**Latest build video**

Documentation: https://hackaday.io/project/183821-build-a-conveyor-belt-3d-printer-openbelt

**NOTE: If you are hoping to get a quick overview of this project, please watch the videos list under Figure 1, Figure 2, and Figure 3.

[Figure 1: Demo of Automatic Infinite 3D Printer Mk. IV]

[Figure 2: Demo of Automatic Infinite 3D Printer Mk III]

[Figure 3: Purpose of Project with Automatic Infinite 3D Printer Mk III]

The Problem

Even though 3D printing is a newly emerging technology, it has rapidly became mainstream in education, manufacturing and many other industries. 3D printers allow anyone to easily produce complex parts.

However, these machines have one critical flaw. After a 3D printer has finished printing a part, a person must physically go to the printer and remove the part from the print bed. A 3D printer cannot start its next print job, until the previous part is removed. This constraint cripples the productivity of 3D printers. If 3D printers could automatically eject their print jobs, then they could print out a constant stream of parts. The efficiency of the machine would drastically increase.

Many businesses already use 3D printers to manufacture products. Currently, their manufacturing capabilities are constrained by the need to manually remove/start print jobs. If this task was automated, it would be easier for more companies to complete volume manufacturing with 3D printers.

Personally, I work in a 3D printing lab that prints hundreds of parts for my fellow university students. From my position, it is obvious that this constraint significantly limits the number of print jobs our lab can complete per day.

[Figure 4: Problem Pitch Video]

The Solution

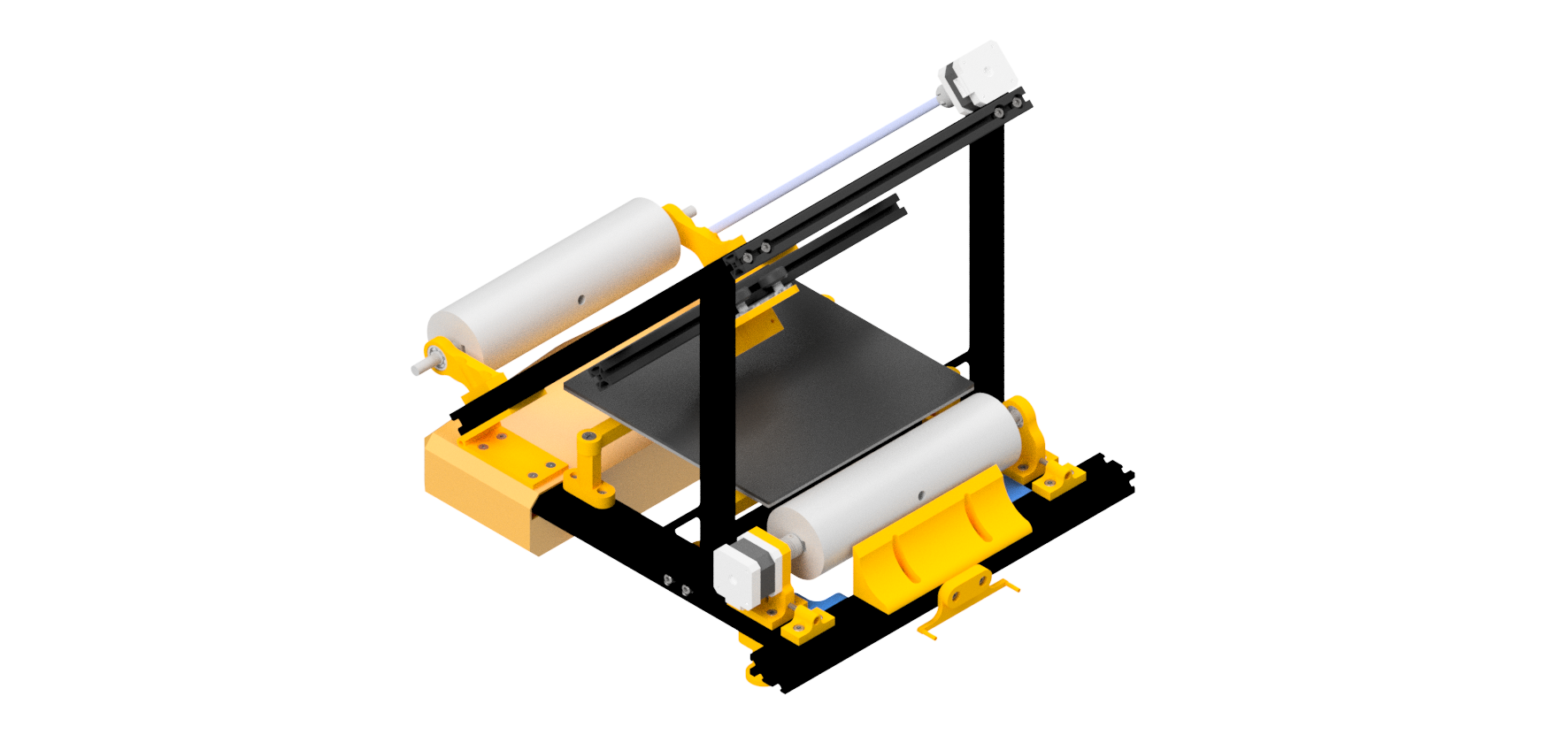

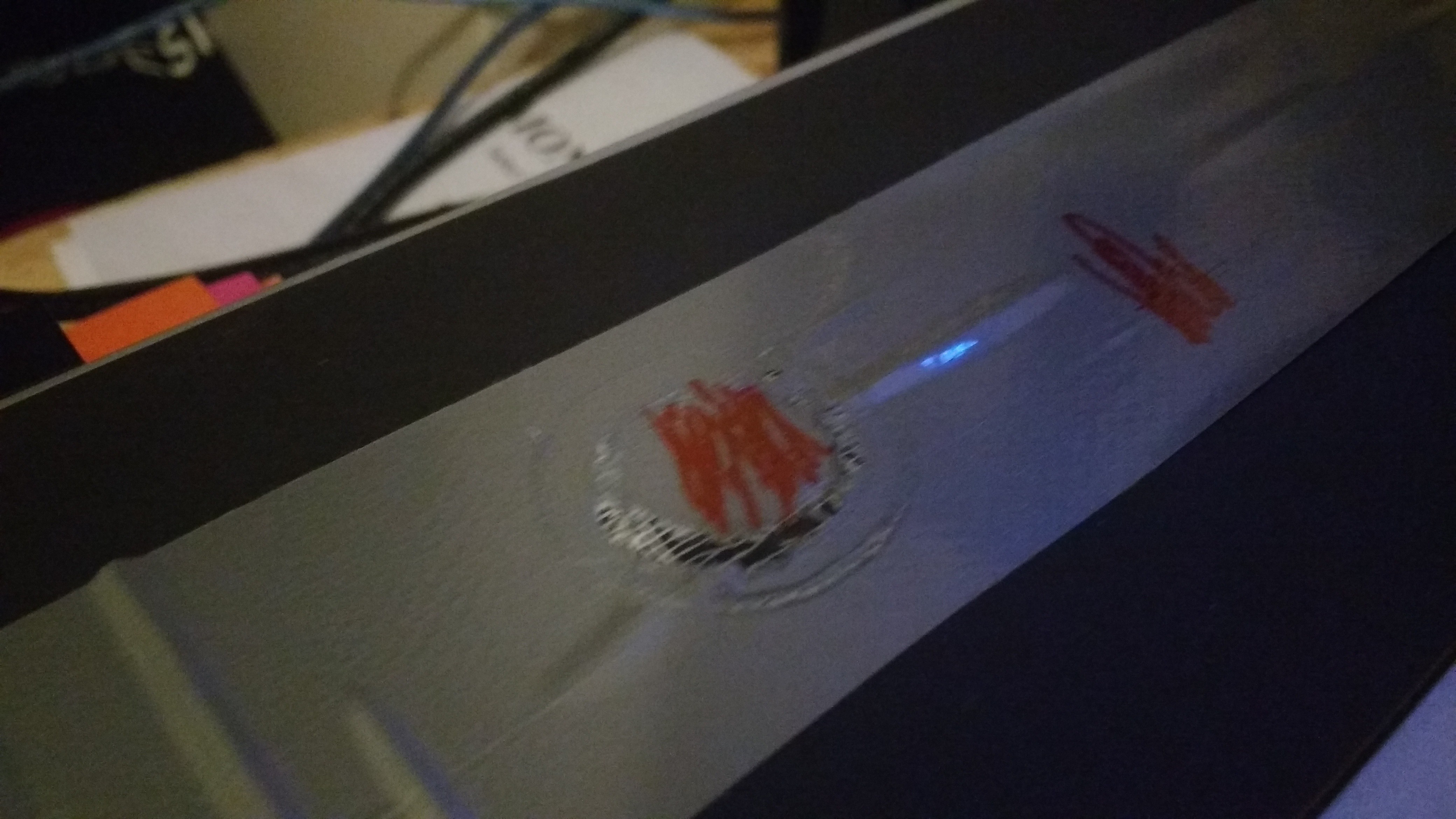

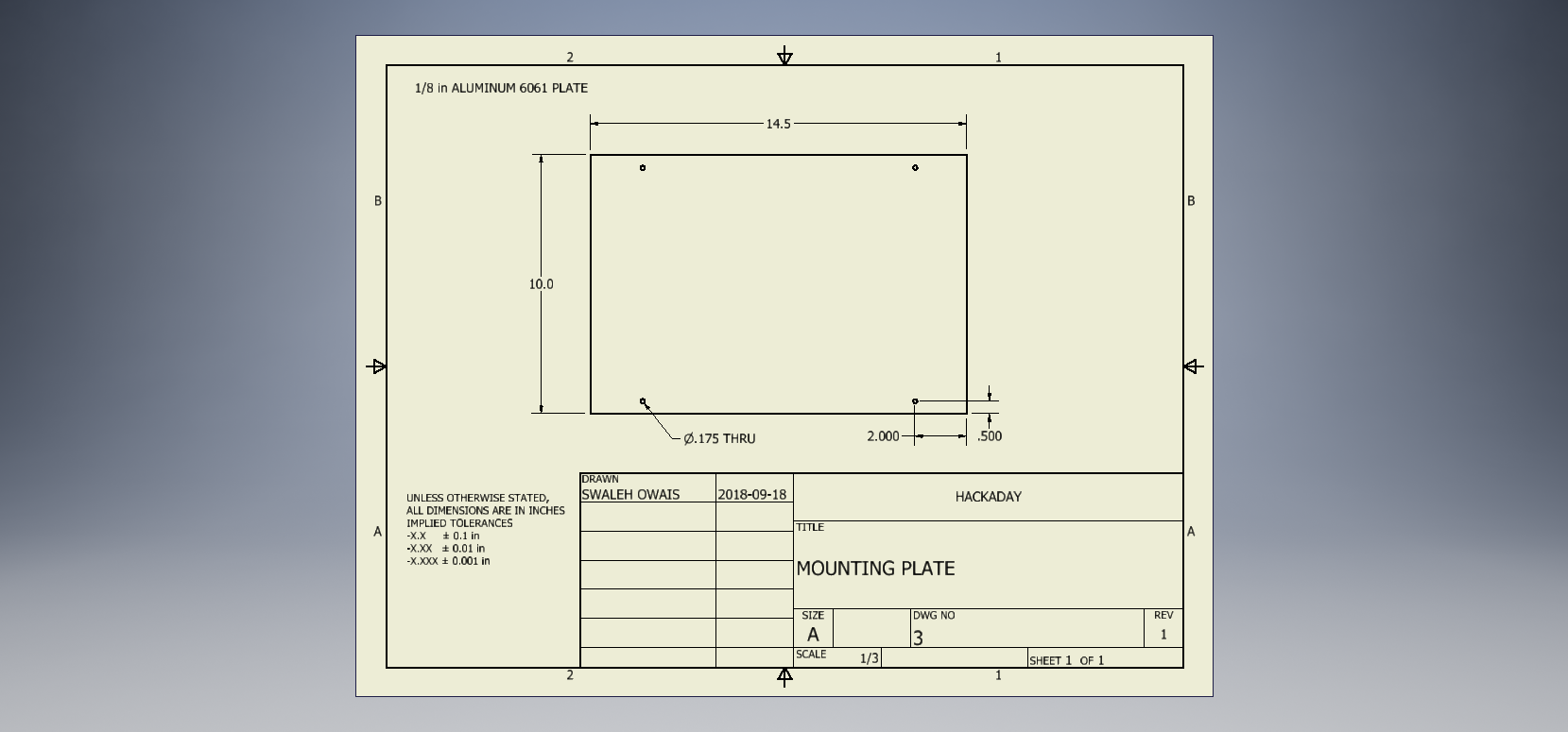

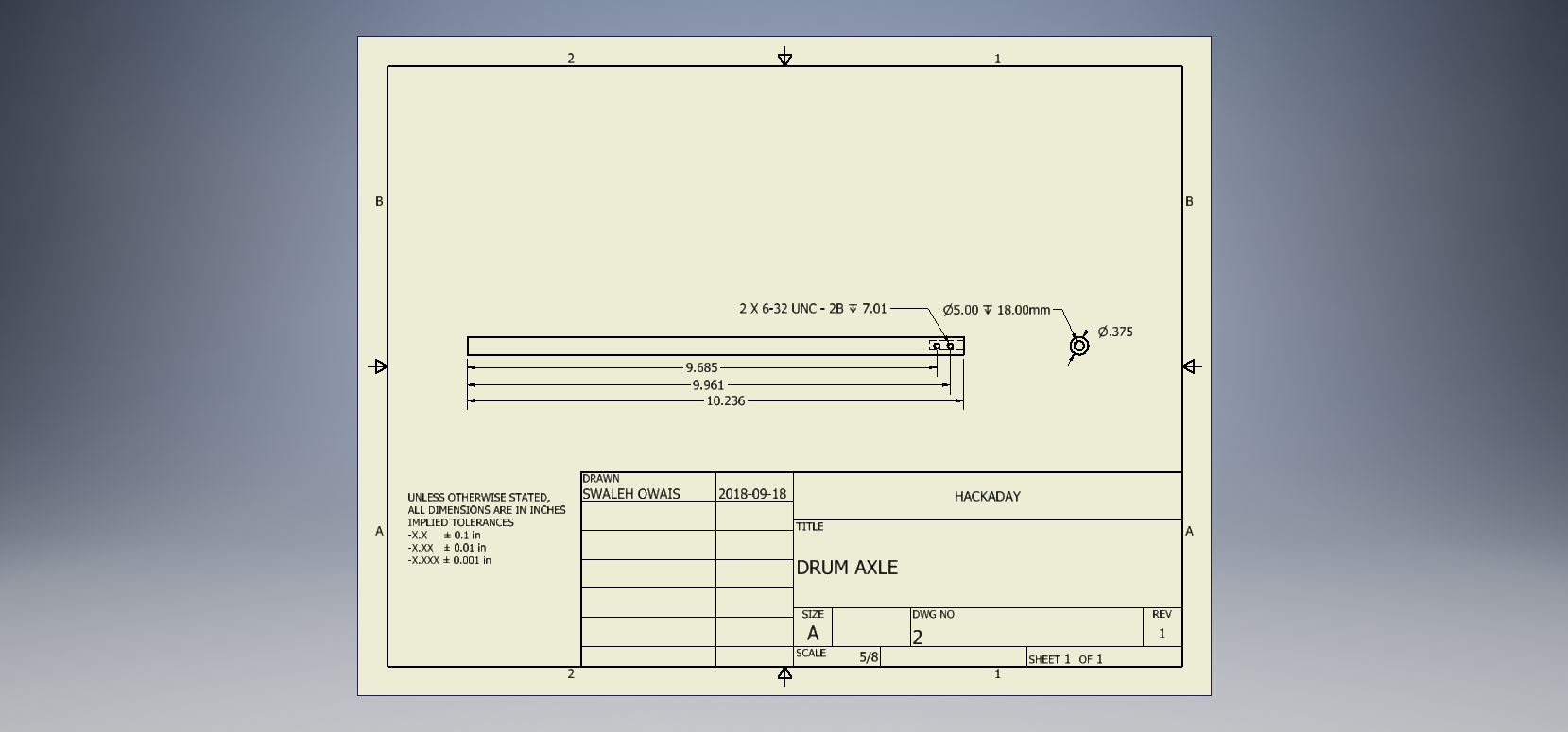

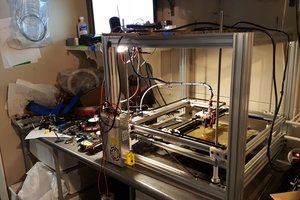

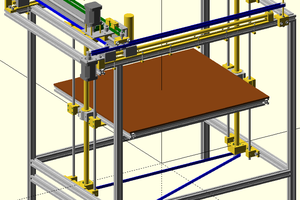

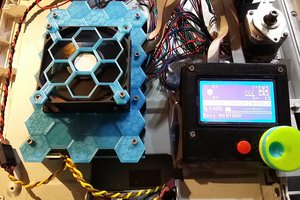

The purpose of this project is to build a fully automated 3D Printer: The Automatic Infinite 3D Printer. The Automatic Infinite 3D Printer has a conveyor belt module that autonomously ejects finished print jobs from the printer. With this novel feature, the 3D Printer is able to print a constant stream of print jobs without human intervention. This is a breakthrough for the 3D printing industry. Automatic part ejection will improve the functionality and capability of 3D printers. Within the next decade, autonomous part ejectors will be as ubiquitous to 3D printers as paper ejectors are to paper printers.

Furthermore, the custom conveyor belt allows users to print infinitely in the y axis. This allows users to make a much wider variety of parts. The Automatic Infinite 3D Printer monitors print jobs with a computer vision program and a series of webcams. In the unlikely event that a print jobs fails, the machine will autonomously eject the failed print and restart the job.

I have built four successful prototypes of the Automatic Infinite 3D Printer (Mk. I, Mk. II, Mk. III, Mk. IV). The features of Mk. IV are detailed below. Mk I, Mk II, and Mk III are discussed in the Previous Prototypes section.

Build Hope

Over the past few years, people around the world have been empowered by rapid prototyping. Affordable CNC machines, allow anyone to easily put together a prototype. All of the cool hardware recently developed by makers, students, and startups is only possible because of easy access to these powerful machines. However, mass production still remain out of the reach of most people. Currently, makers can only mass produce by placing an order in an overseas factory. This process is expensive, time consuming and prone to error.

Building an affordable automatic 3D printer will open up whole new doors to hackers. An automatic 3D printer will allow any to wield the power of a factory. Once automatic 3D printers become mainstream, conveyor belt lines will not be exclusive to large companies. The technology will truly be democratized. Providing this tool to DIY enthusiasts will once again allow them to make amazing things.

This...

Read more » Swaleh Owais

Swaleh Owais

[Figure 2: Prototype Should be Able to Print Structural Pieces as Seen Above]

[Figure 2: Prototype Should be Able to Print Structural Pieces as Seen Above]

adamfilip

adamfilip

saarbastler

saarbastler

RenierM

RenierM

https://github.com/Autodrop3d/BeltEngine