Ran into a few design-flaws along the way...

First was this:

Yeah, that's a 2.5ish-D system, and that third-axis... how the heck was I planning to transfer motion to Z for the pen-up/down...? Came up with some lever-system (the teal thing in the middle) but it seemed pretty wonky, to say the least. Also, this system requires pulleys to be *really high* off their attached-surfaces, which would cause some torquing on the material...

This is what I'm on, now:

Was pretty proud of that, have it even more completely-drawn-out on paper... including the pulley-layout which results in very little torque. But just realized another design-flaw... Always figured the Z-axis wouldn't be particularly strong, what with the number of pulleys it'd have to go through, but certainly good 'nough for a pen... but, I was kinda hoping to at least have the *option* for 3D-something... who knows what... Well, this doesn't lend itself to that well, at all... the Y-Axis carriage would hit whatever 3D thing was under it. Woot!

Early pen-and-paper sketches suggest swapping the Y and Z axes... have Z be the vertical plate attached directly to the X gliders, then slide Y left-to-right on that... Great! Except... very little stability, I'm sure. It'd require cutting out a significant amount of the structural-support provided by the Y (now Z) plate, and all that that was going to go behind it.

We'll see... Again, this was mostly just to get this darned pulley-thing out my system; a glorified etch-a-sketch would be a great start...

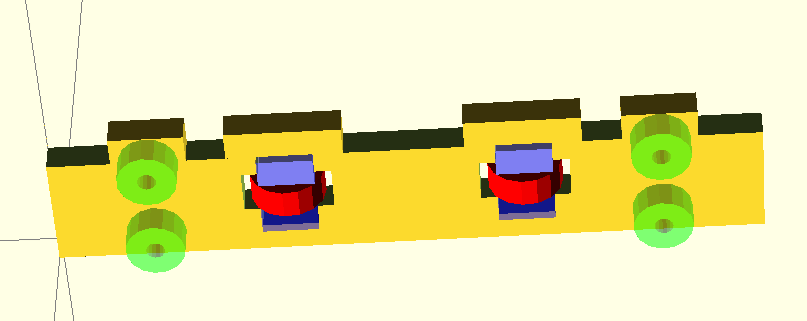

Here's the wheel-plates... I'm particularly proud of the red-wheel-mounts which are snap-in. Though, I'm still trying to figure out what to do about the green-wheel spacing, which would be offset by the laser's tooling-width as well as tolerances in the material-thickness...

Thinking about a diagonal notch and screws... it's vague in my mind, so far.

The whole system is designed to be easily-scaled, so I'm kinda thinking about the smallest-size sheets they have available 7in x 7in, and possibly trying to fit everything on a single sheet... A tiny little cartesian system for fun. Maybe even snap-together... held together still as a sheet which can be snapped-apart... I dunno.

The only things necessary besides the lasered-material, then, would be cable, pins, (glue?) and pulleys... and I'm contemplating how to cut a notch into laser-cut cylinders with the tools I have available...

Eric Hertz

Eric Hertz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.