I've been using a sleep mask since my undergrad dorm living days, and it makes for a rough night if I don't have one now. Sadly though, I've gone through a lot over the past few years. They usually don't take a washing very well, but to skip washing them makes things get pretty gross pretty fast. So I thought to myself, what's a soft bio-safe material that can take a washing really well? Good ol' silicone, of course! I didn't actually have high hopes for this project, but I figured it would be a good experiment none the less.

Thankfully, I already had a pretty good 3D scan of my face (using DAVID Structured Light 3D scanning). I just needed to convert it from the mesh *.stl file into something SolidWorks could use. While it can input some simple *.stl files directly, something as complex as a 3D scan is pretty much never gonna fly without some intermediary steps. In this case, I went through Geomagic Studio in order to convert my face from a mesh into a solid that SolidWorks could work with. Once that was done, it was just a matter of cutting my face up and building the mold around it. Again, if you're using SolidWorks too and haven't done mold making, this tutorial seems like a good place to start! (http://learnsolidworks.com/solidworks_features/how-to-draw-a-coke-bottle-mold-in-solidworks)

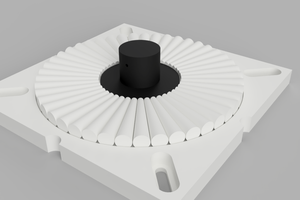

After the design work is done, it's time to print it out. This was a pretty large print, and it took a while for each piece. Nonetheless, I probably would go with a higher infill than I did (10% was pretty low). While it worked, the mold broke pretty bad when I was prying things apart in de-molding. But if you only want a one-shot mold, don't worry about the infill as long as it successfully prints. I'm sure de-molding spray would help a lot too, if you want to get fancy!

**Making a creepy puppet out of all your 3D scanned body parts at this point isn't required, but highly recommended!!**

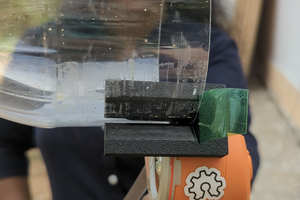

Once the molds were done, I mixed up a big gob of 100% silicone caulk and some cornstarch (like 5:1 silicone to cornstarch), filled the mold, and squished the two halves together. About 20 minutes later, everything was cured--but be careful of fumes when working with this much caulk cured so quickly! If you know that sour burny smell uncured caulk normally makes, imagine all that released at once instead of over the course of hours or days. It'll really curl your nose hairs!

Really, I wouldn't recommend using caulk for an application this big to be placed in such close proximity to your body. While it's hard to beat its price, caulk like this releases acetic acid as it polymerizes. This isn't so bad in most cases (it's basically just vinegar) the mask wound up leeching it for over a week, and I didn't want to put it on my face overnight until it was done - It was really frustrating to wait on it. Once it finally does its thing though, it is safe and inert; but you can get way better results immediately with a good casting silicone. You can get much softer, more comfortable types that are used for things like prosthetics, too. It can be on the pricey side, though.

Last steps were sewing up an elastic strap. I just sewed through the silicone to attach it.

Voila! Sleep in 3D printed customized comfort!!

Joe M.

Joe M.

Mike Turvey

Mike Turvey

cprossu

cprossu

blorgggg

blorgggg