OVERVIEW

Smartphones are becoming a staple piece of technology for many citizens in North America and around the World. Smartphones and touchscreen devices enable users to navigate around their city better, to communicate with others more freely, and to operate applications which can promote happy and productive lives. Currently, there exist a limited number of practical devices for people with limited hand function such as quadriplegics to use touchscreen devices - this is where we step in.

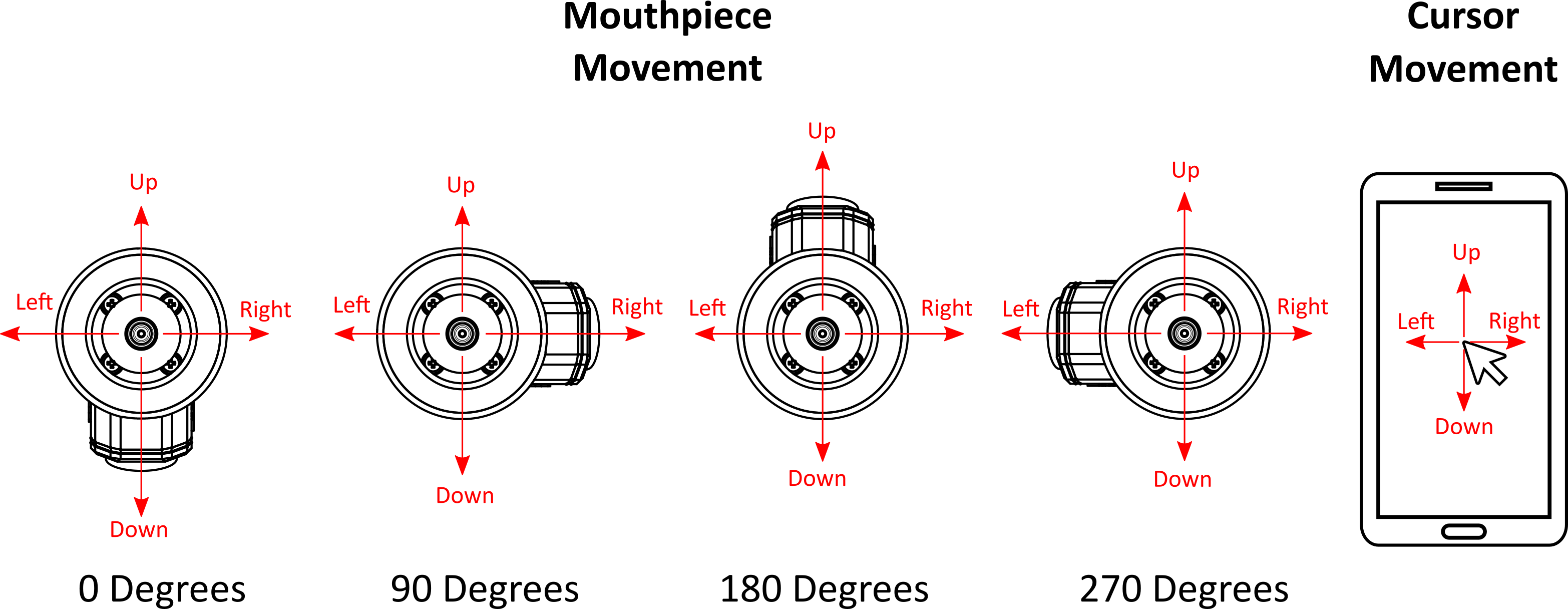

The LipSync is a mouth-operated alternative input device that enables people with limited hand function to use smartphones, tablets, and computers. It is primarily intended to be a low-cost, portable option for enabling access to devices with a touchscreen. The device is operated by moving the mouthpiece joystick with the lips or teeth and Moving the mouthpiece joystick with the lips or teeth will move a mouse cursor and applying sips or puffs on the mouthpiece straw will input a left click, right click, or tap.

COMPATIBILITY AND VARIANTS

The Lipsync will work with any device including desktop and laptop computers that support mice through a universal serial bus (USB) or a Bluetooth connection. Specifically, the LipSync is compatible with smartphones (Android 4.0+, iOS 13+, Windows), tablets (Android 4.0+, iOS 13+, Windows) and computers (Windows, MacOS, Linux). There are now several versions available:

- The Lipsync emulates a USB mouse.

- The LipSync Wireless emulates a Bluetooth mouse.

- The Lipsync Gaming emulates a USB joystick or USB gamepad. It is compatible with the Xbox Adaptive Controller and any desktop or laptop.

- The LipSync Macro emulates a USB keyboard. It can be used with iOS 12 and older devices to provide switch access through the accessibility features.

The LipSync Switch Input Module can be used to modify one of the above versions so that a user can use switches instead of sip and puff. This can be a useful option for those unable to form their lips around mouthpiece or apply the positive / negative pressure to generate sips and puffs. The Switch Input module enables two assistive switches to be connected via 3.5 mm jacks to use the sip and puff functions.

GETTING A LIPSYNC

The LipSync is an open-source hardware project where all of the 3D printer files, component lists and microcontroller code are public. In the spirit of accessibility, the housing can be 3D printed, the electronic components are readily available, and the assembly is as straightforward as possible.

There are a couple of options to obtain a LipSync:

1. You are free to download the files and build a LipSync for yourself or someone you know.

2. You can submit a build request through the Makers Making Change website. In this case, we'll try to pair you with a volunteer maker to complete the build, and you will reimburse them for the cost of materials.

LIPSYNC PROJECT GOALS

- Oct-Dec 2016:

refine designs and usability with user testing- DONE - Jan-Mar 2017:

host a “buildathon” where students, makers and volunteer teams will form around people with disabilities to build and mount LipSyncs- DONE - Apr-Dec 2017:

Support a network of makers to connect directly with people with disabilities and creating 150 LipSyncs through the Pacific Northwest- DONE - Jan-Dec 2018:

Scale maker-disability matchmaking service across North America, to support 1,500 LipSyncs being created at the local level, as well as developing and applying other assistive technologies.- DONE In addition, the Neil Squire Society has been working on a service delivery model for the technology. It will soon be launching the Makers Making Change initiative. Makers Make Change has the goal of creating one-on-one relationships between makers and people with disabilities. The Makers Making Change initiative will provide the infrastructure to connect makers, open assistive technologies, and people with disabilities...

Makers Making Change

Makers Making Change

Our Low-Tech AT Kit, which includes (clockwise from top right): bottle opener, palm pen holder, ball pen holder, key turner, nail clipper

Our Low-Tech AT Kit, which includes (clockwise from top right): bottle opener, palm pen holder, ball pen holder, key turner, nail clipper Please fill out our Switch Survey:

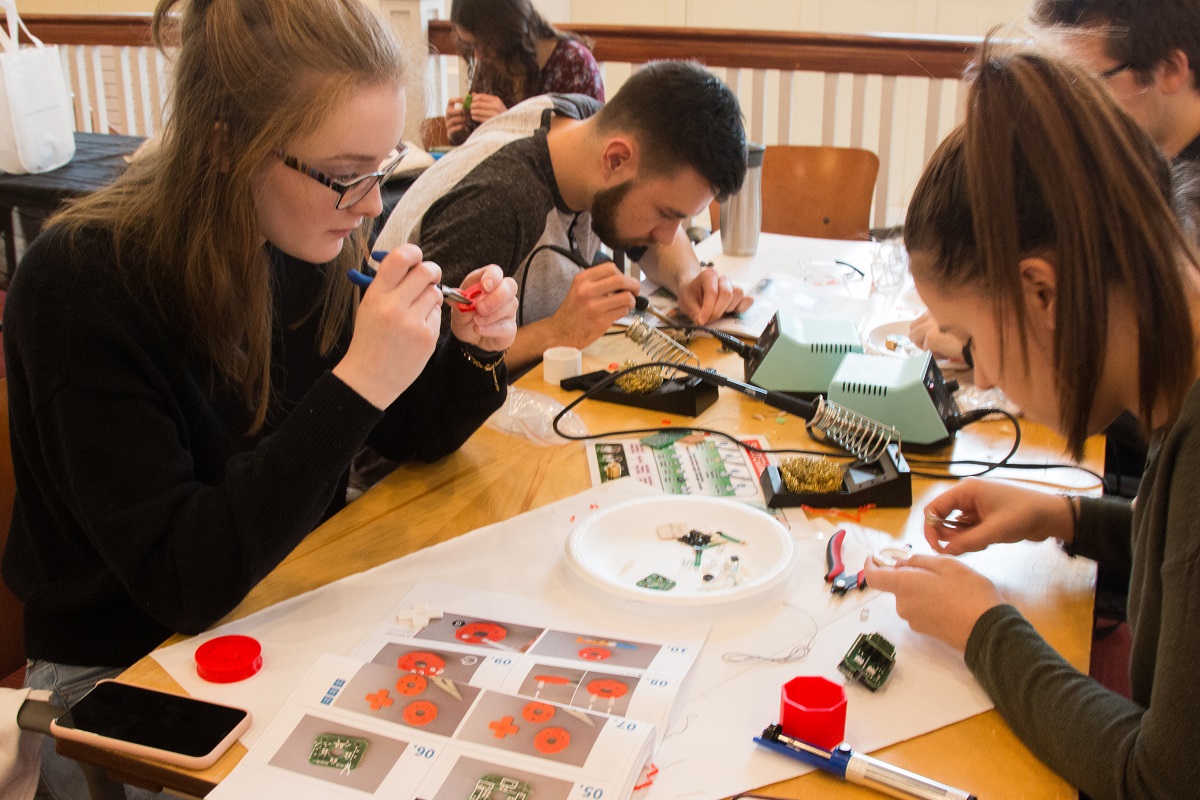

Please fill out our Switch Survey:  Student makers working on LipSyncs at a prior buildathon

Student makers working on LipSyncs at a prior buildathon

Coby Unger

Coby Unger

T3rr0rByte13

T3rr0rByte13

is anyone still working on this project? I need some help and ordering information on the mouth piece parts