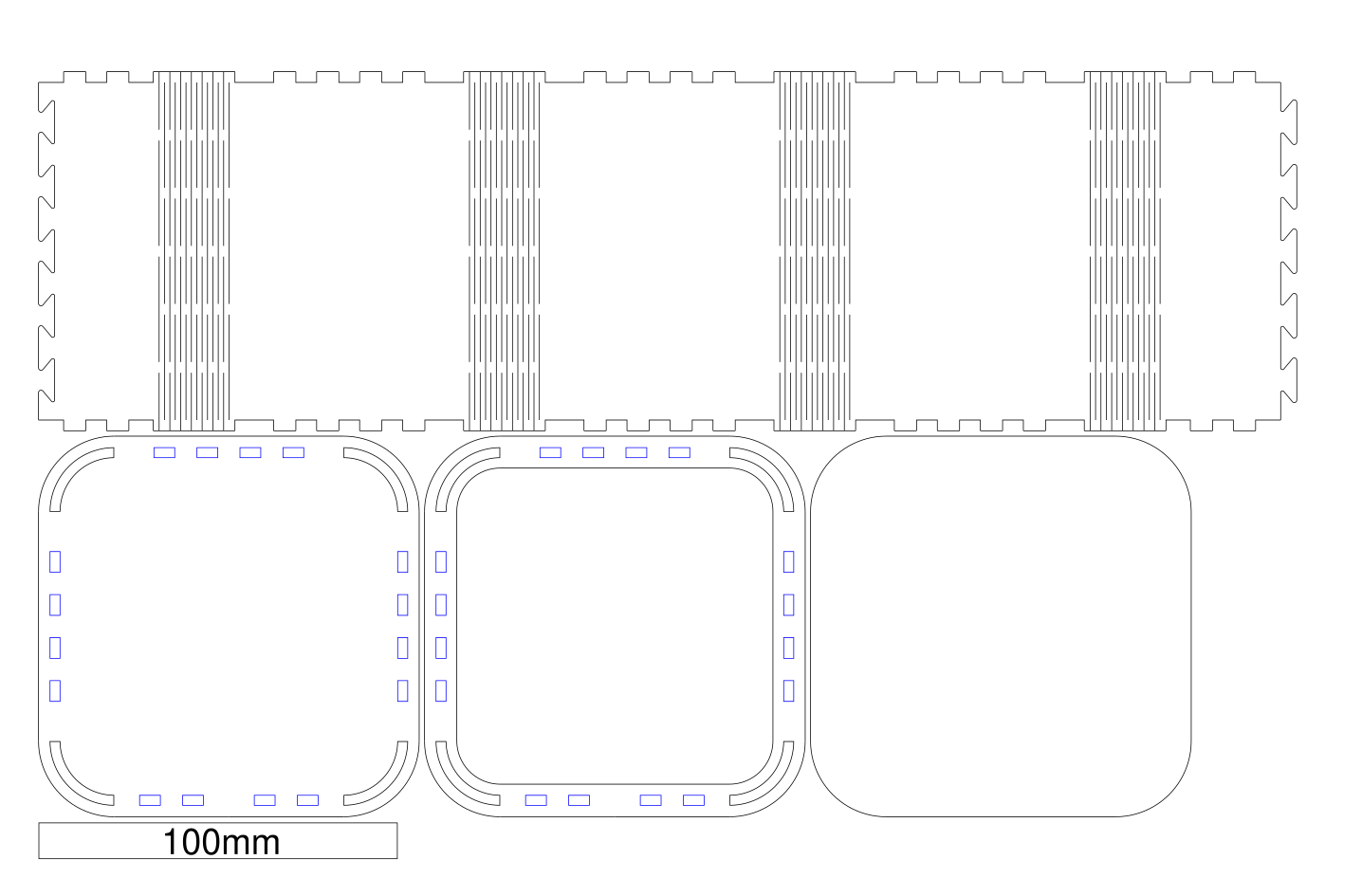

- Boxes․py is an online box generator

- Boxes․py is an Inkscape plug-in

- Boxes․py is library to write your own

- Boxes․py is free software licensed under GPL v3+

- Boxes․py is written in Python 3

Boxes․py comes with a growing set of ready-to-use, fully parametrized generators. See https://florianfesti.github.io/boxes/html/generators.html for the full list.

Features

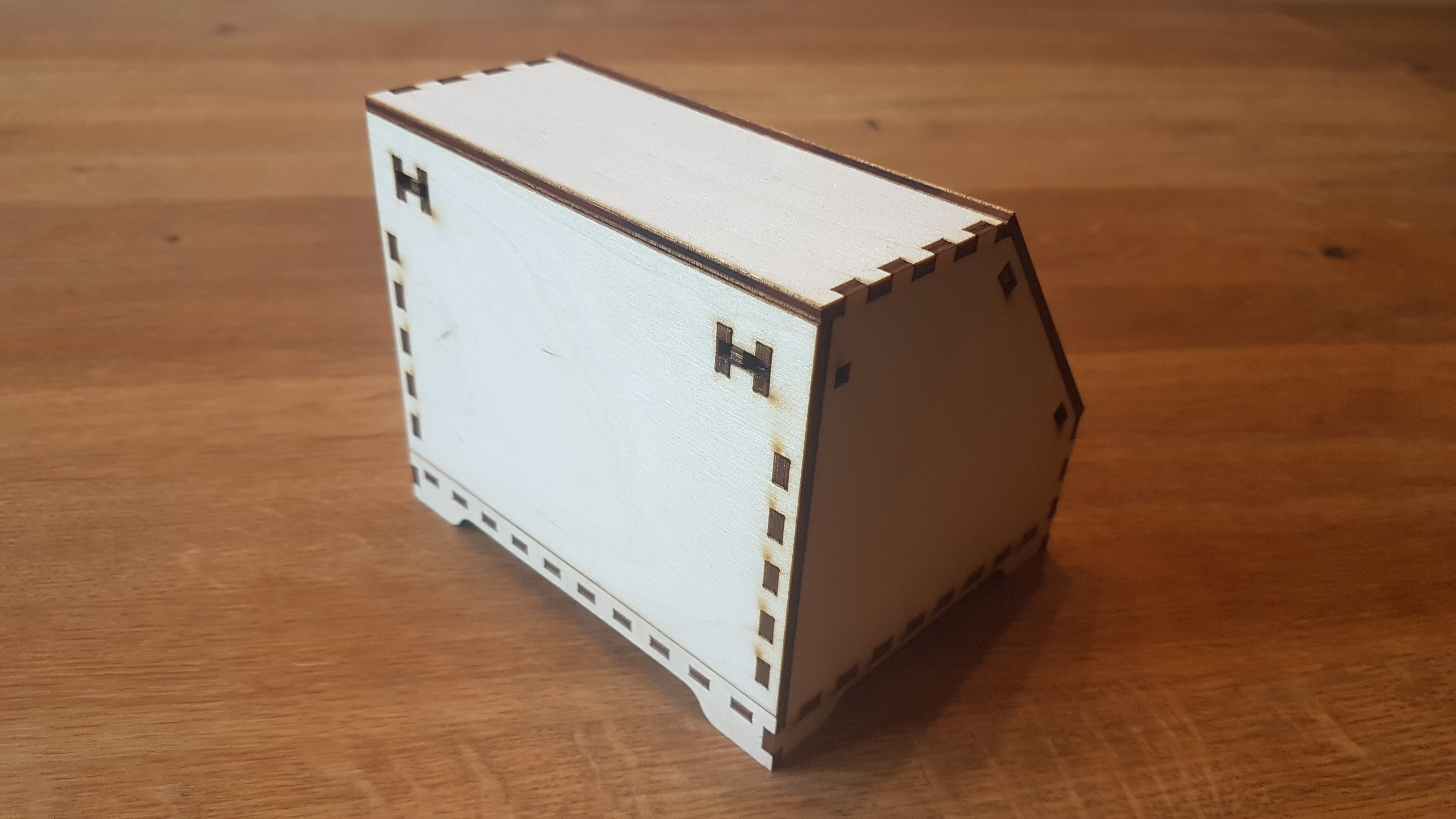

Of course the library and the generators allow selecting the "thickness"

of the material used and automatically adjusts lengths and width of

joining fingers and other elements.

The "burn" parameter compensates for the material removed by the laser. This

allows fine tuning the gaps between joins up to the point where plywood

can be press fitted even without any glue.

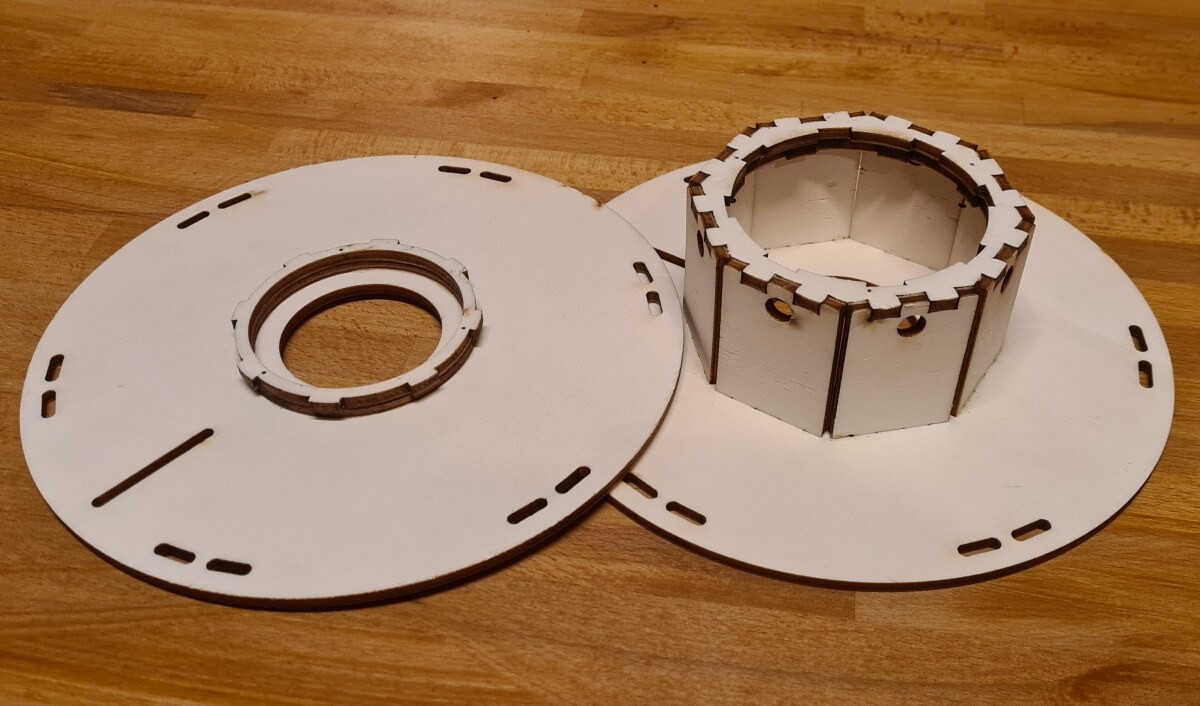

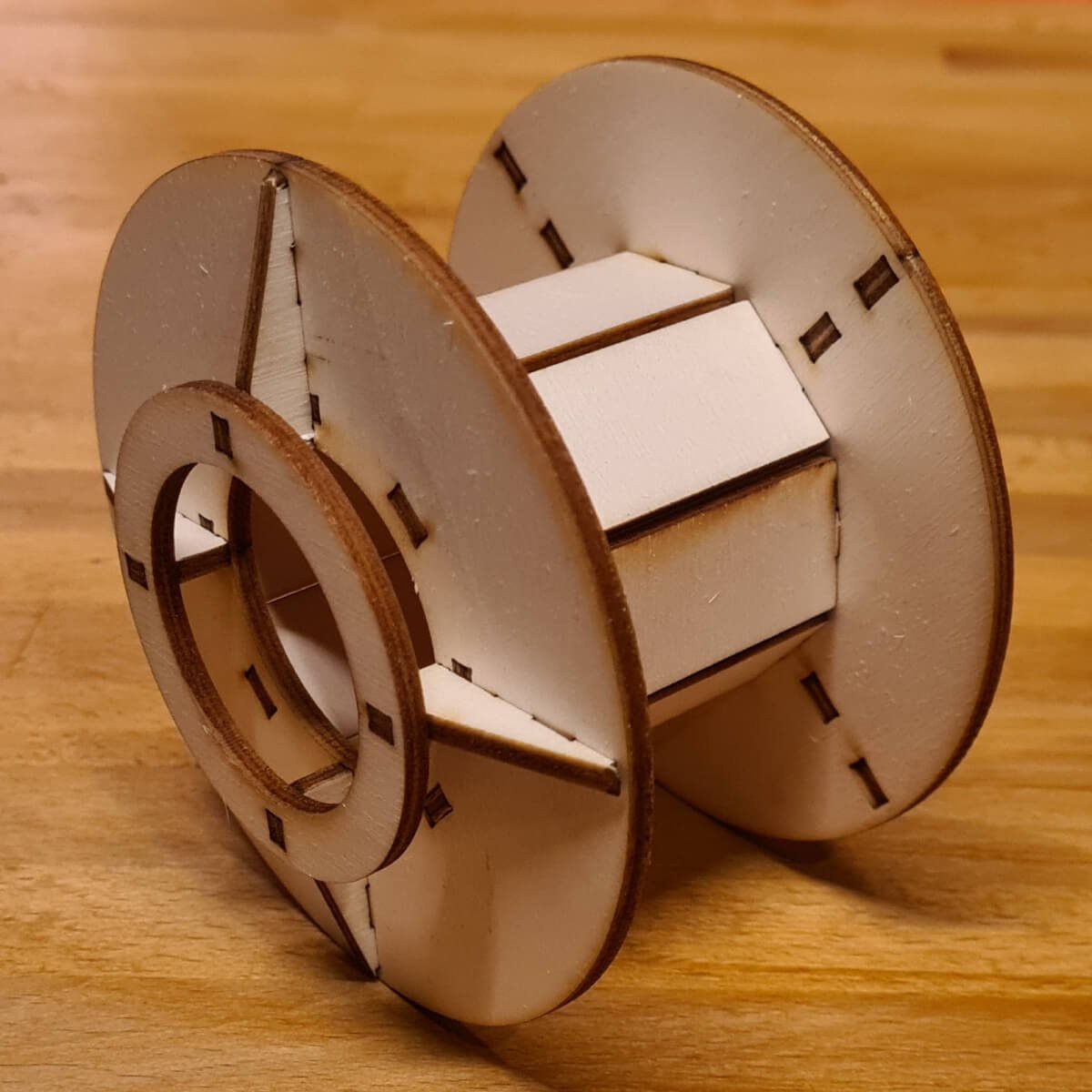

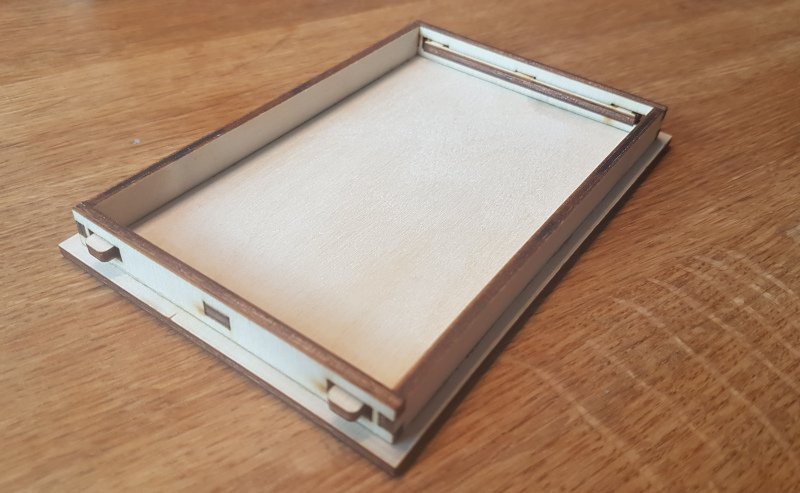

Finger Joints are the work horse of the library. They allow edges

and T connections. Their size is scaled up with the material

"thickness" to maintain the same appearance. The library also allows

putting holes and slots for screws (bed bolts) into finger joints,

although this is currently not supported for the available generators.

Dovetail joints can be used to join pieces in the same plane.

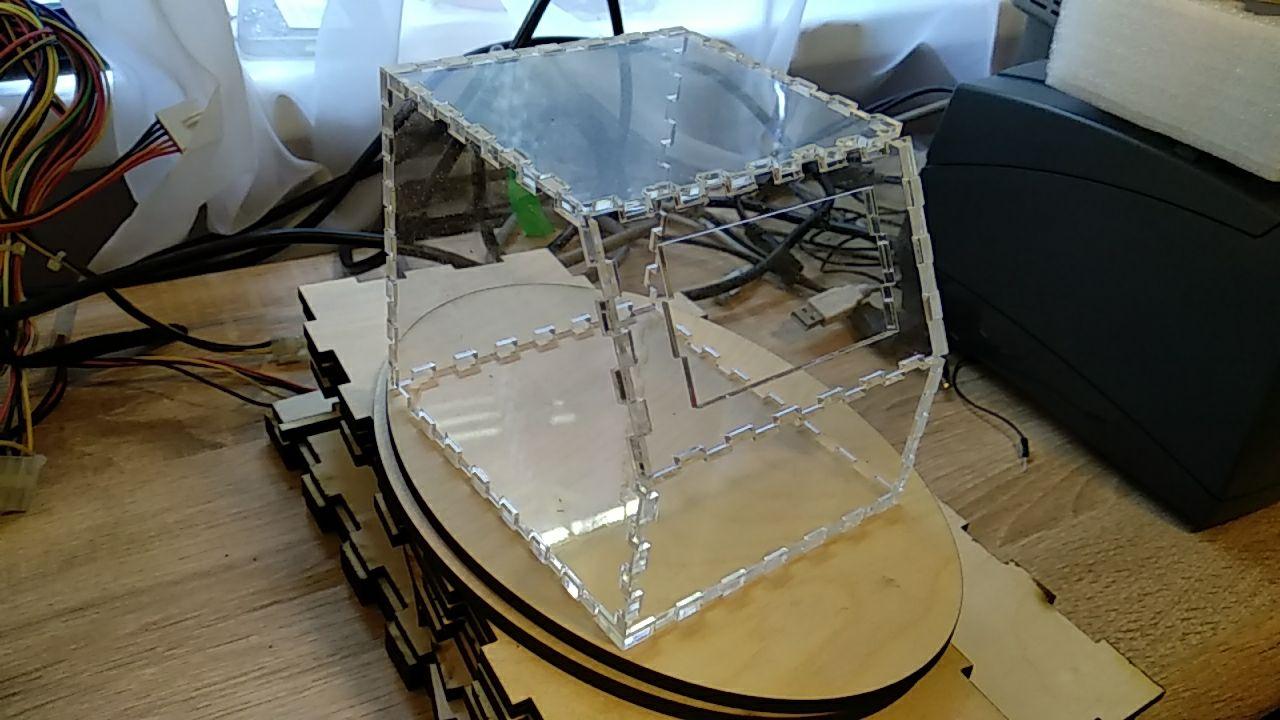

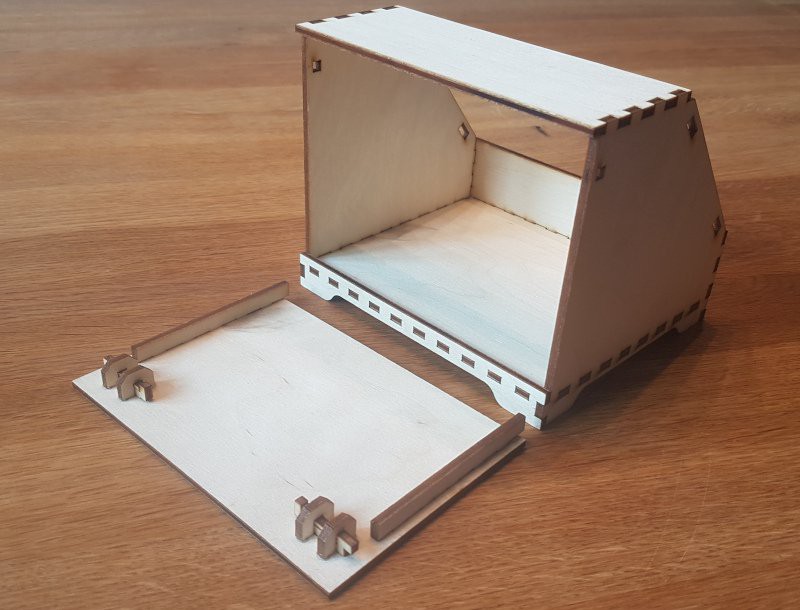

Flex allows bending and stretching the material in one direction. This

is used for rounded edges and living hinges.

Documentation

Florian Festi

Florian Festi

kristina panos

kristina panos

blorgggg

blorgggg

phryk

phryk

Xasin

Xasin

Hi, thank you for the great job you did!

The generator does the job.

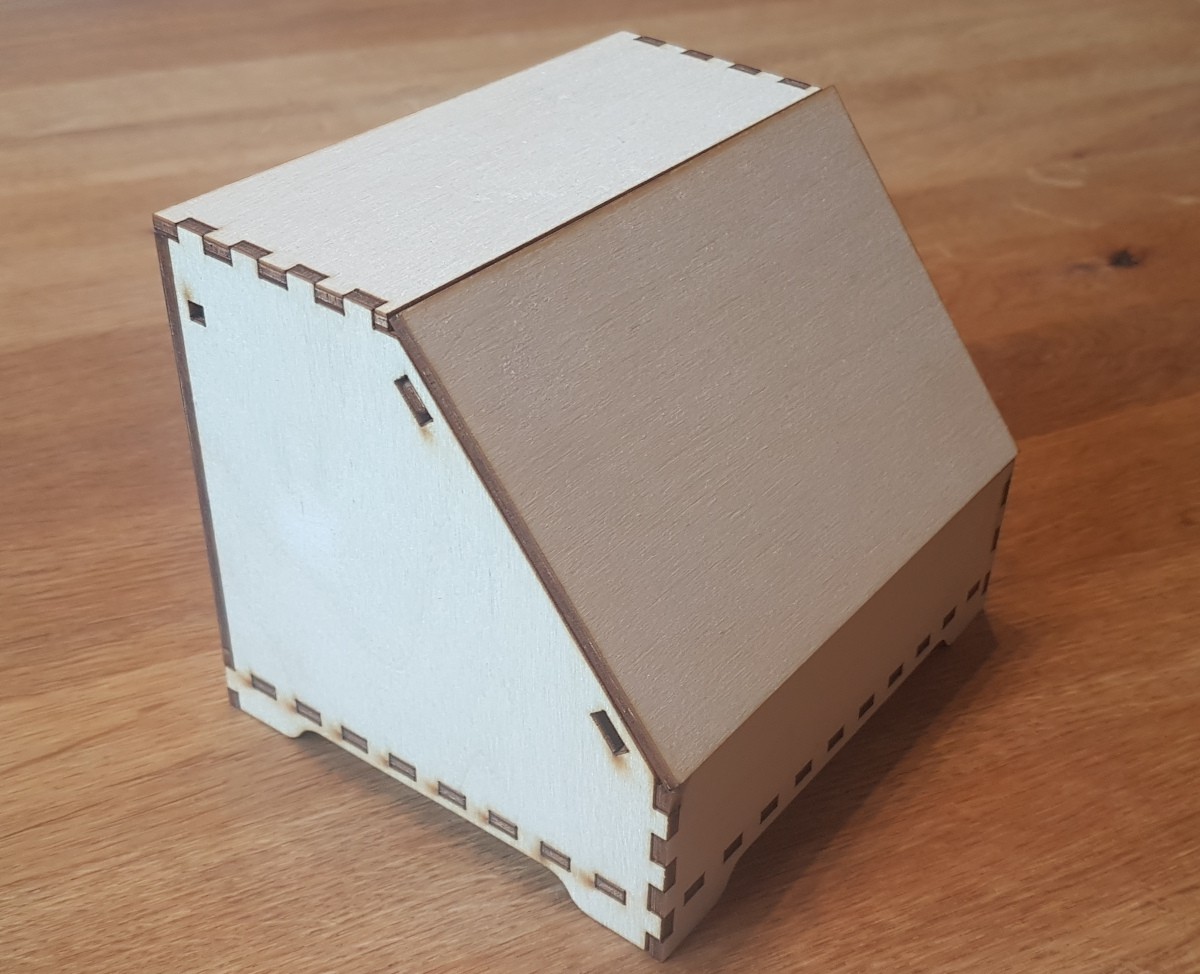

Today I used it to create a kind of box rig to place the external laptop monitor on it.

It would be awesome to have a live preview mode to understand how the different options affect the result. It takes some time to generate a new preview, download, and check it (or open in a new tab).

Thanks again!