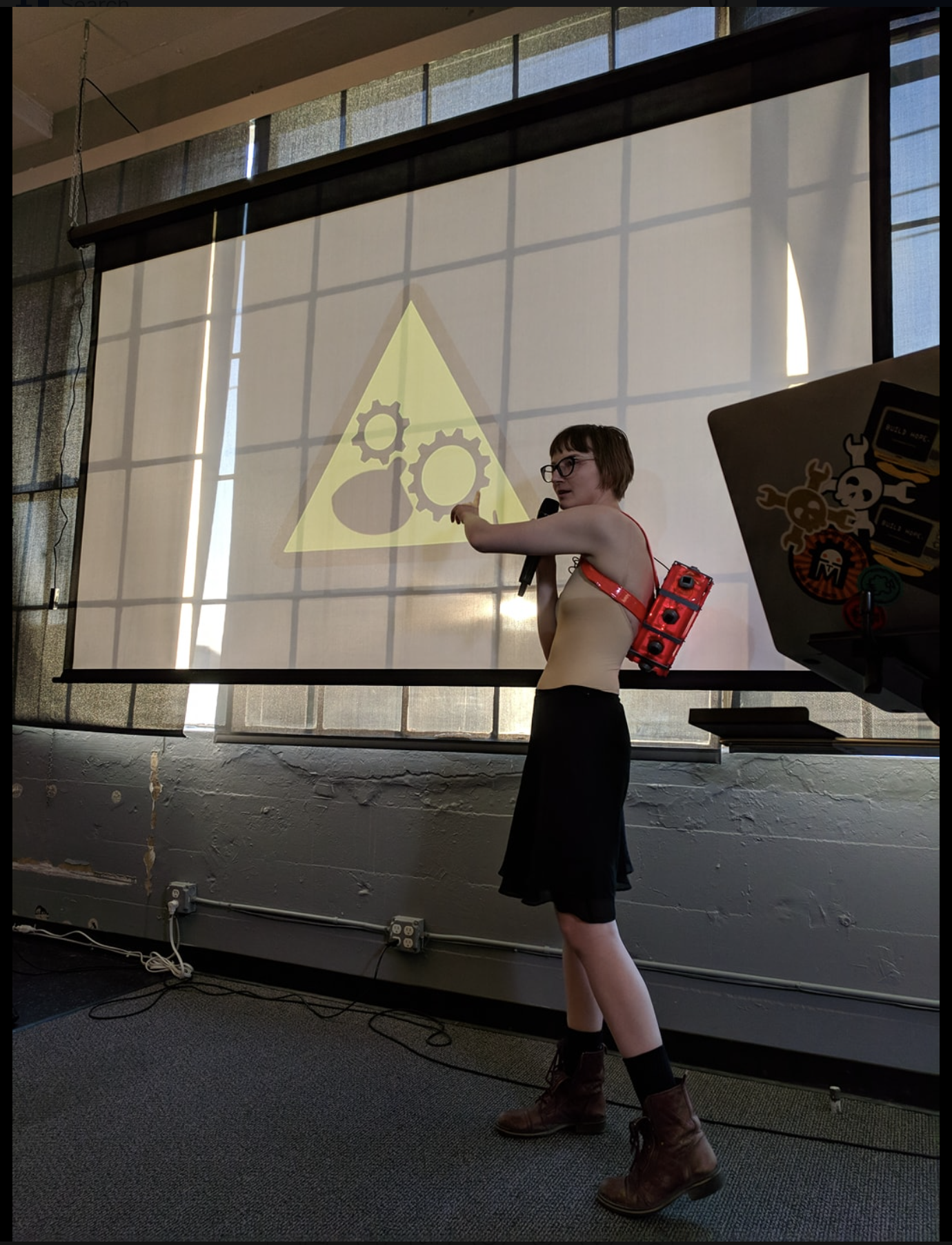

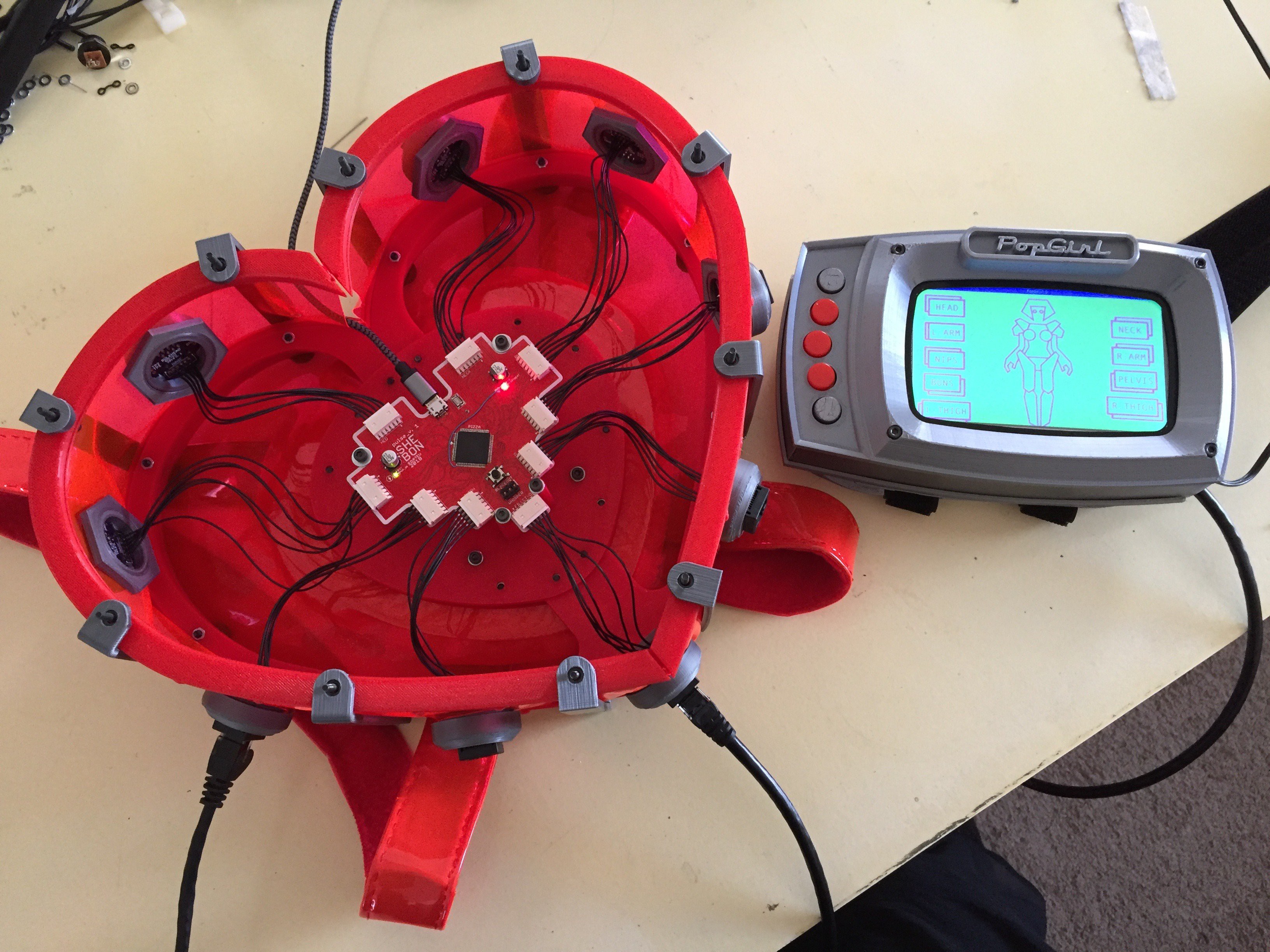

Hi everyone! This spring I've committed to make myself "a suit of amour" that will indicate my physical status... particularly my level of excitement. My intention is to manipulate a multitude of sensors in order to track my physical status, so that when I reach a heightened state, some other mechanical wearables will actuate to indicate when this threshold is reached!

As a creator of technology and physical things, I would like to live in a world where our bio-data can be used to communicate what is otherwise invisible... and as a result, grants us humans the ability to express our individuality in new and unique ways.

I wish to wield technology in order to make life more interesting for myself, and everyone I interact with. If you would like to accomplish the same thing, I welcome you, fellow maker/hacker, to talk to me about your thoughts and reflections. Lets make the world awesome by choosing to know ourselves, and each other better. <3

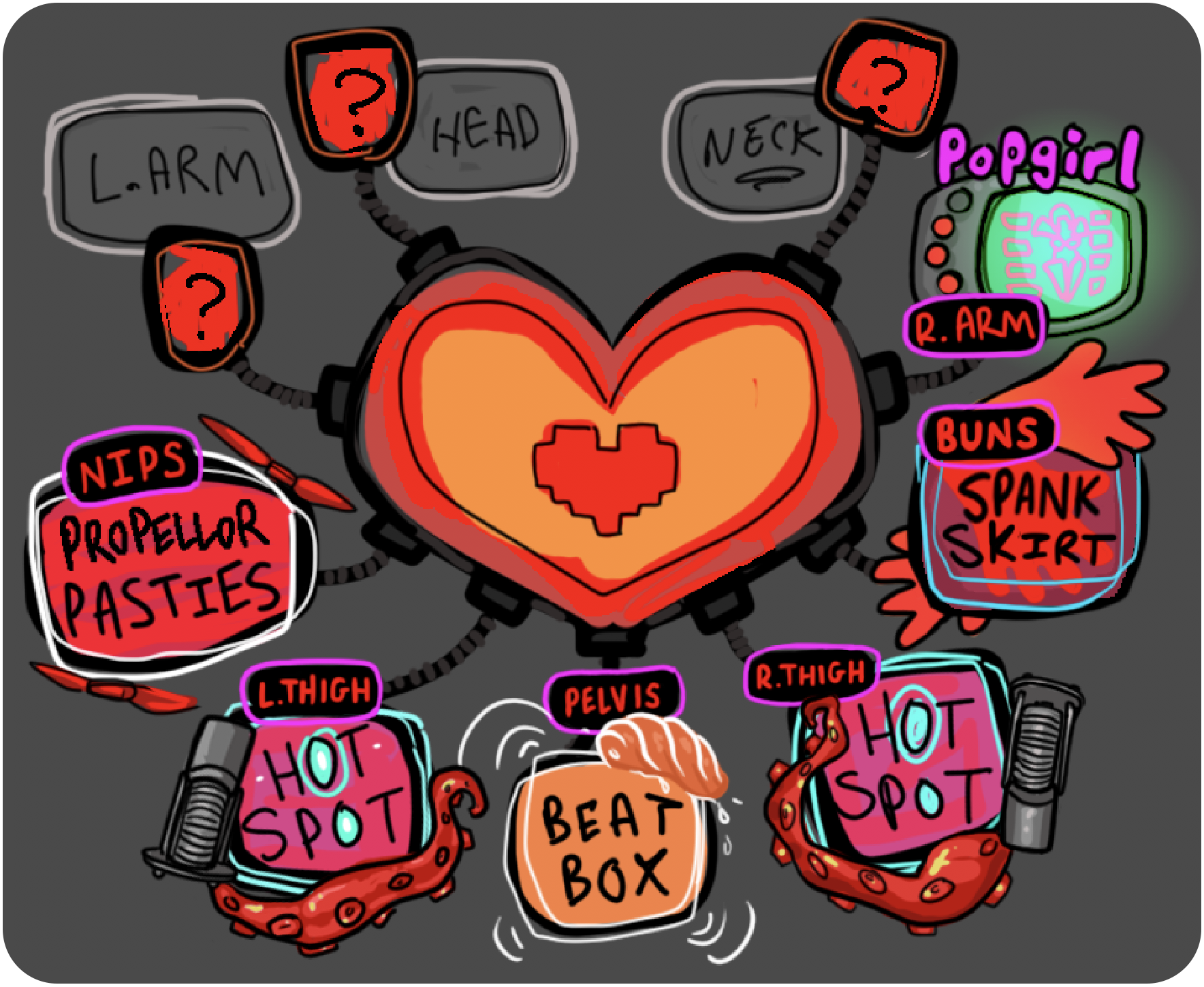

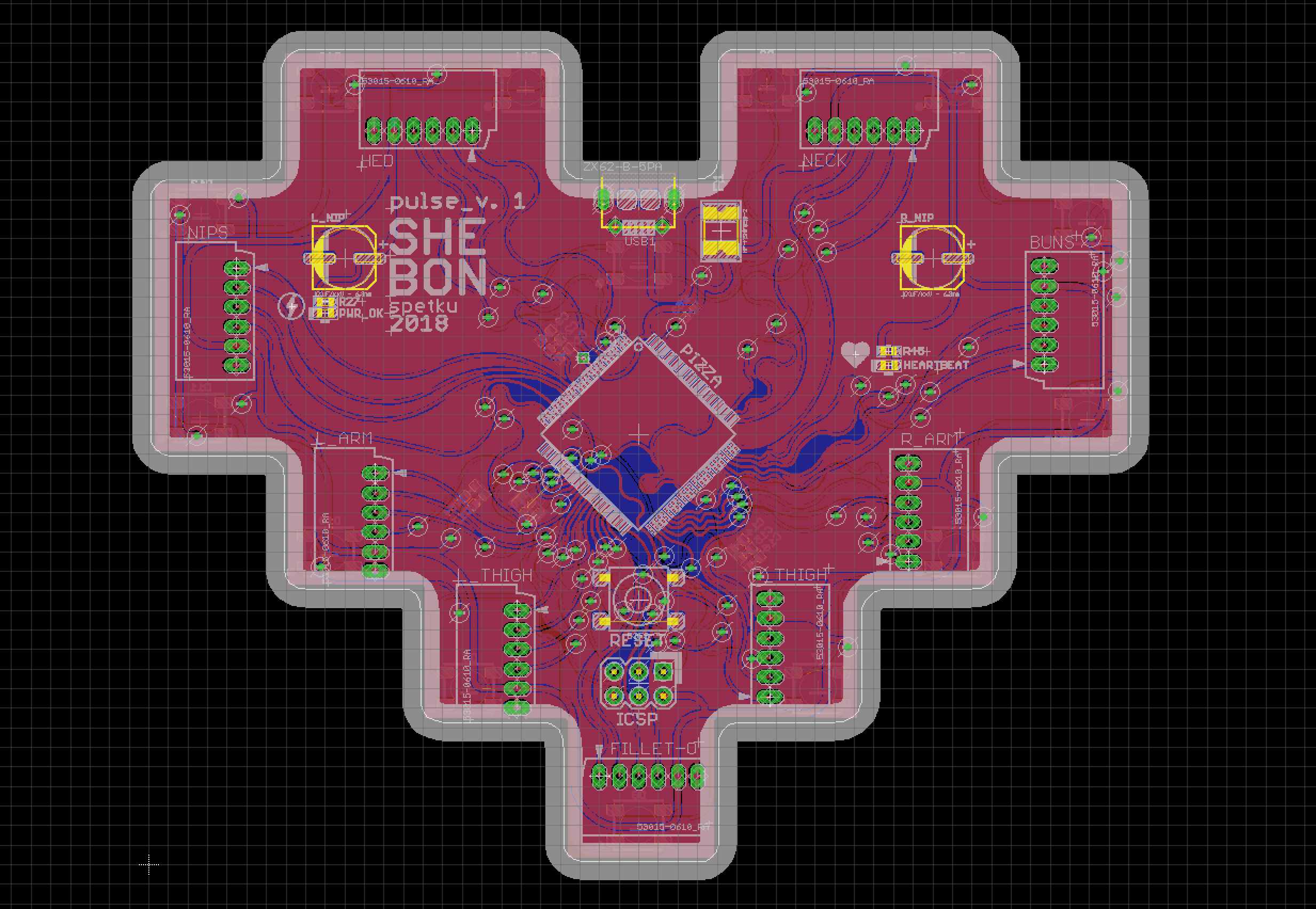

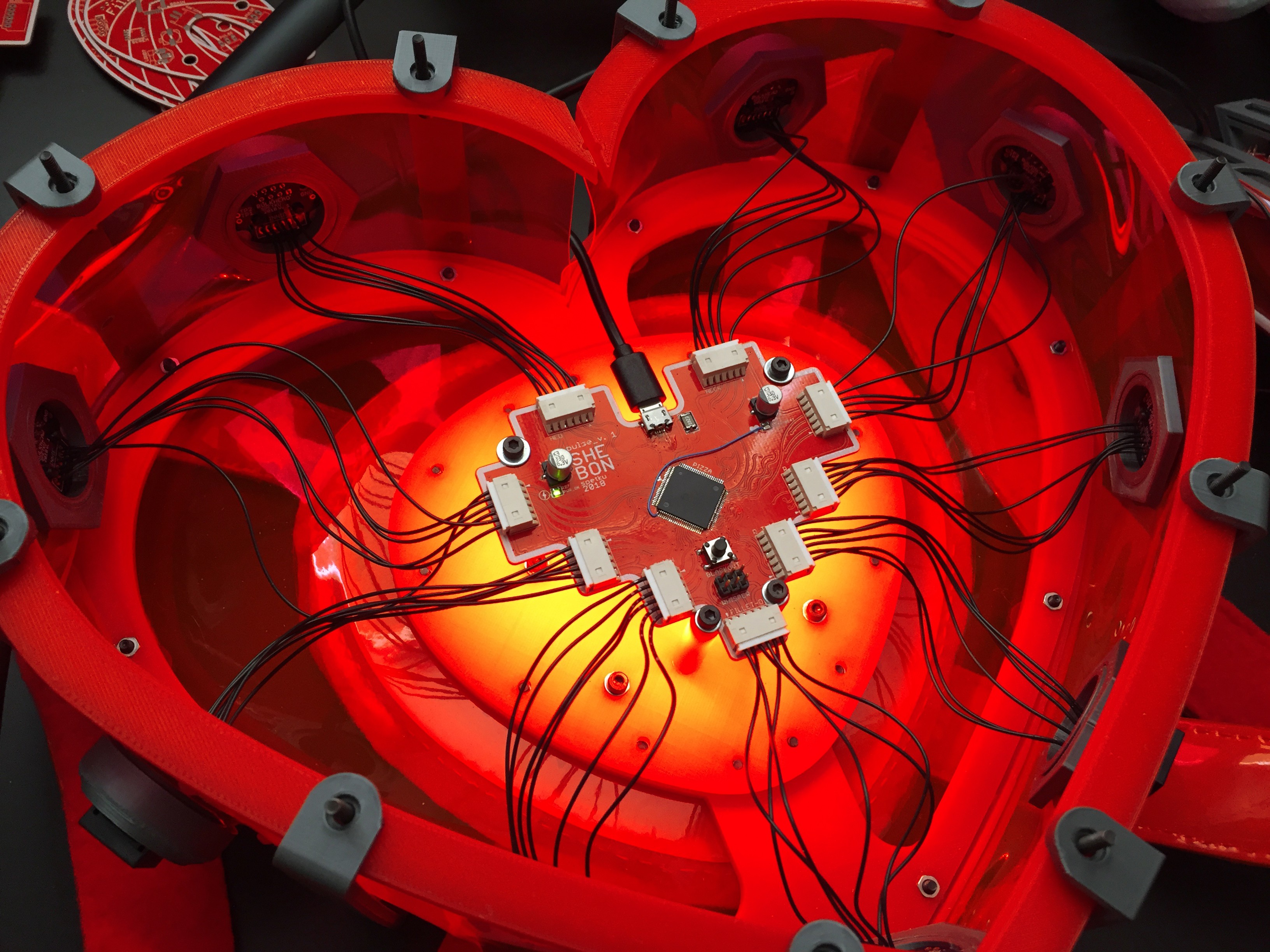

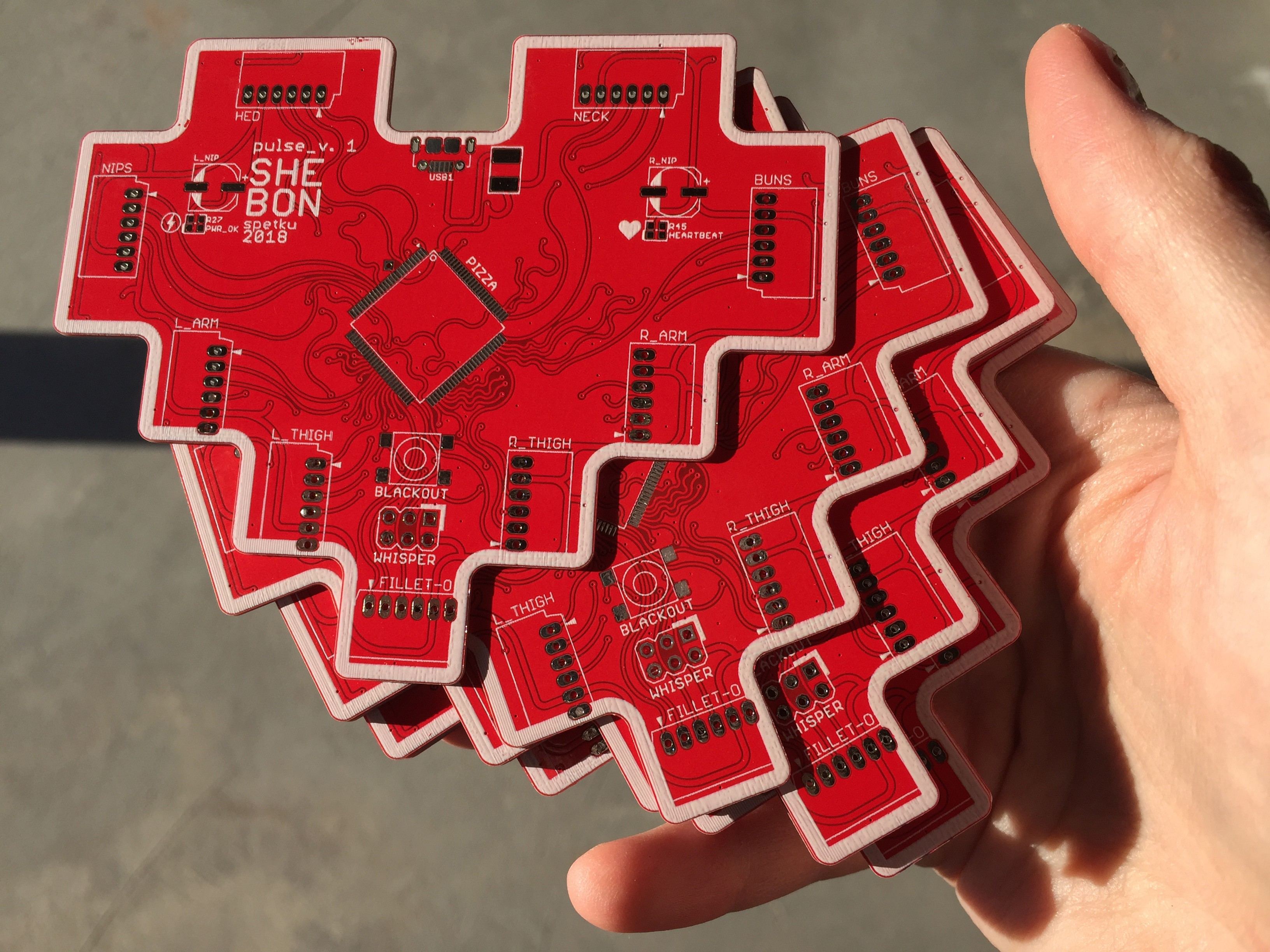

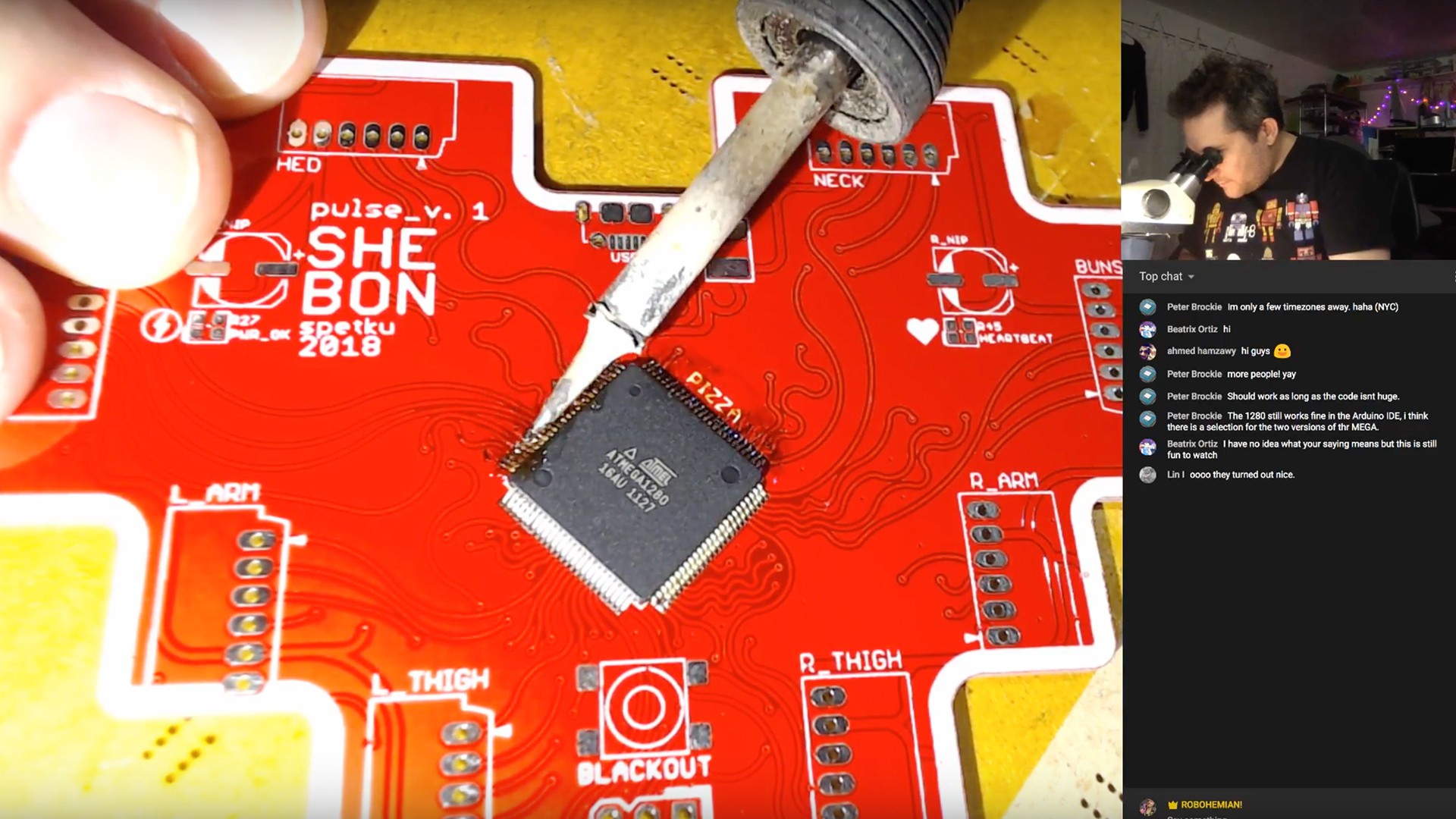

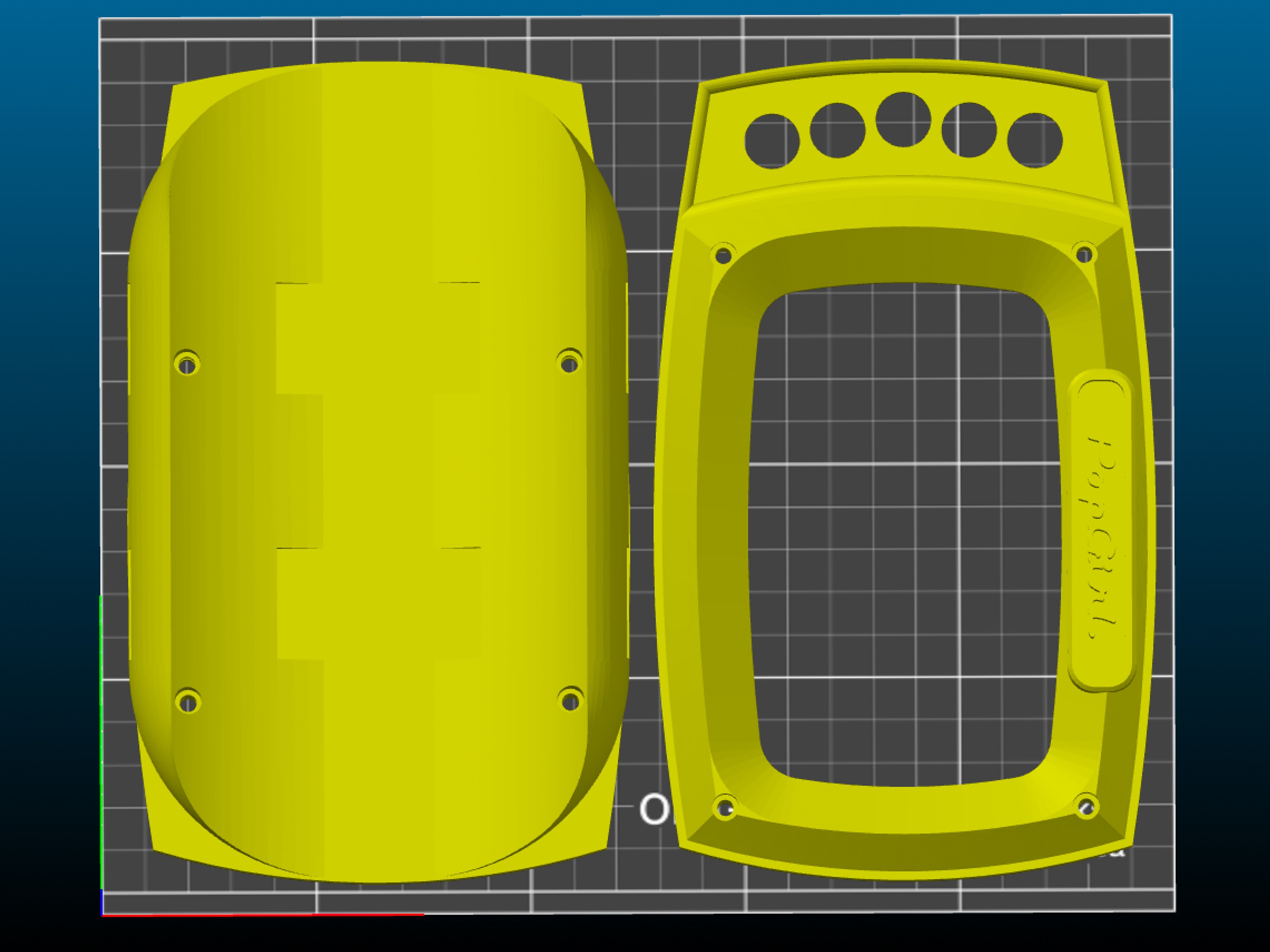

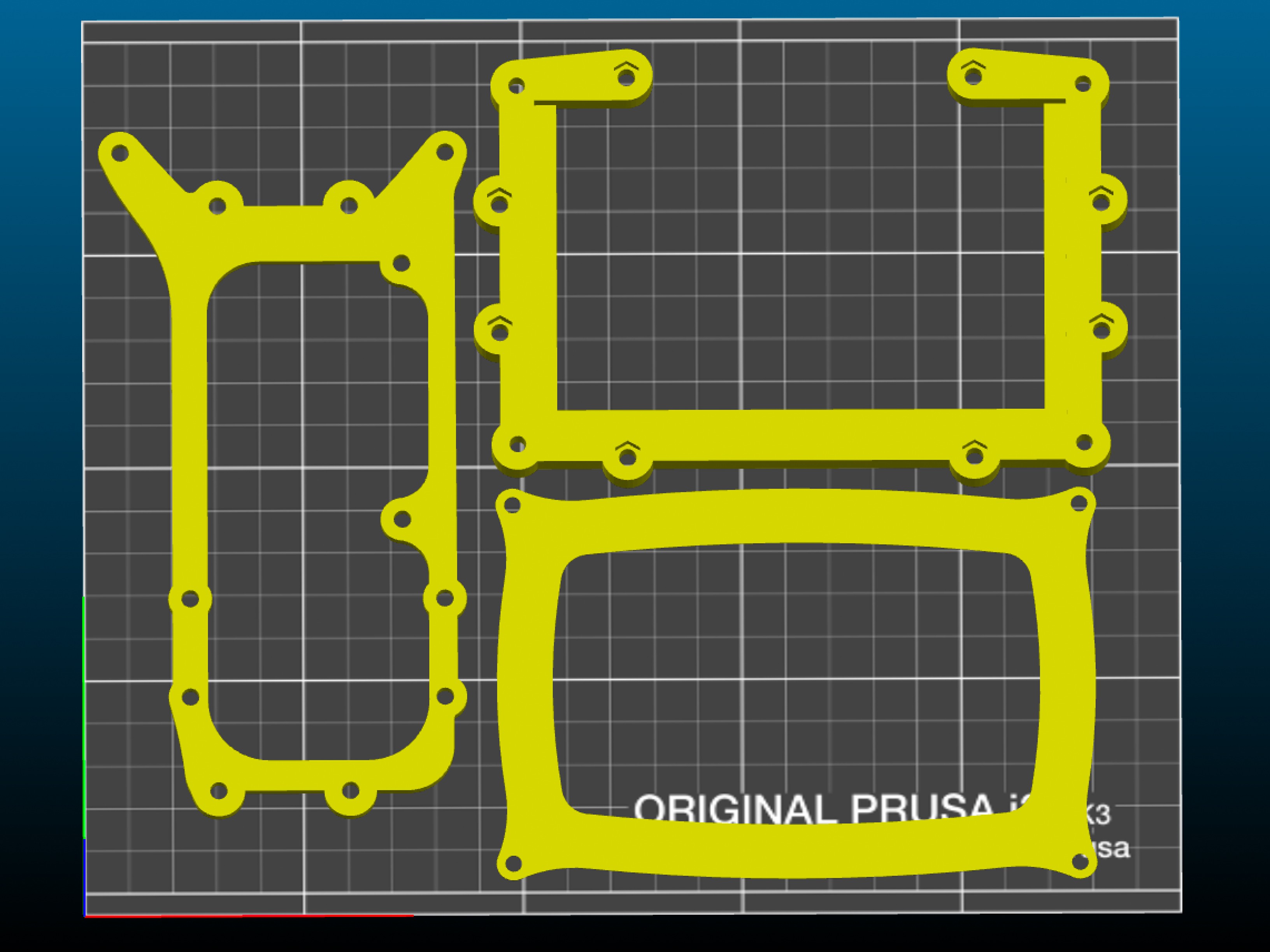

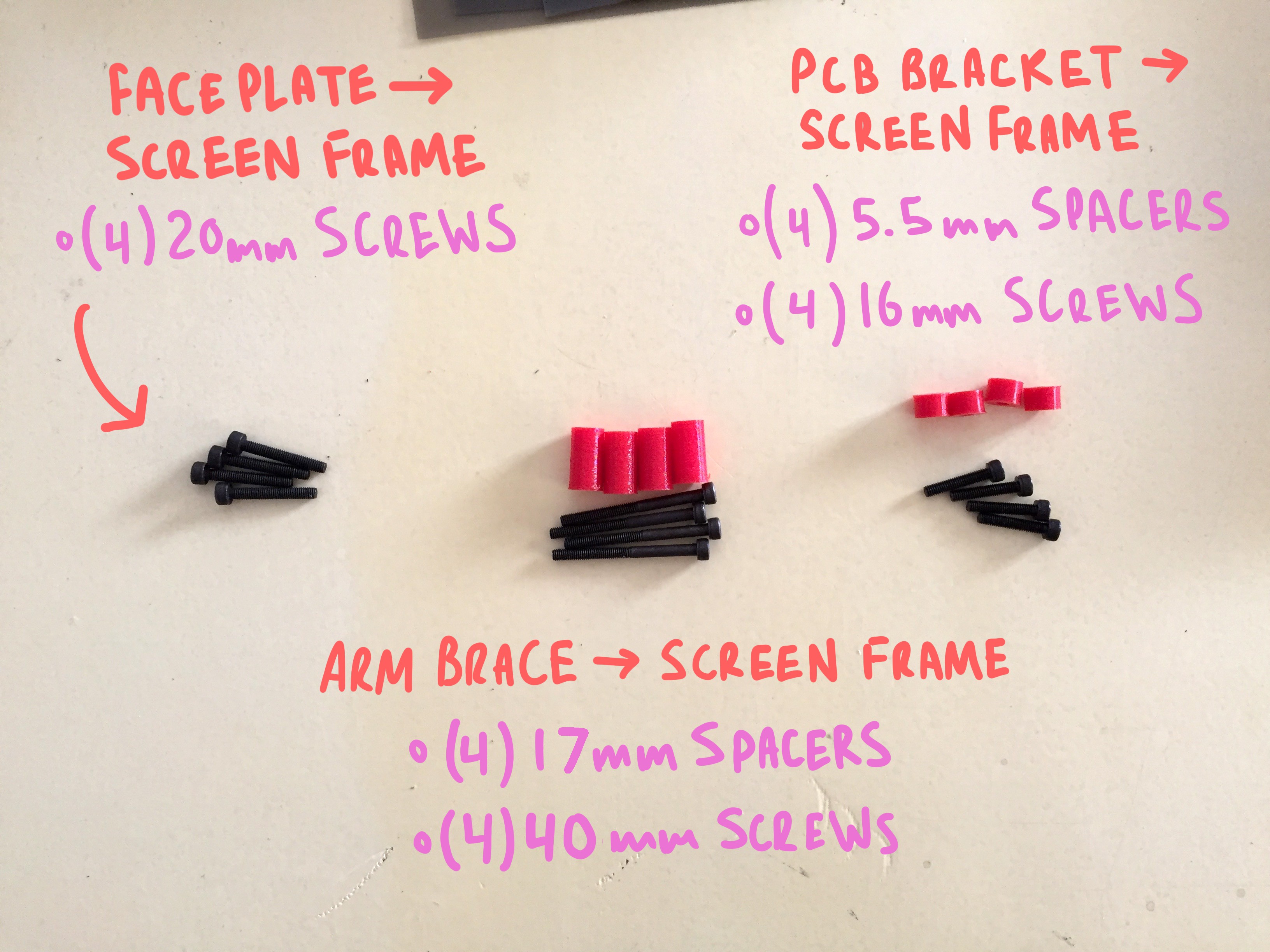

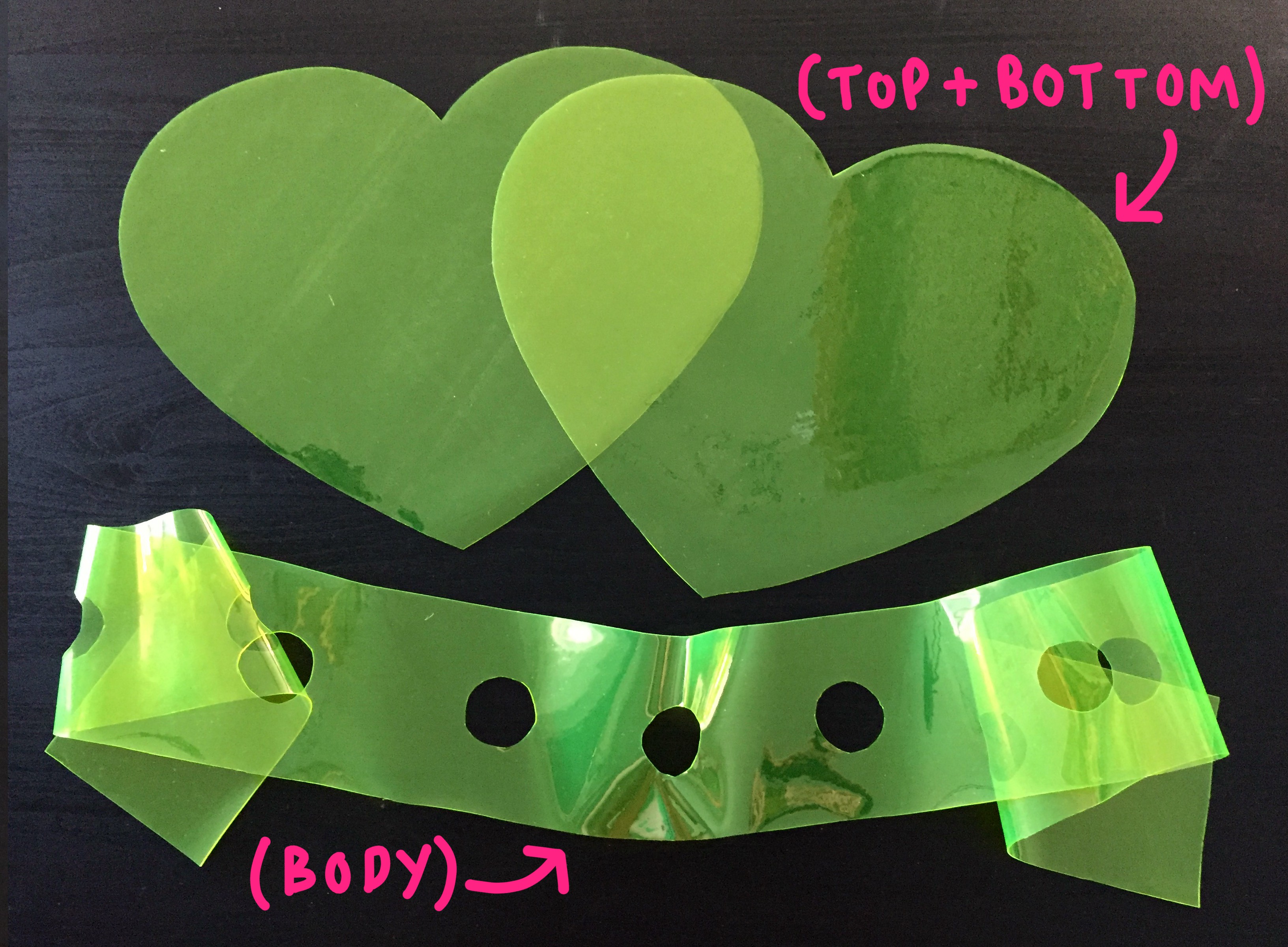

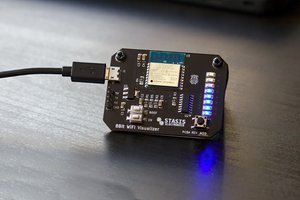

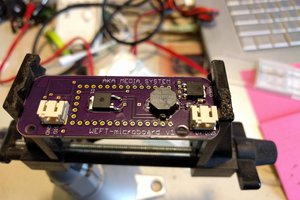

The scope of this project involves the creation of many individual systems, all with their own poetry and quirks. So far I have finished one peripheral, the "BEAT BOX" - however, several others are in the works right now for other parts of the body...

Sarah Petkus

Sarah Petkus

Chandler McCowan

Chandler McCowan

AKA

AKA

Thaddaeus

Thaddaeus

jarocks

jarocks

I hope it's not inappropriate to post this, it might sound like an ad but it's not. I used to be "Doctor X. Treme" of "X. Treme Orgasmatronics". We built a machine we called the "Ambrosia Vibe" or "Bionic Dildo", which was a strap on dildo with a vibrator in the base and a hollow space along the underside. We had a simple board based on Arduino which detected the air pressure in the cavity in the dildo, did some simple math to make it what we hoped would be a realistic touch sensation, and connected that to the vibrator in the base. The idea was to make the simplest and most compact possible system in which the wearer of a strap on could get haptic feedback that would mimic the basic user experience of the biological organ it's modeled after. It cost about 40 bucks to make and we retailed it for from 150 to 200 bucks. Customers loved it, and we got some very moving reviews from people who really needed a thing like that. Then our company fell apart because I was a bad CEO(didn't raise enough capital, borrowed too much money, spent too much time/money on R&D instead of marketing etc., typical tech founder nonsense).

All the work we did we released as open source as we went along, and after the bankruptcy it is totally free open and available technology...and yet no one cares. I mean our former customers cared, and hobbyists sort of care, but the technology is still orphaned and that's a major bummer. I have a day job doing more normal applied physics things now, and never want to do startups again, nor attempt to make any money on sex tech. Every few years someone comes along and says they want to build this thing, then after a bit of time they lose interest and move on.

I"m posting here in the hope that this technology can finally find the advocate it deserves, maybe somewhere out there in hobbyist land? Please? Any takers? I'll help for free, give you schematics, code, 3d files, contacts in China for the manufacturing, and some other useful industry contacts, again all for free, but please please care. Folks without bio-cocks who want to have that feeling want this, and the only reason they don't have it is that we, collectively, the sex tech hobbyists, have dropped the ball. Anyone?

My feeling is that while this CAN make tons of money for someone that since there are simple ways to make tons of money that what this technology really needs is an advocate who cares more about the tech than the business, who has the people skills to get the dildo companies to embrace it in a series of specific deals, rather than build up a business from scratch. Dildo companies are weirdly secretive and frustrating to deal with but I do have some ideas of how to do this.

If interested, I guess PM me or post comment responses, and again I'm sorry if this comes off as spammy, I just saw some fantastic tech being shown here in the same line with a community of fans and hoped this was the right demographic. Thank you for your time.

Lafe(Dr. X.)