So, altoids tins. Staple of Makers everywhere. Electrically conductive metal boxes of shorts, sparks, and letting the magic blue smoke out.

But there is a solution. I ran across this instructable on how to make your altoids tine electrically inert. Really awesome solution, but I have yet to see how well it wears. Basically, there is a spray on plastic coating you can get from your local big-box store that will cure on the internal surfaces of your tins, and render them safe(r) for electronics.

Here's my basic procedure.

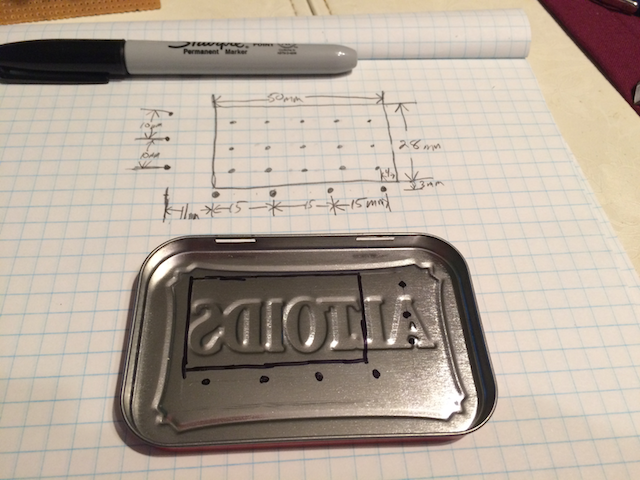

First, I lay out the design for my lid backwards, so that when I flip it over, it is the right way. Actually, I didn't the first time. Don't do that. That sucks.

Then, I punch and drill the lid. The big drills in the corners of the black square are where I will use my dremel tool to cutoff in between for the large opening. The punch sets the center of the holes so the drill bit doesn't wander. Nobody likes wandering bits.

Then, after making sure there aren't any burrs to cut myself on, I attempt to fit the parts into the lid. This fails miserably. Multiple times. After much foul language, sandpaper rework, and re-drilling with larger bits, everything fits perfectly.

Nailed it.

(If you check out the "l" from Altoids, you can plainly see where the sandpaper wore off the paint.)

Then, I masked off the outside of the tin with painter's tape, and sprayed it. Note the chunk of the lid sitting behind it.

Once sprayed ( 30 minutes between coats, 3-4 coats, 4 hours to cure), this is what mine looks like. Because I like blue. A lot. Boy, from this angle, you can really see my oval holes. Note to self: destroy this picture before posting. Also, through no fault of my own, and in no way the result of sub-standard spraying process, or really really cold temperatures in my garage, or the fact that it was late at night, and I had either too much or too little caffeine, or anything I may or may not have done at all, there are bubbles in the corner of that one side of the lid. I'll live, and so will you.

In all, this technique leaves a semi-stretchy rubbery plastic coating on the surface of the tin. Seems pretty thick, and has a very nice matte finish. For what it is worth, I really like the way it came out for my first time.

One thing I think I will do differently next time is remove the masking tape before the thing fully cures. Would have made less work in the clean up phase.

Korishev

Korishev

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.