I can tell you that I searched a lot on the internet on every corner I could find and I only came across speculations. No argument or statement supported by some measurements regarding the type of the Hakko t12 tip thermocouple. 80% of the posts out there would say it's type K and the rest will say it's not Type K, but they won't say anything about what is it.

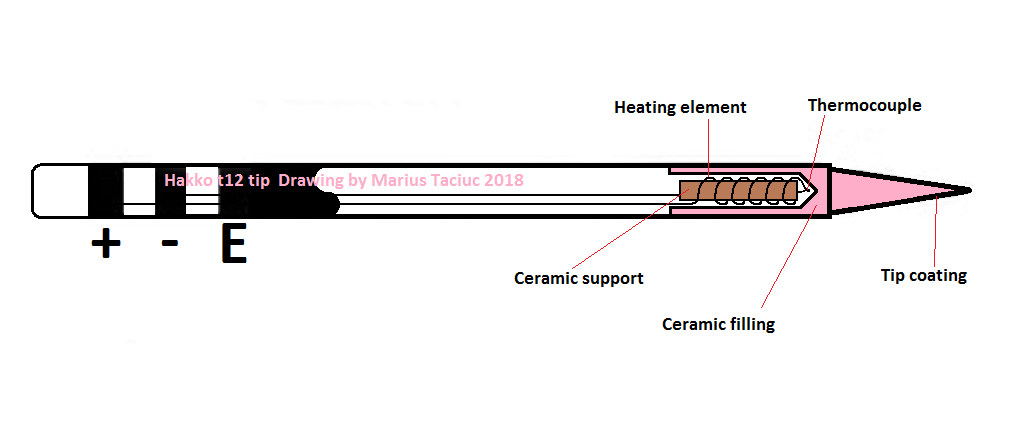

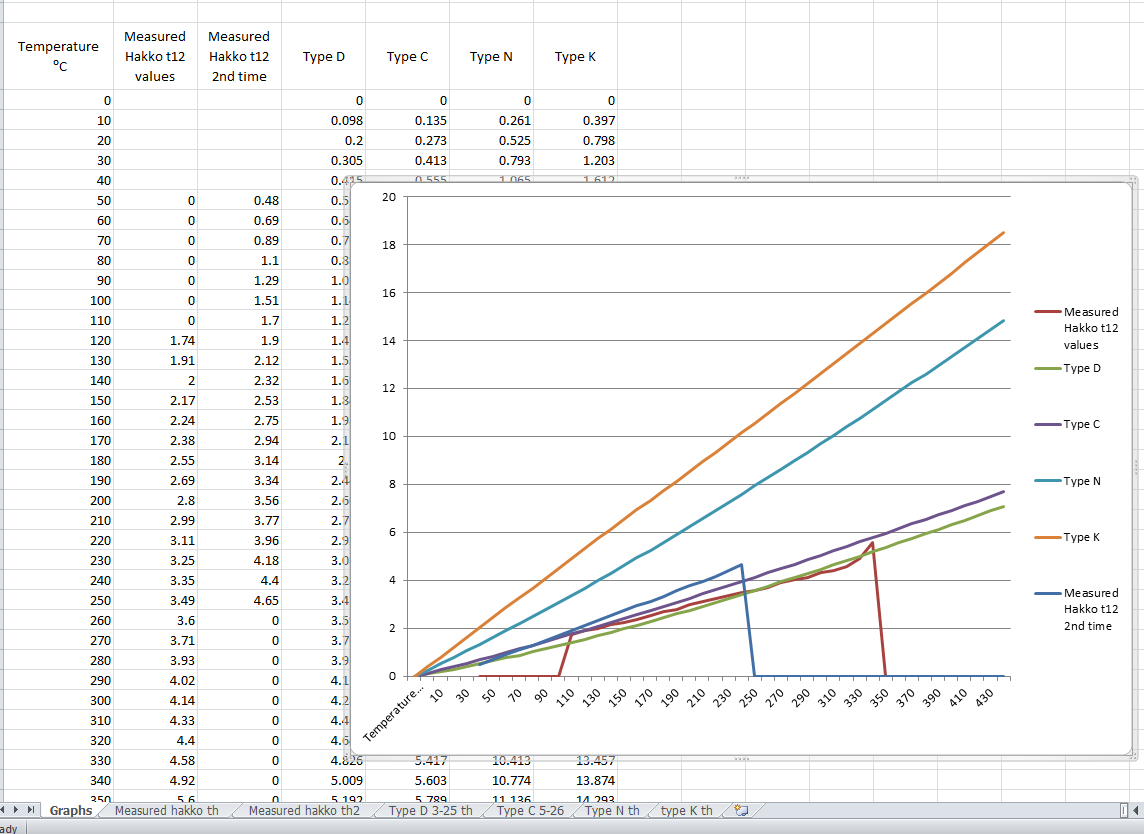

Well, I am ready to support my theory with some facts. First of all, this is how a tip structure looks inside. I took a look inside of one of these tips which paid with it's life for science. Then I draw this as accurate as I could. In what comes the graphs, I made a couple of sets of measurements and compared these measurements with all the known and most common thermocouple types on the market. they look like this:

I will post a video to show you how I measured these values, but until then, I can tell you that the 1st measurement was made using another soldering station as a heating element and a Fluke 87-V with original thermocouple as a temperature measuring device. The second measurement was made in a bowl of heated oil. I firs heated the oil to about 300*C and then I placed the Fluke's sensor and the tip in the same bowl of oil. I read the voltage values generated by the hakko tip using another Fluke 87-V set to high resolution mode.

I have to admit that this method is not very precise and you can see this from the two different measurements I made. They came to be so different, because of the temperature gradient in the hakko tip. The higher the temperature difference between the heat source and the environment, the larger the error. This conducts me to the logical conclusion that I must approach the right measured values at lower temperatures. If I look at the graphs, I can see that at lower temperatures, my measurements are overlapping with the graph of the Type C thermocouple. If I had a thermal chamber I would definitely take some more accurate measurements, but until then, I can tell you one thing for sure: this thing is definitely not Type K. Not even close.

I remember reading somewhere on the internet some contradiction related to this. A guy was saying that is Type K and that he measured it and it had around 20uV/*C at some certain temperature. Well that's a misleading statement. Type K thermocouples are having around 41uV/*C at 1000*.

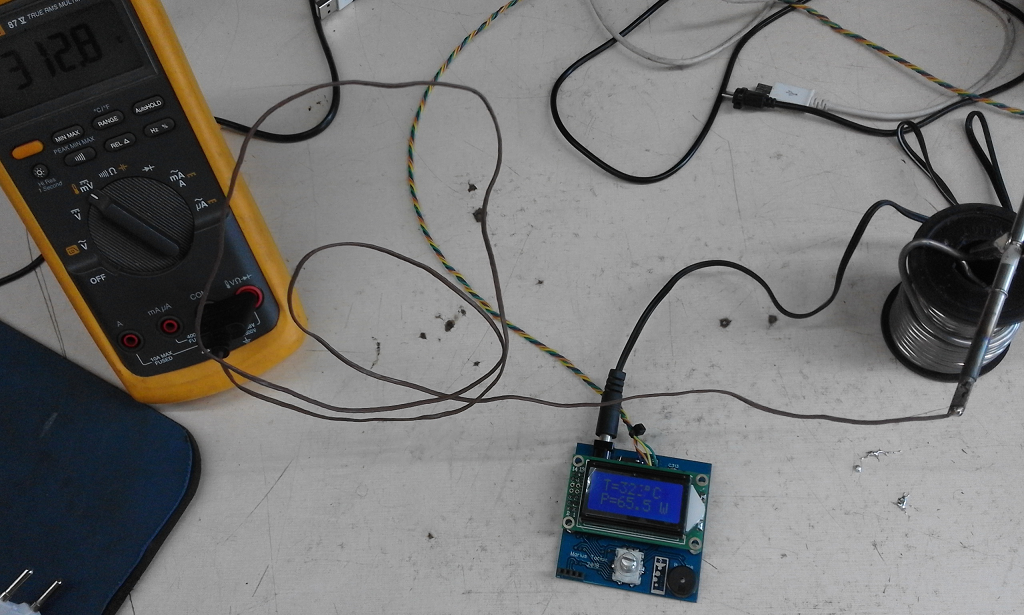

I implemented the 21uV/*C value in software and later on, I tested the system with different values such as 19uV/*C, 20uV/*C and others. I was measuring the tip temperature using a Fluke while testing it and I can tell you that the hakko tip seems to be pretty linear. Moreover, I managed to achieve a less than 10*C difference between the temperature displayed on the screen of the soldering station and the externally measured temperature of the tip. And I expect that the Fluke thermocouple would have it's own mass and act like a heat sink on it's length. Therefore it's good to see the heating element and the core of the hakko tip at a temperature greater with 10* than the tip itself.

It actually makes sense to have the heating element made out of some tungsten alloy rather than nichrome, because the design is airtight and tungsten is cheap. Type C thermocouples are 95%W/5%Re–74%W/26%Re. The heating element is probably made out of 95%W and the other wire that comes form the socket and joins with the heating element creating the thermocouple is probably 74%W/26%Re. Problem solved.

This brings me to blaming these failed soldering station kits again:

I don't know who designed these, but they only have the possibility to set the uV/*C from 41 down to about 30 from the internal menu and this says it all.

Marius Taciuc

Marius Taciuc

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hi!

It's not type C, C is intended for inert environment, with presence of oxygen it dies.

Also, thrermocouple isn't the small welding point at the tip, thermocouple is always some lenght of two (couple) wires. Inside T12 the whole heater with wires to contact pads is a thermocouple consisted of nickel and kanthalD. And it has delta approx 20uV/degC.

https://patents.google.com/patent/US6054678A/en

Are you sure? yes | no

I am not sure about the C type thermocouple.

Please look what OMEGA writes about this and other types:

https://www.omega.com/en-us/colorcodes

https://assets.omega.com/landing-pages/colorcodes/tc_colorcodes.pdf

Paul

Are you sure? yes | no

You are so wrong!

There are two different temperatures.

The soldering station and the external tip thermometer display the temperature on the exterior of the tip, that is what is useful for soldering.

The sensor built into the cartridge measures the temperature in the windings of the heating resistor - that is another temperature at the inside of the cartridge, significantly higher than the one on the tip.

You assume that it is the same temperature, rather wrongly.

The two temperatures vary with different slopes.

Confunzi temperatura din interior, citita de senzorul din cartus cu temperatura masurata la exterior, pe varf. Ele sunt diferite, cea din interior este mult mai mare. Deci toata demonstratia este gresita, ca de altfel si concluzia. Nu ai decat sa repeti rationamentul cu un Gordak, vei gasi ceva asemanator... dar acolo este usor sa scoti termocuplul (prin spargerea rezistentei) si sa te lamuresti ca este tip K, deci te vei convinge singur.

Are you sure? yes | no

Awesome writeup...any idea why the heating tip will run wide open and make the tip glow hot? My T12 won't regulate and just glows red.

Are you sure? yes | no

Can you give me more details? did you attempt to build this project and it's not working? Or do you have another t12 based soldering station which gives you a hard time?

Are you sure? yes | no

It worked for a while...now it runs wide open (aka the tip glows red after about 10 sec on a 24vdc build)...even checked the wires in the plug in case of shorts...still runs wide open. Not trying to build this project...trying to unbork my T12...

From your image...looks like I only need 3 pins to have it run...not all 5...

Are you sure? yes | no

The tip only has two wires. You can check the first image of this log. These wires are both the heating element and the themperature readout. So technically, you don't need the other three wires. I personally think this got nothing to do with the tip or any whire in the handle. It could be something from the soldering station's board. Maybe a diode, an Op Amp or even the MCU's pin.

Are you sure? yes | no

It's definitely type C. I building one arduino based soldering station and I finally found equation for this one. ((0.02537307*x - 1.0236416)*x + 65.600825)*x - 9.744966. X is thermocouple output in mV. After puting this into my code station showing proper temperature. I just need less noisy opamp and some capacitor for handle because temperature jumps up-down really quickly.

Are you sure? yes | no