Shakelet - alerts for the hard of hearing

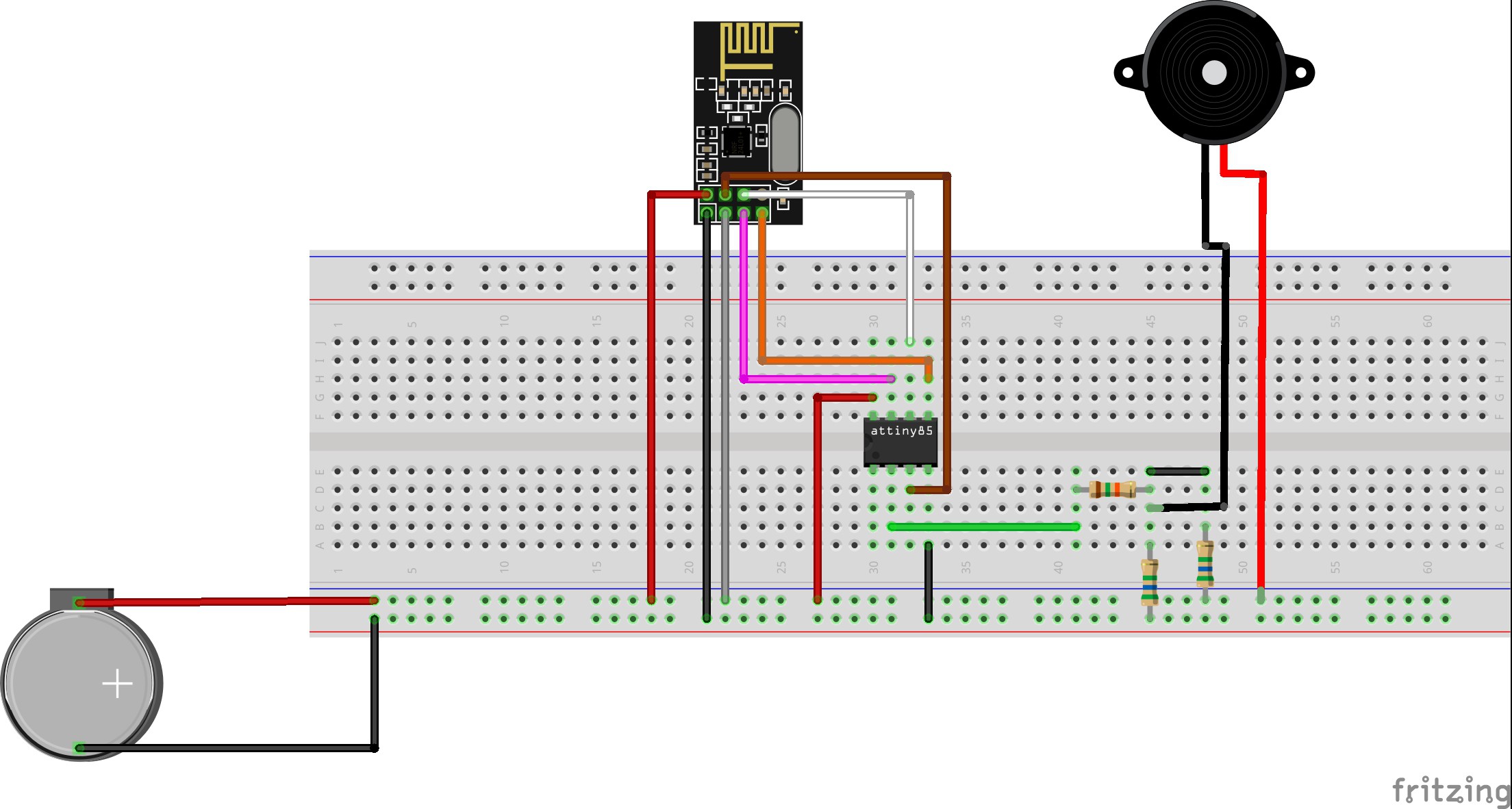

A wireless vibrating wristband to notify hard of hearing people of telephones, doorbells and other sound alerts.

A wireless vibrating wristband to notify hard of hearing people of telephones, doorbells and other sound alerts.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Alex's Library.lbrLibrary with custom Eagle CAD parts for NRF24L01 mini board, CR2032 battery clip and vibrating motor.lbr - 25.42 kB - 10/02/2016 at 14:24 |

|

|

|

sch - 601.19 kB - 10/02/2016 at 14:24 |

|

|

|

sch - 480.59 kB - 10/02/2016 at 14:24 |

|

|

|

brd - 265.53 kB - 10/02/2016 at 14:24 |

|

|

|

brd - 266.08 kB - 10/02/2016 at 14:24 |

|

If you want to see an awkward Englishman presenting a YouTube video, here's your chance! This is my attempt at explaining and demonstrating the project in video format. Enjoy!

I have spent a bit of time producing a write up of this project, not least for my own benefit so that when I look back in a few months time I can remember how everything works. The write up is availalble in the ZIP folder attached to this project (along with all of the other files) and also on GitHub here.

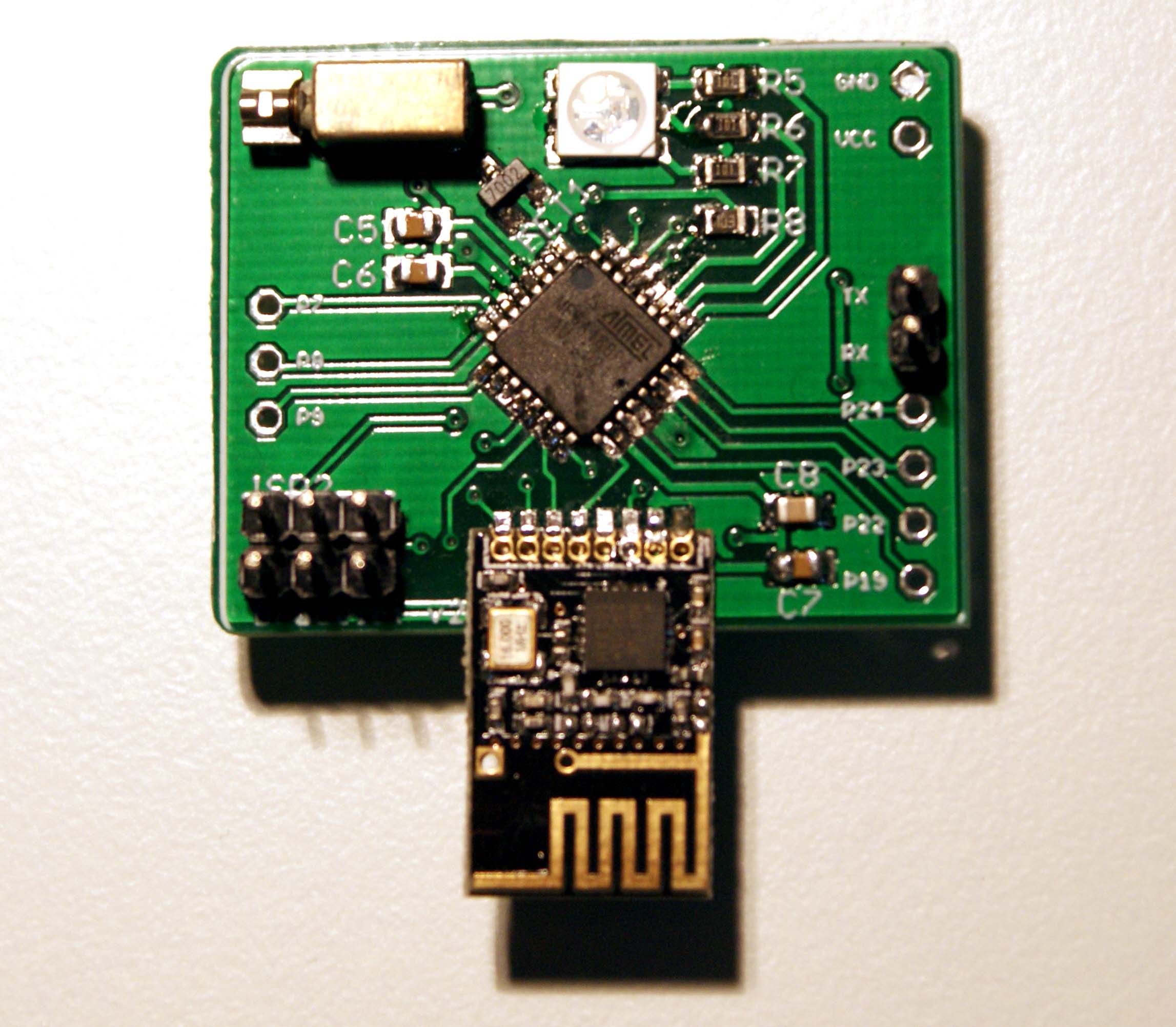

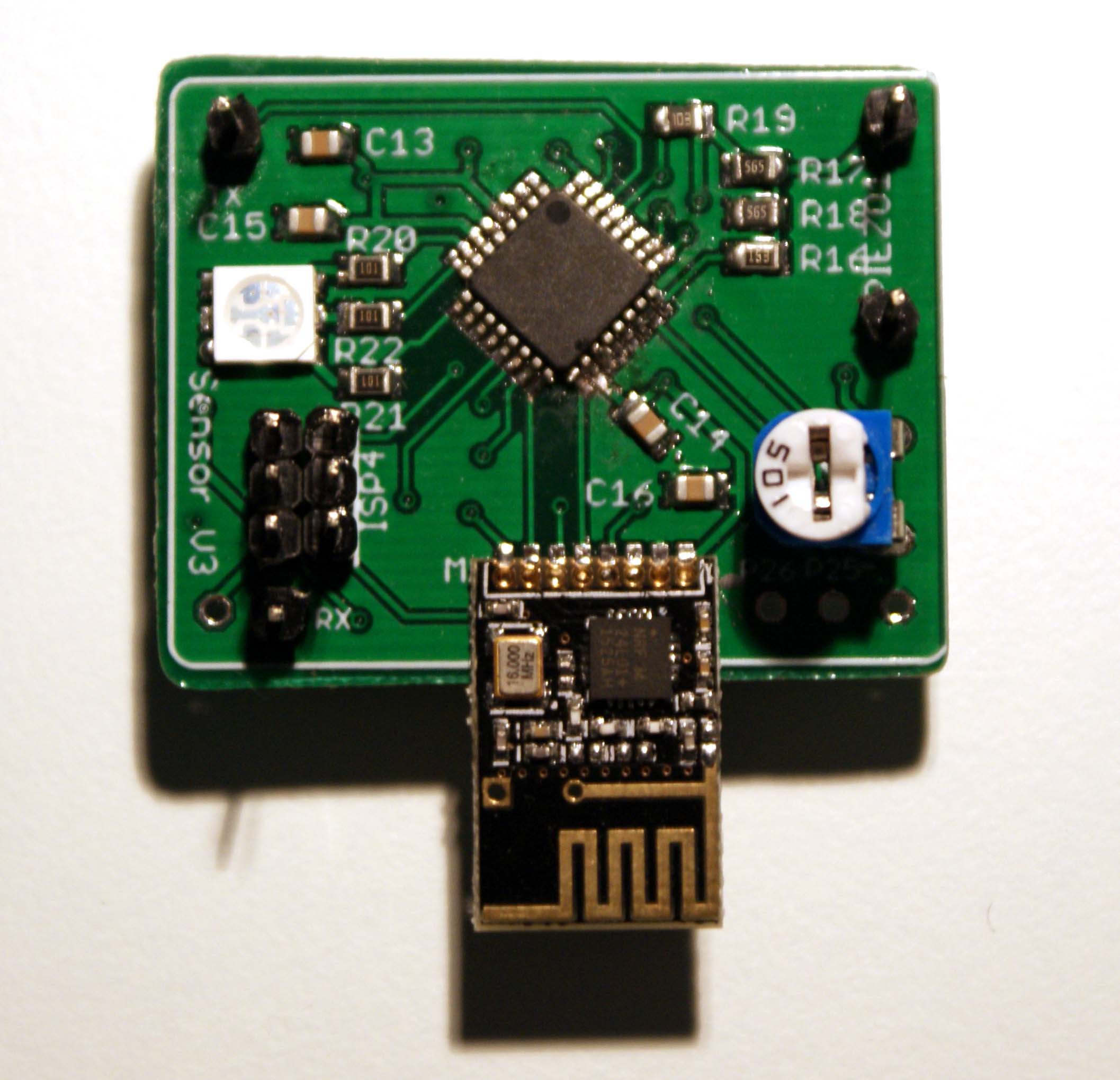

I have also taken a few photos of the soldered boards. Ideally I would like to make the bracelet board a little smaller. The limiting factor is the size of the coin battery holder on the rear. The size of each board is around 4cm squared (c. 1.5 inches).

Bracelet board

Sensor board

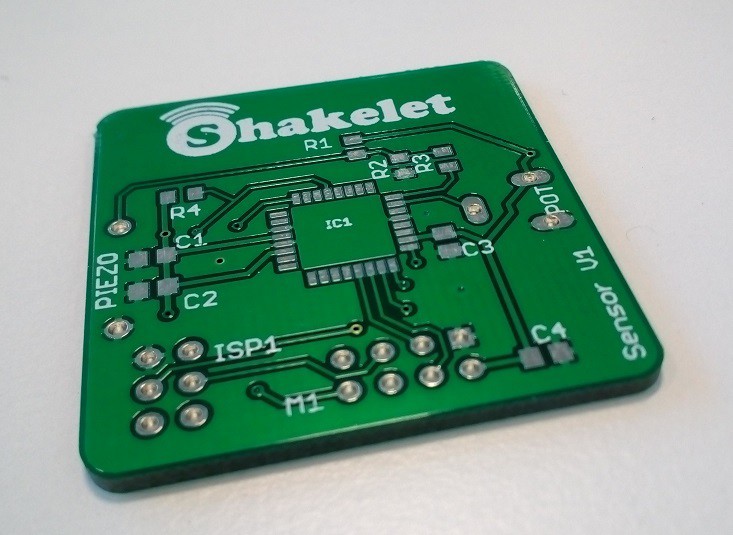

Since receiving my first PCBs there has been a flurry of activity. Naturally, the first thing I did was to solder one up:

Having never used SMD components before I was pretty pleased with the results. For the moment I am attaching the Piezo sensor with crocodile clips to the top two holes. The wires on them are quite delicate and I was concerned they would break. After an anxious few minutes uploading the code, I am delighted to report that it works!

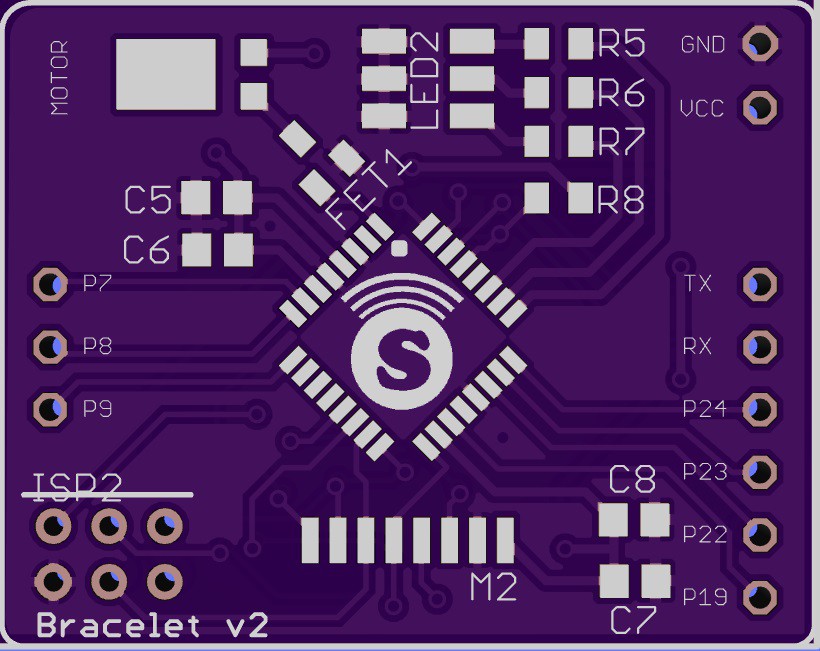

Light-headed with success I decided to complete the PCB design for the bracelet part. Having learnt a lot from my first experience, I was feeling slightly more ambitious and this is what I came up with:

I decided to break out the RX and TX pins to help with testing and also some other unused pins as I have a vague plan to add a button in future for muting the bracelet.

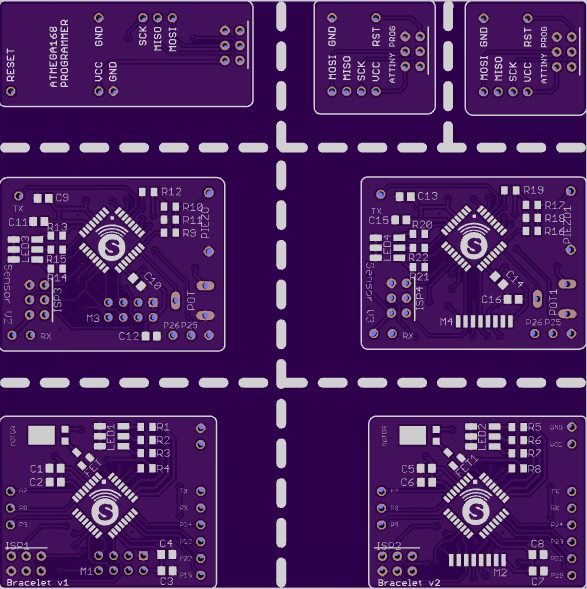

By this point I was overcome by confidence and decided to update the sensor board as well. I have swapped the large NRF24L01 for one of the mini-boards, added an LED (again, future plans for this) and broke out a couple of pins. Finally I decided to panelise my designs and also add in a couple of extra boards to make programming the DIP ATMEGAs and TINYs easier.

Now it's off to the folk at smart-prototyping to work their magic. I used Maker Studio for the first round of boards and was delighted with the results. However, smart-prototyping offer slightly cheaper express delivery and so I'm going to give them a shot.

So what's left to do? A few things spring immediately to mind:

Other suggestions are always welcome.

The sensor boards have arrived!

Being my first ever PCB I am unreasonably excited about this. A huge thanks to Gabe Buckmaster for his generous help and wisdom with the design - it looks much better than my first attempt and I have learnt a huge amount. Time to crack out the soldering iron.

Being my first ever PCB I am unreasonably excited about this. A huge thanks to Gabe Buckmaster for his generous help and wisdom with the design - it looks much better than my first attempt and I have learnt a huge amount. Time to crack out the soldering iron.

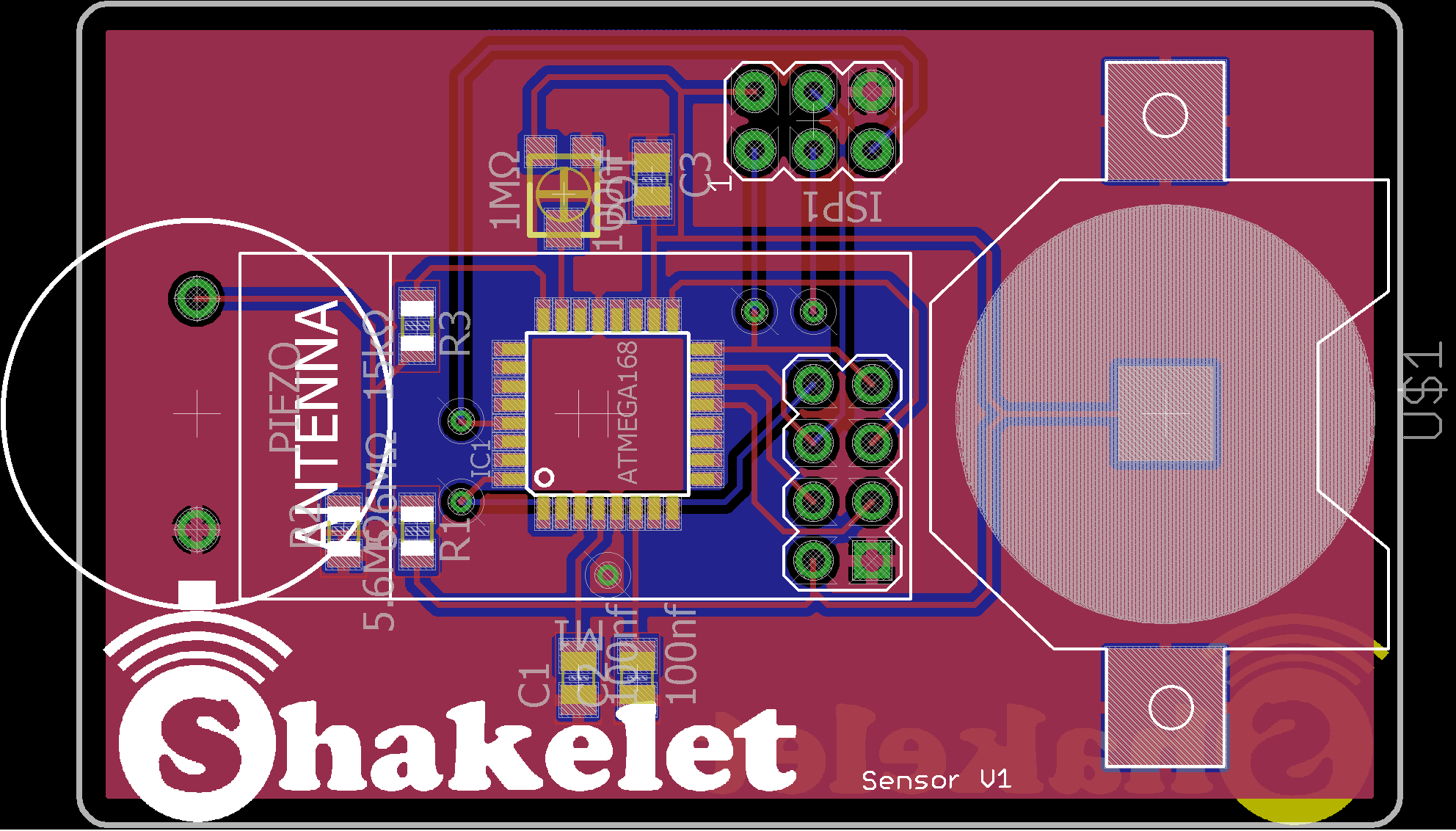

Although there has been radio silence for a few weeks, I have been working hard(ish) on the project. Today I designed my very first PCB, which is the sensor part of the project.

The full PCB file can be found in the documents section and I would love and feedback anybody would care to give! In particular, I'm slightly concerned that pin 6 isn't connected to ground, although Eagle did not throw up any errors.

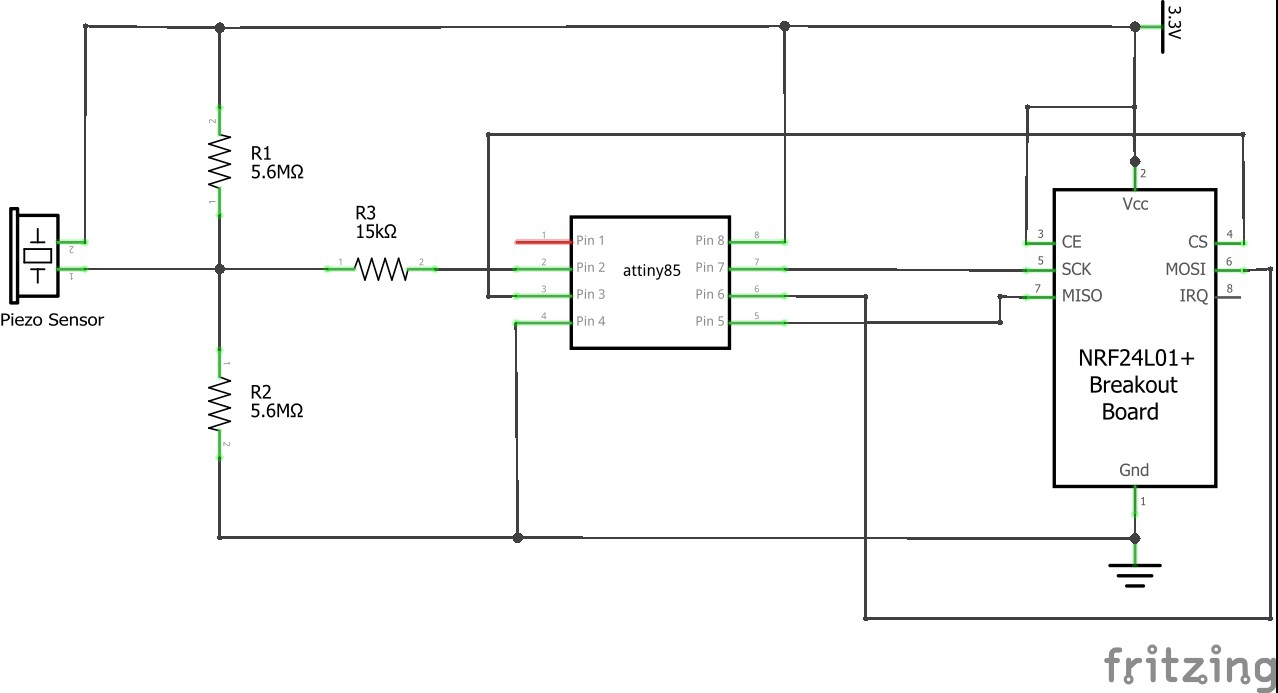

One addition to the circuit is a potentiometer in the top right. I am using this to provide a threshold to the AVR to use for sensitivity adjustments. The code is now much improved and I will upload in the next couple of weeks.

Next step, the bracelet PCB!

I have finally got round to putting my draft code online (GitHub). This is probably the weakest part of the project at the moment. In this post I will concentrate on the issues with the sensor code. Here is the full main.c:

// ------- Preamble -------- //

#include <avr/io.h> // Defines pins, ports, etc

#include <util/delay.h> // Functions to waste time

#include <stdlib.h>

#include "pinDefines.h"

#include "piezo.h"

#include "nrf24l01.h"

#include <avr/interrupt.h>

volatile uint16_t adcValue = 0;

volatile uint16_t middleValue = 511;

volatile uint16_t highValue = 520;

volatile uint16_t lowValue = 500;

volatile uint16_t noiseVolume = 0;

volatile uint8_t padding = 20;

volatile uint8_t ADCCount = 0;

void sendSignal(void){

initNRF24L01();

//Reset MOSI pin (PB0) to allow signal to be sent again

RF_DDR &= ~(1<<RF_MOSI);

RF_PORT|= (1<<RF_MOSI);

reset();

uint8_t W_buffer;

W_buffer=0x01;

int retries; //Send signal multiple times

for (retries=0;retries<5;retries++){

transmit_payload(W_buffer);

}

}

ISR(ADC_vect){

//Shift result left by 8 bits as using left align - allows full 10 bits to be captured

adcValue = ADCH;

// moving average -- tracks sensor's bias voltage

middleValue = adcValue + middleValue - ((middleValue - 8) >> 4);

// moving averages for positive and negative parts of signal

if (adcValue > (middleValue >> 4)) {

highValue = adcValue + highValue - ((highValue - 8) >> 4);

}

if (adcValue < (middleValue >> 4)) {

lowValue = adcValue + lowValue - ((lowValue - 8) >> 4);

}

// "padding" provides a minimum value for the noise volume

noiseVolume = highValue - lowValue + padding;

// Now check to see if ADC value above or below thresholds

// Comparison with >> 4 b/c EWMA is on different scale

if (adcValue < ((middleValue - noiseVolume) >> 4)) {

sendSignal();

}

else if (adcValue > ((middleValue + noiseVolume) >> 4)) {

sendSignal();

}

}

int main(void)

{

initSPI();

initADC();

initNRF24L01();

while(1)

{

if (adcValue>2000){

sendSignal();

}

}

return 0;

}ADC ISR is intended to use an exponentially weighted moving average for assessing when the ADC value is significantly high enough. The key parts were taken from the excellent book Make: AVR Programming by Elliott Williams (available on amazon.co.uk) which was my gateway drug into this hobby and which I really can't recommend highly enough.

The ADC is running in free-running mode. However, as I haven't yet looked at how to put the attiny into sleep mode whilst keeping the ADC running, I have fudged the main loop at the moment by just including a conditional statement that can never be met. This is something I hope to correct over the next week as it is clearly not an efficient way to program.

The other thing you will notice is that the data sent is just a random buffer. Eventually I will send a separate identification code for each sensor so that the bracelet will be able to determine which one has been triggered. However, for reasons I can't quite work out the data received by the bracelet is not the same as that being sent so this is again an issue that needs looking at.

The bracelet is another hornet's nest of patchy coding and I will turn my attention to this once I am happy with the sensor side. The list of things to do seems to be getting longer!

9 June

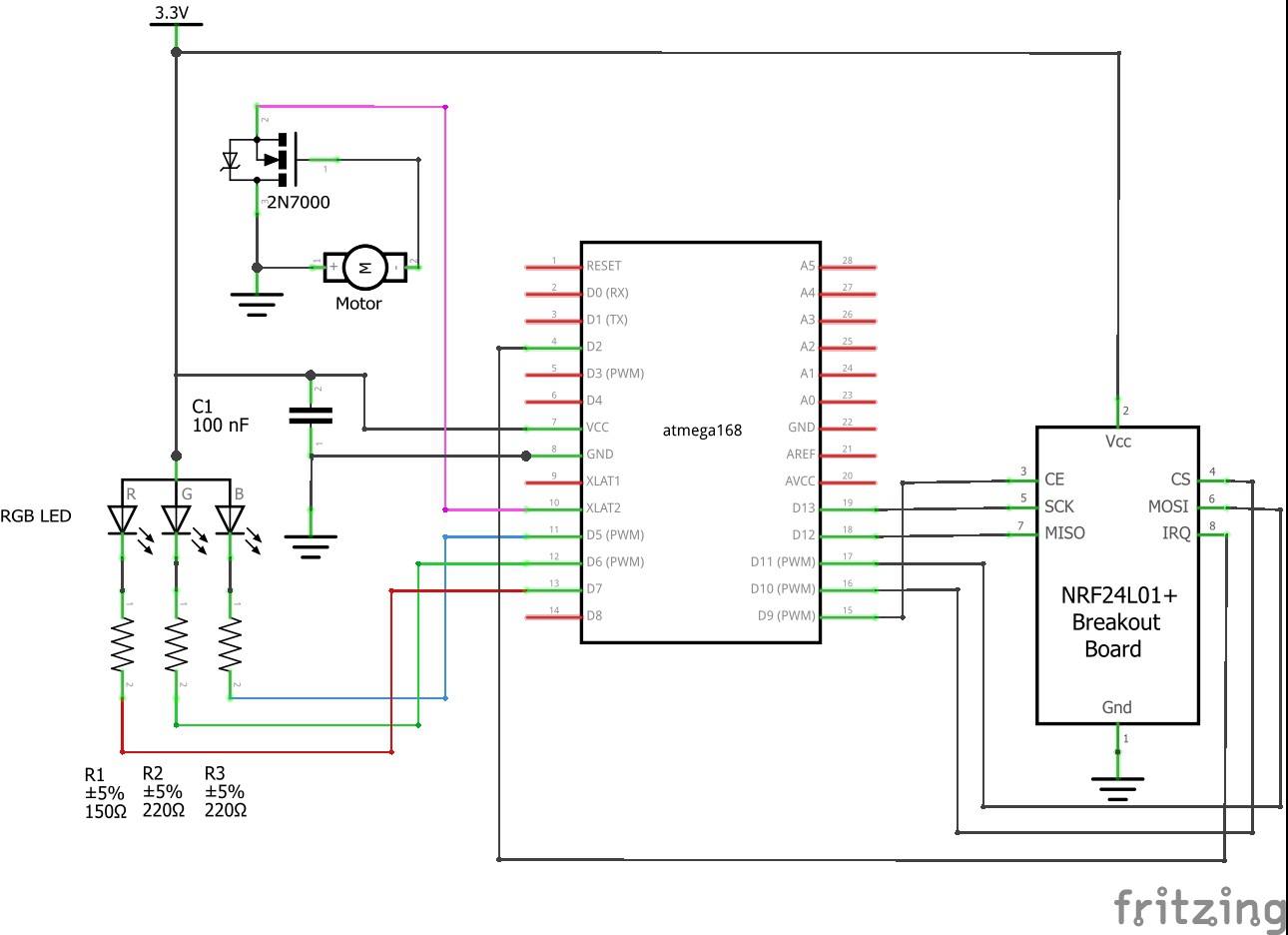

I think I'm getting the hang of this circuit diagram business now. Here are the ones for the bracelet side of the system. Next stop - code (ohh err...)!

In other news, it turns out that the name "Vibracelet" has been used before commercially. A new name is therefore in order. I have gone for "Shakelet" for now due to coming up with nothing better. Maybe inspiration will strike. Please do let me know if you have any ideas!!

8 June

I have always wondered what I would say if I won an Oscar and for me getting through to the Hackaday competition final is about as close as I will ever come! Just like a self-absorbed Hollywood actor, I would like to put down a few words to mark the occasion. I am shocked and humbled to have made it through. There are so many fantastic projects out there that it comes as a huge surprise that my slightly amateurish attempt has made it. Thank you to everybody who has taken an interest in what I am trying to achieve!

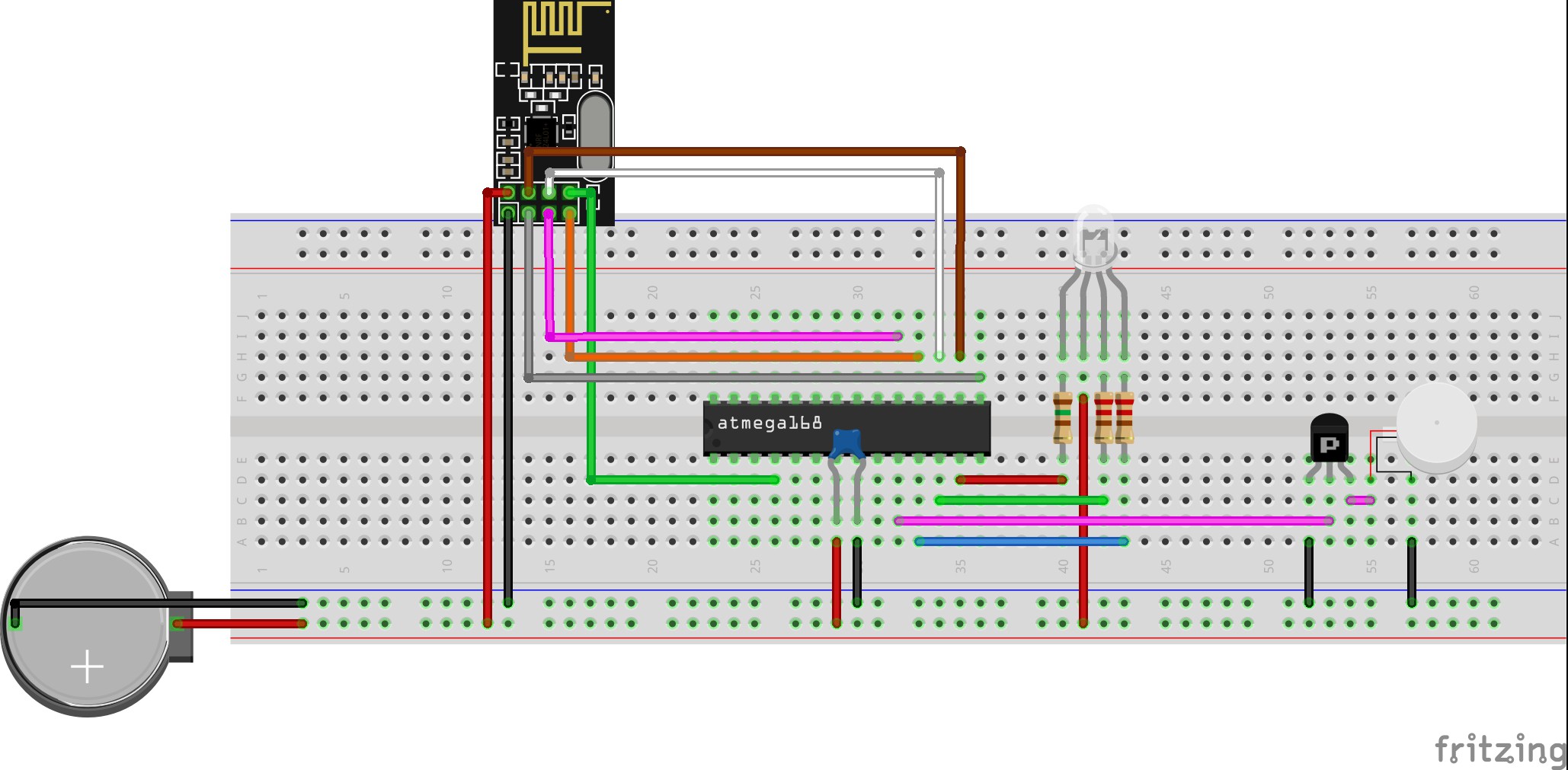

Anyway, I promised that my next post would include a circuit diagram and I am a man of my word. I have started with the sensor diagram and will produce the bracelet diagram over the weekend.

The next step will be cleaning up my code and trying to get around the problem with the CE pin on the RF transceiver which has been bugging me for some time. Once that has been done it will be time to start designing cases for everything, which is completely uncharted territory for me. I may also need to give some thought to whether the NRF24 is the right transceiver for the finished product once range and size considerations have been taken into account. Time to get reading up on designing PCBs!

but a switch ain't one!

Before I get ahead of myself and work on designing a PCB and sensor cases / bracelets, I thought I should have a quick recap of the challenges that lay ahead. This is therefore a reasonably comprehensive list of difficulties that I have come across but (so far) ignored and how I think they might be overcome. Any advice would be most welcome.

The next post will definitely include my circuit diagram!

After a frustrating few days I have finally got the Vibracelet working. There were two problems to note:

The piezo sensor was nowhere near sensitive enough to pick up normal level sounds from a mobile phone or doorbell. However, I finally managed to solve this by using an exponentially weighted moving average in the ADC code of the attiny. The sensitivity still needs some adjustment and a method of adjusting/calibrating on the fly but that can wait for another day.

The difficulty with the wiring resulted from a lack of pins on the attiny. I solved this by tying the CE pin of the NRF24L01 to VCC (3.3v). This isn't ideal as it will increase battery drain but I will look at ways of multiplexing the CE pin later. If I can find no other solutions I may need to change my microcontroller. Any suggestions are gladly welcome.

Finally, I took a short video to show it working in all its glory. There is still a lot to do but I am pleased with progress to date.

Great Success!! Anyway, I had best tidy up before my wife realises I have mutilated her doorbell...

Download gerber files from the zip file included in the project documents and send to your local fab lab to print.

Order components in component list.

Solder components (I used a cheap hot air station)

Create an account to leave a comment. Already have an account? Log In.

Thanks Aresnijs! The code is in a slightly sorry state at the moment but it's coming soon - I promise!

Become a member to follow this project and never miss any updates

Bud Bennett

Bud Bennett

Enzo Lombardi

Enzo Lombardi

Wesley Ellis

Wesley Ellis

Wonderful project! Congrats on being funded! I can't wait to see some code =)