What is this all about?

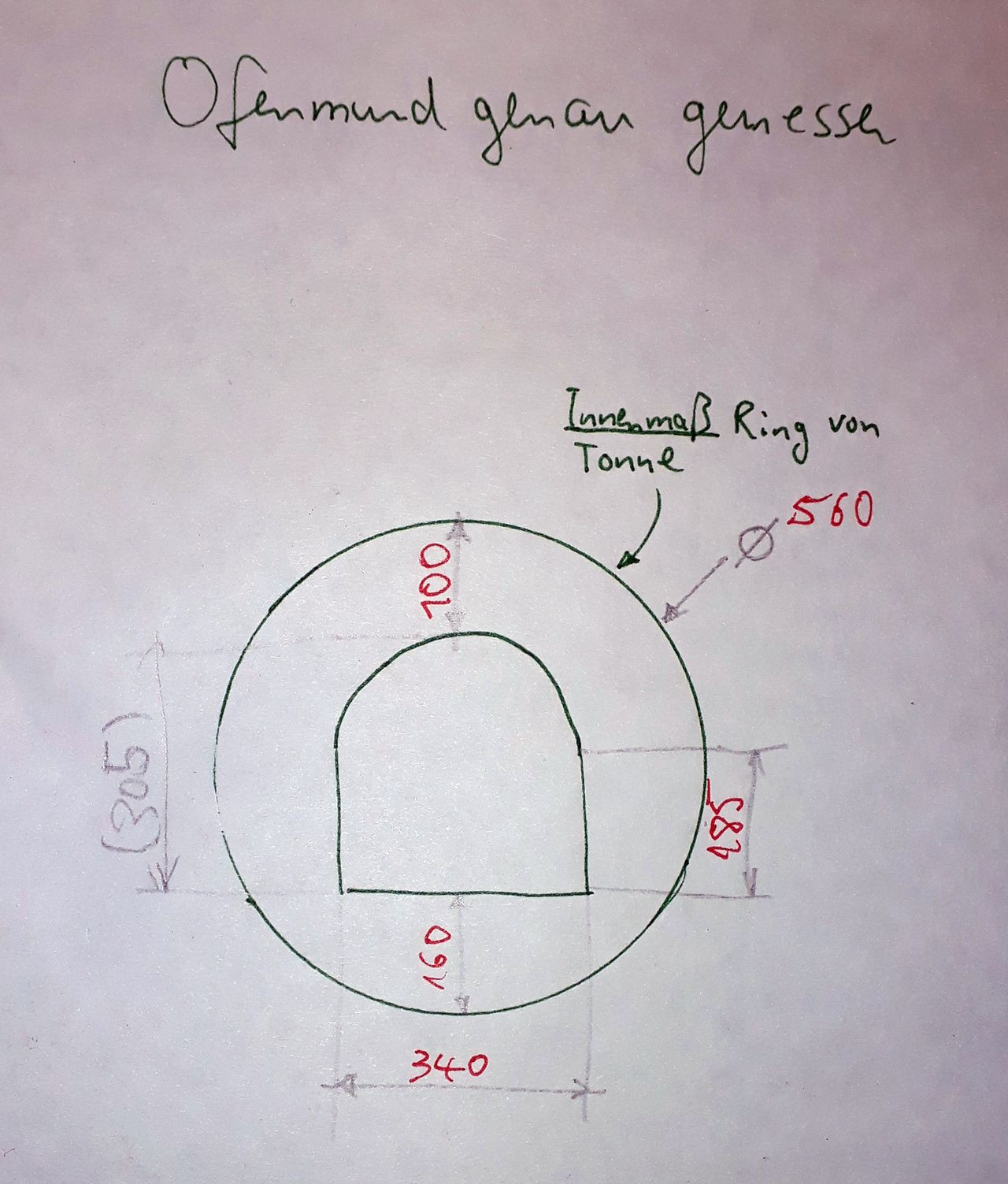

Put simple, it's about creating a fully functional wood fired clay/loam oven from scratch. Capacity is one Pizza at a time only due to limited space, but the oven can bake 4 breads at a time.

These were my restrictions:

- limited space in my garden: 1.5 x 1.5m

- using natural resources for everything directly in contact with the baked goods

- using clay/loam which is easily available in my region for the "heat storage"

- upcycling other stuff to finish the build

Some restrictions were easier to overcome than others. You'll see what I mean when reading through all the build logs.

Have fun reading!

Literature and Resources

I read the German (unfortunately shortened) translation of Kiko Denzers "Build Your Own Earth Oven" to get started. It was of much help, especially regarding getting the right ratio clay/sand/straw.

The internet is full of build instructions, too!

Jan

Jan

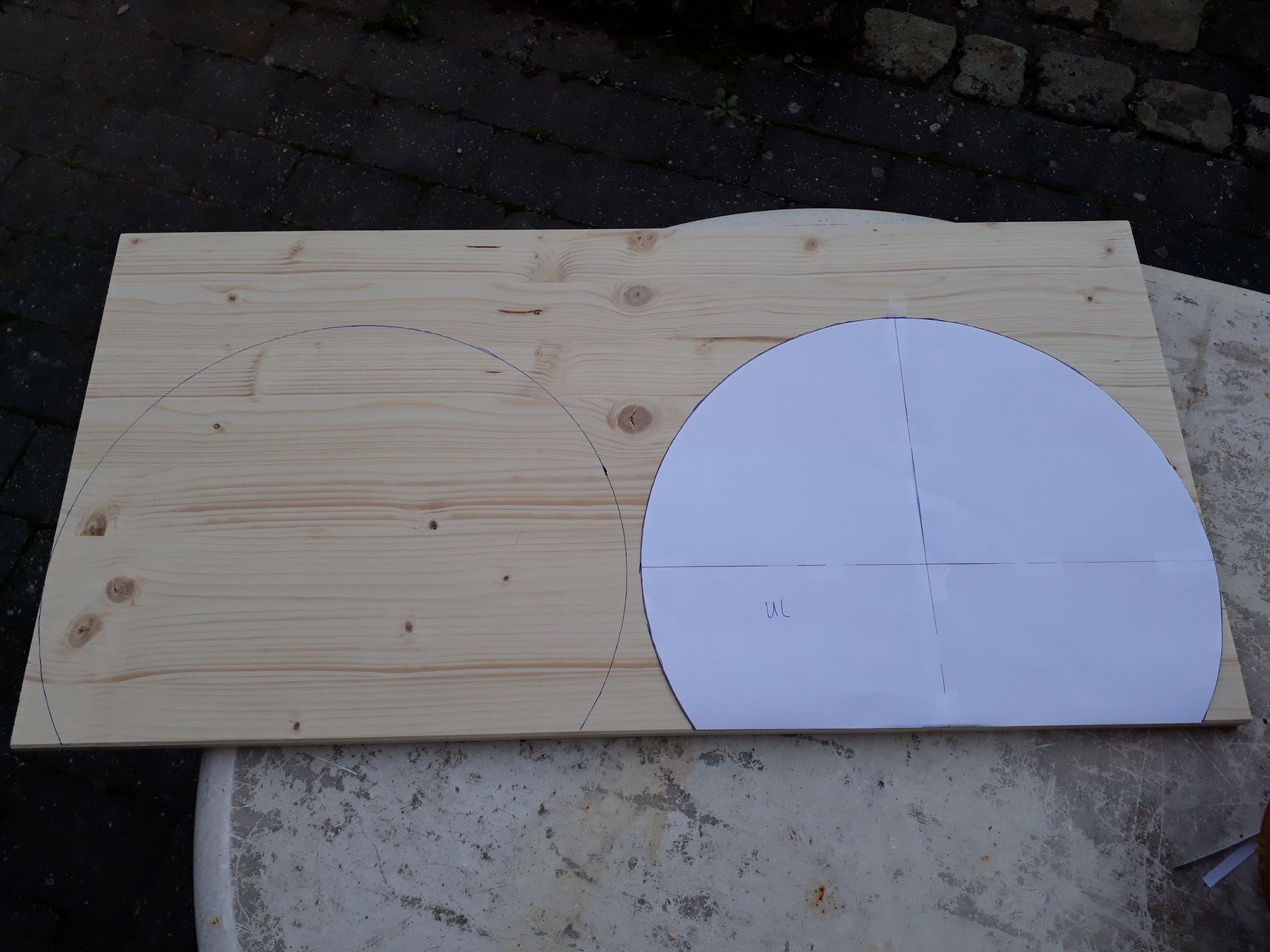

I then screwed wooden slats to both faces to create some kind of trough:

I then screwed wooden slats to both faces to create some kind of trough:

This mould fits perfectly this time. You can see the shitty one in the lower right corner. It got destroyed later and used as fire wood :)

This mould fits perfectly this time. You can see the shitty one in the lower right corner. It got destroyed later and used as fire wood :)

The mix was still quite rich but worked perfectly:

The mix was still quite rich but worked perfectly:

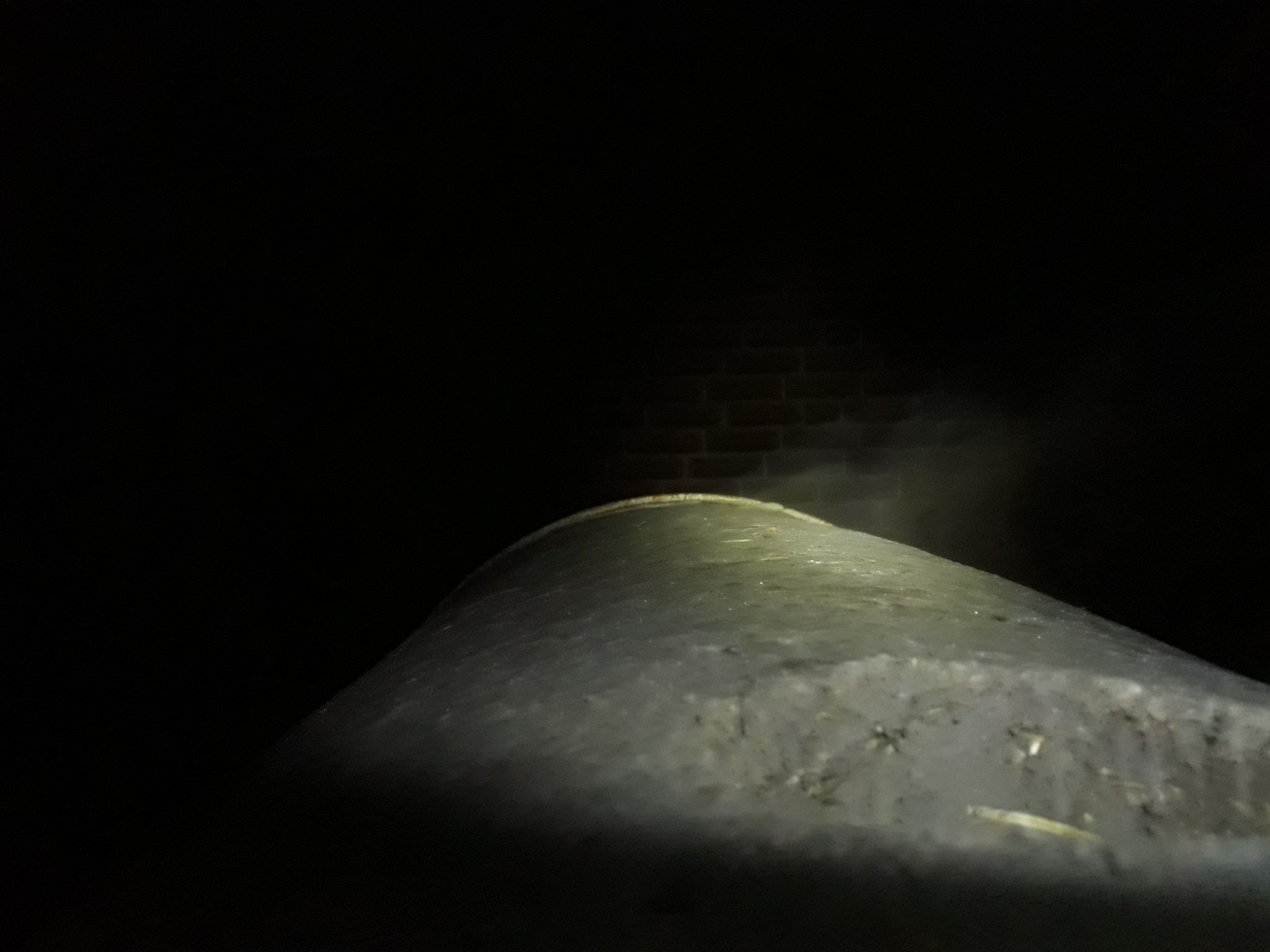

The chamotte bricks are not yet pit in place in the above picture. It was just to test the fit. So, we made a huge batch of mud/sand/straw and began building the dome:

The chamotte bricks are not yet pit in place in the above picture. It was just to test the fit. So, we made a huge batch of mud/sand/straw and began building the dome:

matthewkleinmann

matthewkleinmann

WJCarpenter

WJCarpenter

Scott G

Scott G

Moritz Wenzel

Moritz Wenzel

It is very great to make wood fired clay oven and I want to connect it with my webpage.so I usually recommend Burning Wood