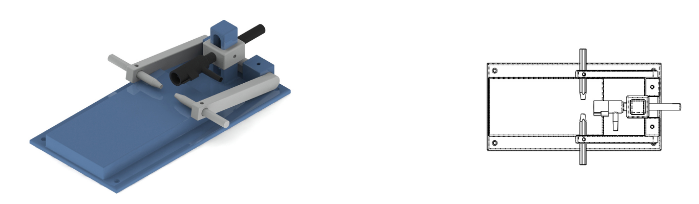

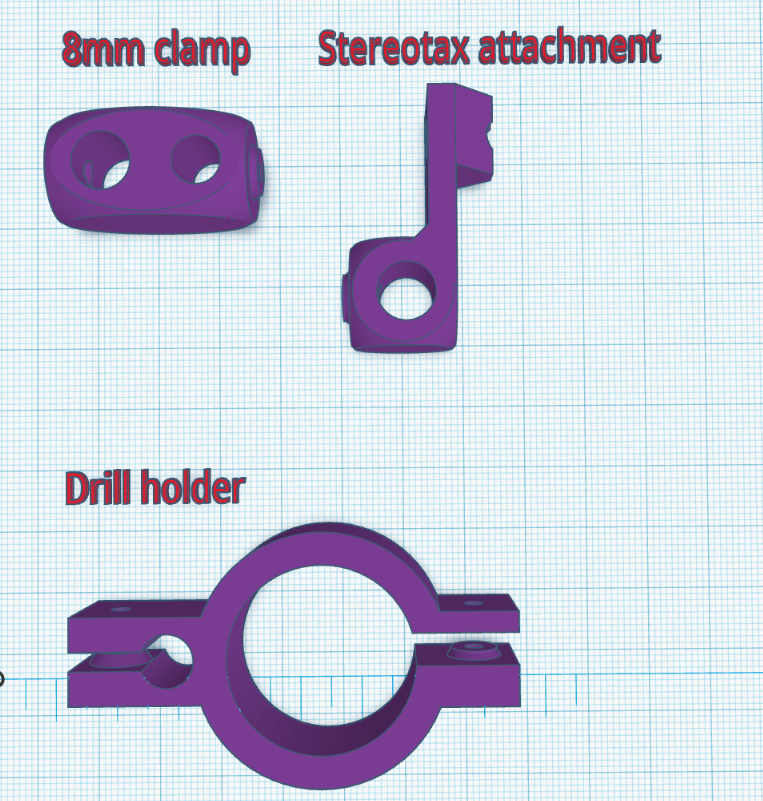

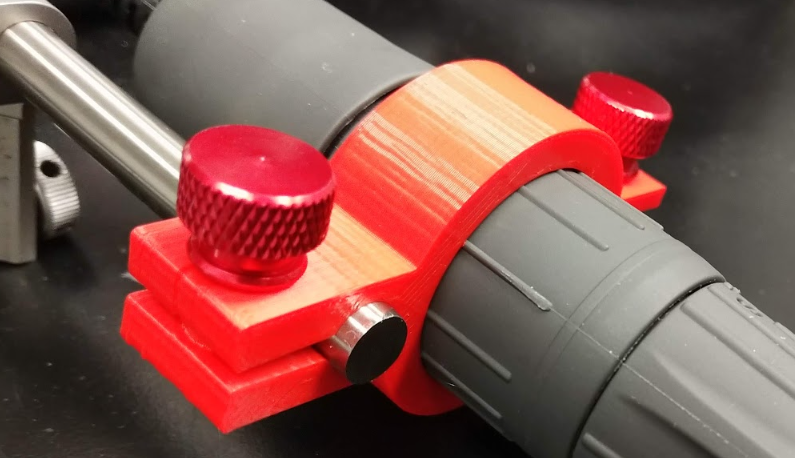

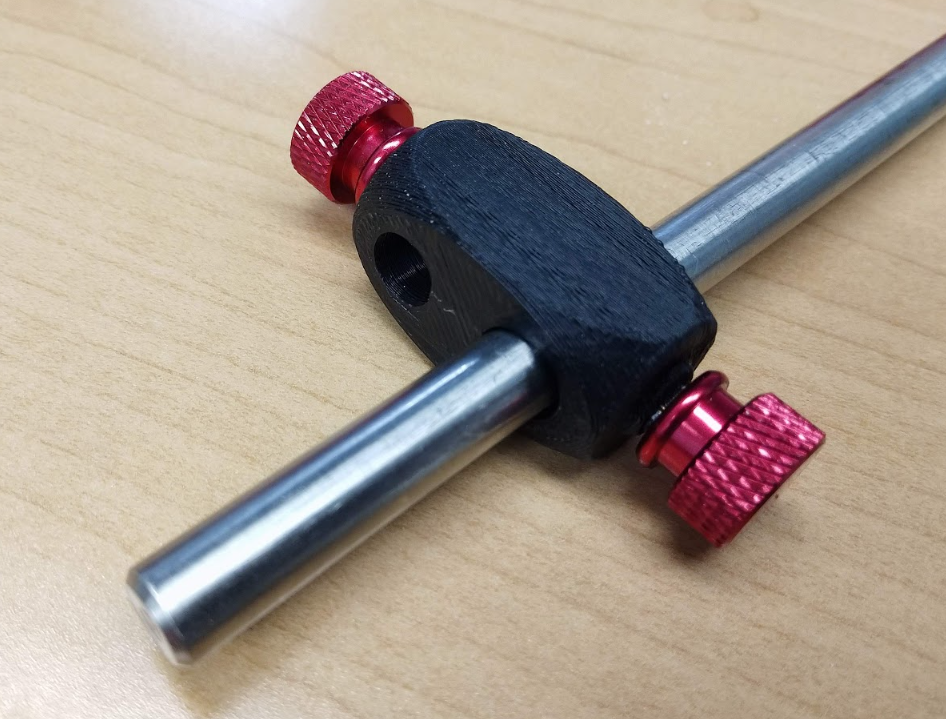

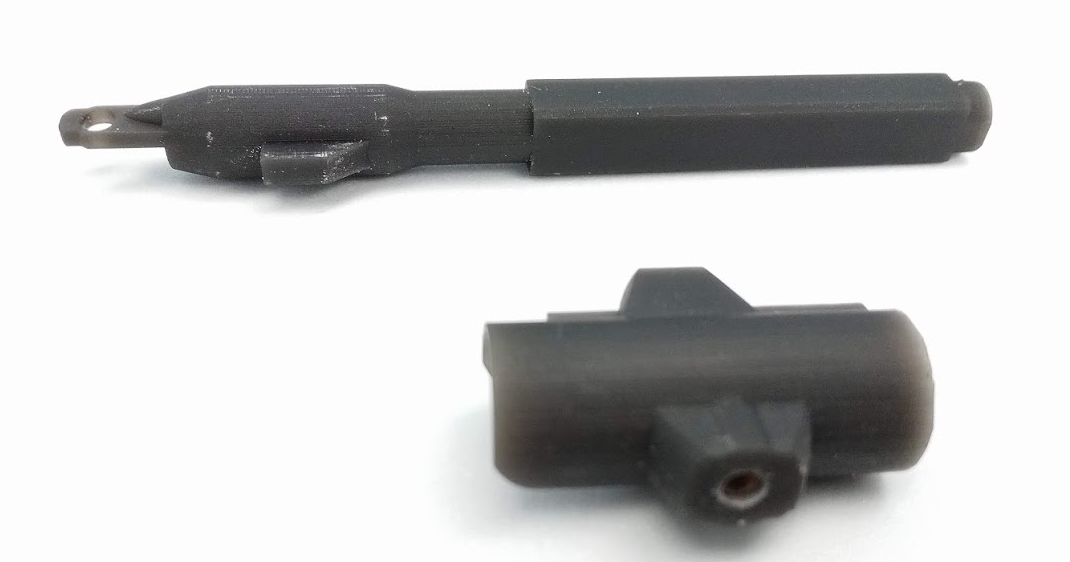

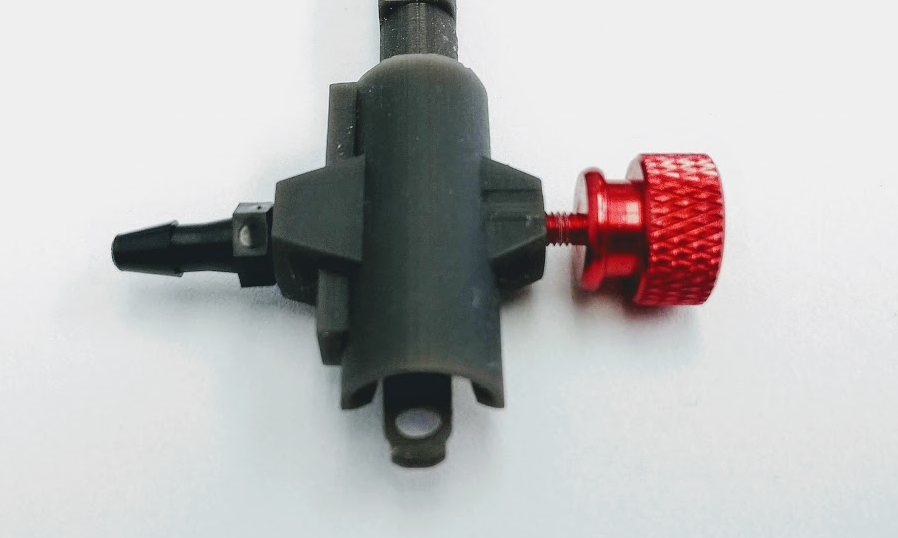

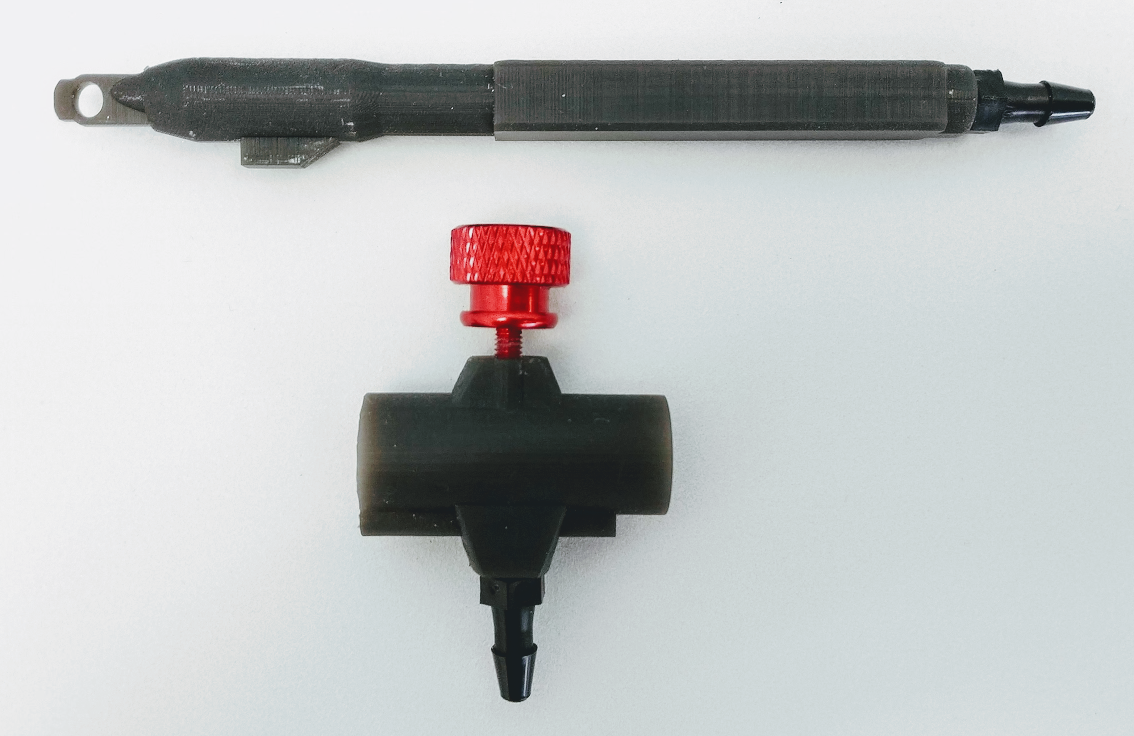

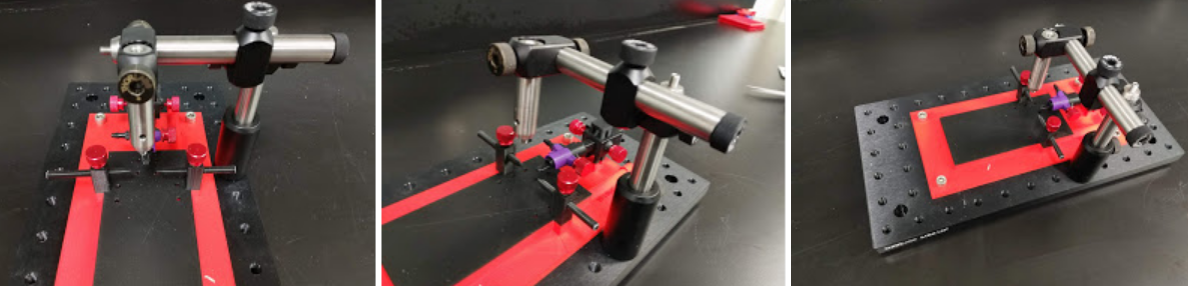

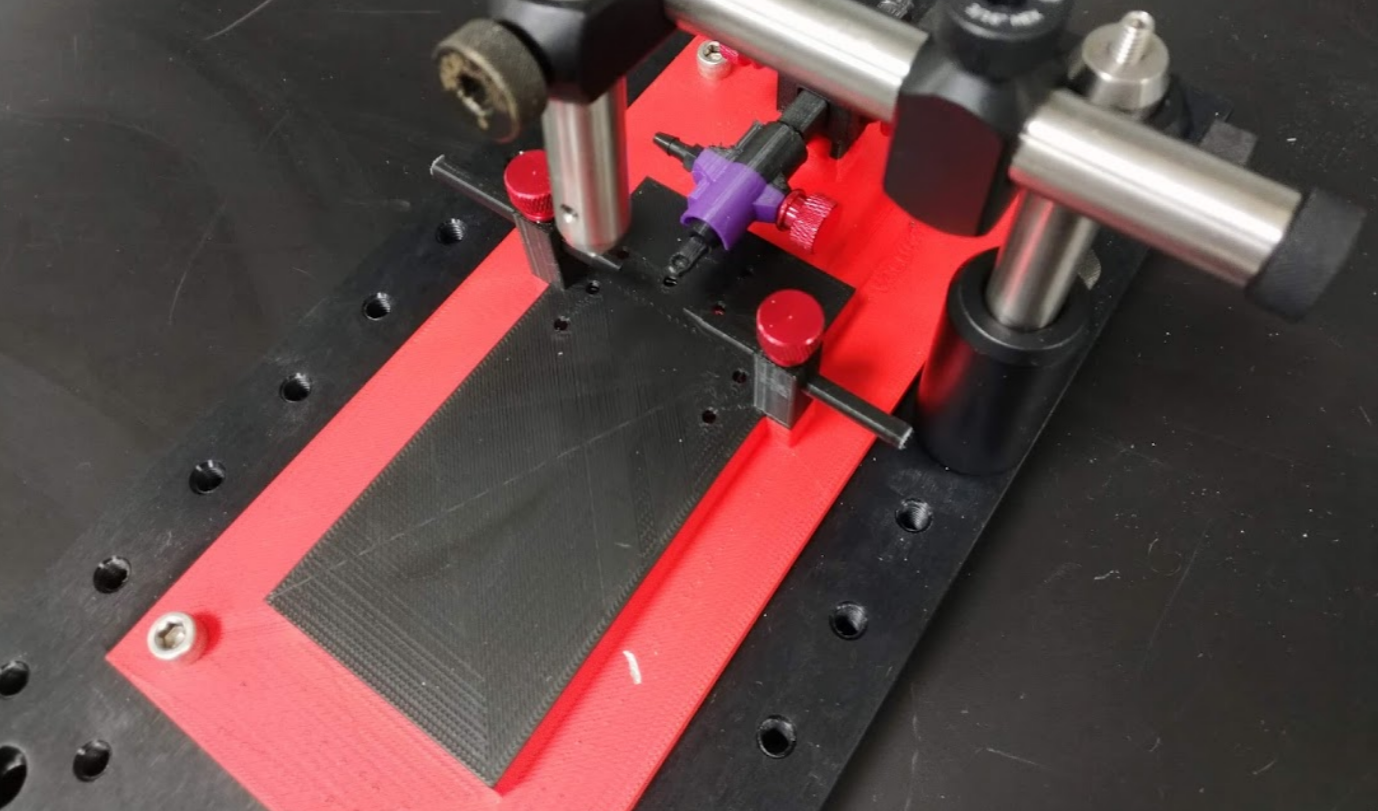

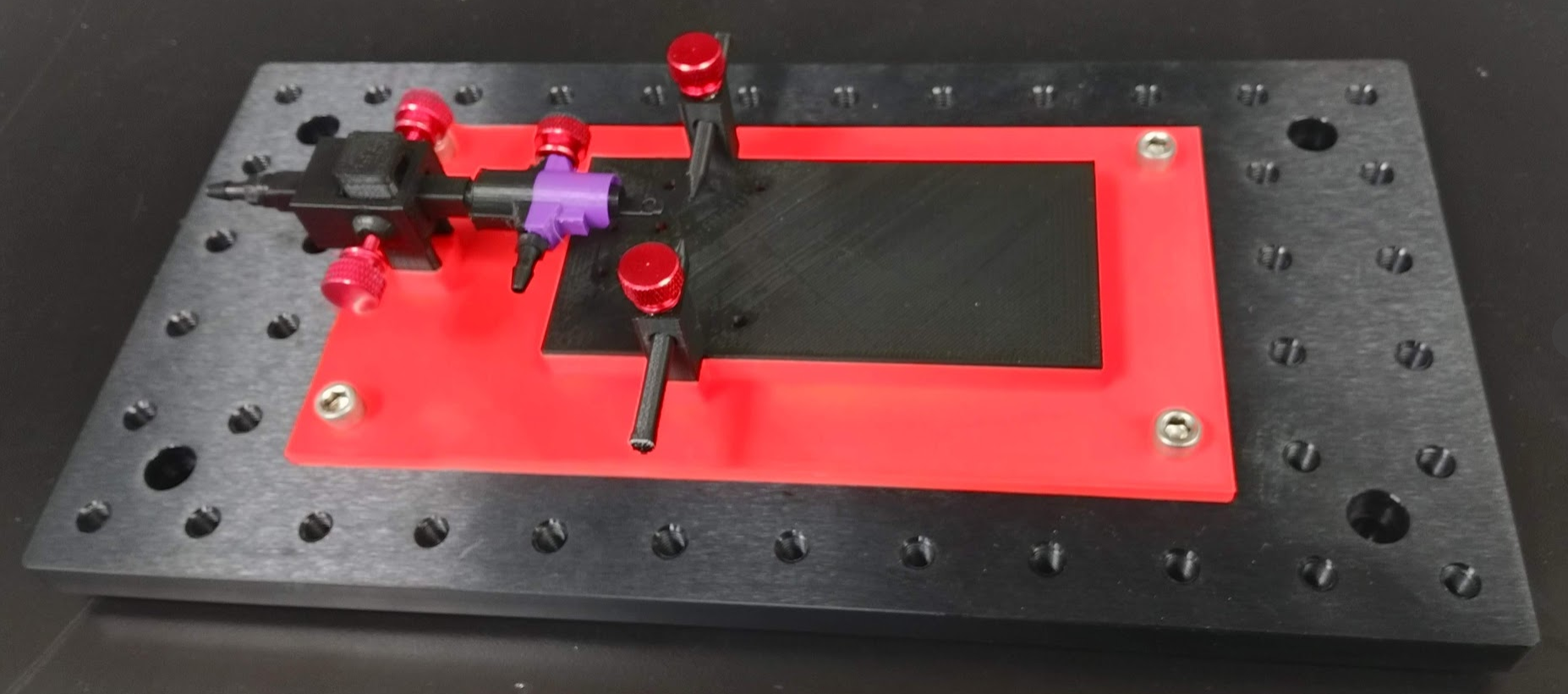

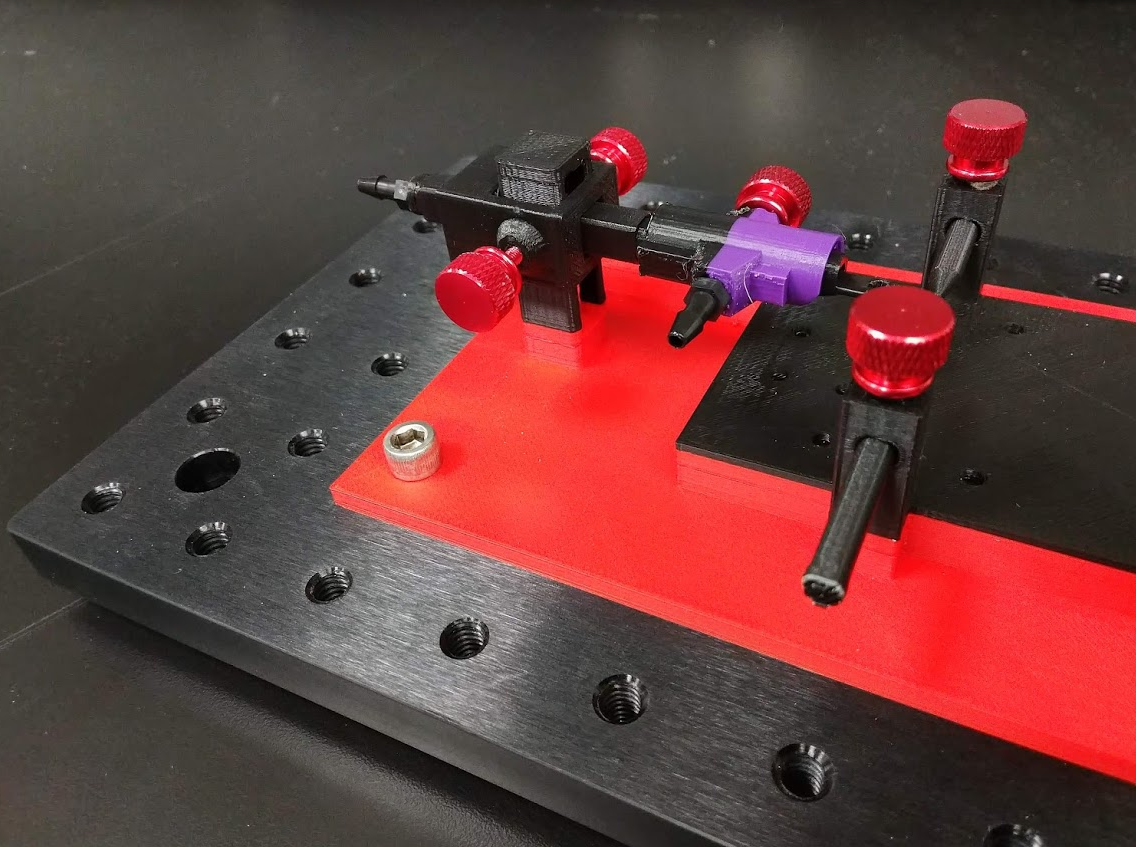

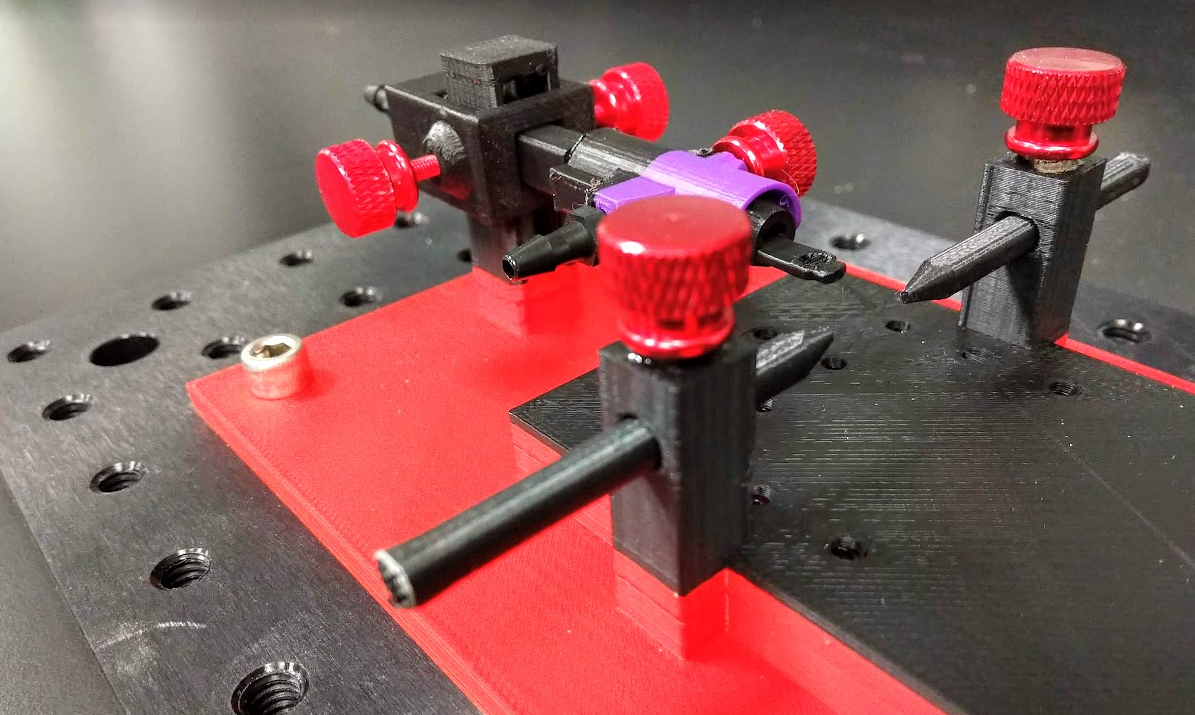

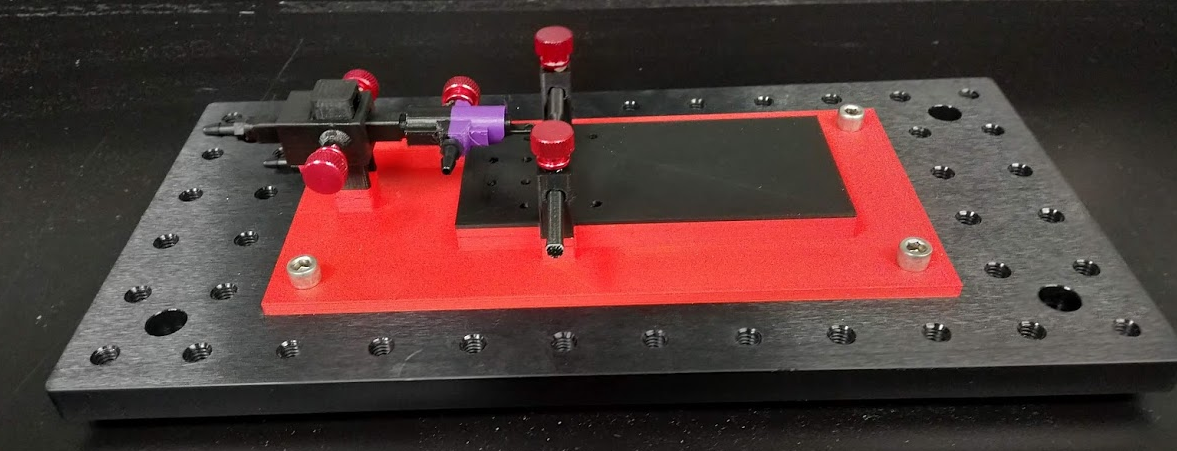

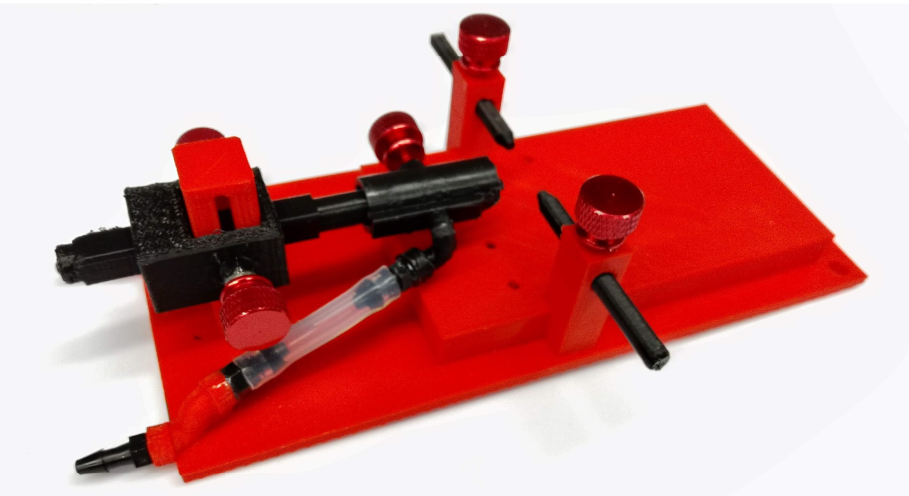

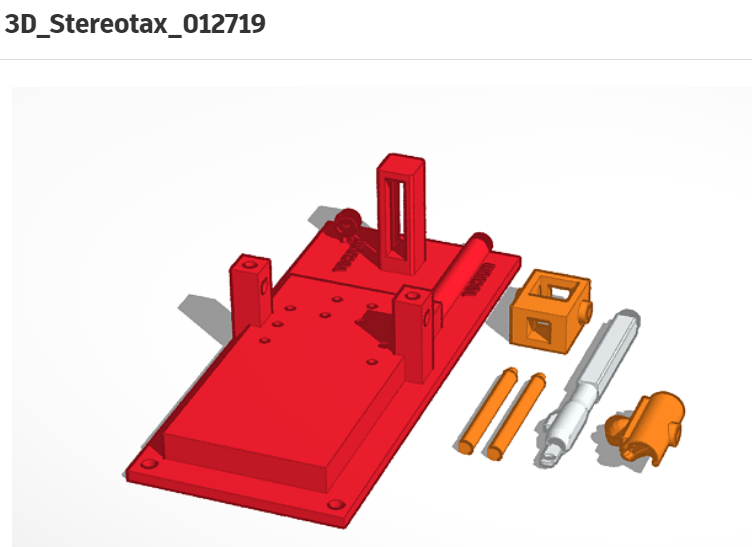

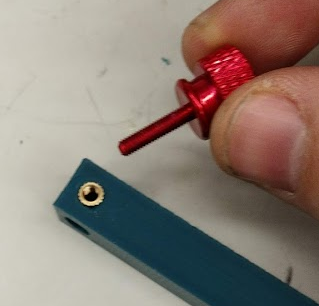

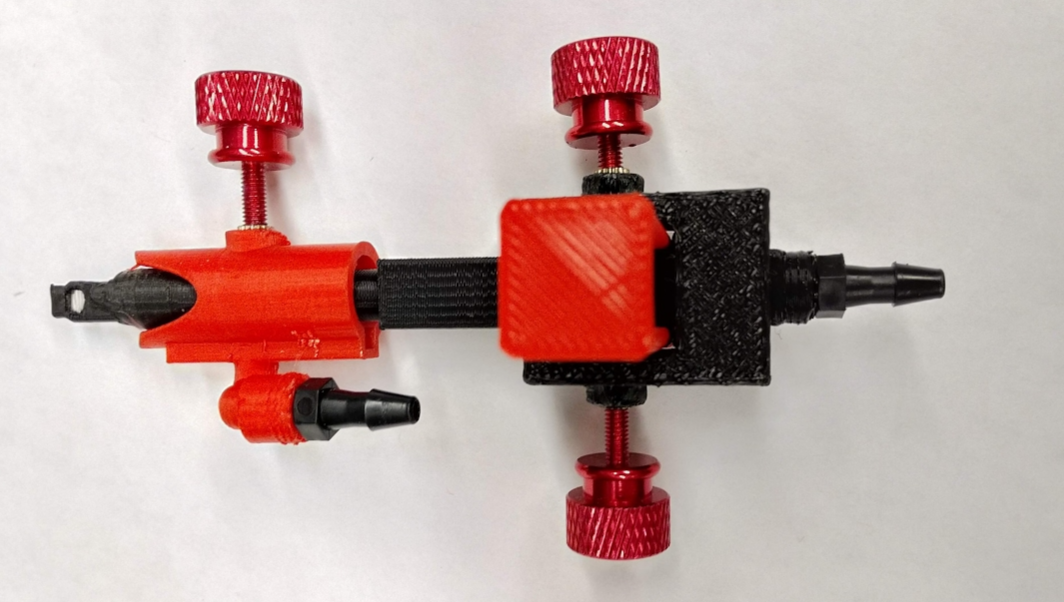

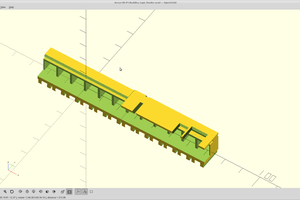

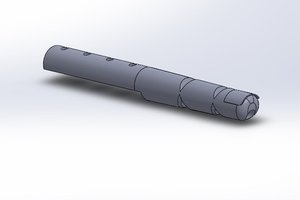

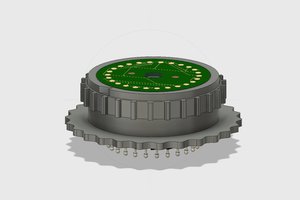

This 3D printed stereotaxic device was designed to be simple, modifiable, and low profile. It includes a gas anesthesia mask which has a vacuum line attached to the mask, as well as a mini down-draft table below the animal to scavenge excess gas.

Disclaimer: your printer might not print air-tight parts, so if you use this with anesthetic gasses make sure to monitor for leaks - if you can smell the anesthetic gas it means there's a leak and you should stop using it! Coating the parts with acrylic or epoxy may reduce leaks.

This project is released under the terms of the Creative Commons - Attribution - ShareAlike 3.0 license:

human readable: https://creativecommons.org/licenses/by-sa/3.0/

legal wording: https://creativecommons.org/licenses/by-sa/3.0/legalcode

This project was based on an earlier design by John E Martin that was generously shared with me by the author.

Lex Kravitz

Lex Kravitz

Daren Schwenke

Daren Schwenke

Alan Chambers

Alan Chambers

Lolsborn

Lolsborn

Is this for rat or mouse?