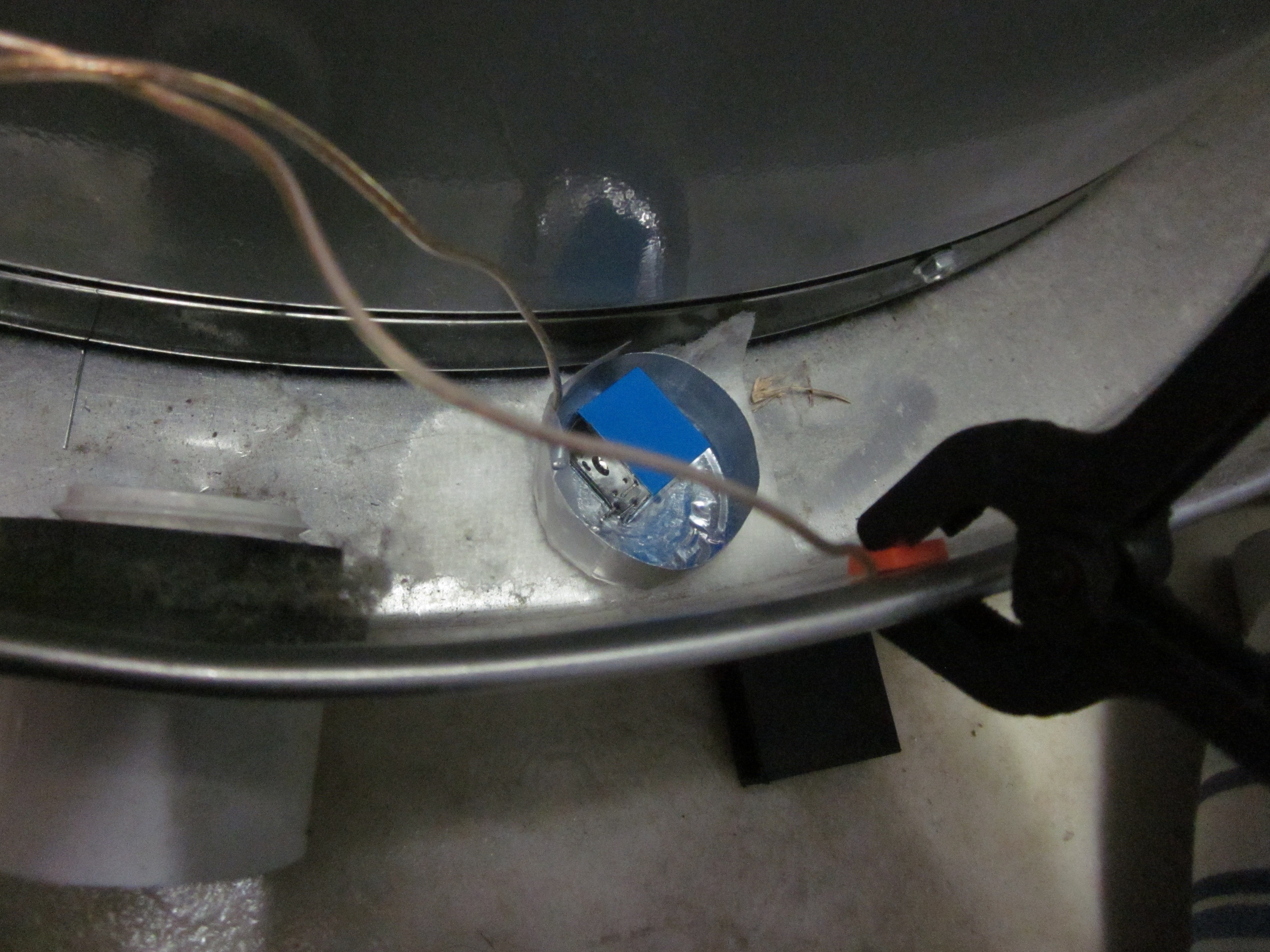

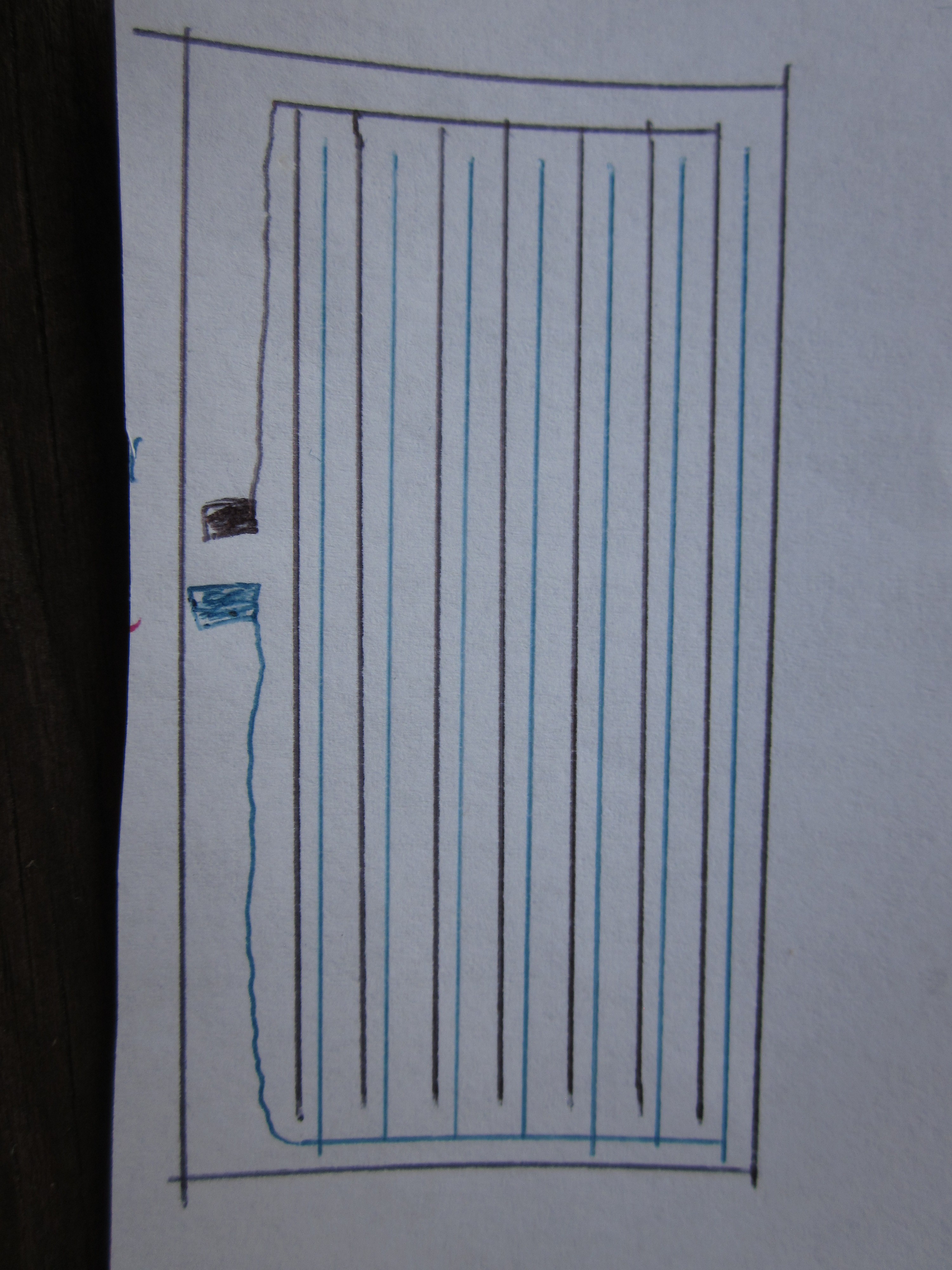

I've learned a few things from the original project. The most important how to set up to leads to be most effective. If something such as a water heater sits on a metal drain pan, it makes sense to attach one of the leads to it, and thus make the drain pain an electrode. Using something such like an aluminium shell of a tealight candle can be used for the other electrode and the two can be separated by a piece of paper towel as shown in the photo below.

If one isn't lucky enough to have something in the environment to serve as an electrode one could use something such as a piece of aluminum foil placed flat on the floor, a piece of paper towel, and the other electrode on top.

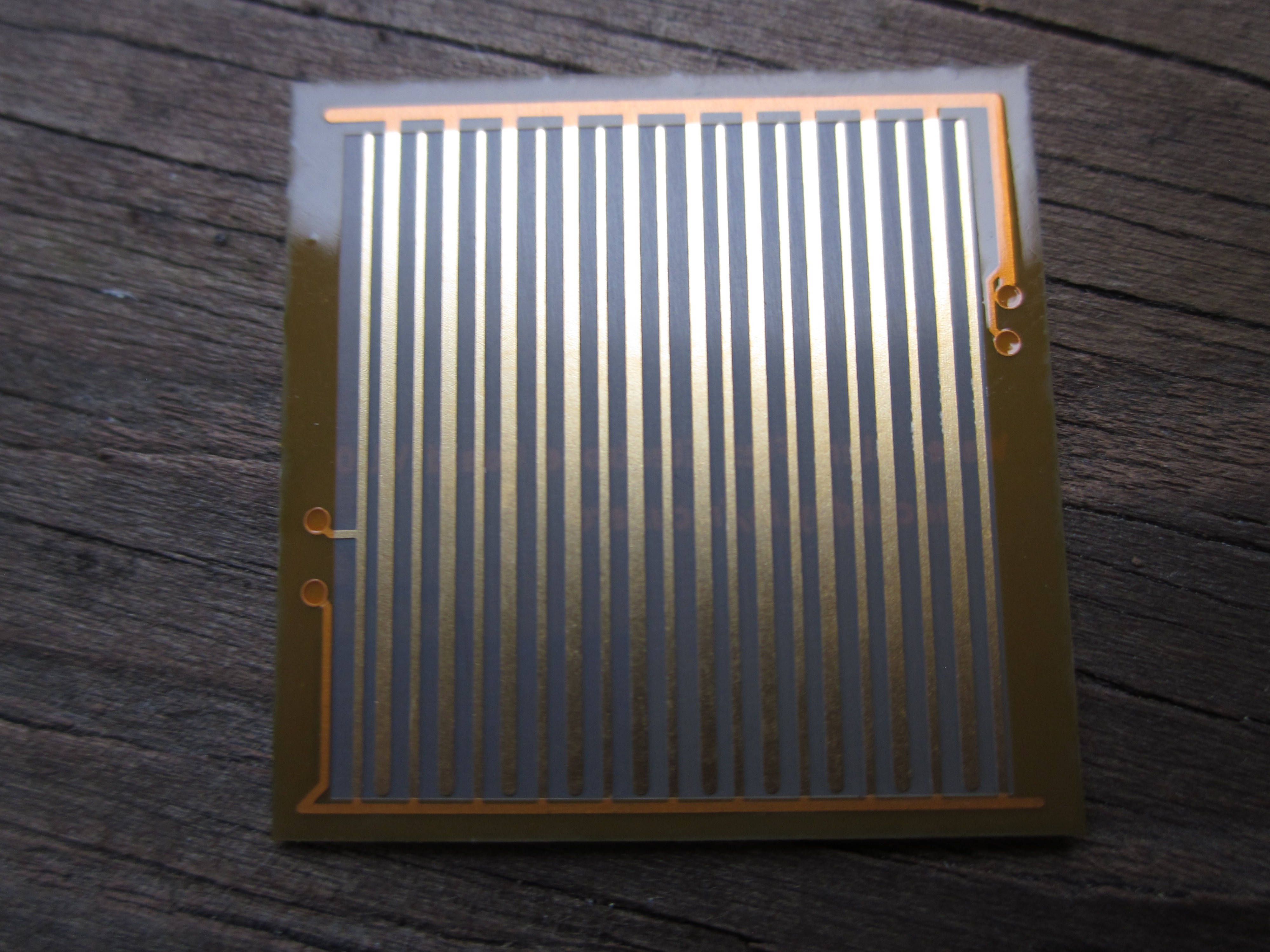

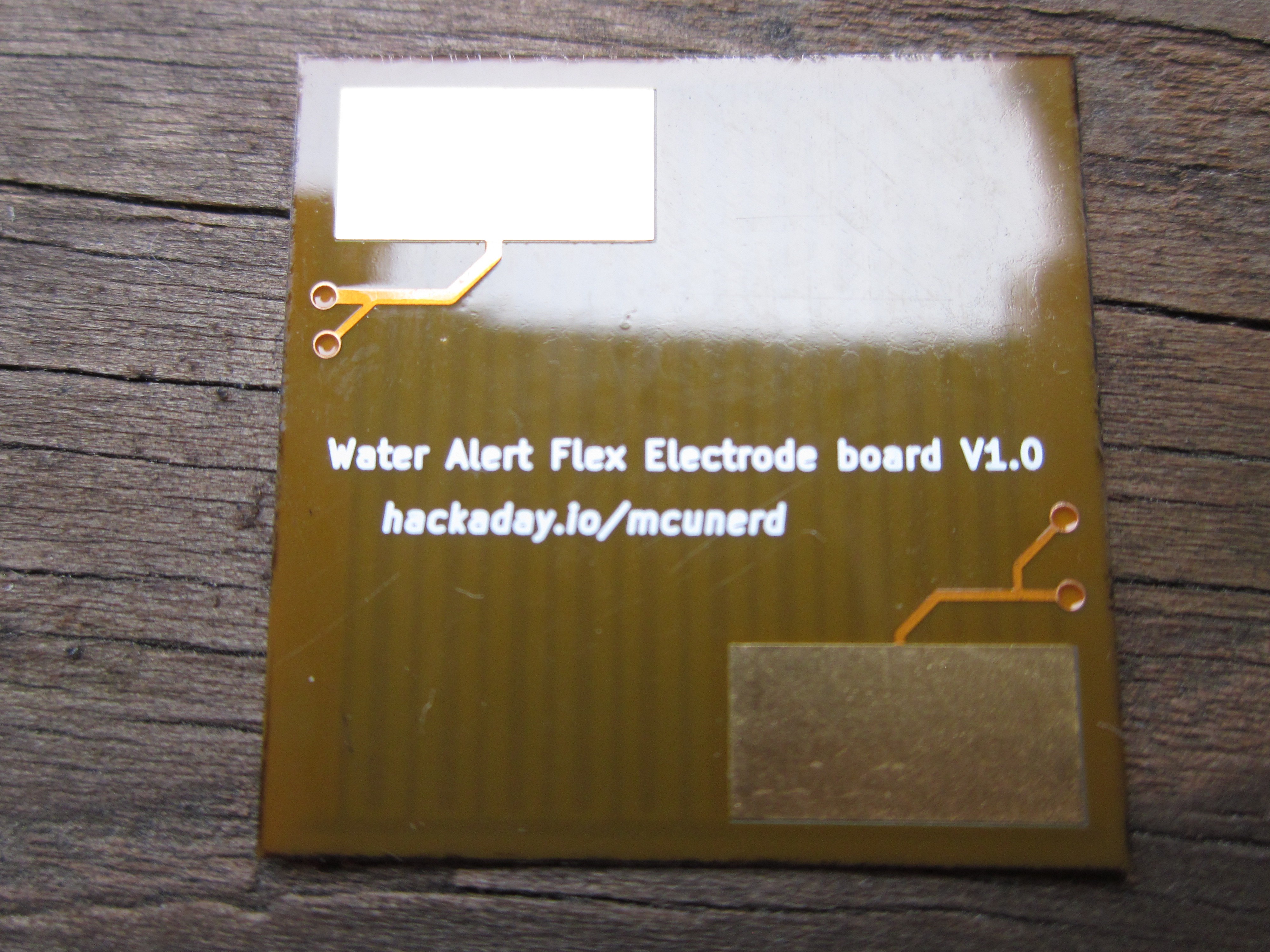

Flexible PCB concept is located on this project log entry page:

https://hackaday.io/project/164512-water-alert/log/163404-flexible-pcb-contest-entry

Paul Andrews

Paul Andrews

Matthew James Bellafaire

Matthew James Bellafaire