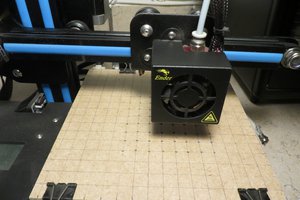

Print details

- Part designed in 123D Design

- Sliced using the Lulzbot-provided PLA-fine configuration profile in Cura

- Printed on a Lulzbot Taz4

- Nozzle diameter of 0.35mm, at 230C

- Blue tape on bed, no bed heat

Using ninjaflex, I have revived a dead Phillips CD-i

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Print details

ccyktvc.jpgUnderneath the CD drive.JPEG Image - 694.96 kB - 02/20/2018 at 17:50 |

|

|

20180210_174809.jpgNice interior picture of CD-i motherboard.JPEG Image - 3.51 MB - 02/20/2018 at 17:45 |

|

|

cd-belt-v4.123dxThis belt fits the disc tray pulleys of a Phillips Cd-i model 220.123dx - 39.84 kB - 02/14/2018 at 05:16 |

|

|

Tear down the CD-i until you can access the disc tray pulleys.

Here we can see where the belt should be. I've removed the perished belt already.

The front panel needs to come off to remove the disc tray.

You can probably reach the pulleys at this point, but further disassembly is easy enough.

This latch must be moved to pull the tray out completely.

With the tray out of the way, now we can proceed.

Use a piece of string to measure the length of belt needed.

Measure the string. This will be your inner circumference of the new belt.

Create an account to leave a comment. Already have an account? Log In.

And there I saw the ministrations of an electromechanical necromancer.

The necromancer had a dark sense of humor which seemed appropriate given their line of research.

In awe I whispered, "Neat."

Very cool!

It can solve a lot of players!

Congratulations!

For more info about CD-I Philips:

www.theworldofcdi.com

many times you may be able to find an O-ring of the proper size.

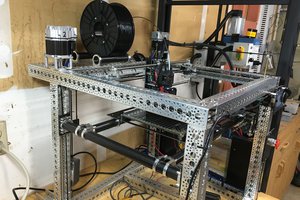

It would be much more difficult to get this special filament and convince the printer to work with it, than getting a regular belt. If you get only one which is too long, they are easily cut and glued with superglue. Or you get a kit with just the rubber "string" and the glue.

Surprisingly, I didn't have to do any convincing at all!

For the TAZ4 this was printed on, the manufacturer recommends using their proprietary "flexystruder" but I didn't have any issues running it with the stock extruder, just slowly.

The small volume of the final print means a very quick and very cheap print, on the order of 10 minutes and pennies, which is preferable to the week or more it usually takes to get a belt off ebay.

We are hackers after all ? :D why buy if we can hack !

Become a member to follow this project and never miss any updates

Greg Zumwalt

Greg Zumwalt

edkirk1

edkirk1

Thanks for this! I've never printed TPU but I need a belt for my CDI220/37 (NTSC) and I'm not finding them with my usual suppliers.

It's very strange that the only filament material mentioned where all the temps and settings are mentioned is "PLA" ("PLA-fine configuration settings). Obviously, it's not PLA but all the settings are useless without knowing the material. I was very confused! Might be worth mentioning that it's Ninjaflex TPU in a few more places.