-

Teardown and partial schematics of a battery charger

03/10/2024 at 04:47 • 0 commentsI got bored one day, so I cracked open a battery charger I got. I was curious if it was just a dumb charger when it came to 9v batteries like many chargers out there, or it actually monitored the state of charge. The model of the charger: EBL-C802.

![]()

With it opened up:![]()

It quickly became obvious why this charger requires charging AA/AAA cells in pairs. It charges two cells in series. It's likely done this way as a cost reduction measure. Sadly the main chip that controls the charging is missing a label, almost certainly sanded off.

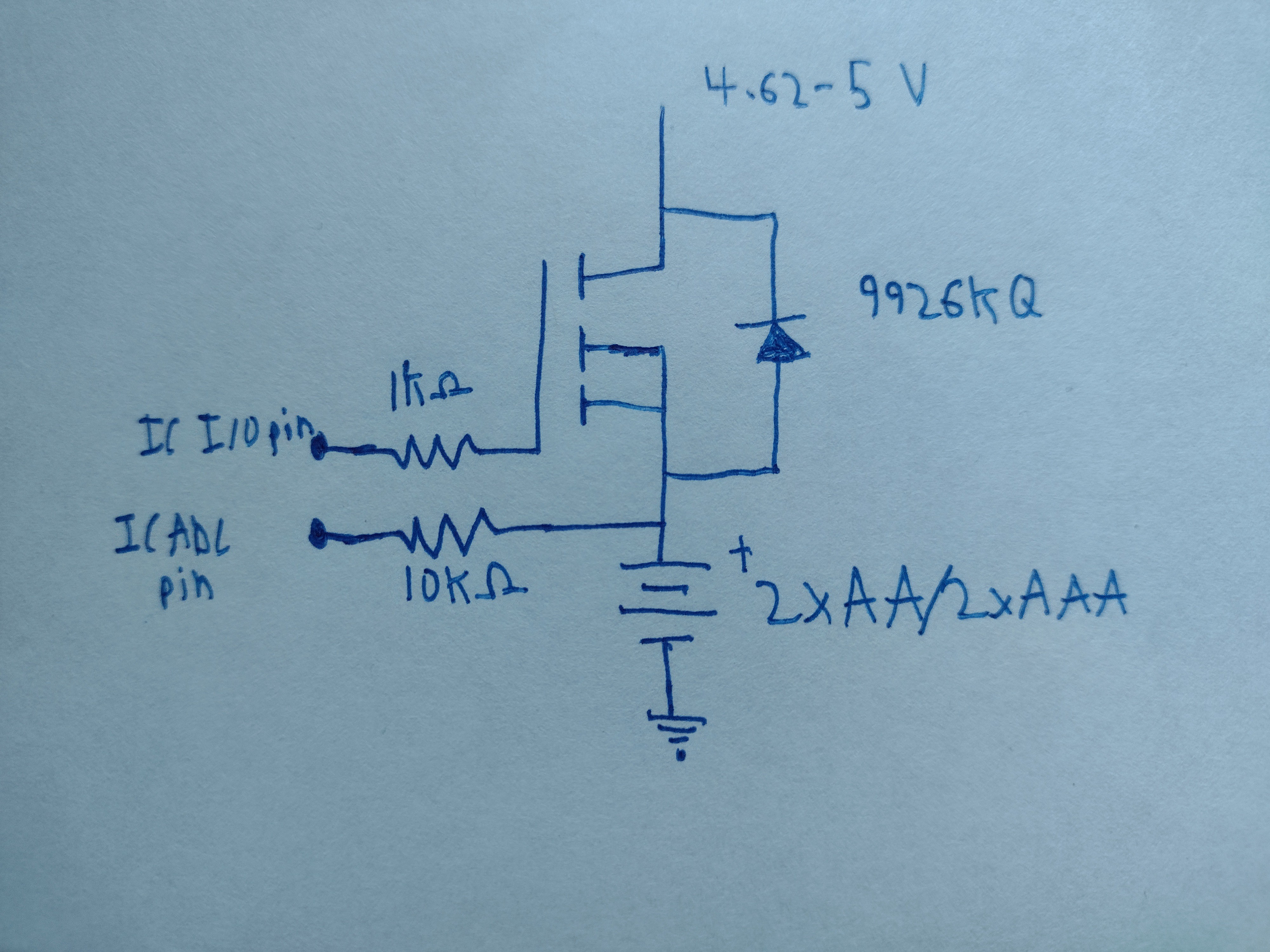

Below is a schematic for the AA/AAA charging circuit. There's two circuits for charging two pairs in total. It's a pretty simple circuit. A mosfet is turned on/off to control charging and voltage of the two cells in series is monitored by the controller chip though a 10K ohm resistor.

![]()

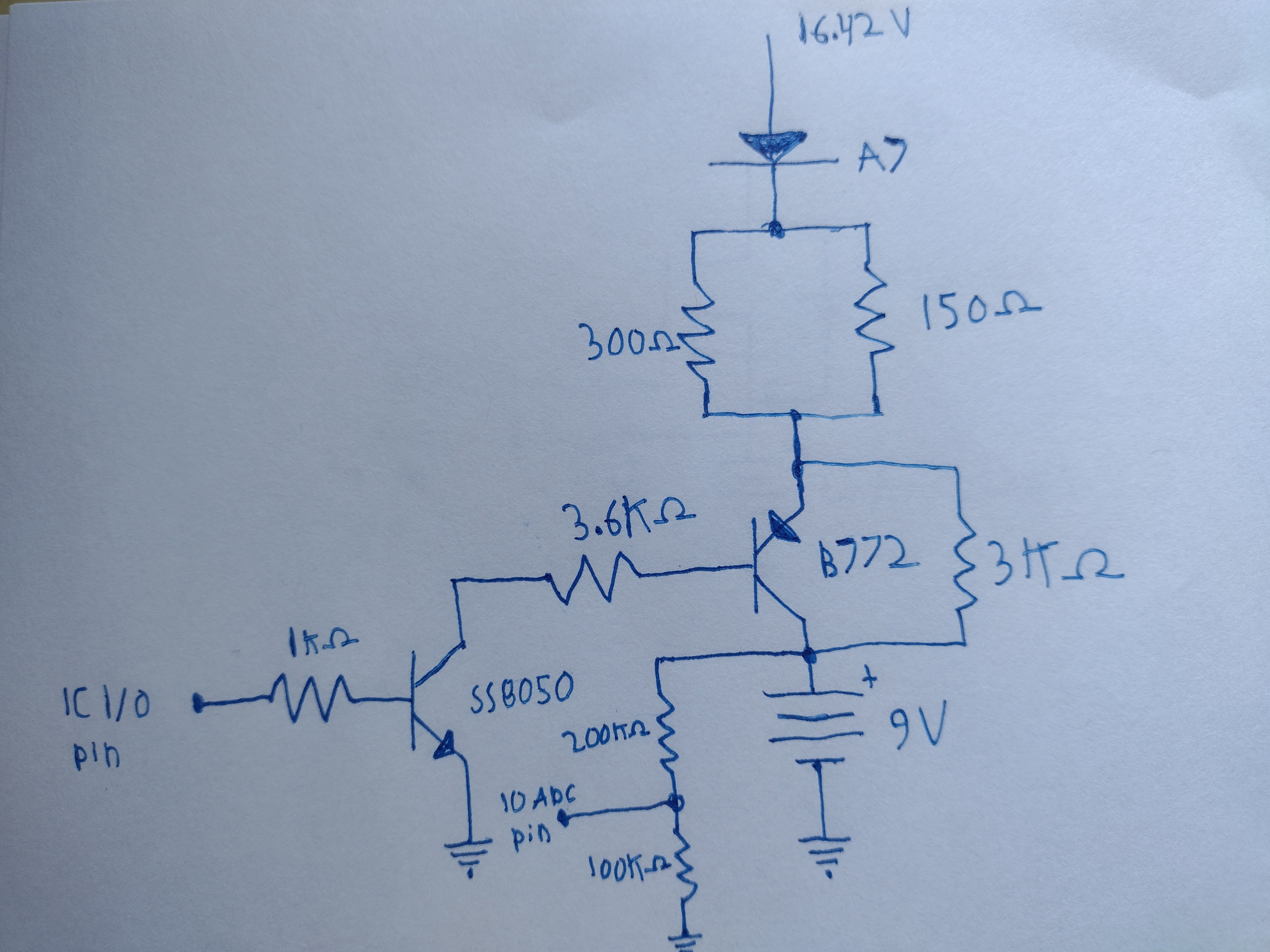

Below is a schematic for the 9V charging circuit. There's two circuits as two 9V batteries can be charged at a time. This circuit is a bit more interesting. It doesn't operate as a dumb charger as the controller chip is apparently monitoring the battery voltage via a resistor divider. The circuit trickle charges the battery even when the B772 transistor is turned off via a 3K ohm resistor.

![]()

I have some other observations to note about the charger, but it's close to midnight for me. I'll be sure to update the page later.

-

Be careful about using ultrasonic cleaners with UV LEDs on PCBs

02/11/2024 at 15:07 • 0 commentsA little backstory: I got invited to a review program a while back and get various products in exchange for leaving reviews. When I saw I could get an ultrasonic cleaner, I grabbed it. It's fairly small in size, and the indented usage is for cleaning dental related products and hence why is has UV LEDs for sanitation.

I decided to see how well it does at removing flux on a PCB, so I placed a small PCB with some detergent 8 and let it run. After its 5 minute timer expired I checked it and it was far from done. After running it again, again, and again (there's no longer runtime timers for it) it got cleaned.

Later on I noticed something looked "off." I compared an unused PCB from the same batch with one that I put in the ultrasonic cleaner and saw a stark difference:

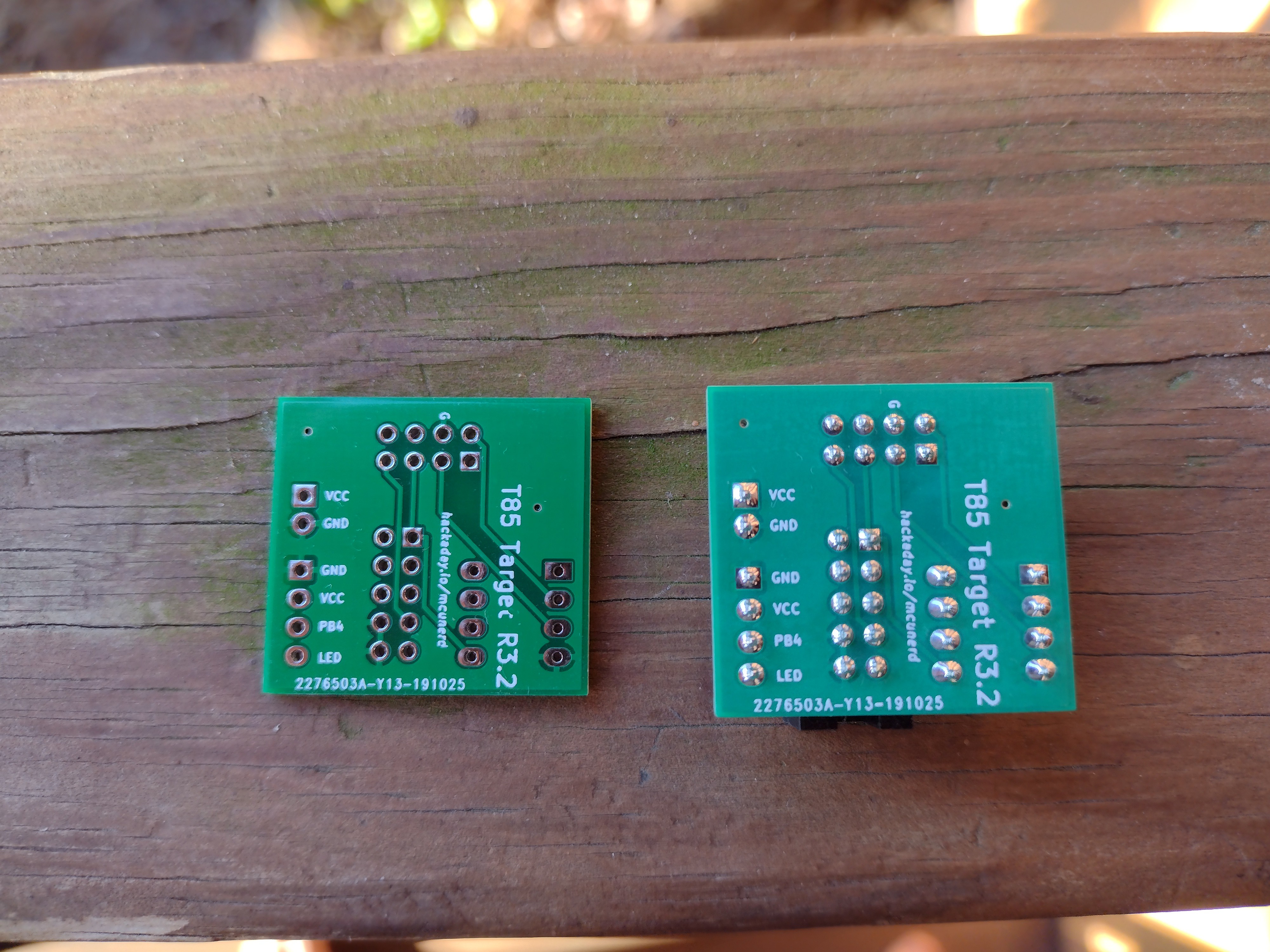

![]()

Yup, those UV LEDs apparently faded the soldermask. Looks like using the little ultrasonic in this manner isn't feasible without either modifying the cleaner by cutting power to those LEDs or by using something to block out the light from them.

-

Easy socket for thru-hole crystals (HC-49 variants)

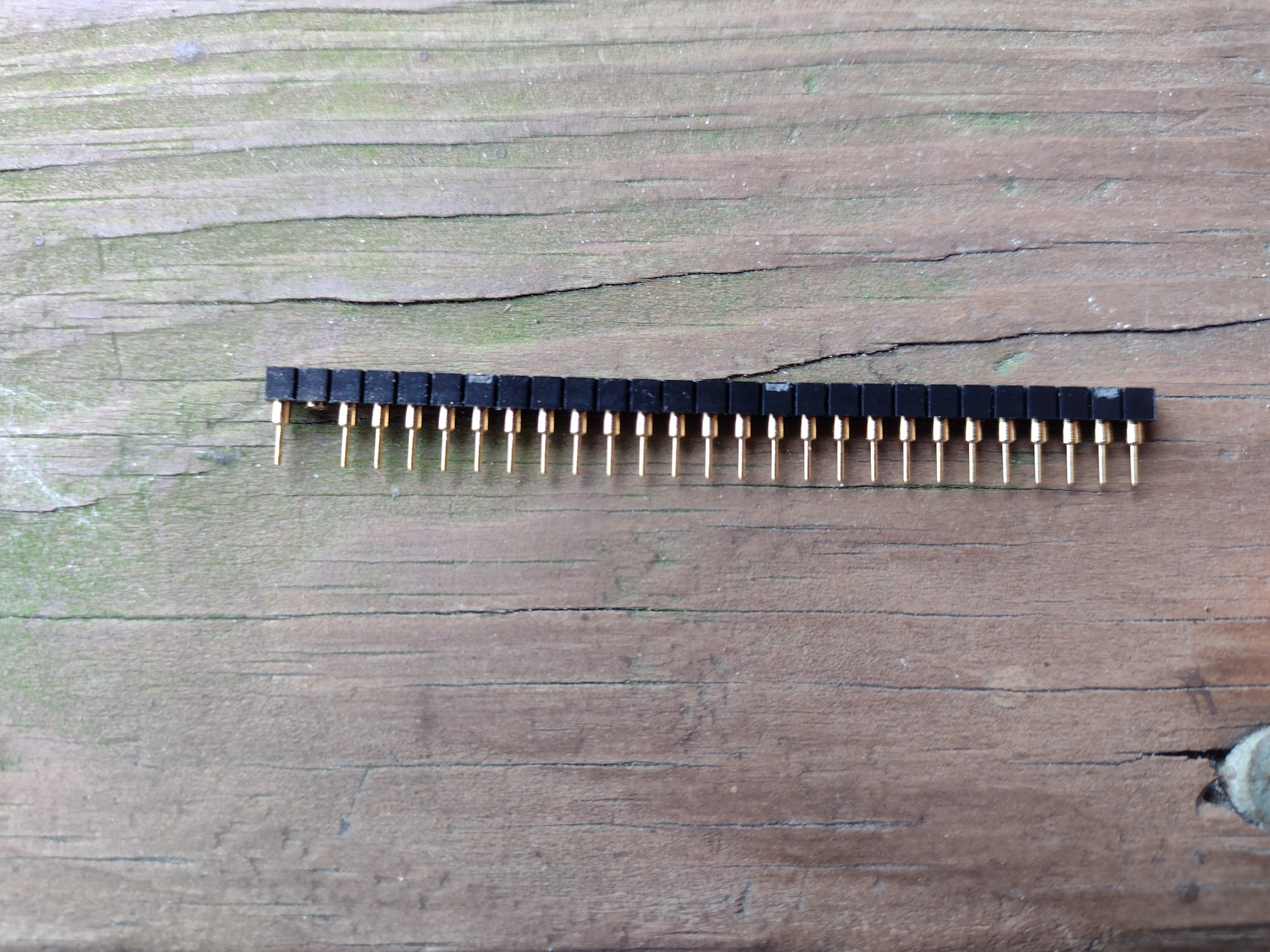

01/21/2024 at 00:15 • 2 commentsI wanted to make a socket for swapping out crystals on some of my development boards. Using .1"/2.54mm machined pin headers was a good start as the pins from a crystal fit in quite well and the spacing is perfect.

![]()

The question now became the best way to go about it. I could break off two separate pins and solder them in individually, but from experience soldering in and nicely aligning single pins is rather tedious. I could do board revisions to have a middle, unused pin resulting in soldering a segment of three pins that would make things a bit easier, but that wouldn't help with the existing boards I have on hand.

The chosen solution was to simply remove the solder leg of the middle pin, resulting in a three pin segment that will fit in unmodified crystal footprints.

![]()

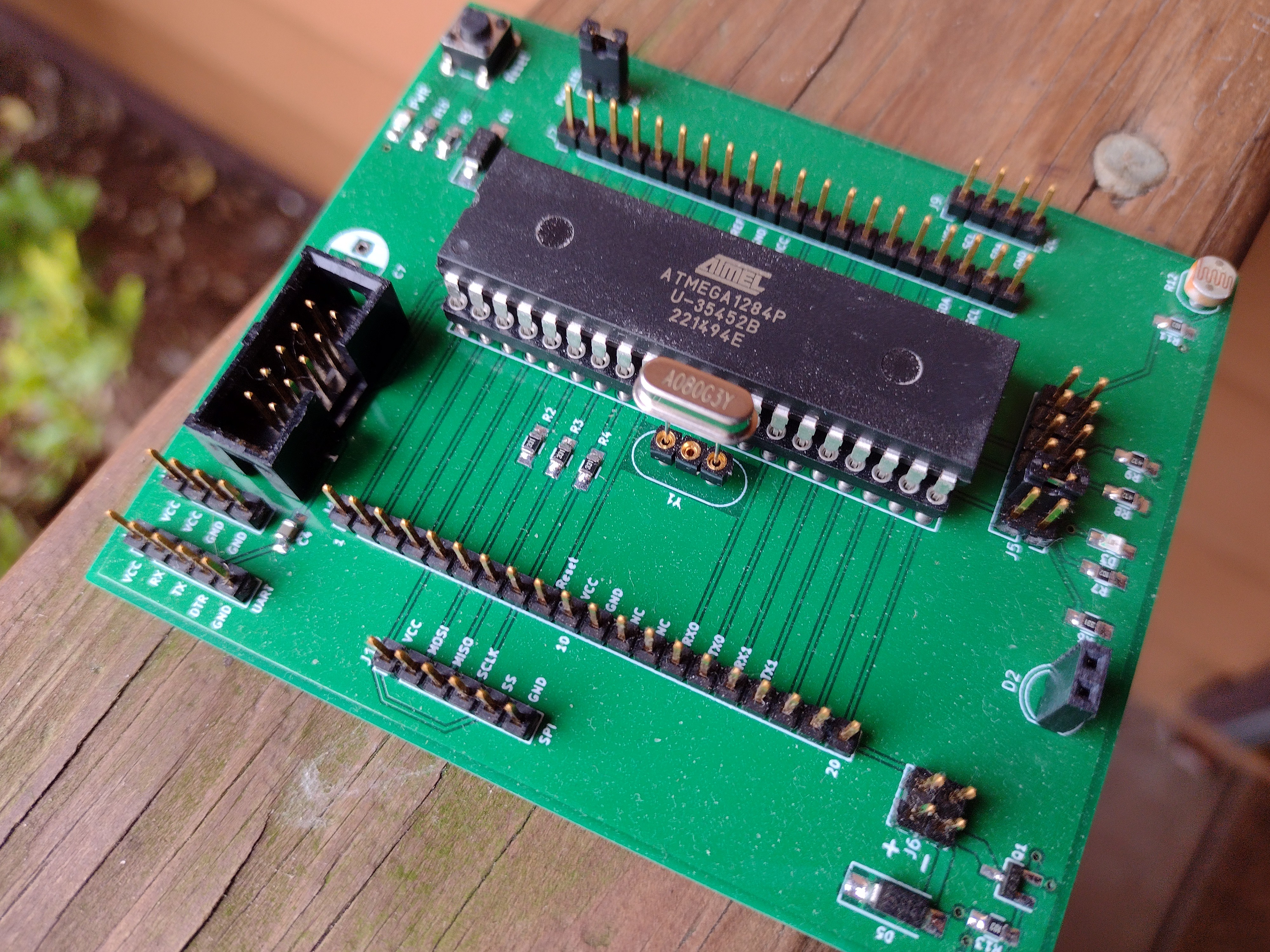

I ended up using a rotary tool with a cut-off wheel to grind away the middle pin. While it was a little tedious, I actually enjoyed it in a strange way. I did the grinding before breaking the segment off to made the grinding process easier to control. I then broke off the segment. I could have tried my side-cutters, but I didn't want to risk damaging them.

![]()

A board with one installed:

![]()

It works well and doesn't look too bad. I have some crystals with shorter legs that make for a nicer appearance, but I was pressed for time to dig for them.

My Projects

My Pages

Projects I Like & Follow

Share this profile

ShareBits

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Good morning and thank you for the like for #Light Logic . I like to bend the rules sometimes :-)

[this comment has been deleted]

thanks for liking my #Multi fx Stomp Box project buddy!

Hi, thank you very much for like #Upgrade your 3D printer from 8bit to 32bit

Thanks for the like on the 3Force Proto! I really appreciate the support!

Hey, thanks for the like for #Arduino Blocks for MIDI Controllers

Hi mcu_nerd, thaks for liking the One Transistor Flipflop, https://hackaday.io/project/112126-one-transistor-flipflop !

Thank You mcu_nerd fot likin' #Smart remote for robot Pablo . Cool !

Hey mcu_nerd! Thanks for the like on FloppyBird! and others! :)

Hi mcu_nerd, thank you for liking my "3D-brain simulation" NeuronZoo, https://hackaday.io/project/19287-neuronzoo

Did you also try to run an example ?

Thank you for like my # Box for Resume 3D Print automatically

[this comment has been deleted]

Hey thanks for liking my #wESP32: Wired ESP32 with Ethernet and PoE project, appreciate it!

Thanks for the like on Windicator! Project logs coming this week!

Mike Moore

Mike Moore Dan Royer

Dan Royer bobricius

bobricius flow

flow Jake P

Jake P Faselunare

Faselunare Jakob Faltisek

Jakob Faltisek M. Bindhammer

M. Bindhammer Mark Omo

Mark Omo RichardCollins

RichardCollins Blixa Morgan

Blixa Morgan Nikhil M Jeby

Nikhil M Jeby Carlos Barrera

Carlos Barrera Alex Ryker

Alex Ryker

Thanks for like to my project https://hackaday.io/project/164233-leavening-cell