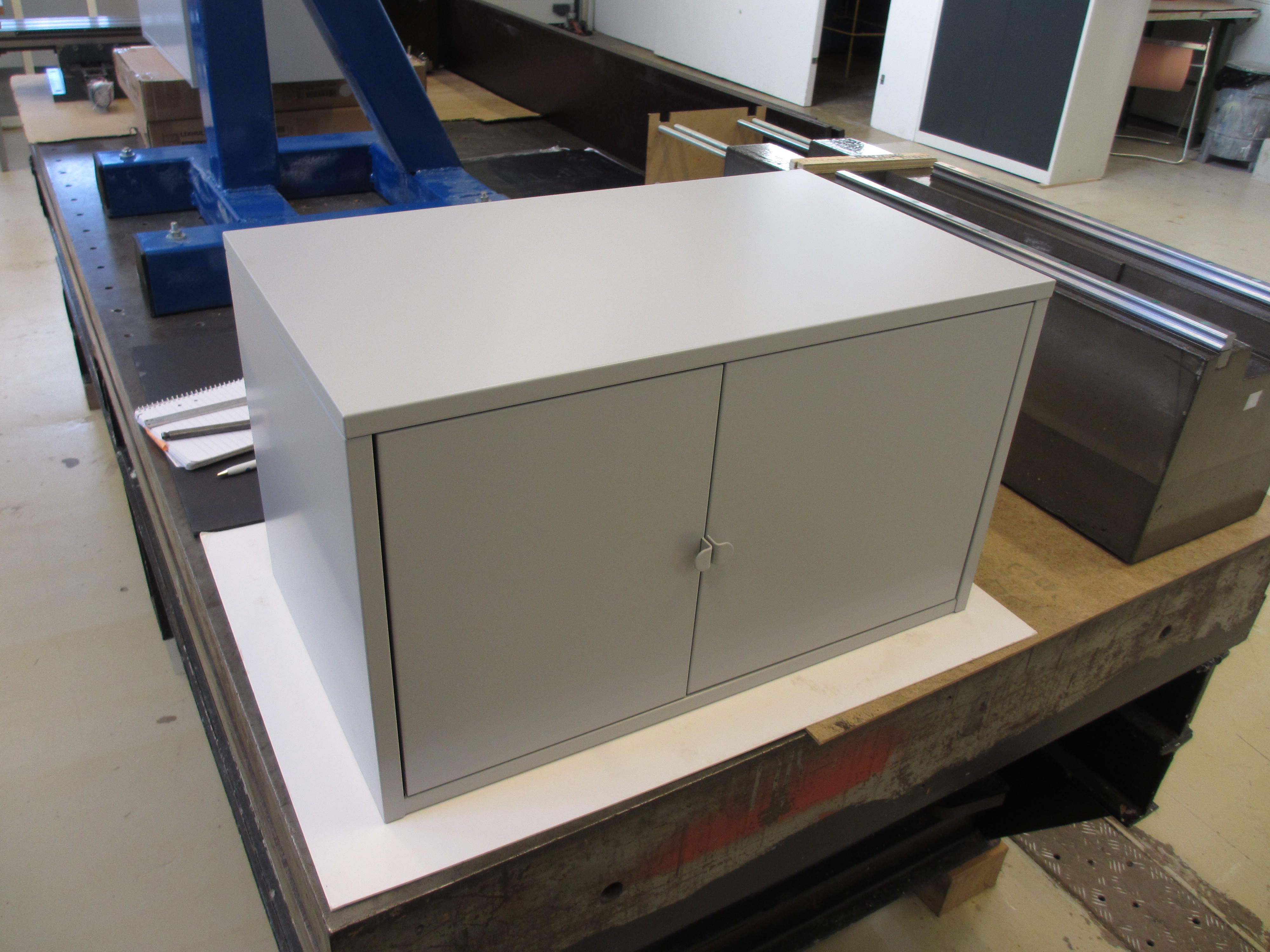

So I came up with the idea of placing it on top of a sheet metal cupboard with wheels! May as well have some storage in close proximity to the machine. Looking around for something cheap I soon stumbled on this product from IKEA that comes in a beautiful workshop grey:

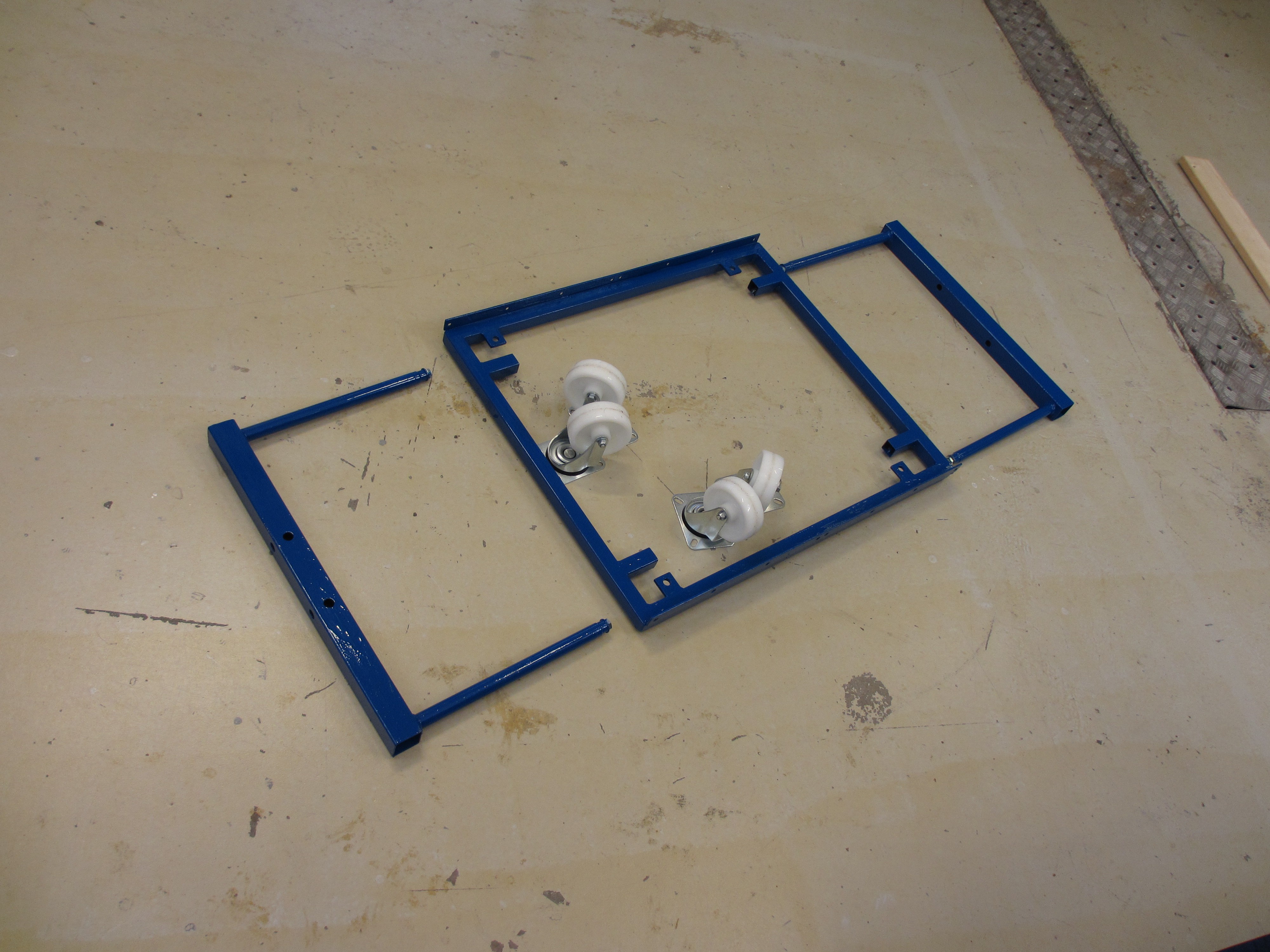

A single cupboard like this is too small, so I bought two of them and will place them back-to-back. This way, the rear cupboard can serve as the electronics housing! Fantastic! Unfortunately these are nowhere strong enough to support the weight of the machine, so I welded a support structure for it:

I started adapting one of the cupboards by riveting all the sides together. These cupboards are normally assembled almost entirely without tools, a clever design but I want more stability. Also I imagine they may rattle from vibrations while milling otherwise.

I then bolted it to the support frame.

It is also supported internally to cope with the load of the entire machine.

I'm standing by with the second cupboard since it is going to be adapted for housing electronics. Here is a teaser:

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.