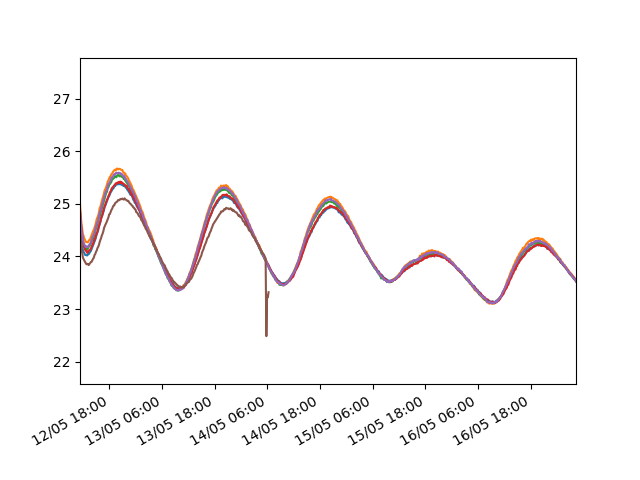

Temperature is one of the primary factors for sea turtle egg incubation success as well as sex determination. While a lot is already known, the onset of climate change makes more research a priority to mitigate the impact of increasing temperatures and changing climate patterns across sea turtle nesting habitats.

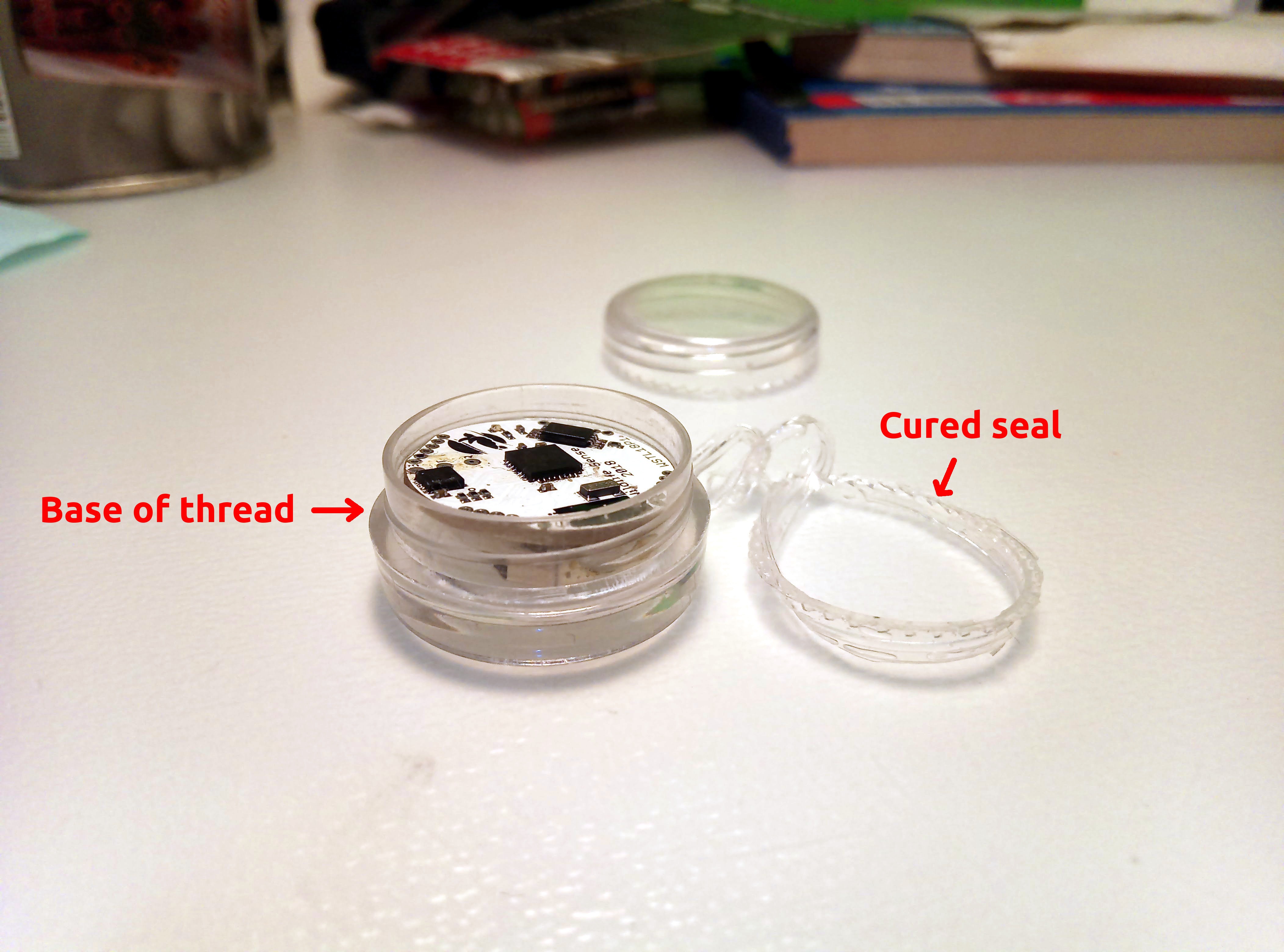

One of the challenges is the collection of enough data for statistically robust results. Deploying a large number of loggers is only an option for large institutions. Even there, researchers want to stop using them after they've lost a few in the field.

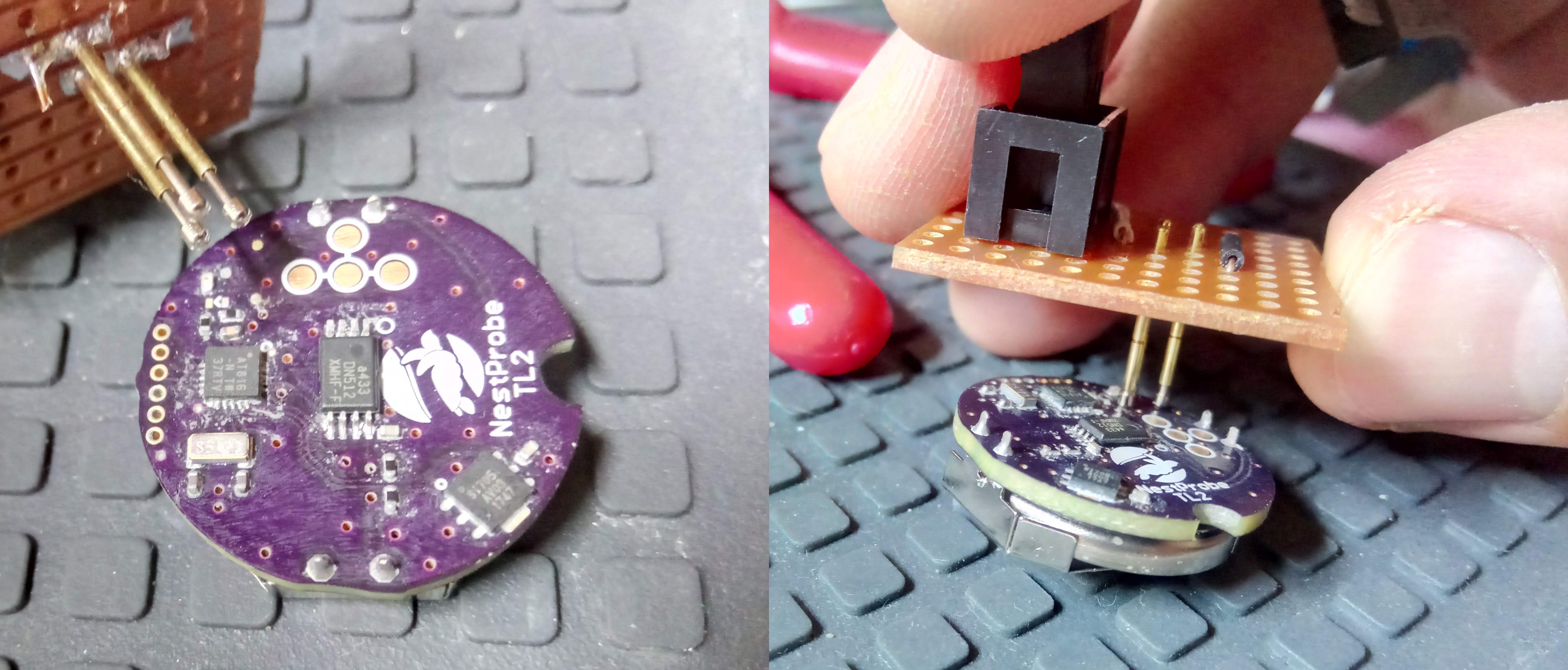

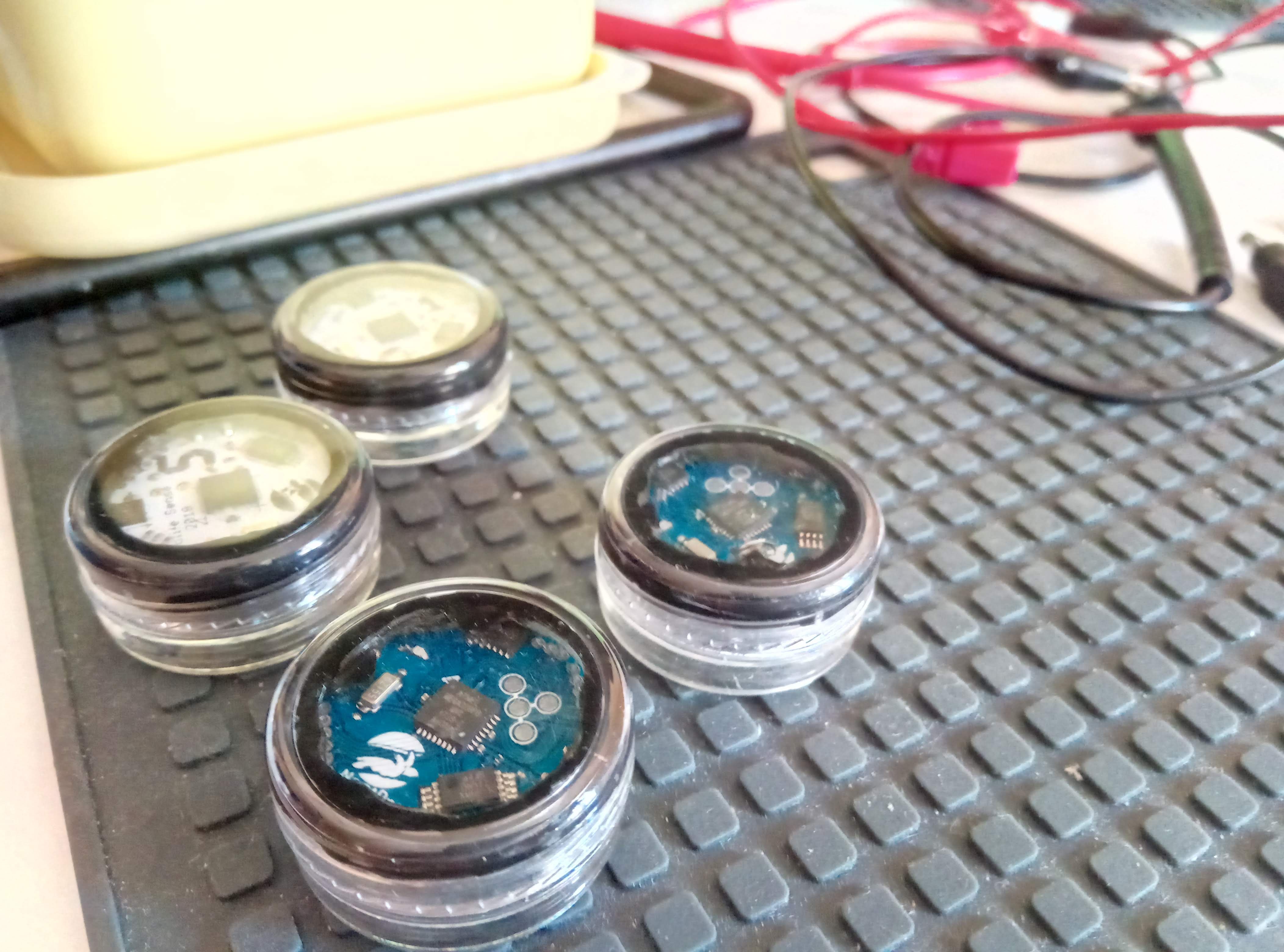

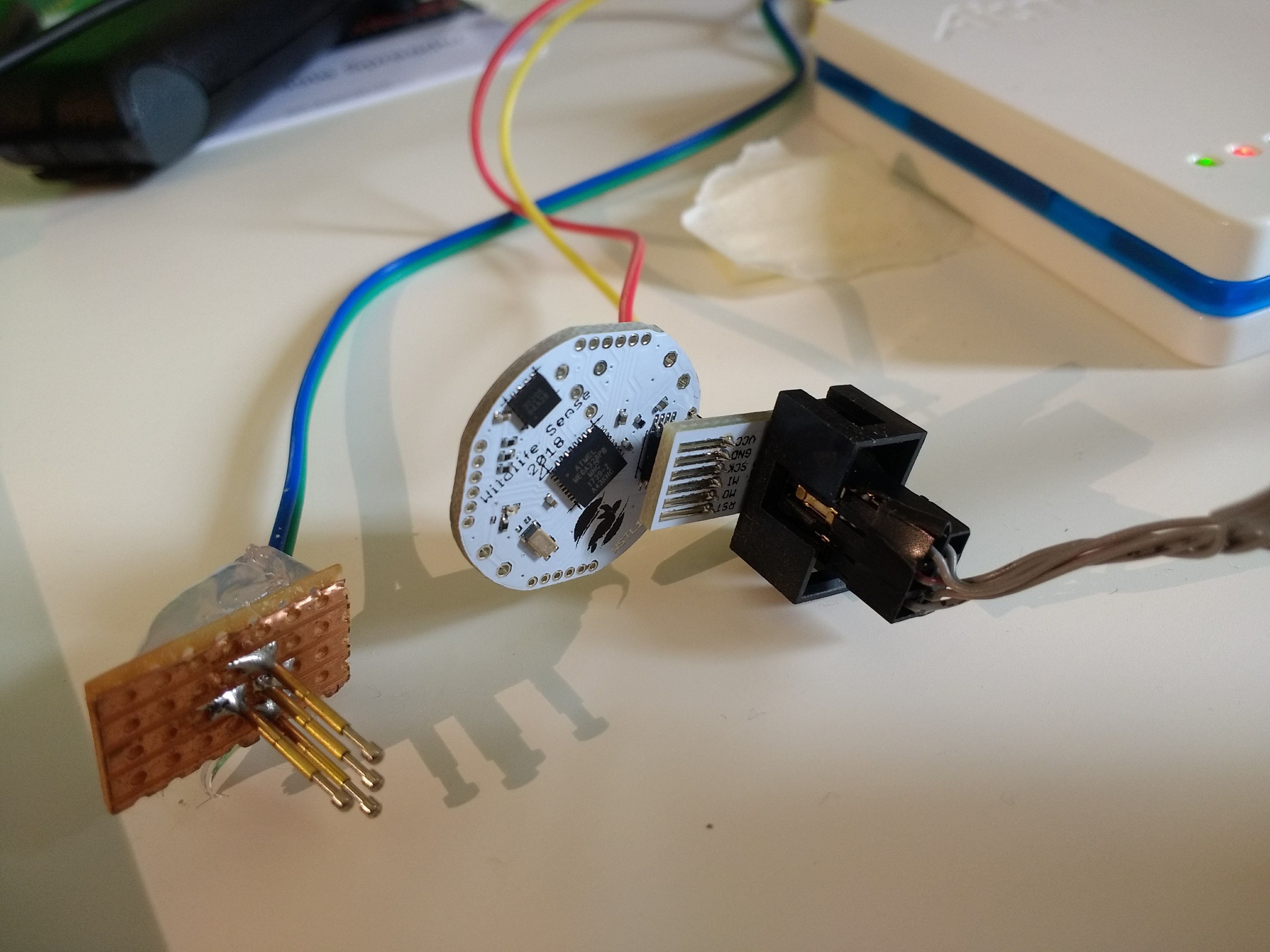

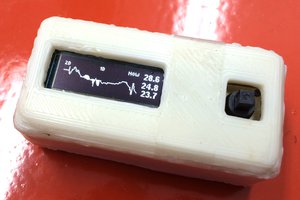

While I'd still recommend buying a commercial logger for anyone who just needs a few, I specifically started this project with the goal of building 50 units without the need to seek external funding.

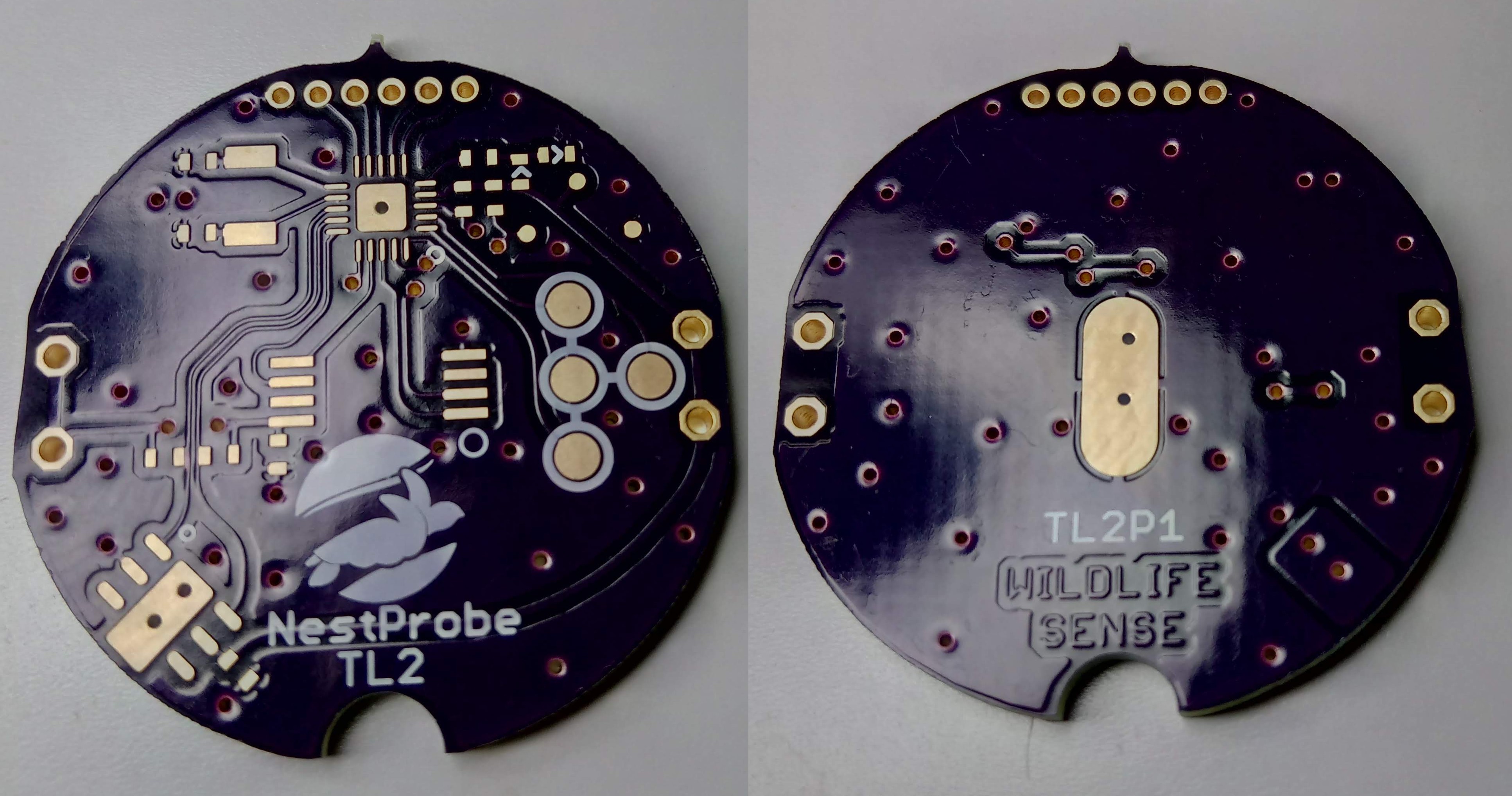

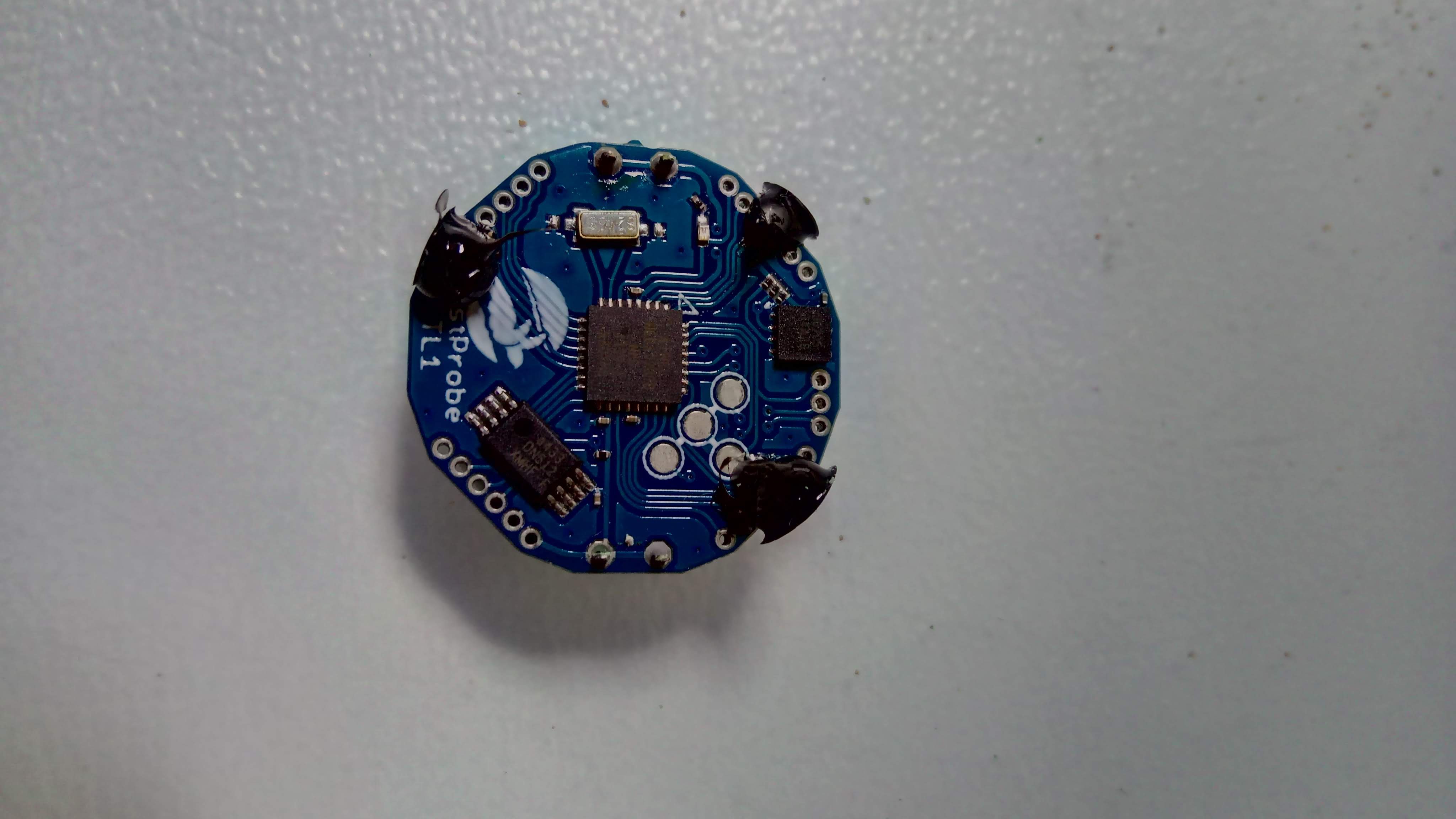

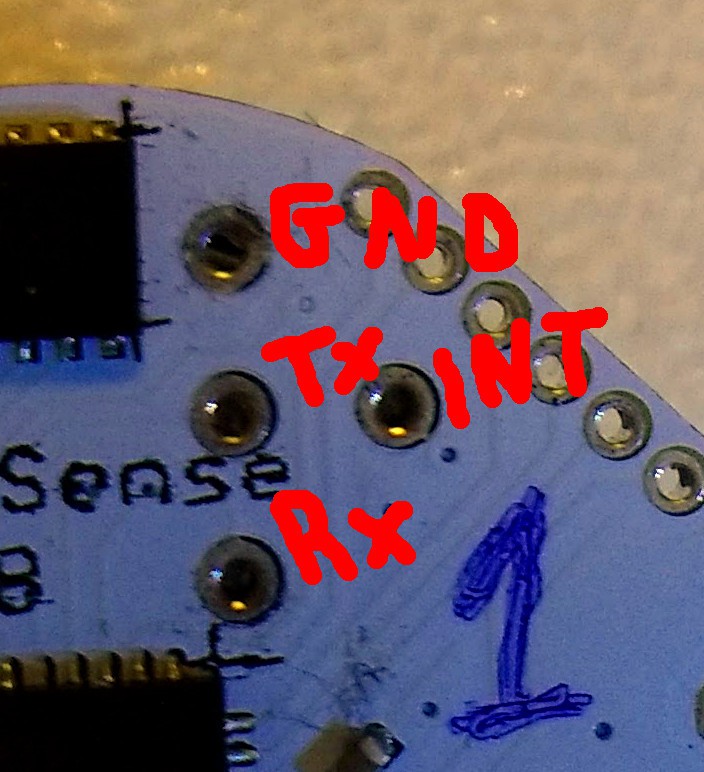

Temperature Sensor

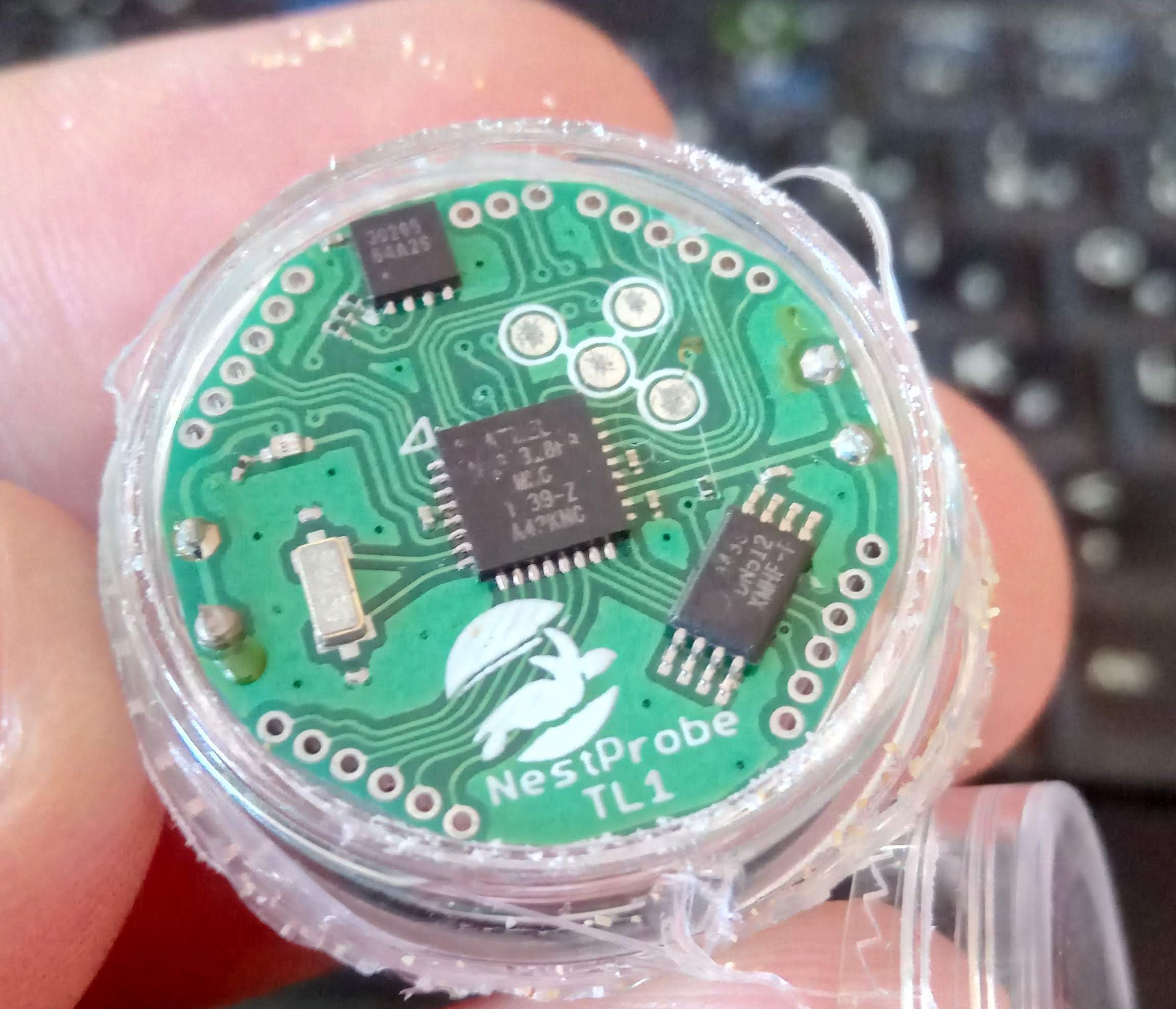

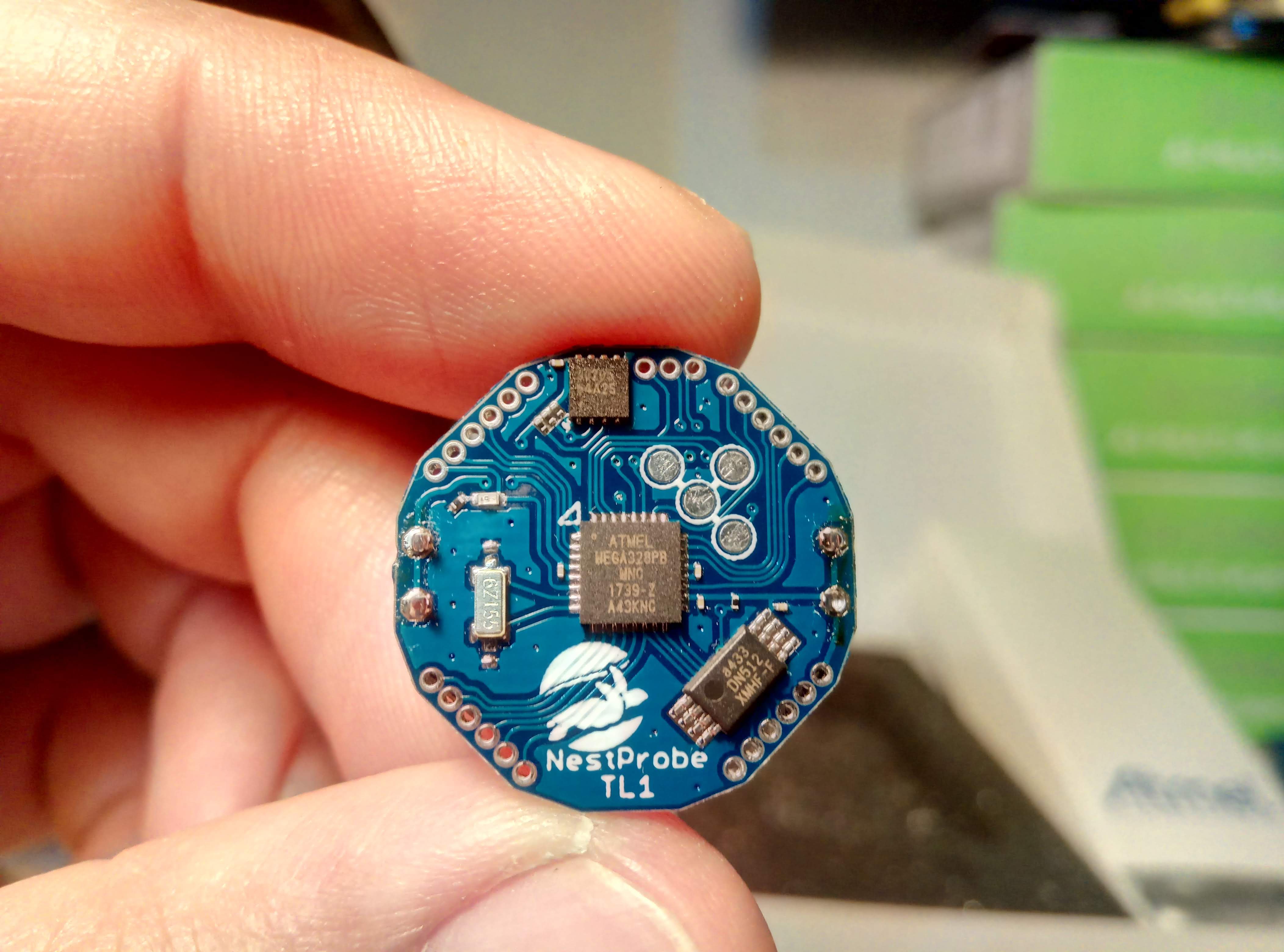

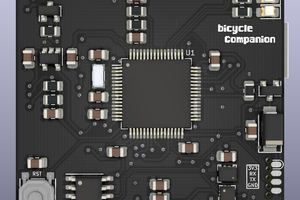

The temperature sensor used in this logger fits four requirements: High accuracy, digital output, small footprint, and low cost. The MAX30205 has an I2C interface. A sensor with an analogue output would require a small army of external components to achieve anything over the AVR's 10-bit resolution. This wouldn't fit with the size restrictions but would also consume too much power. The above sensor can achieve 16-bit resolution at a fraction of consumption and cost. While choosing, I was also considering Silicon Labs' Si7051 and Texas Instruments' HDC1080. I preferred the MAX30205 because it had more details on accuracy over its operating range, which is preferable for scientific research.

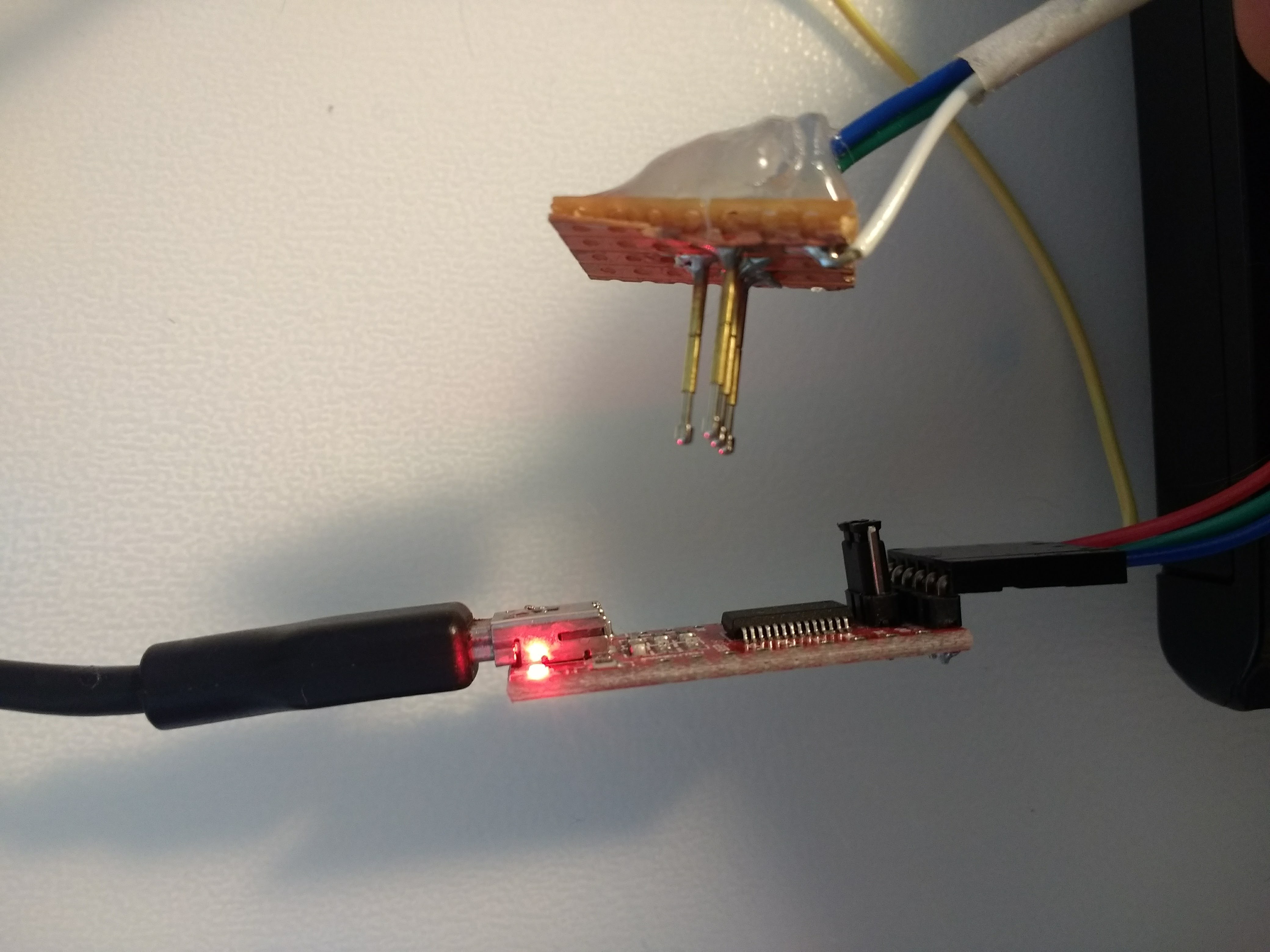

Memory

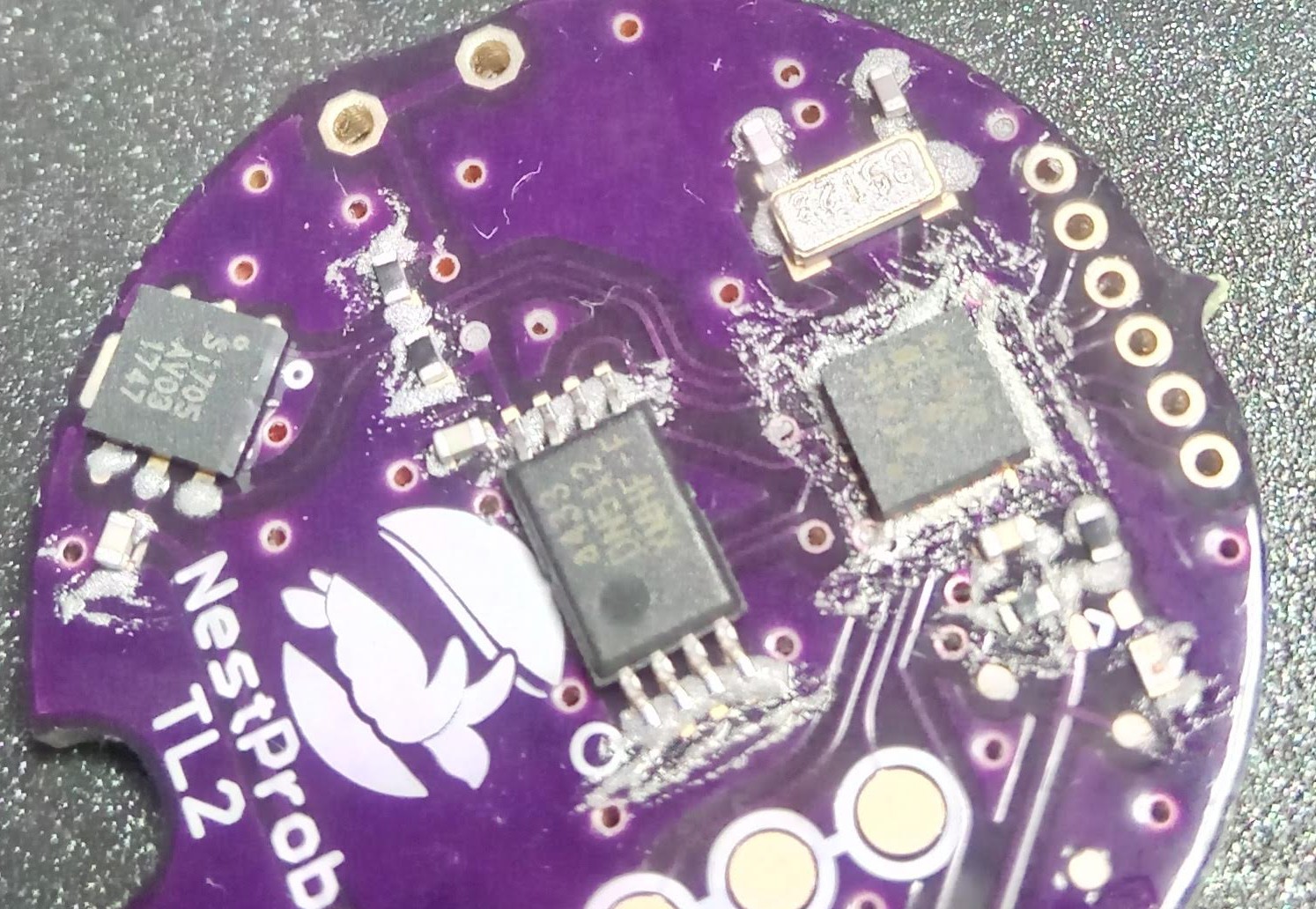

The temperature sensor gives its reading in two bytes. 180 days of ten-minute readings need 414720 bits plus some extra, so a 512kbit memory will do. The cheapest memory chip that's not a SOIC8 is Adesto's AT25DN512C. That comes in a TSSOP-8 package, which is small enough. The same package is available in up to 4Mbit versions, so extra memory can be used if needed.

Nikos

Nikos

Ruslan

Ruslan

Linus Dillon

Linus Dillon

Matias N.

Matias N.

Max.K

Max.K

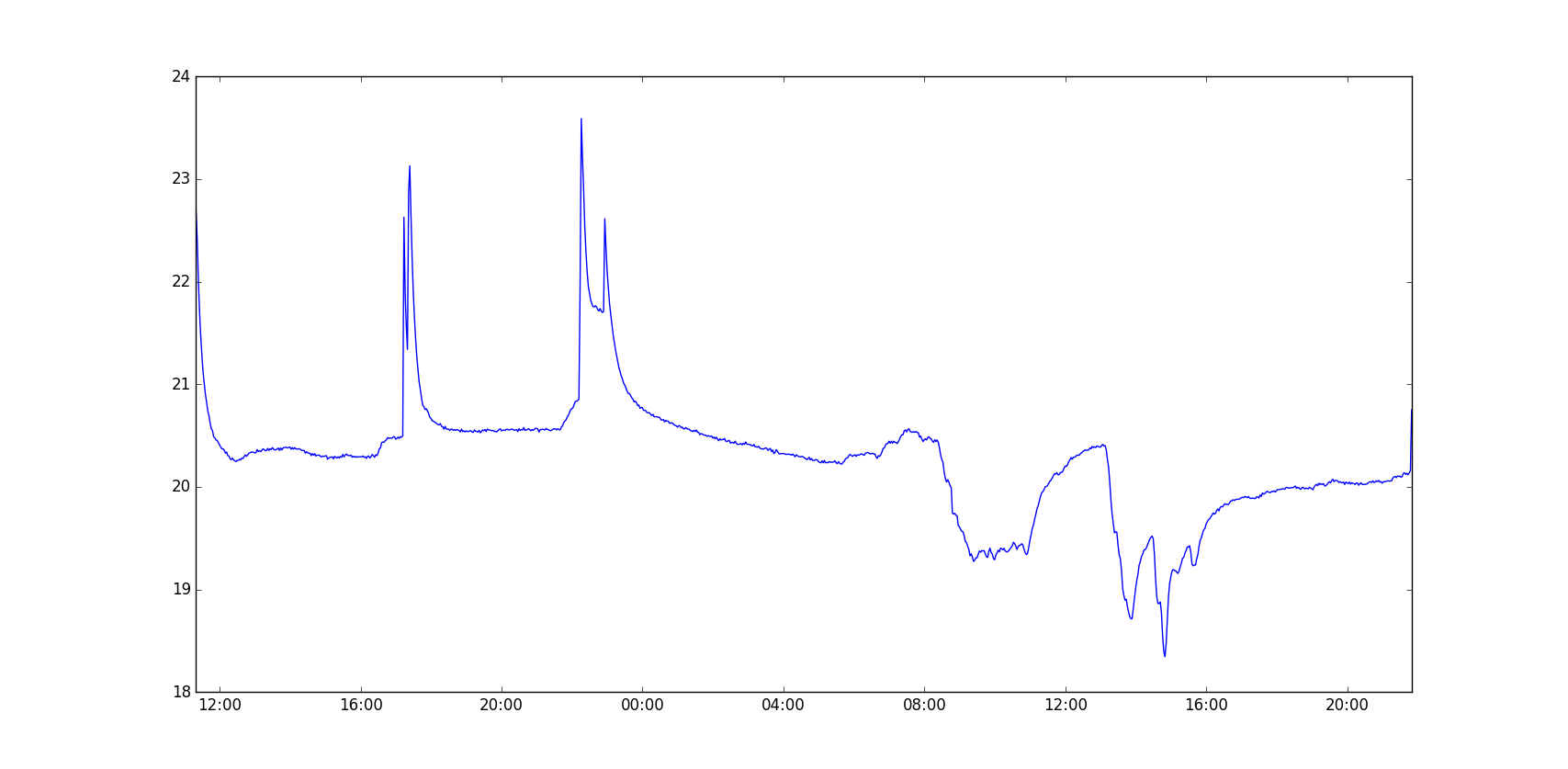

Good morning!

For my latest logger I came across that MAX sensor you chose too. I ordered a good quality genuine breakout bord and another one with a SI7051. Problem is: the MAX sensor is only accurate to 0.1 at a very narrow range (body temperature level). Which is not the range which can be expected in a turtles nest on the beach I guess? The SI is 0.1 over the whole range. Now why I write you: At least my MAX chip was off more than the plus minus 0.3 in the datasheet at the given range.

I suggest you check your temperature data against a known good sensor. All other sensors I tested, even the humble DS18B20, were much closer to the SI7051 which is guaranteed 0.1 full range.

Cheers, Jan