So I've got this nice little shack in the backyard that I use as my office. Mostly I write in here, but I also work the day job here, plus I've got my workbench out here for dorking around. It's small, only 10'x12', but it's enough for what I do.

Now, I have electric run out here, one 20-amp circuit, which is plenty for my laptop and monitors and LED lighting. As it turns out, it's also enough to run an electric space heater, which is how I kept the place warm last winter. But the electric bills got out of hand, and I decided to go "off-grid" with my heating this year.

Natural gas would be my fuel of choice, but trenching from the house to the shack for a buried gas line would have been prohibitive. So propane it was to be. I found a wall-mount direct vent propane heater rated at 8000 BTU/hr, which seems about right for this size space. Trouble is: how fast will I go through a tank? And what happens if a tank runs dry in the middle of the night?

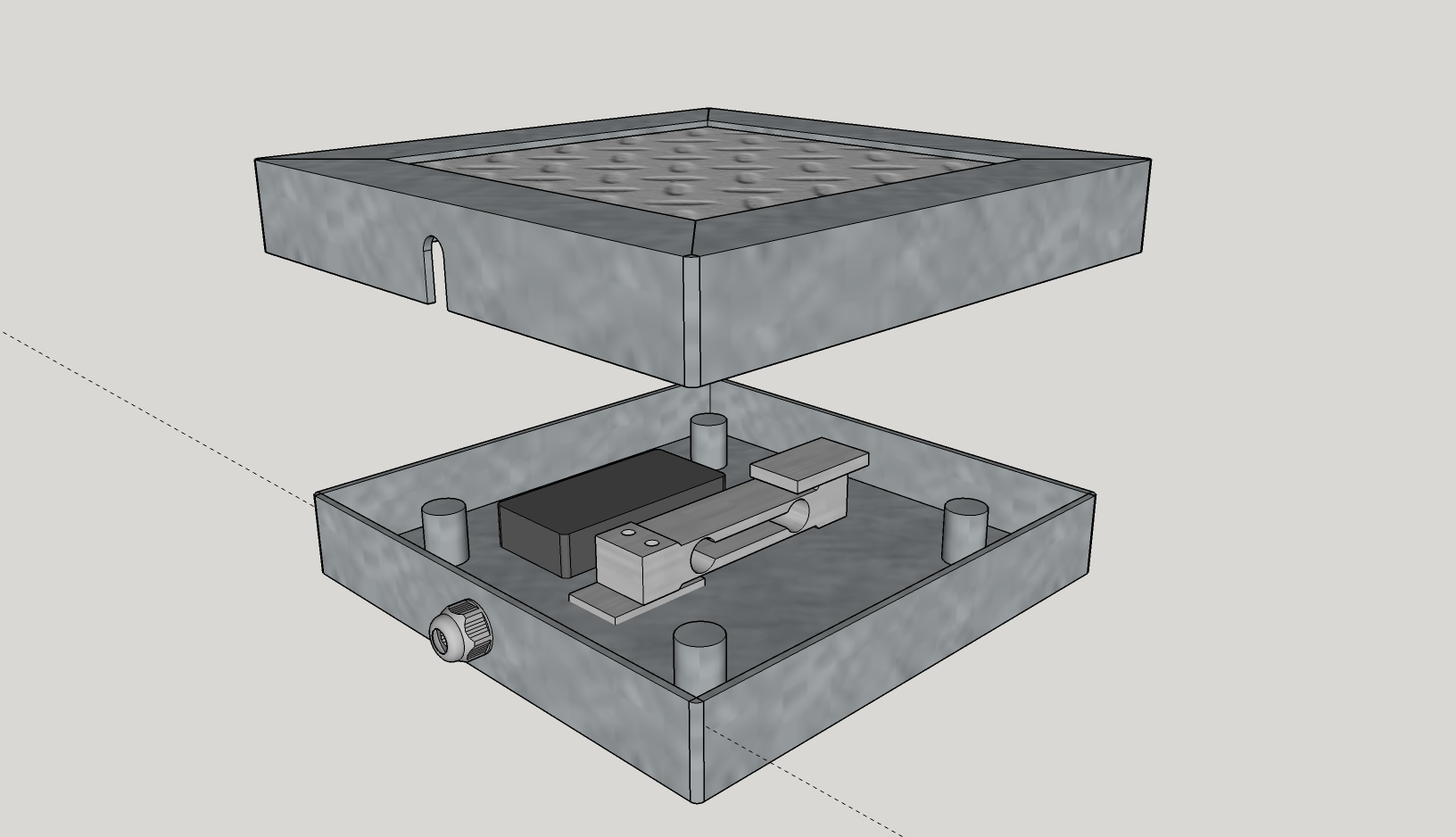

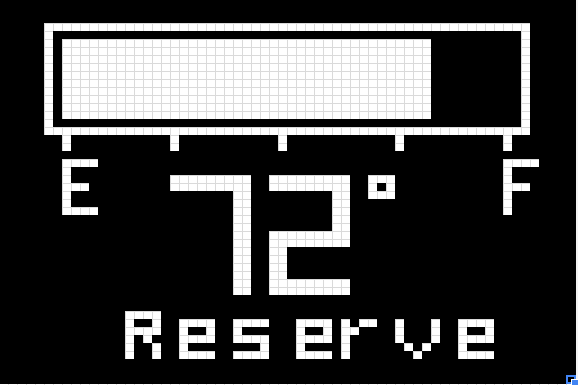

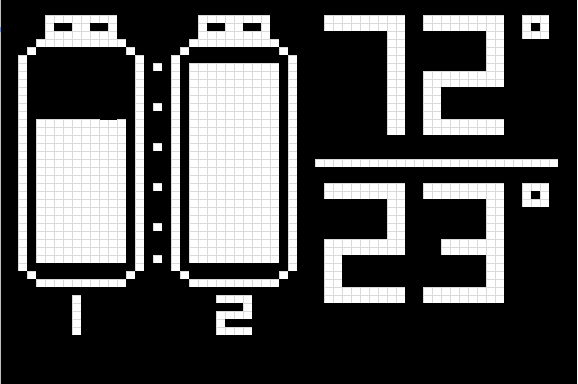

My immediate goal here is to build scales to sit each of the two 40-pound propane tanks on, and connect those scales to some kind of IoT system. I want to be able to graph change in weight over time, so I get an idea of the rate of fuel consumption. I also want a heads up on when a tank will be going dry, in the form of an email or text. I may also include an outdoor temperature monitor so I can correlate degree days with fuel usage.

Stretch goals include adding remote control to the heater so I can warm the shack up in the morning without getting out of bed. That might prove challenging since I'd have to link the heater's mechanical controls to a servo. We'll see where that goes.

Dan Maloney

Dan Maloney

Jake P

Jake P

Ronald McCollam

Ronald McCollam

Jorj Bauer

Jorj Bauer

Alan Kilian

Alan Kilian

But... but... then I won't be welding! You can see how that would present a problem! And I've already bought the material and everything...

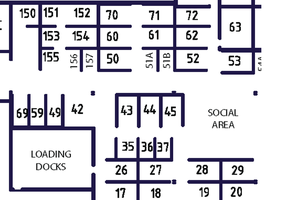

Sadly, you're right, and try as I might to find a justification to roll my own, the possibility of being done with the hardware for $50 is just too tempting. It remains to be seen whether the load cells in that base ring will have the range to measure the weight of my tanks, since it's built to monitor 20-pound barbecue tanks. China-made stuff like this probably is usually is engineered to save every possible penny, so if something is made to weigh a 20-pound tank, chances are good it won't like a 40-pounder. I'd also have to fiddle with the interface to see what the signal is like, but that's what hacking is all about.

So yeah, for $25 it's worth investigating. And if it won't work for my shack, I can still use it either on my gas grill or RV. Thanks for finding this!