Stenotyping lets you type faster than speak -- in particular, it lets you easily write down what other speak in real time, with some margin to spare. All you need is to learn the system of phonetic chords that correspond to the individual words.

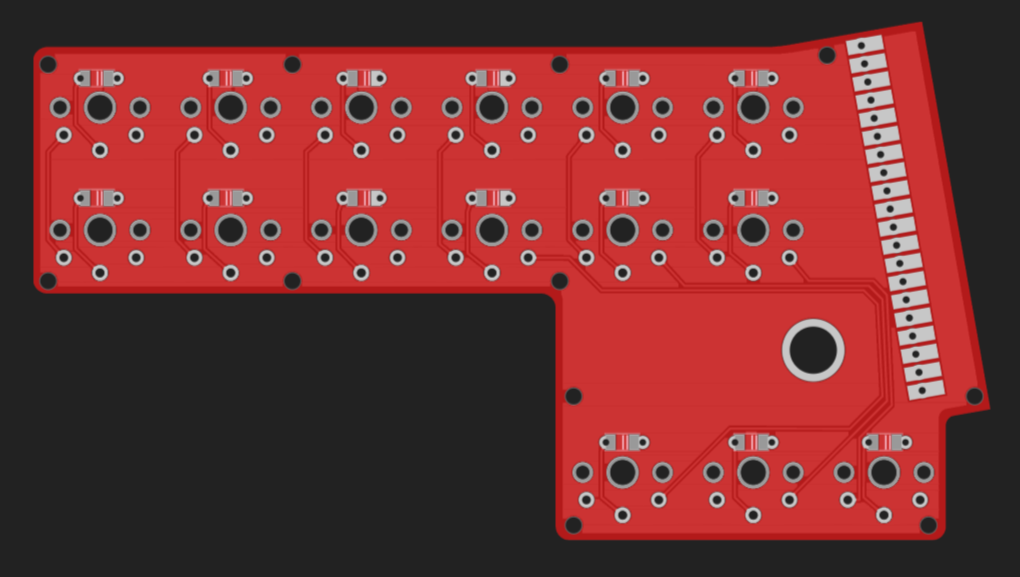

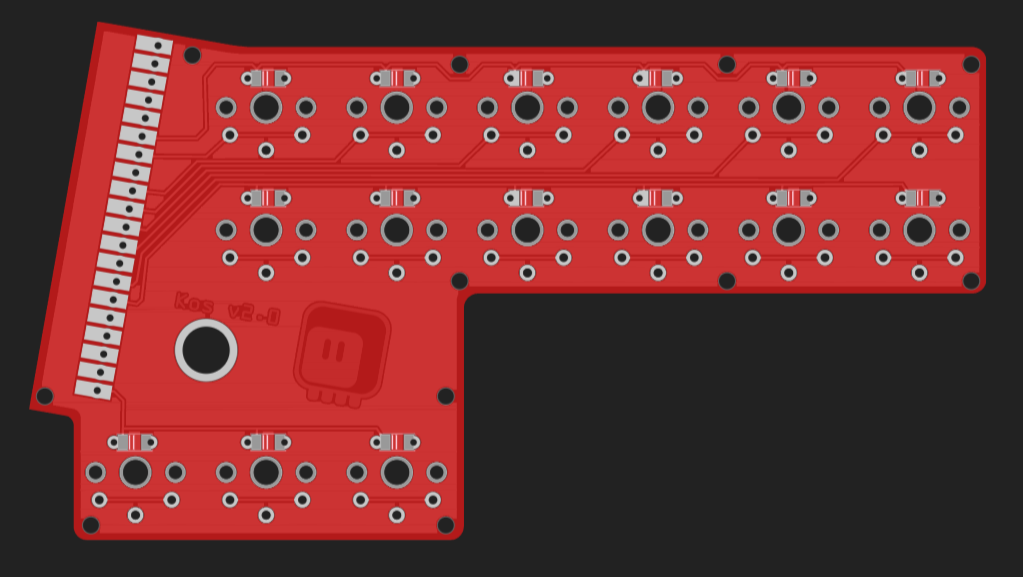

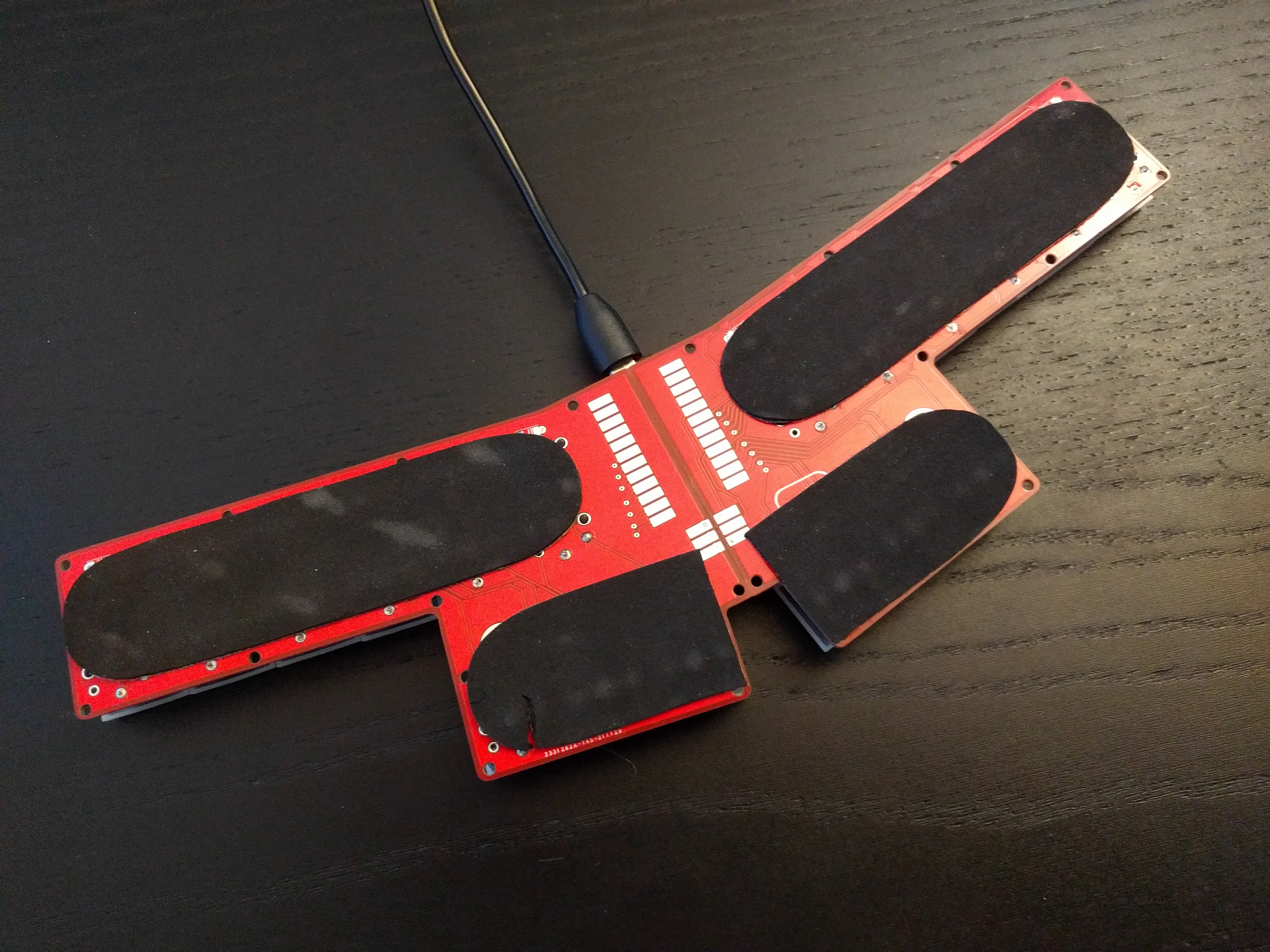

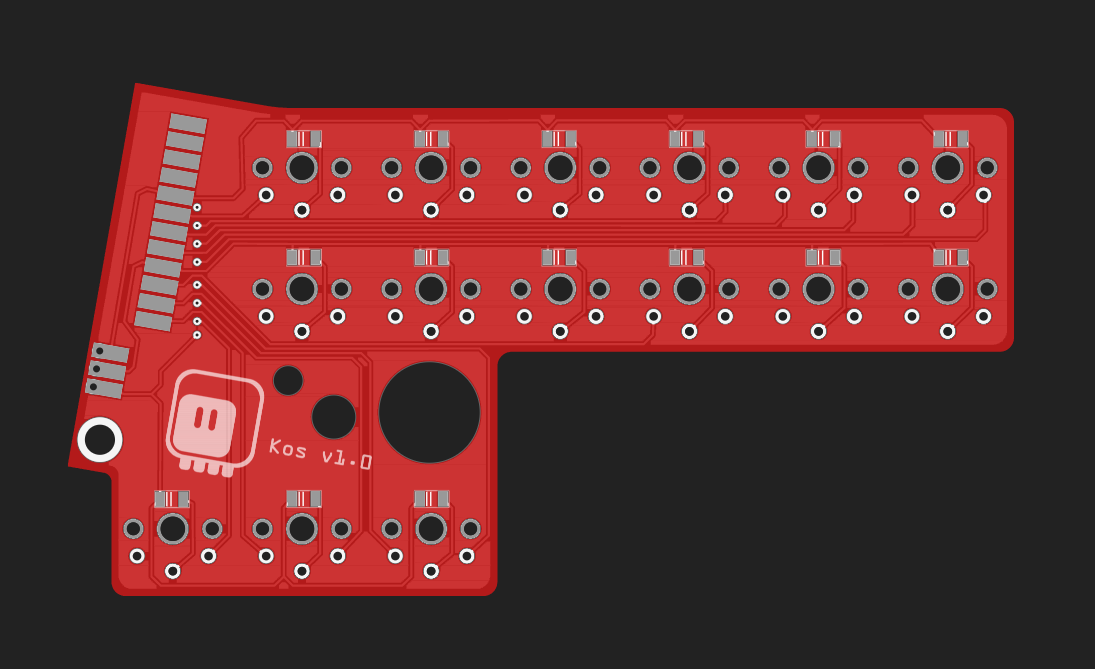

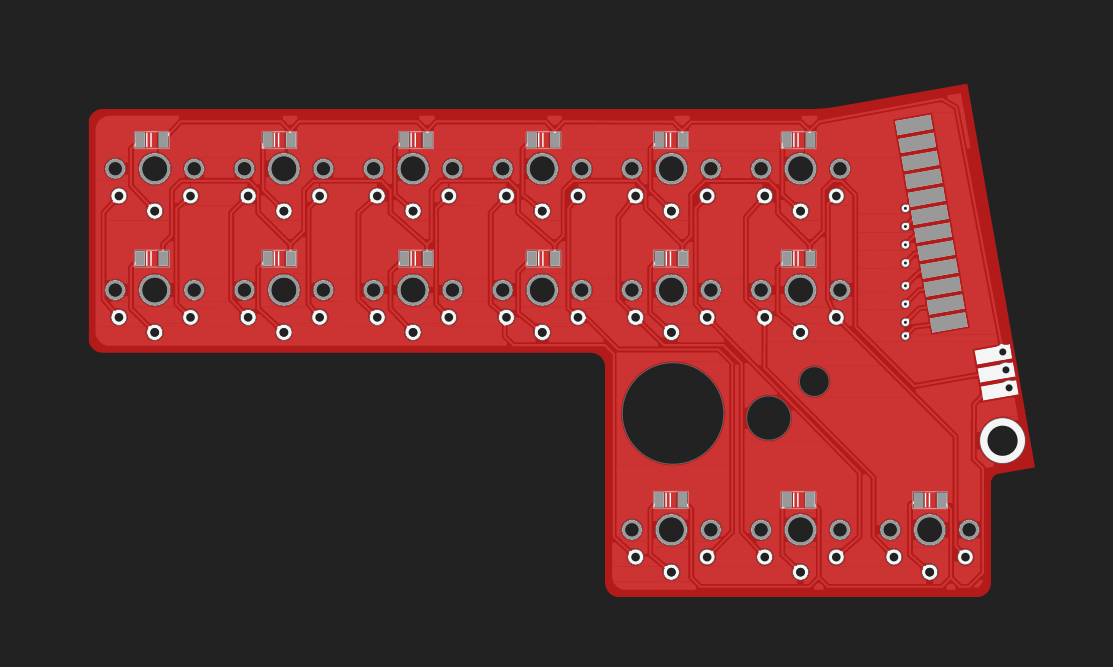

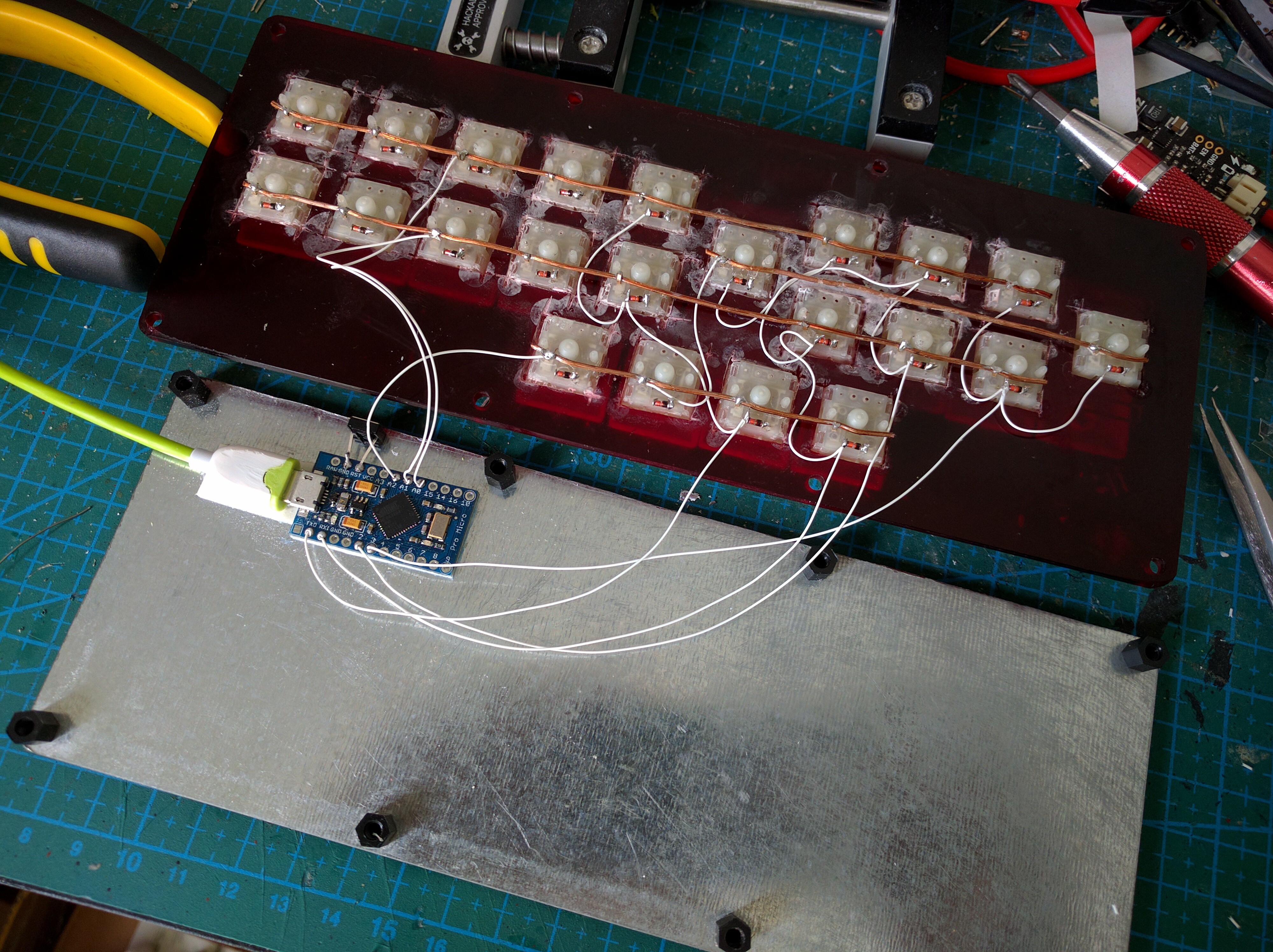

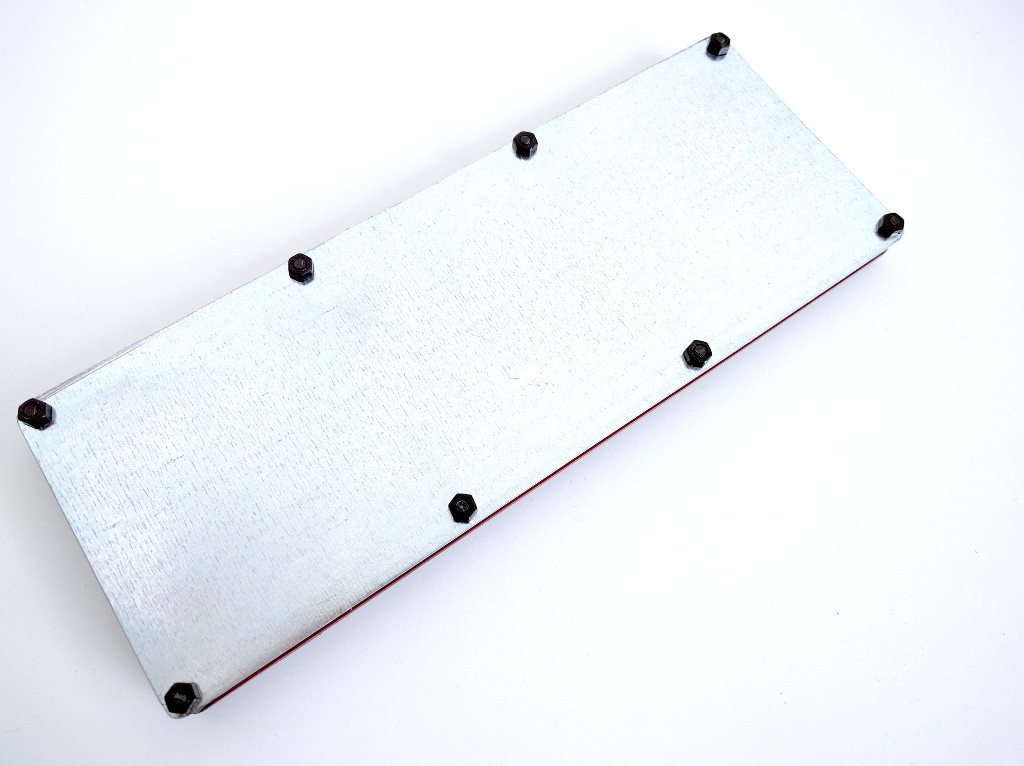

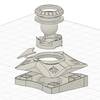

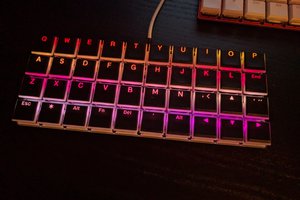

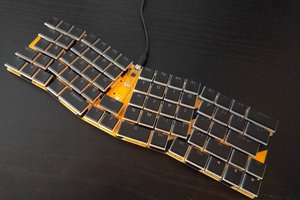

It is possible to do it on standard PC keyboard (as long as it allows you to press so many keys at once), there is even very nice software that lets you do that. However, it's easier and more convenient to use a dedicated keyboard. And that's what this project is all about.

deʃhipu

deʃhipu

Stoked to see then newest build. I am making an English steno version so the previous pcb design is the one I am using. Thank you so much for your open source efforts! truly makes things possible for people like me who dont know how to design in cad.