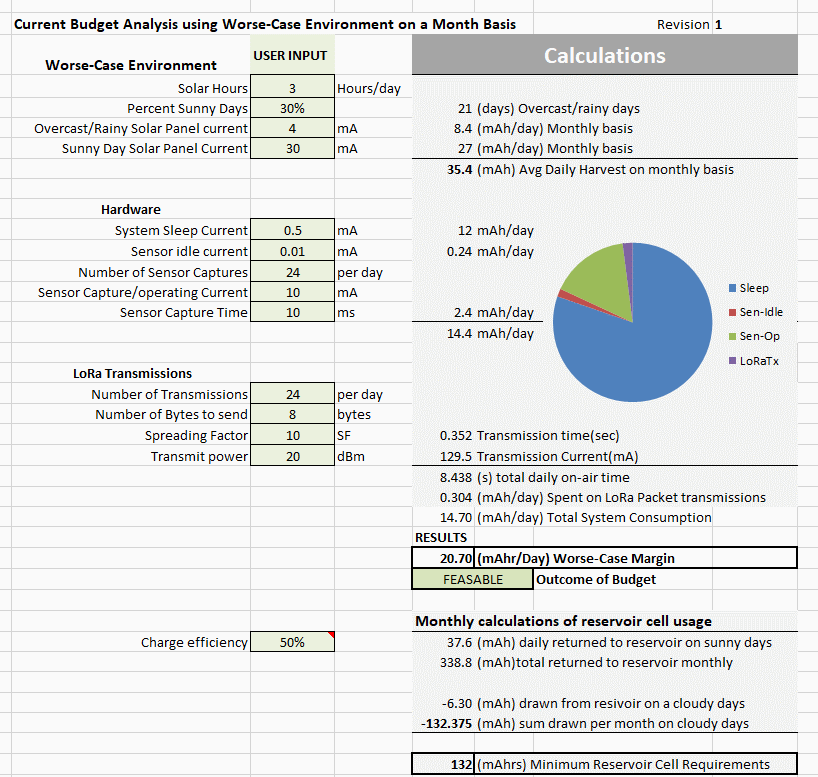

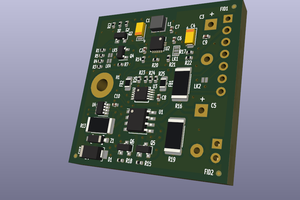

Detailed design analysis on the power management and software systems used on the SOLoRa board will be presented in an upcoming post.

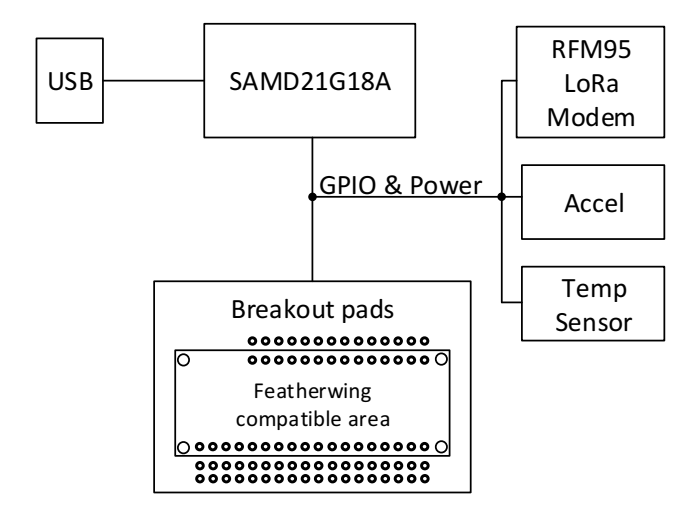

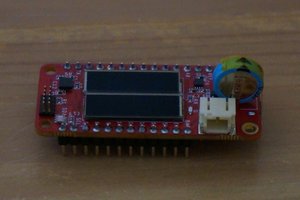

The hardware features of the SOLoRa board include:

- Low-cost components.

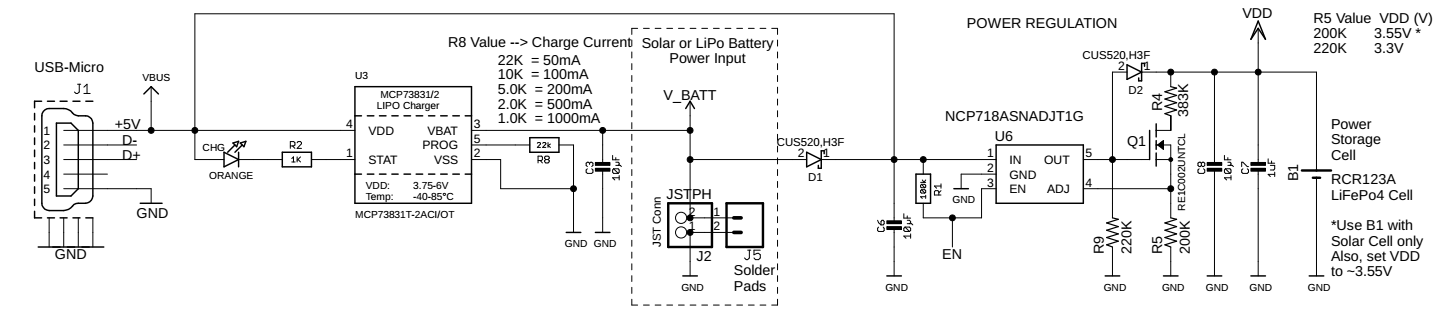

- Inexpensive standard components in novel configuration are used instead of specialize energy harvesting ICs

- Easy (ish) Assembly.

- QFP package processor and 0603 Rs and Cs.

- Can be soldered by hand using standard soldering iron. One exception is the accelerometer, which can be soldered using a reflow heat gun and a little training.

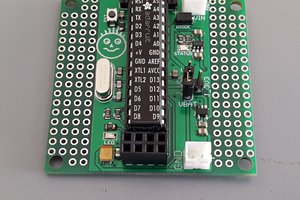

- Arduino compatible: Uses the same device as the Arduino Zero. Uses Arduino bootloader.

- Featherwing compatible: Can use with Adafruit’s Featherwing expansion boards or use the header for a protoboard mezzanine

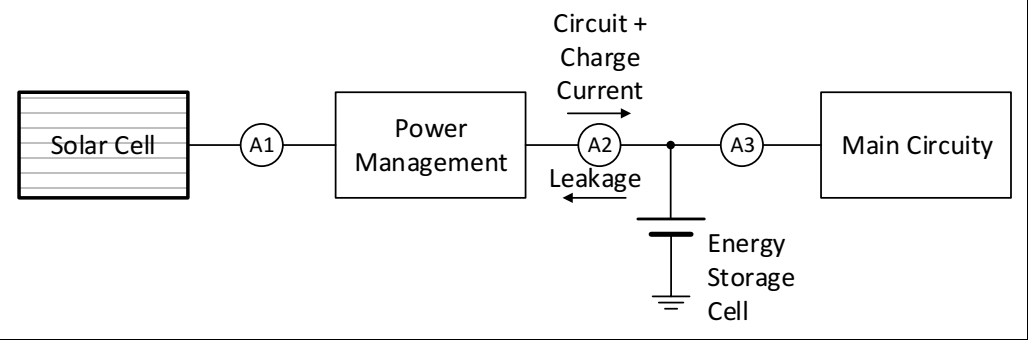

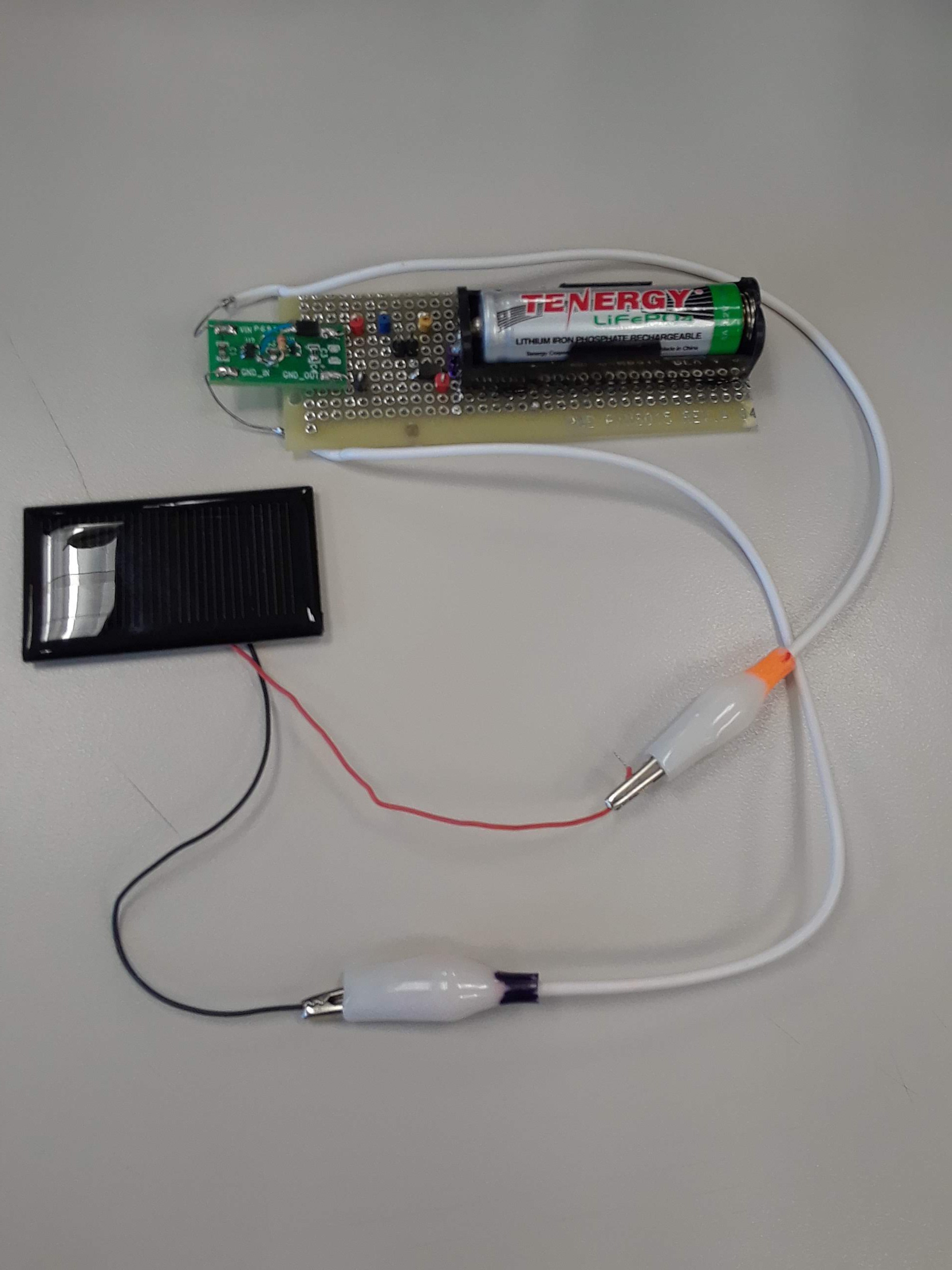

- Multiple power options to targeting additional IoT applications, particularly field applications

- Solar. The main subject of this blog.

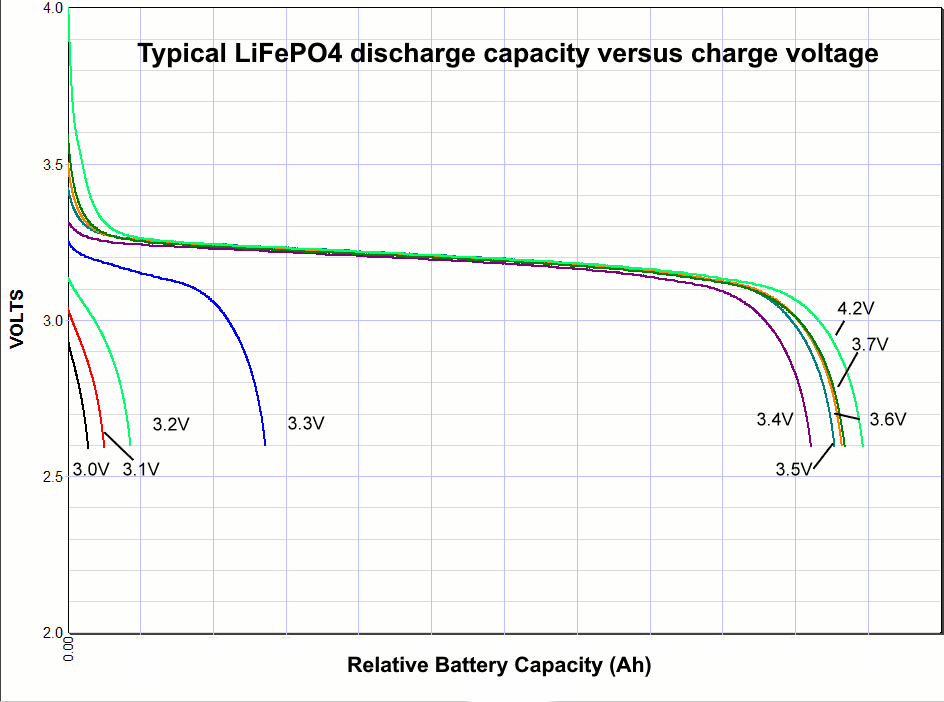

- a CR123 battery clip for a LiFePo4 battery used as a power reservoir. (~400mAh)

- On-board regulator charges LiFePo4 to constant voltage.

- Solar cell size constrains max charge current.

- Rechargeable Li-Po or external battery pack

- For standard indoor applications

- On-board USB micro connector and charger IC

- Lithium (primary cell)

- Battery clip will also house a standard CR123 3V Lithium, which has ~1000mAH capacity

- USB 5V for desktop development (or use with a USB battery bank?)

- On- board adjustable regulator

- Change Resistor values to adjust VDD

- Adjust to 3.3V to regulate Li-Po or external battery pack and USB 5V

- Adjust to 3.5V for LiFePo4 constant voltage charging.

- Solar. The main subject of this blog.

- Small size: 2.3 x 2 inches

- Has mounting holes to match an inexpensive water tight enclosure

- All components mount on one-size only. Bottom is free to increase mounting versatility.

- 2-layer board, cheaper to fabricate.

- Optional on-board sensors, indicators

- 3-Axis Accelerometer

- Temperature

- Programmable Red LED

- Development Options

- Arduino IDE (use as an Arduino Zero)

- Atmel Studio

- Atmel Studio has Arduino templates to program like Arduino, or use standard C form

- Full debugging capability (breakpoints, watch variables). a $20 JTAG debugger hardware required for this feature

Joe Miller

Joe Miller

Darryl Norman

Darryl Norman

Arkadi

Arkadi

Hi Joe, I'm from the SoLoRa meetup, and saw your board.

Thanks for putting all the detail on the design. I did find your sw examples https://github.com/180Studios/SOLoRa_TTN

I'm just wondering, if they are uptodate, reasonably recommendable. I used a LMIC tutorial from elsewhere but it had some unreliabilities in it, so scouting around for a working reference example. many thanks Neil