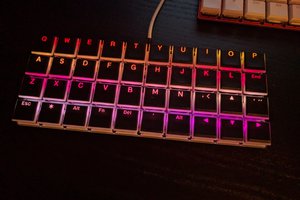

Thumb Keyboard

Experimental thumb keyboard, suitable for a hand held device

Experimental thumb keyboard, suitable for a hand held device

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

I'm working on a new method for producing the labels. The existing system (mis)uses a spreadsheet, but I would like something better.

The new method uses a Python program with the Python Image Library (PIL) to create a bitmap image of the labels. The required layout will be defined in a separate file that the program will process. The resulting bitmap can then be

So far I've hit a couple of snags. The first one is that despite the resulting bitmap having a DPI setting to indicate what size it should be printed at, many programs that print bitmaps "helpfully" scale it to fit the page, even when I think I've turned off all the "scale to fit page" options. I've found that GIMP will print at the correct size as long as I don't print preview first.

I can't control what software will be used to print the bitmap, so I've added a couple of scales, one in centimetres and one in inches, so at least you can check if it's printed correctly.

The second snag is that fonts in PIL are not anti-aliased, reducing the print quality. Producing the bitmap at a higher resolution should work around this.

This is not finished yet but when it is I'll compare it with the old method to see if it's worth switching.

I've updated the base library at https://dboucher.org.uk/keyboard/Thumb_Keyboard.zip to the current Arduino and PlatformIO standards, so you can now install it in Arduino using the "Add .ZIP Library" option or in PlatformIO using:

platformio lib install https://dboucher.org.uk/keyboard/Thumb_Keyboard.zip

My next task is to do the same for the 23017 version of the library and move the key label and 3D printed part files into the "extras" directory of the base library to finish tidying things up.

EDIT: All done.

After I uploaded the last version, I realised that I had forgotten something in the event reporting: raw key numbers. These give the position of the key regardless of what that key is mapped to. For example, key 15 might be a "y" in an English layout or a "z" in a German one. As this can be useful in some applications I have added it to the library.

Keys are numbered left to right, top to bottom, with the top left key being zero. As usual, the downloads can be found at https://dboucher.org.uk/keyboard/.

As promised, I've updated the main download and you can get the new version here. This contains the Arduino libraries from the last update, the improved label spreadsheet and the new keyboard back panel as shown below:

This is the same as the previous version, just with new labels and the back panel. I also removed a row of holes from the bottom and sides of the perfboard as they were surplus to requirements.

The case back slides up and over the sides of the bezel and the end result is a nice tight fit.

This update has been delayed a little due to other commitments, but I've finally finished converting the keyboard scanning software into Arduino libraries. There are currently two versions: the base version is for use when connecting the keyboard via GPIO pins (download link) and there is a second version for connecting via an MCP23017 I/O expander chip (download link).

Both versions come with an example program which will appear in the Arduino IDE's examples menu when the library is installed. The base version has no dependencies but the 23017 version depends on both the base version and the Adafruit 23017 library, which you can install from the library manager.

My next task is to update the main download (the one with the software, labels and 3D models). Hopefully, that won't be delayed as much as this update!

There are currently two versions of the software in the download: one that connects to the keyboard directly via GPIO pins and targets an Arduino Uno, and one that connects via an MCP23017 I/O expander and targets an ESP8622 board. Both versions take the form of a single source code file.

To make things more flexible, I'm in the process of converting the software to a set of Arduino libraries. There will be one library for the hardware independent code and libraries for each interfacing method (direct GPIO, I/O expender, whatever else).

Once I have converted the code, the steps needed to use it will be as follows:

I've also finished tweaking the layout spreadsheet, at least for now, however I've not uploaded the new version yet. I'll add that update when I've finished the software changes.

Currently working on improving the labels.

Here is what I've found so far:

This is never going to be a mass produced product but I would like assembly to be as simple as possible, so I'm going to keep working on this until I have a good system.

I've improved the key label spreadsheet (LibreOffice) so that you can just enter what you want to appear on each label, run a couple of macros, and get a page of labels ready to print.

You set the number of rows and columns that you want, the colours that you want to use and what you would like to see for the unmodified key plus the two modifier states. Press the "Create Key Label" button and a macro will construct each label in the "Key Label" column. If you don't like how any of the have turned out, put what you would like to see in the "Override" column and press "Create Key Label" again and the value from the "Override" column will be used. Finally press "Create Label Page" and a page of labels, repeated as many times as will fit on the page, will be produced in the "Labels" sheet ready for printing.

There is more information in the "Instructions" sheet. I've updated the download and you can get the new version here.

As promised, I've uploaded the ESP8266 version here. You will need an MCP23071 I/O expander chip for this one (see previous log).

Although the version in the archive targets an Adafruit Huzzah ESP8266 board specifically, the target can easily be changed to another ESP8266 board or anything that has an I2C bus and a PlatformIO target.

As some point I'll convert the software to an Arduino library. As there are multiple ways to interface to the hardware (GPIO pins, I/O expander chip), I think I'll need to need to split the code across two libraries in the same way that the Adafruit TFT libraries work: a low level library that accesses the hardware and a high level one for the keyboard handling code that's independent of the hardware access method. This is something for later though.

My keyboard needs one GPIO pin for each row and column, so for a 10x4 layout that's 14 GPIOs. Most Arduino style boards can accommodate this, but it takes up most of the pins. Other types of board, such as ESP8266 and Raspberry PI, don't have nearly enough pins though. What to do? Use an IO expander chip of course! These types of chip provide a number of GPIO pins that the host accesses via a serial protocol, usually I2C or SPI. This means that the host only needs to support the relevant serial protocol which generally only requires 2-5 pins. You could also run other devices off the same serial bus without using any more pins.

Here I am using an MCP23017 IO Expander chip with a Teensy LC. The only other components needed are two 4.7KOhm resistors to pull up the signals on the I2C bus. I'll document this properly another time, but you can see from the picture above I'm only using a small number of pins on the Teensy, leaving most of them free for other things. Only minor changes are needed to the software, Adafruit produce a library for the 23017 which provides equivalents to the standard Arduino digitalRead()/digitalWrite().

The 23017 has 16 GPIOs, which means that I have two spare here which I could you to add more rows or columns. The chip also has three address pins which can be pulled high or low allowing for a up to eight chips on one I2C bus, giving a total of 128 GPIOs, more than enough for any thumb keyboard.

I'll release the software soon, including a version for ESP8266.

Create an account to leave a comment. Already have an account? Log In.

Interesting device. Let me share this with our team at https://www.queensnycconcrete.com, I'll let you know if they liked it as well.

I'm working on something similar. Your key label system is really well done!

I'm thinking of using a specialized keyboard breakout like the ADP5588 instead of a generic GPIO breakout. Did you explore that option?

I'd not thought about the ADP5588, but it would be a good thing to add. Thanks for pointing it out.

I've had good luck with the TCA8418 so far. Seems like there's support for it in the Linux kernel too so it may be usable on the raspberry pi. These folks got it working: https://hackaday.io/project/5081-malti/log/17068-it-lives

See how this feels before thinking about using staggered rows. Staggered rows were introduced in typewriters originally so that the typebar mechanisms would be spaced at a regular interval. This is completely unnecessary with electronic keyboards, but still the tradition lives on.

I agree that staggered rows are not necessary here, but some people might want them as an aesthetic feature. If I add them it will be as an optional element of the design.

Staggered rows are not strictly aesthetic; they help the typist locate their fingers without looking at the keyboard, they do, however, use more space.

What You think abot this? http://klawiatura.wordpress.com/

Is possible add 2 rotor for sound/volume ,obj 3d manipulation etc. Second trouble are different size of keys.

Interesting article, thank you. The aim seems to be the same as mine, but with a different approach: instead of customising the keyboard, make one keyboard that works for any language. The problem with that approach is even if you make all the necessary character available, every language has a different preferred layout. English speakers want QWERTY, French AZERTY, German QWERTZ and so on.

Second answer: you can add whatever you like to the keyboard, rotors, LEDs, whatever, the design is meant to be flexible. As you say though, different sized keys would be difficult.

The problem is not the layout of the keys, this one can be changed programmatically, but their number.

Unfortunately, for example, the French have a lot of national characters and the Spanish characters are diacratic.On the website you have other layouts, eg adapted to laptops, which are wider in height.

In my opinion, give people a chance for a universal keyboard, and the software will do it themselves.

Rotors are usefull for input analog dataBecome a member to follow this project and never miss any updates

RunnerPack

RunnerPack

Pamungkas Sumasta

Pamungkas Sumasta

deʃhipu

deʃhipu

The printed bezel is an excellent solution! Exactly the kind of thing I was looking for but could not find anywhere else. As far as anti-aliasing goes, you might be able to get around that by using monochromatic bitmaps, which I think has its own file type.