Beginners' Resources

- K40Laser: FAQ and How to

- LaserGods: Beginners' Guide

- Topics:

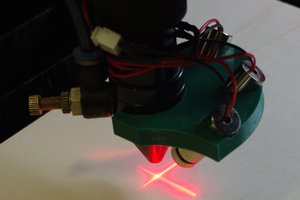

- How to align the mirrors: by HP Persson

- What materials are safe to cut? by ATXHackersspace

- Laser Lenses, Optics, and Focus by Tech Bravo

- Chinese K40 Laser Group. on Facebook

- Lasercutting on Reddit

- Lasercutter FAQ

Software (first two are a must have)

- K40 Whisperer - Alterative software to control the laser cutter (FREE)

- InkScape- Alternative software to draw/edit your designs (FREE)

- LaserGRBL - Alternative software to manipulate images and stream gcode to the laser cutter (FREE)

- Shaper Utilities- Save face/sketch in Fusion360 as SVG

- DXF for Laser (Fusion360 plugin) by Ross Korsky

- Slicer - Converts solids into laser cut slices by AutoDesk

- Stencilfy - Makes to join "islands"

- MakerCase - Simple custom case maker

- Boxes.py - Bazillion custom box scripts

Shopping Links (search for 'co2 laser')

Reviews and Tips from Owners

- Getting Control over a 50 Watt CO2 Laser Cutter from China by Erich Styger

- Test cutting different hard woods by Just Josh rfpom

- Control K40 using Raspberry Pi by NovaSpirit tech

- Don Kleinschnitz Jr.

- Settings (just for ballpark, varies greatly from machine to machine)

- The basic variables you control in operation are the power of the laser, and the movement speed of the head. You control the head speed through software, but the laser power with the control panel dial. You will use faster speeds and lower power for thin materials, and slower speeds and higher power for thicker materials. - Reddit K40 Wiki

- Daniel Flanagan: 10 - 15 mA at 10 - 20 mm/s for cutting (never above 15, as suggested), but for engraving I feel like 4 - 10 mA at 100 - 200 mm/s was working for me.

- Tony Hudson: Id say not fast enough 3mm about 12 as speed

- Nigel Davies: I can cut 3mm in one pass at 10mms 10mA

- Carlos Alberto: I cut 3 mm at 13 mah 11 mm/sec

- Jan Erik Laiti I cut at 8mm/s and 10 mA

- How to shorten the inside duct by Karl Laun

- Keep water temp between 17-20C to prevent blowing out your tube - Starla Fox

- K40 Whisperer > Raster settings > Scanline - start at 0.004 to start - you may have to up the power slightly but it will take half the time - John Bowley

Other Tips

- Use 50L/min aquarium pump for quiet air assist.

- What to do while waiting for the laser to ship.

- The laser is here! Now what?!

Inspiration

- Free SVG Image Gallery

- Topographical World Map by Prime8

- canvas. Spray pink paint, let it dry. Then spray red paint. Let it dry. Then spray black paint. Engrave. by Adam O'Brien

- Tips on etching edge-lit acrylic by Dominique Borer

- Layzor - Kit to completely upgrade the K40 by ManMadeMayhem

- Custom engraved work gloves by Eduardo Cervantes

- Boxed Set of Christmas Ornaments by Alin Draghiceoiu

- Lasercut toys by Ashley M. Kirchner

- HolgaMods - making a living using K40 and 3D-printing by Randy Smith

- Awesome Edge-lit Artworks by David Da Costa & Be Steve

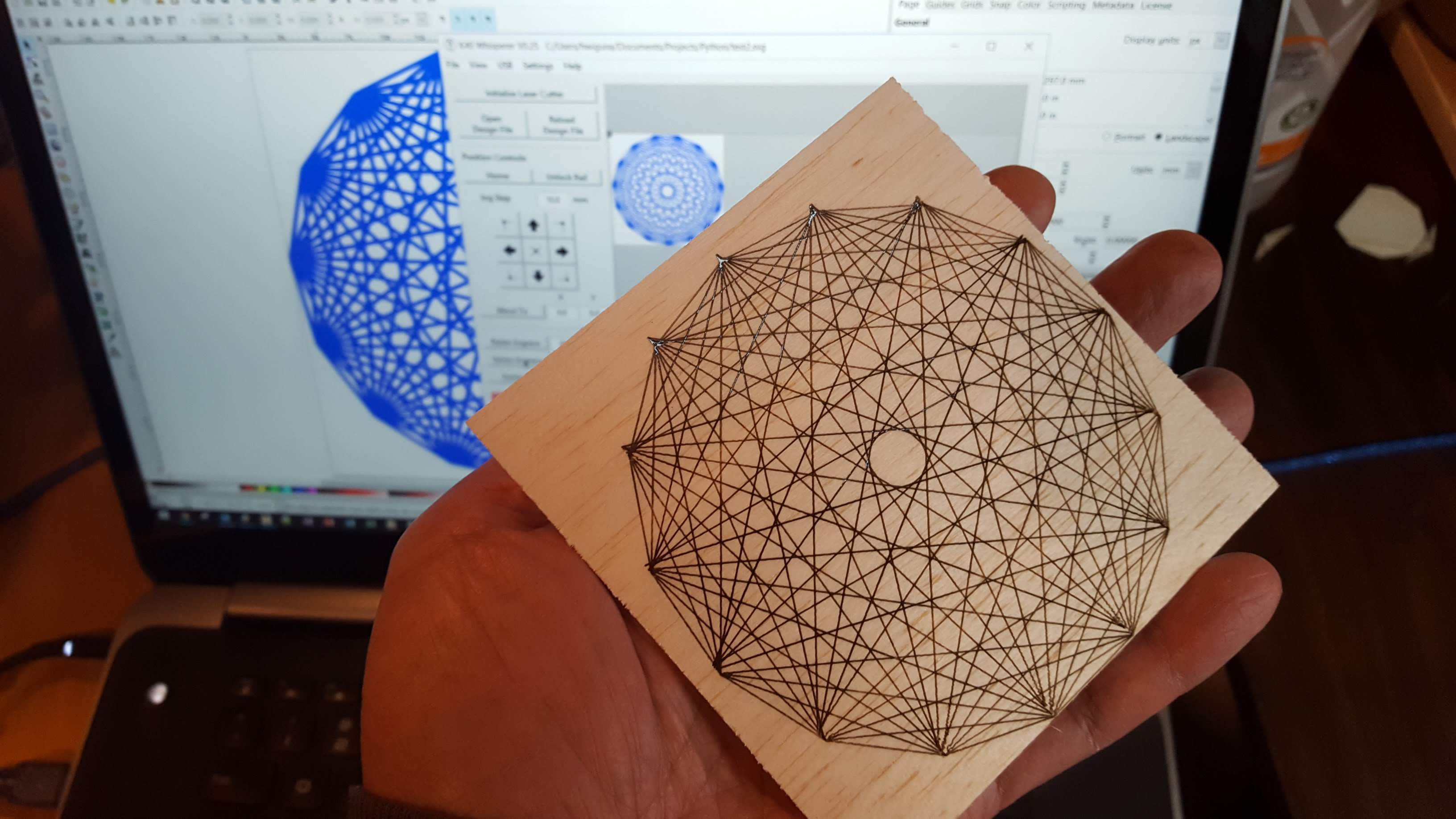

- 3D lasercut mandala by TheGorgonaut

- Jigsaw Puzzle Maker by Draratech

Hari Wiguna

Hari Wiguna

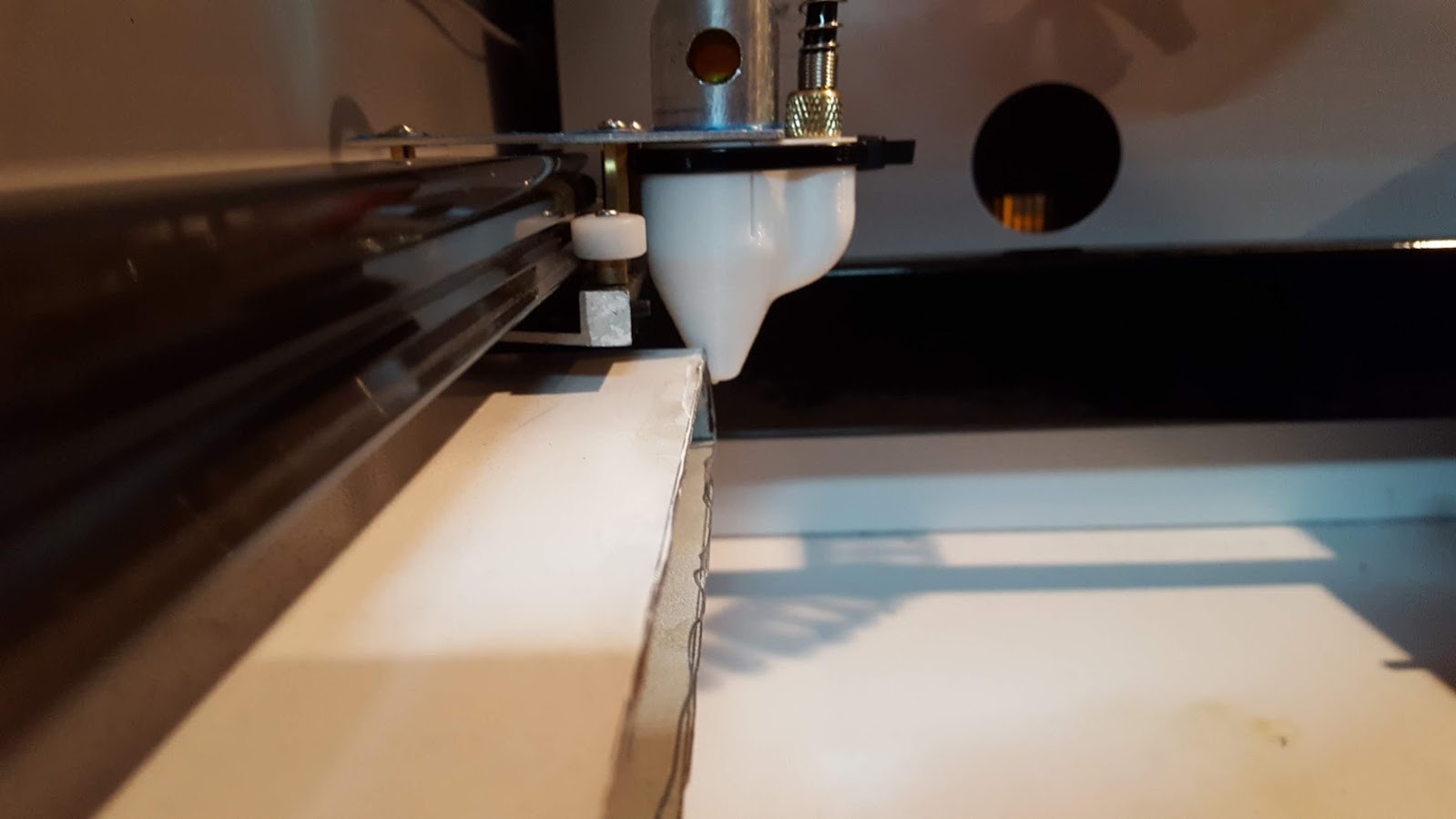

Practice run on cereal box cardboard.

Practice run on cereal box cardboard.

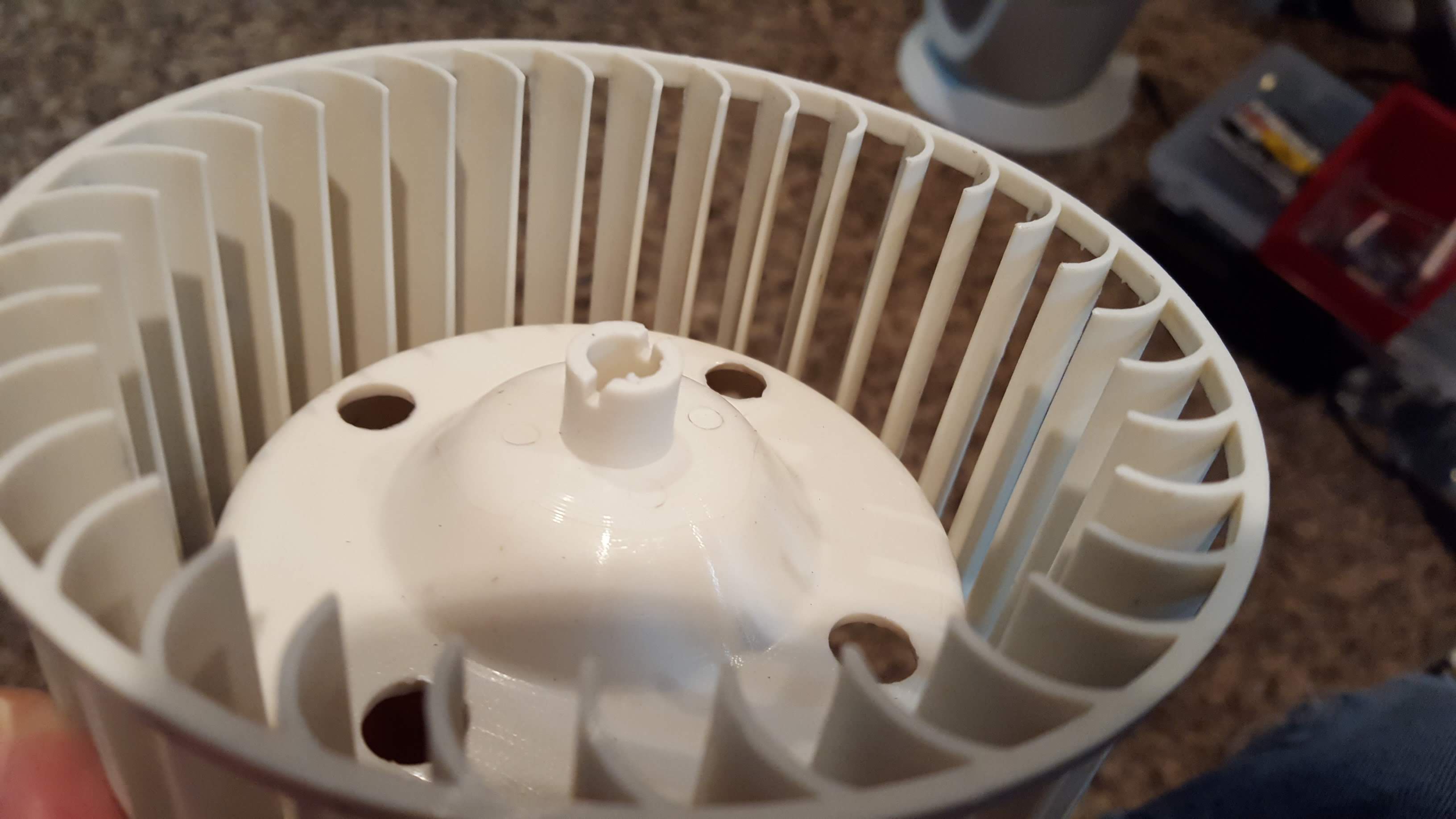

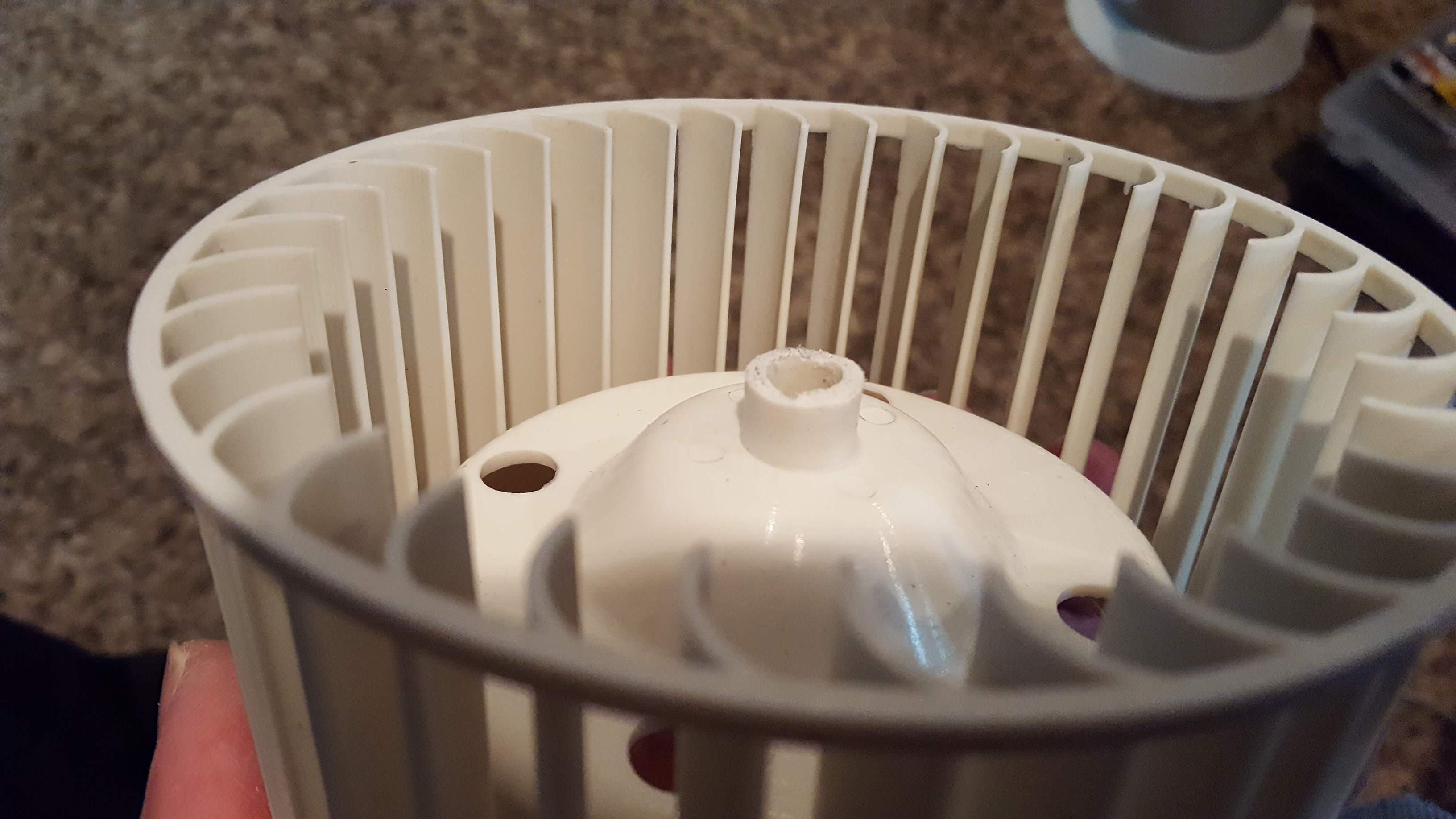

Nut was just a bit too tall. I had to shim the cover with two cardboard pieces so the fan would clear the cover.

Nut was just a bit too tall. I had to shim the cover with two cardboard pieces so the fan would clear the cover.

Peter Walsh

Peter Walsh

Jerry Biehler

Jerry Biehler

Florian Festi

Florian Festi

cpsprocket

cpsprocket

This is an incredible resource you’ve created. I’ve got my laser in a box ready to unpack when I found your project.

Thank.you.very.much!

I read Don’s blog on coolant. I was going to add car antifreeze as the coolant. Sounds like capacitive coupling is a problem. I live in a cooler region where the temperatures get below freezing during the winter. Are you in a similar region and, if so, how do you handle that?