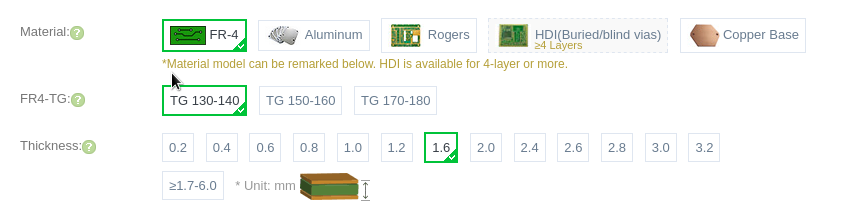

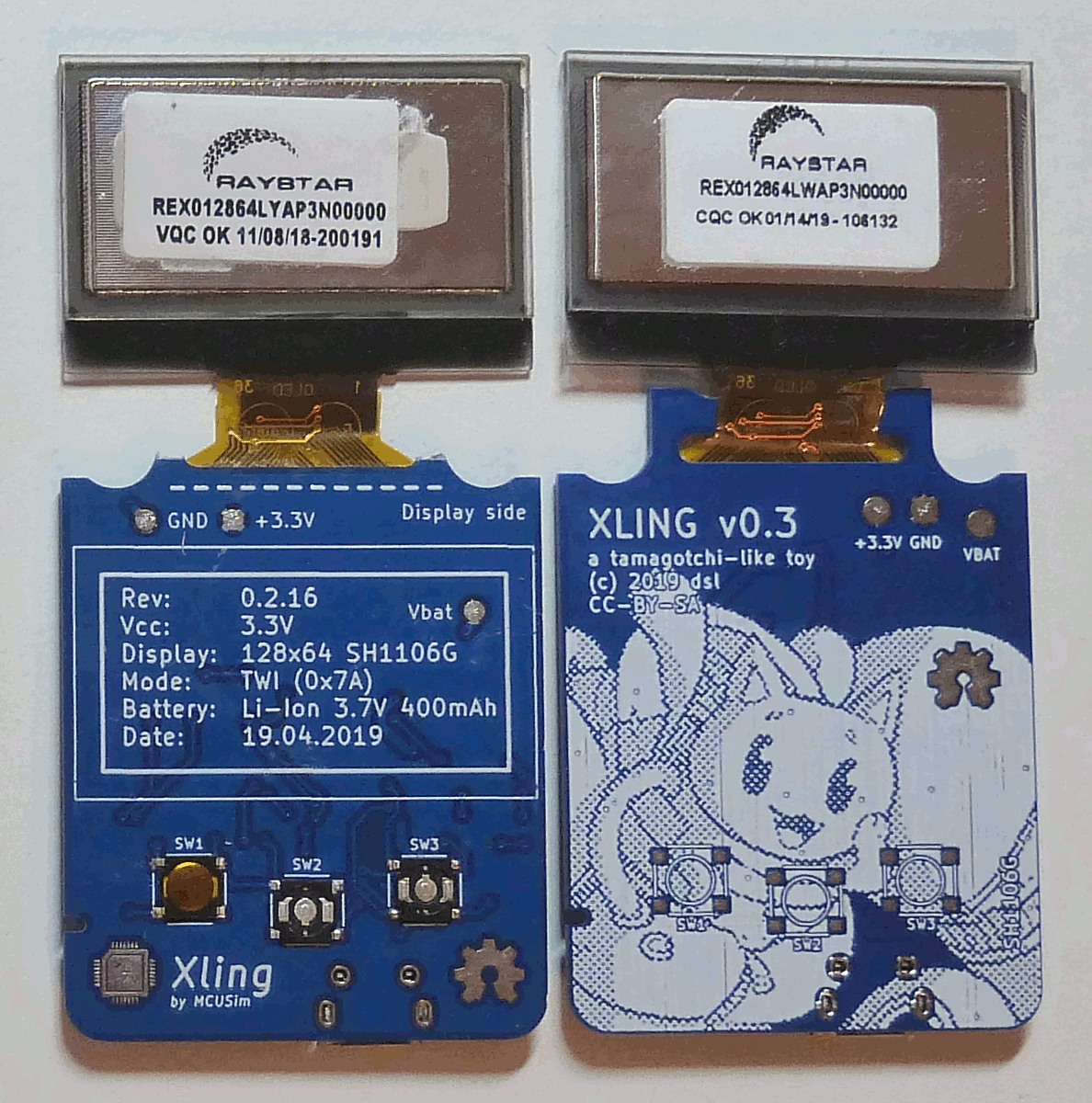

Specifications

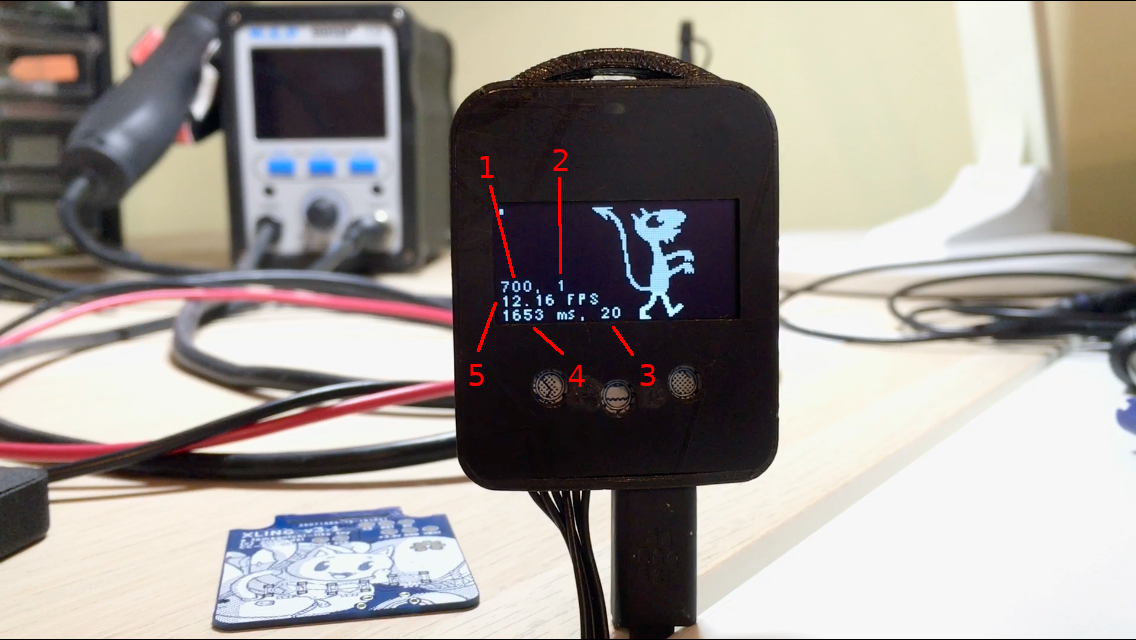

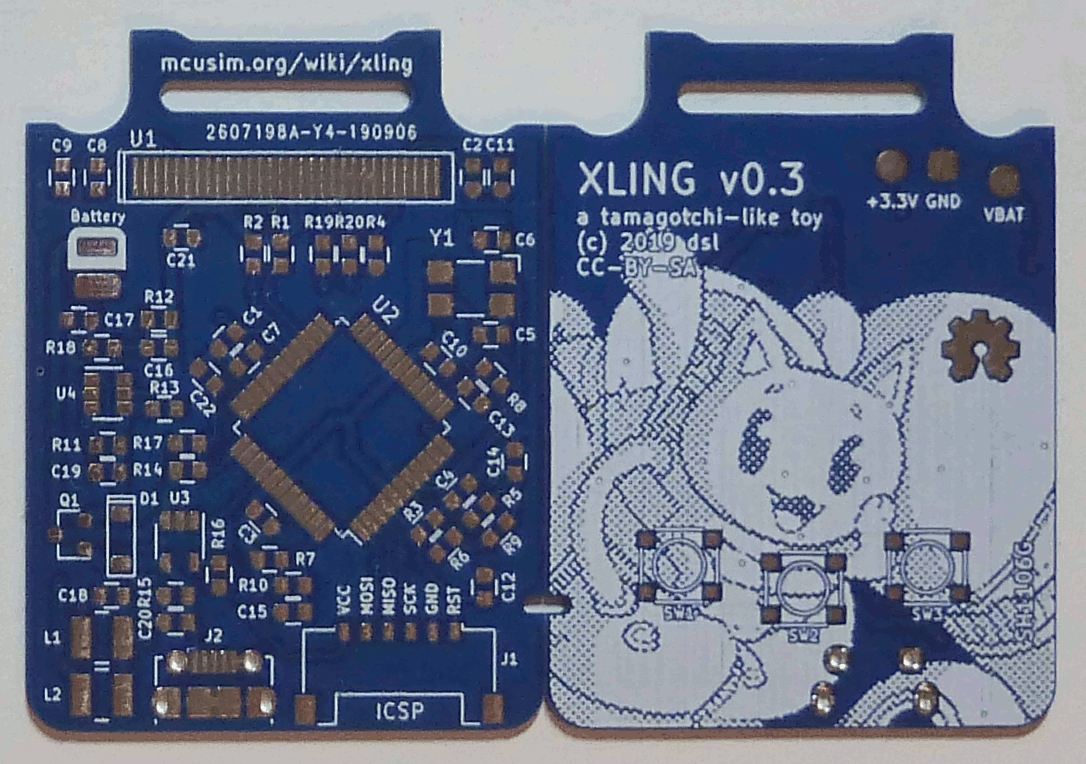

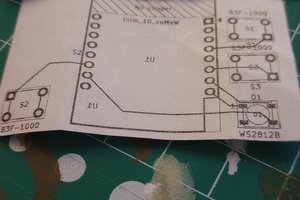

- 35x47mm board

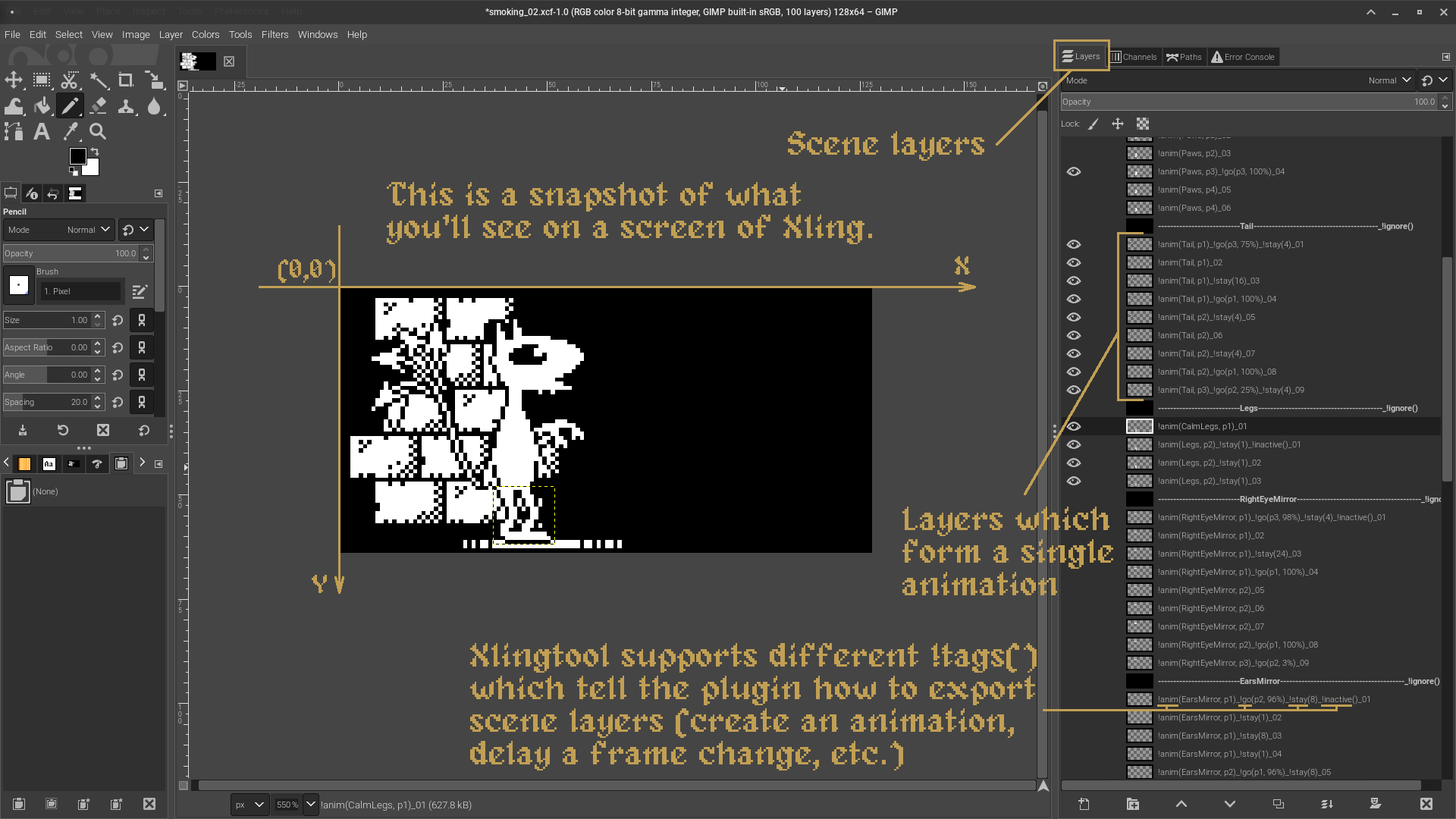

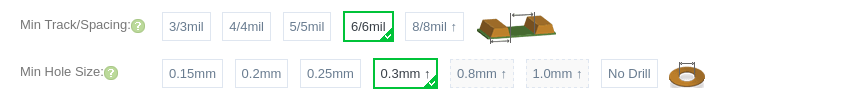

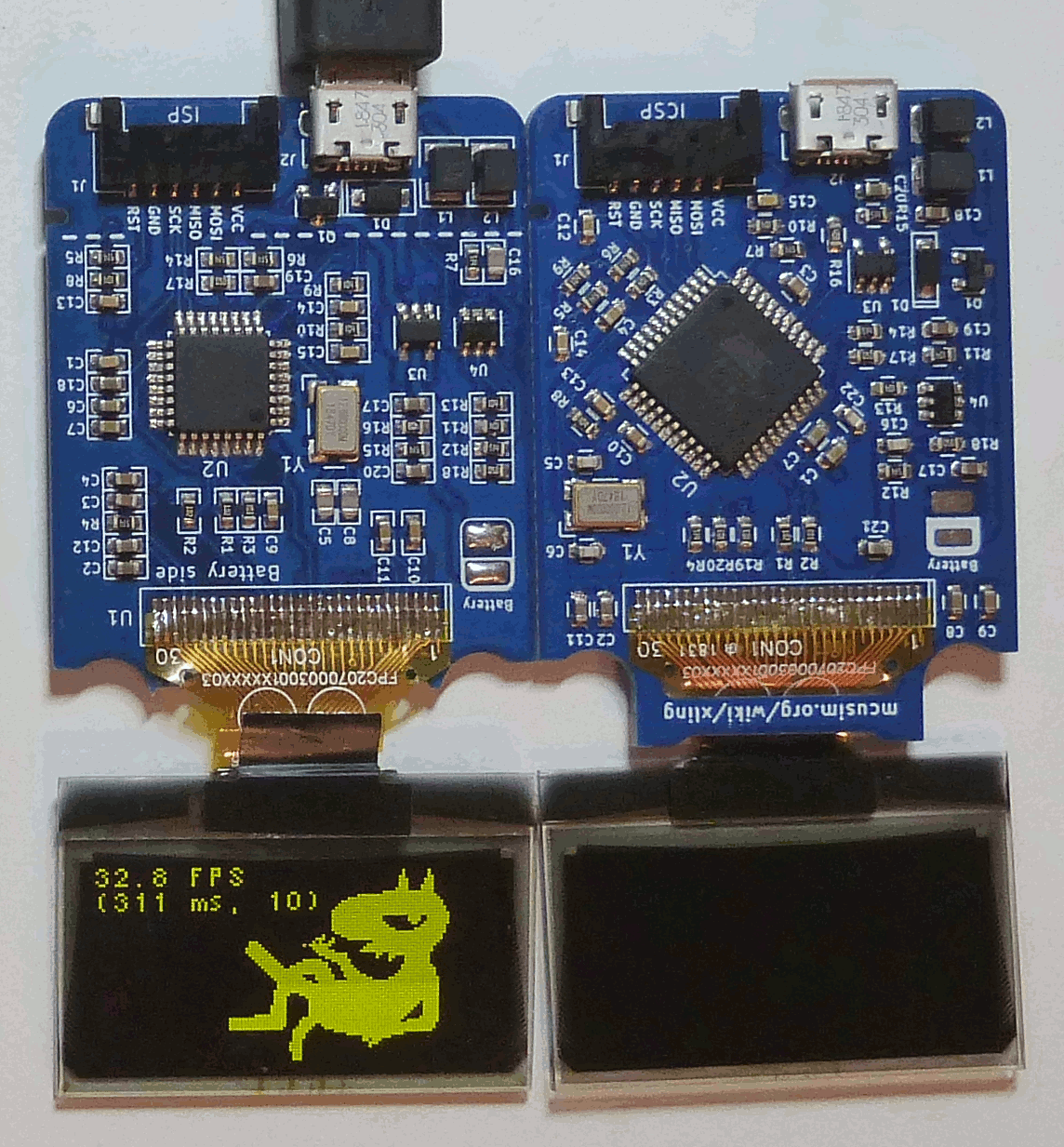

- Monochrome OLED 128x64px

- Low energy consumption (~20mA @ active, 0.75mA @ sleep)

- Hand-soldering friendly (TQFP-44 0.8mm pitch, smallest is 0603)

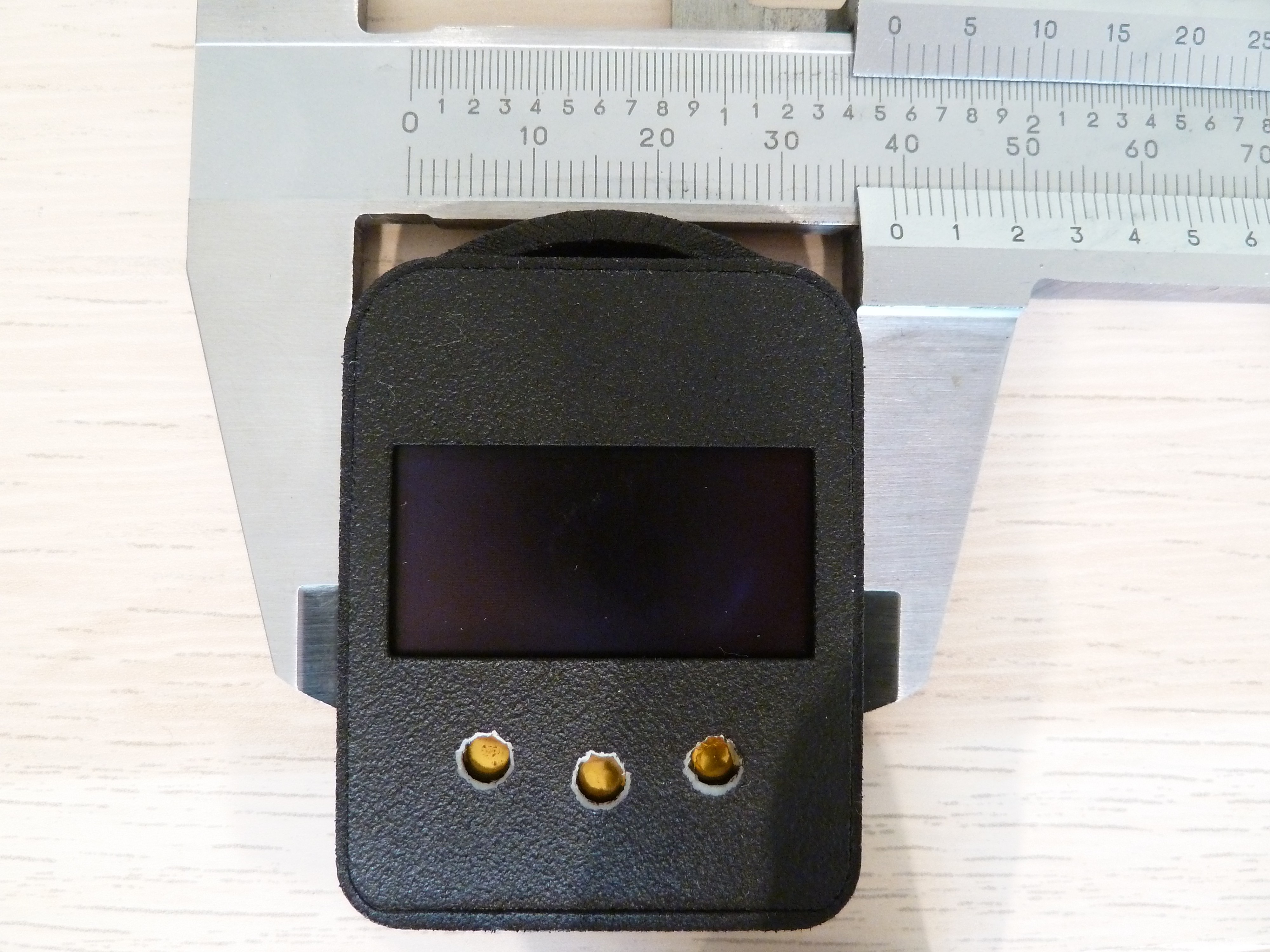

- 3D-printable case

- Open Source Hardware/Firmware

Hardware

- ATmega1284P 8-bit AVR MCU with 128 KiB flash and 16 KiB SRAM

- SH1106G display controller

- MCP73831 charge controller

- AP3401 DC-DC buck converter

- 400mAh 3.7V Li-Po battery (~26h @ active, ~30 days @ sleep)

- Load-sharing circuit (can be powered by USB or battery, like a smartphone)

- KiCad 5.1.0 project for schematic and board designs

- Released under CERN-OHL-W v2 (Rev. 4) and CC-BY-SA (before Rev. 4)

Software

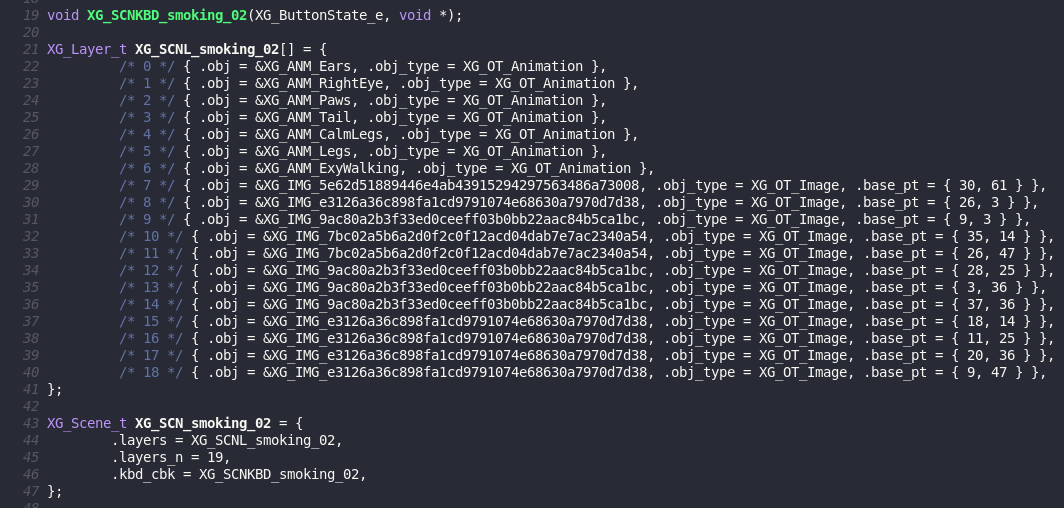

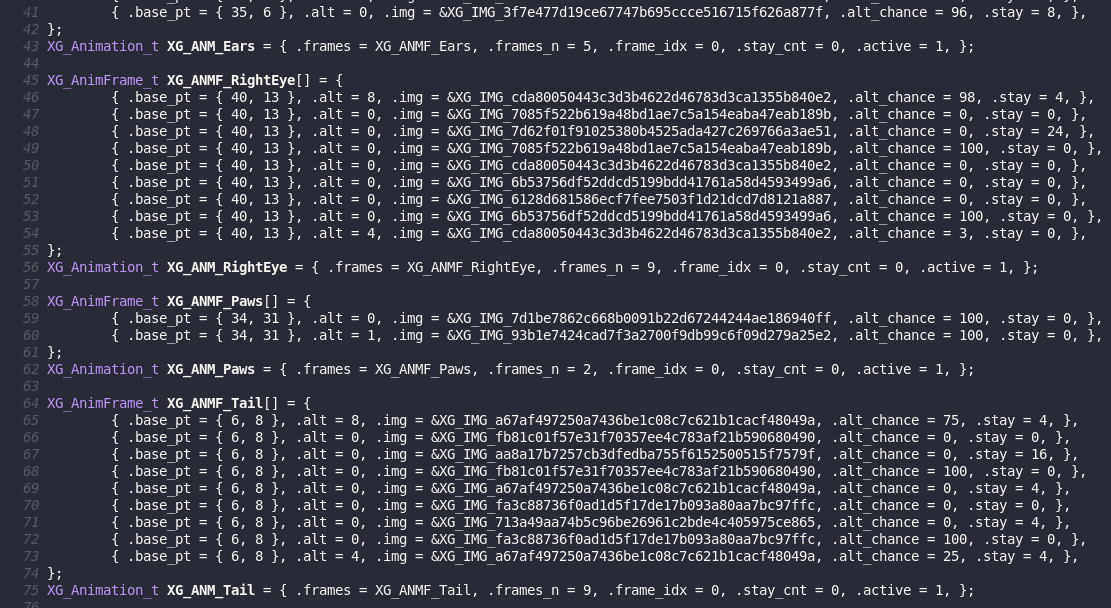

Please, note that the software part of the project isn't finished yet! Xlingtool (a plugin for GIMP) can be used to create complex animated scenes for Xling.

- Programmed in C99 using the FreeRTOS kernel modified for ATmega1284P

- There are four tasks: to update display, to handle keyboard input, to monitor battery, to monitor device activity for sleep mode transition

- Released under GNU GPLv3+

dsl

dsl

C. Scott Ananian

C. Scott Ananian

alongruss

alongruss

Discombobulated8080

Discombobulated8080

Jarrett

Jarrett

Hey! Do you have any updates? how is this little guy doing?