Basic Principle of Treatment :

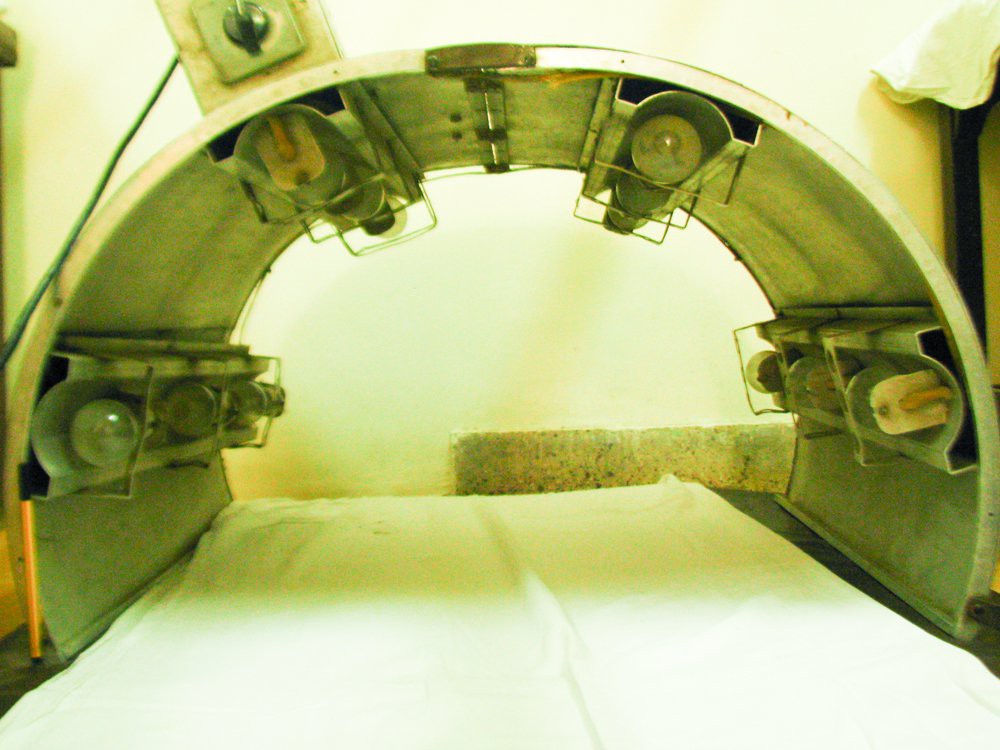

The affected limb(s) are exposed to the radiant heat from the tungsten bulb arrays. The duration is based on the doctor's recommendations and patient's comfort.

Issues with current devices in the market :

- Cost

- Size and weight

- Available only in hospitals/medical centres, due to cost and size

- Accessibility; patients should ideally be using these frequently but having to travel to a hospital means they use the service far less than recommended. Due to the large number of patients, available time per patient is also limited. Besides, traveling while suffering from the condition is not recommended.

- Usability; even at the hospital, the attendants find the device quite large and cumbersome to unload and deploy.

Requirements :

- low cost

- lightweight

- small footprint/easy storage for home use

- simple and low-cost fabrication, avoiding specialized components and tools

Concept :

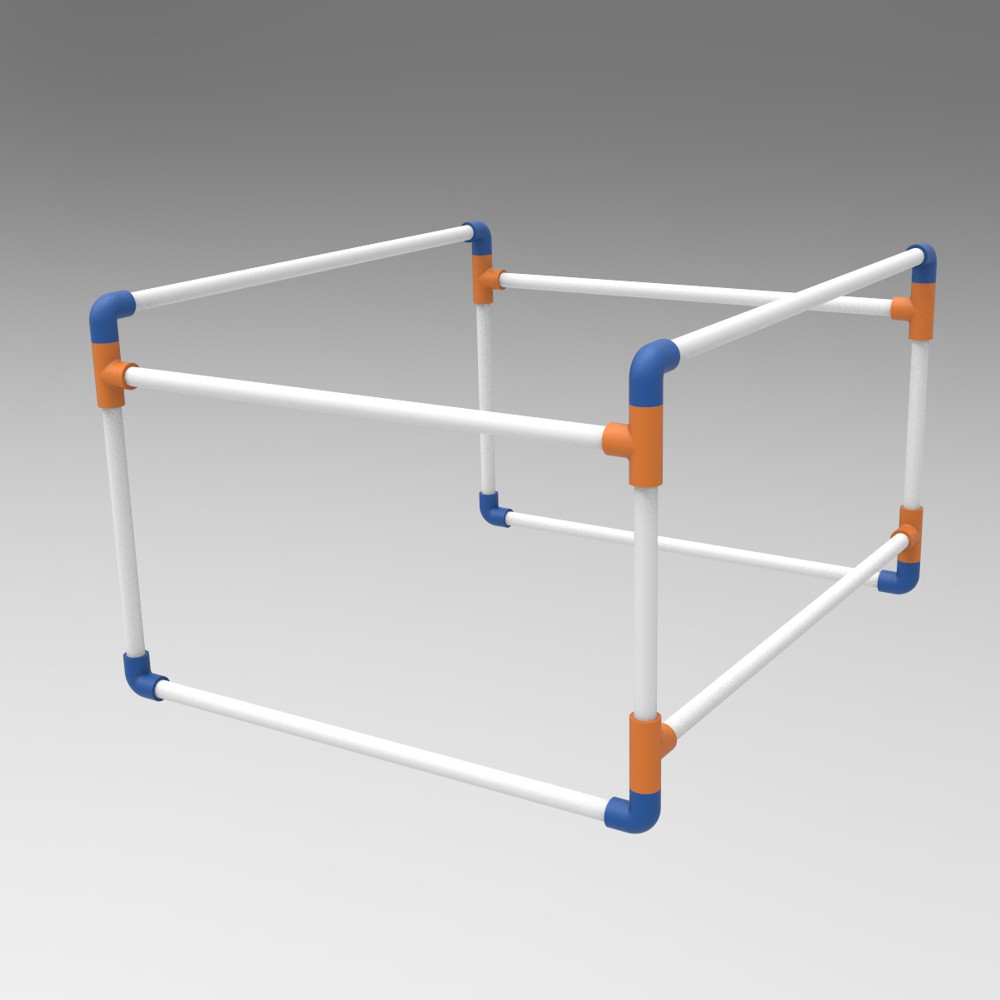

A. The Frame :

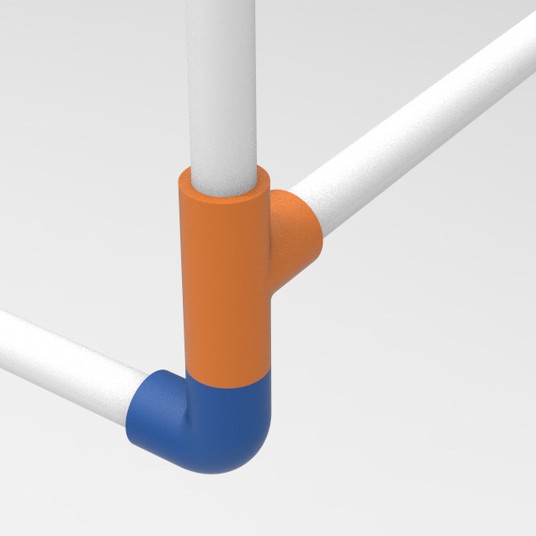

The frame is made of PVC pipe segments. A combination of T and elbow joints is used to create a pivot joint that allows the frame to be flattened and put away when not in use.

B. The Bulb arrays :

The bulb arrays are bulbs in holders screwed on to PVC Wire Casings. There are two modules along the upper face of the frame (3 bulbs each), and one each on each side (2 bulbs each). The wires run through the wire casing.

The PVC casings are two mating pieces that slide along/snap into each other. Square end pieces of one mate are cut off and screwed into the pipes. These act as snap-on holders for each bulb-array.

Each holder is wired in parallel to the others on its module, with a switch at the end, ending in a 2 pin plug.

C. Heat Conservation :

While in use, for more effective treatment, the heat can be contained or regulated by draping a thick wool blanket over the frame, trapping the heat underneath.

Usage :

A. Deployment :

- The patient or a care-giver pivots the frame open.

- The 4 bulb modules are snapped onto the frame, and bulbs are inserted if removed for storage.

- The bulb modules are plugged in and switched on.

B. Usage :

- The patient lies underneath the frame receiving the radiant heat on affected limbs for as long as recommended.

- A blanket is draped over the frame to conserve the heat.

Benefits :

Low Cost : The entire device should come to about Rs. 1000 of material costs.

Ease of fabrication : It should take a couple of hours to fabricate and assemble for the first time. It can be done by almost anyone - caregiver or patient - with a basic skillset and tools, or failing that, the local electrician/carpenter/handyman/fabricator.

Lightweight : Being PVC, as well as modular construction, the device is lightweight.

Easy storage : Since the bulb module comes off and the frame flattens up, it can be stored easily in the home. The bulbs can be removed from the modules as well.

Design Considerations :

PVC pipes are inexpensive, strong and ubiquitously available. The other structural option was aluminum channels, but the risk or short circuits from a loose connection were too high.

PVC wire casings offer a built-in snap-fit structure, so no external components are needed to enable a quick release mechanism. Also inexpensive and ubiquitous.

Beyond the overall sizing, the dimensions have been left open to suit locally available components and choice of build materials.

Jesal Mehta

Jesal Mehta

ssla-couk

ssla-couk

Steve Hernandez

Steve Hernandez

Sameera Chukkapalli

Sameera Chukkapalli

Akshat Wahi

Akshat Wahi