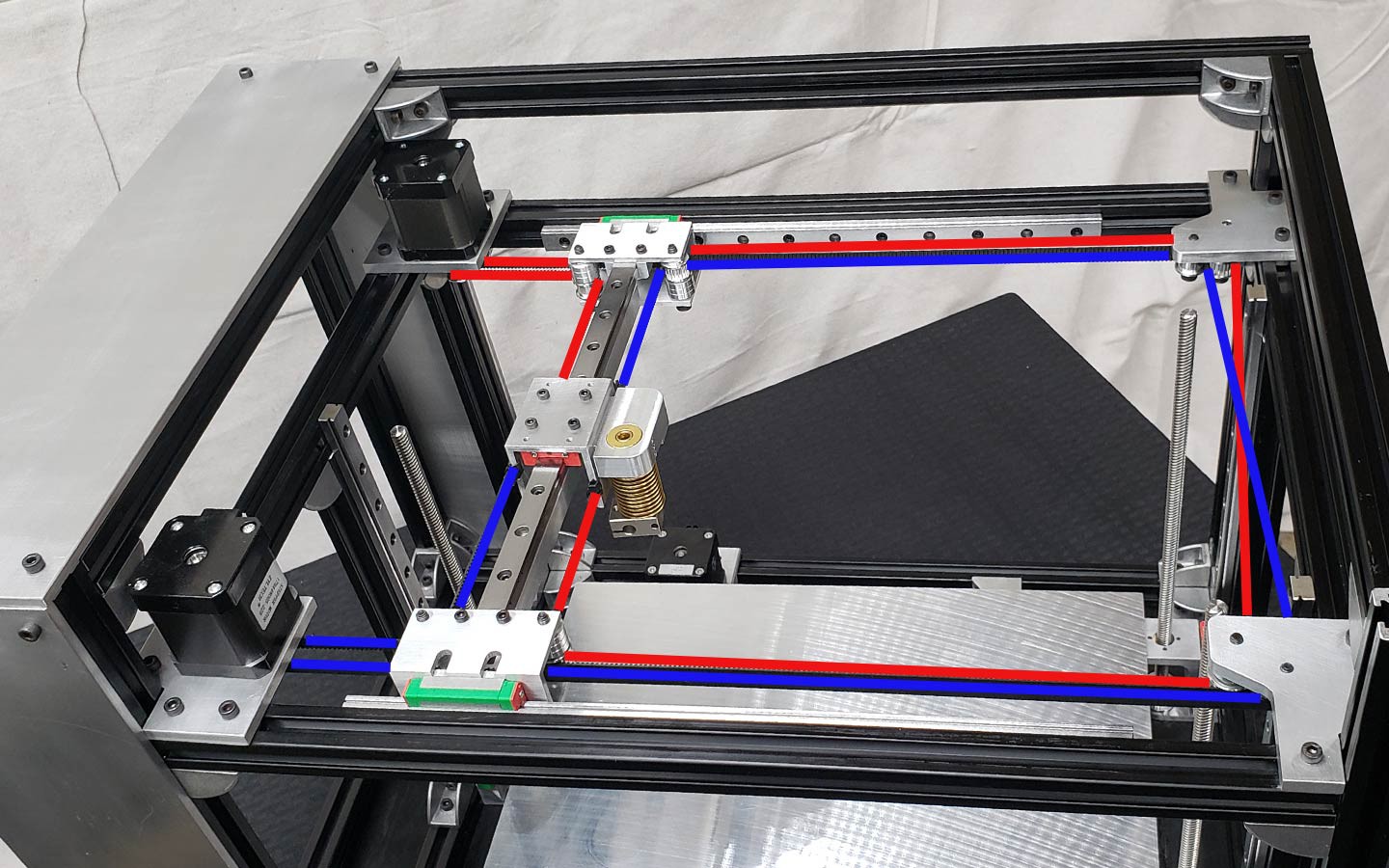

CoreXY Belt Path

CoreXY Diagram

Belt Path Crossing

While the SolidCore 3D Printer design had a lot of influence from the Railcore's design, which also has the "x" shape belt path that some say “serves no purpose.” True, but you see the quality prints that the Railcore community is putting out. The print quality of the RailCore is AMAZING! Although the belts don't have to cross if the pulleys are at different z-levels. I originally thought that the difference between the hbot core xy design was that the corexy belts crossing segment.

We already designed and built the SolidCore with the crossed belt path so we're going to stick with it for now. Later on after many performance tests I'll try out some other design configurations to test out any changes.

Hbot vs CoreXY

The difference between hbot and corexy is that hbot has a single belt on a single plane, corexy can have either two non-intersecting planes or a single plane with pulley idlers on different levels which keeps the belts from rubbing.

While the Hypercube has the stacked belts on different planes configuration unlike the SolidCore corexy configuration "x" crossed belts.

Stacked Pulleys

Offsetting the stepper motors with stacked belt path pulleys may give the belts a clean run and simplify belt alignment. A printer's motors can be offset at different heights so that the belt routing runs a straight belt path and don't have to be twisted. But this belt routing path would also mean that on one side of the gantry the belt would have the teeth on the side of the idler wheel which wouldn't run as smooth and could lead to artifacts within printed parts.

SolidCore and RailCore Crossing Belt Segments

While many frown upon the crossed belts configuration found on the Railcore or SolidCore due to the y-axis could possibly bind if the y-axis isn't completely perpendicular to each other.

Linear Rail: Supported vs Unsupported

I'm using a crossbar made from u-shaped aluminum extrusion. Depending on the rail length if the y-axis has an unsupported linear rail it could possibly lead to deflection. The load of the belt paths have to be balanced along the running plane with the pulleys. An unbalanced load can lead to the belts trying to slip off the pulleys and premature wear of the bearings.

Shane Hooper

Shane Hooper

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.