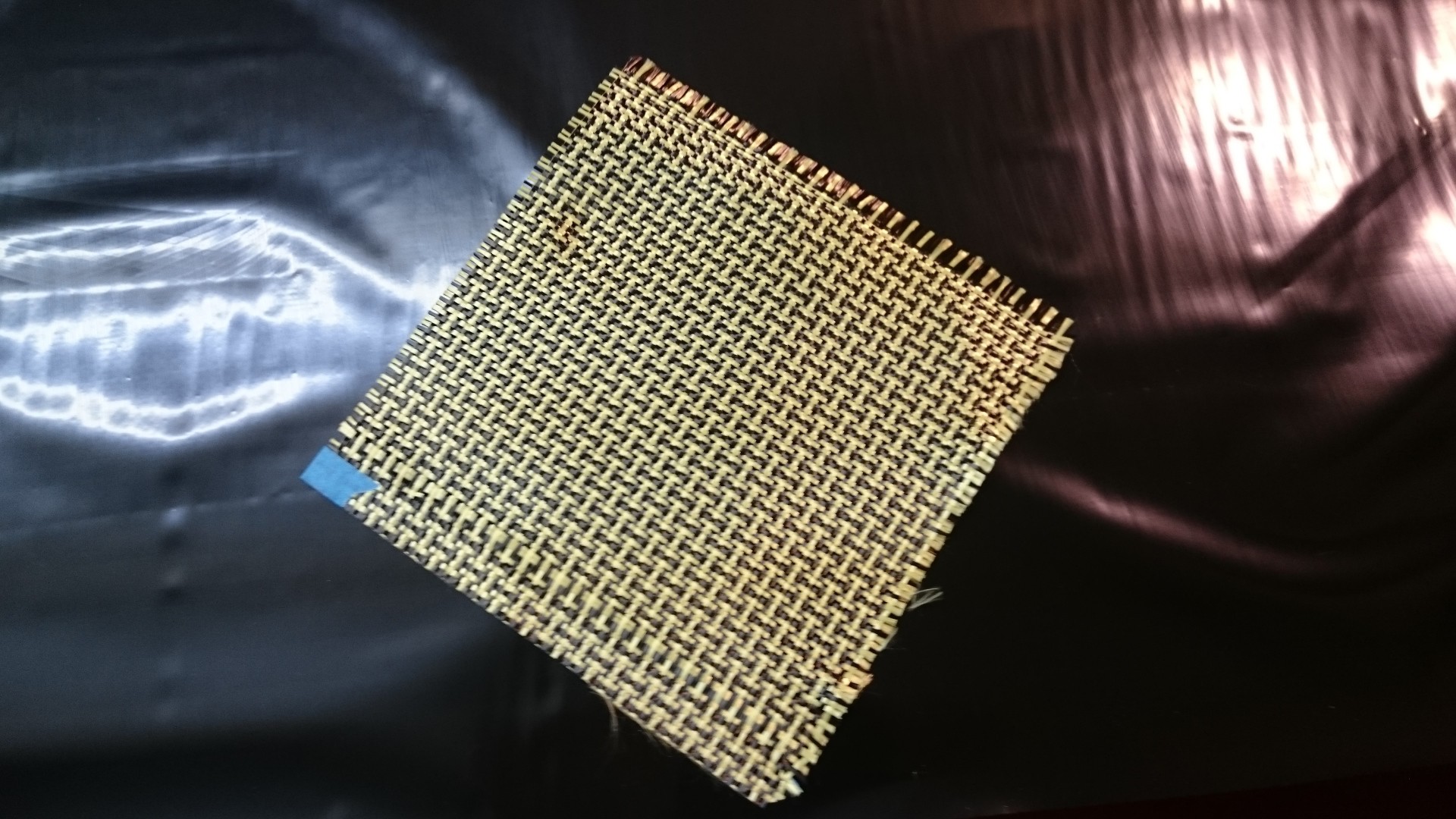

This carbon/aramid fabric is nasty. After about 30 minutes of cutting, fixing, taping, pushing single filaments around with tweezers I ended up with this (quite nice) piece of fabric:

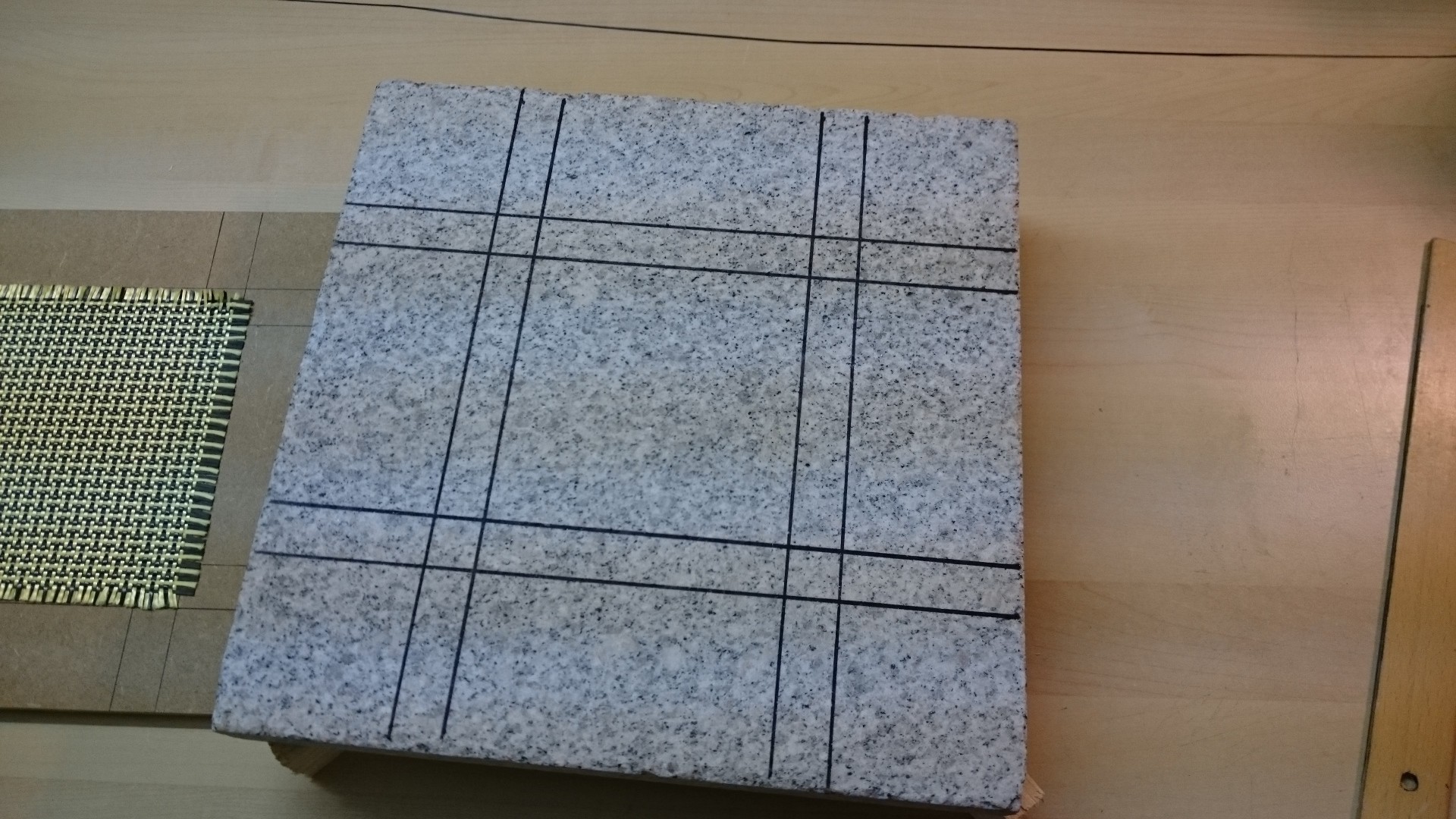

This needs some more trimming until it gets its final shape, and some of the filaments must be removed. This should be done in a fixture where it will remain until the internal connections have been tested, so the fixture must withstand the heat dissipated by the carbon when current flows through it. I wanted to use a tile first, but I could only find this granite plate:

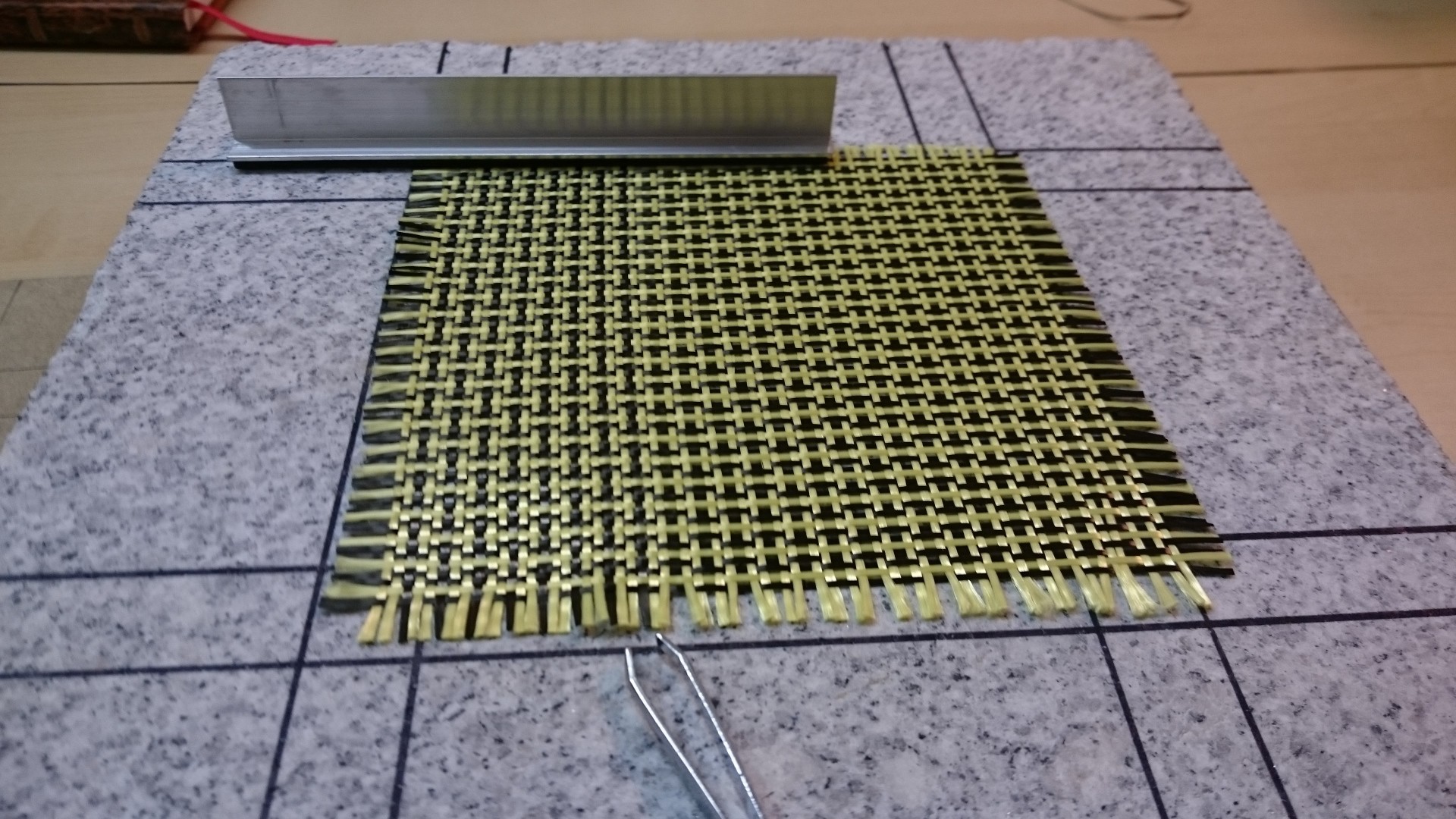

The inner marked area is 120 mm x 120 mm, just like the aluminium plate. The 20 mm border around it allows for some connections. Now in order to pull out single filaments the fabric must be tied down to the plate, but that one filament should be free to move. For that purpose I used a piece of aluminium T-bar with soft foam sticked to it (I also prepared two flat strips with foam for later):

The small gap in the T-bar foam is where the "moving" filament is:

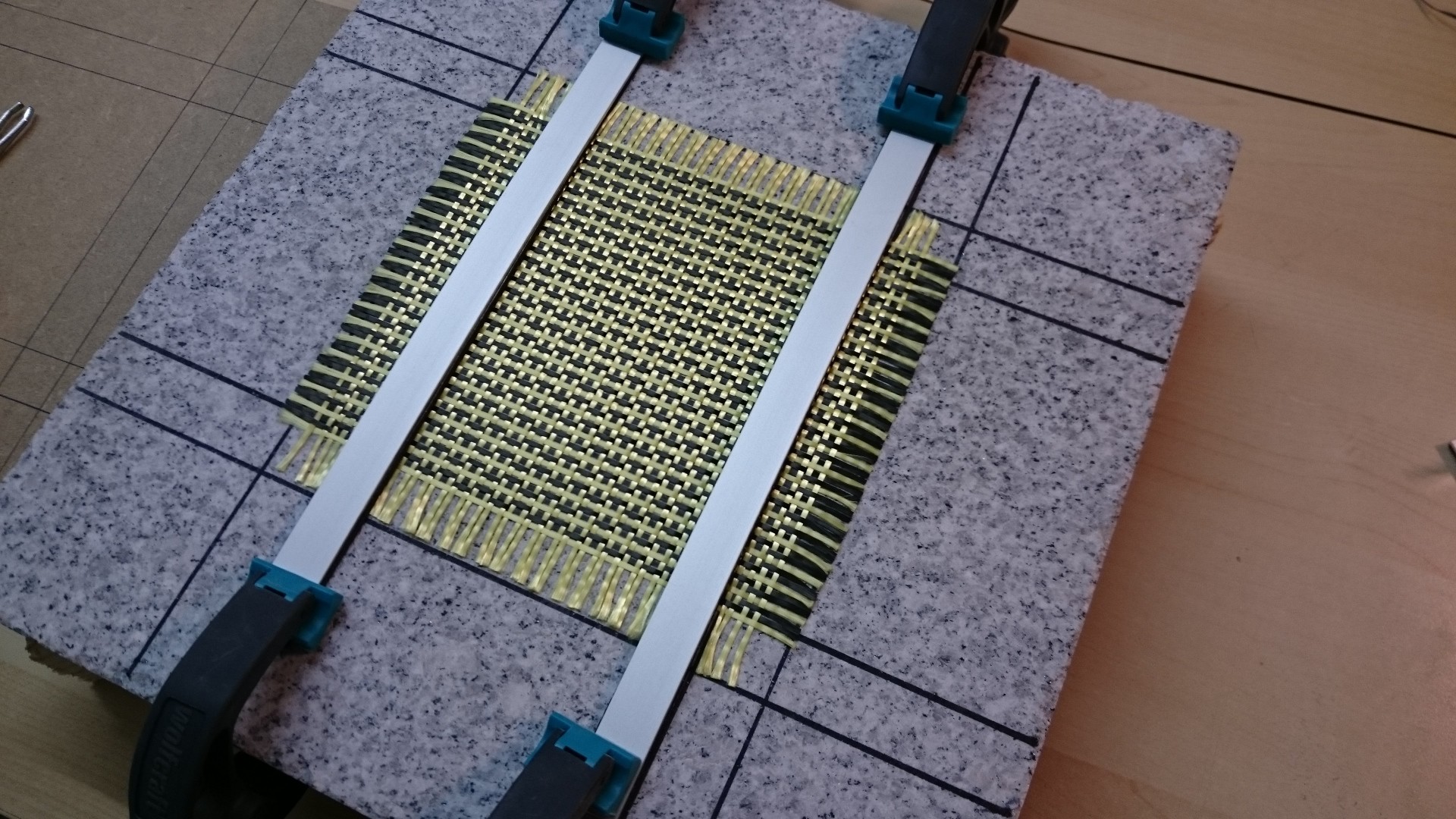

As you can see I started pulling out all the carbon in the one direction where the fabric has 2 aramid filaments per carbon filament. The aramid is left in pairs of two. Then I clamped the fabric with the two flat strips:

This is not going to move any more. Unless I do something very stupid.

Now I need to figure out how I want to connect the carbon filaments. Here's a closeup of the edge:

42 filaments, about 130 mm in length (120 plus a bit) in pairs of two, each pair separated by one aramid filament. I measured the resistance of one meter of filament, and it was about

Connecting filaments in series is probably very tedious, so I'll want to go for a low resistance. The lowest (all filaments parallel) and highest (all pairs in series) resistance I can create are

With a 12V supply and minimum resistance I'd get a maximum power of about 320 W. A decent ATX power supply can handle that without problems. So from now on we don't need to worry about isolation from an "is-that-a-threat-to-health!?" perspective.

The next step is to dress up the filaments with cable end sleeves (those without plastic!) and somehow connect them. I guess I can't solder the sleeves to anything, because the solder joints might melt if the whole thing gets too hot unless I can braze them (never did that before) without burning the carbon.

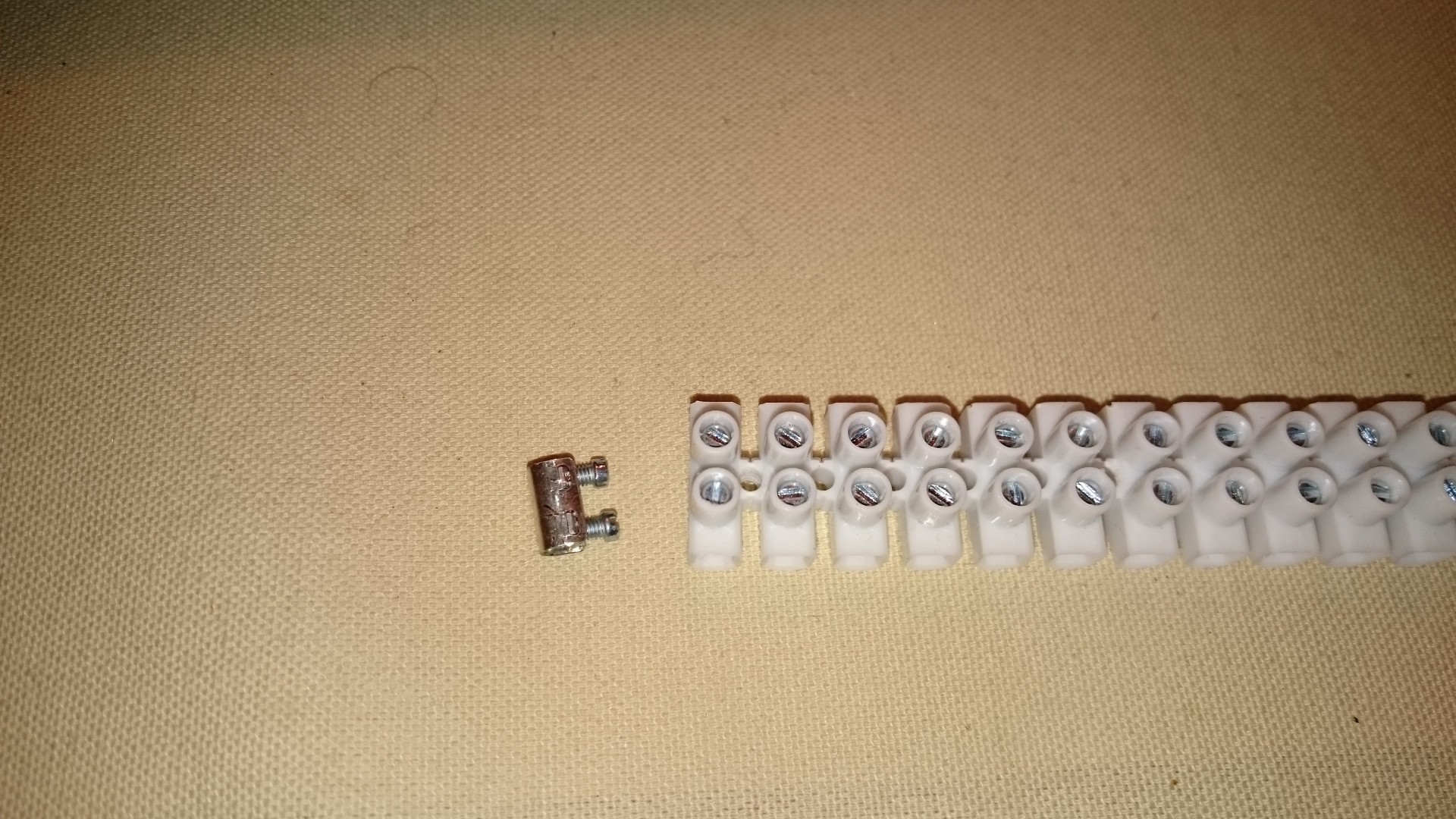

I might also try screw terminals from terminal strips:

I'll try brazing before I start to pry out another 41 of those screw terminals...

Christoph

Christoph

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.