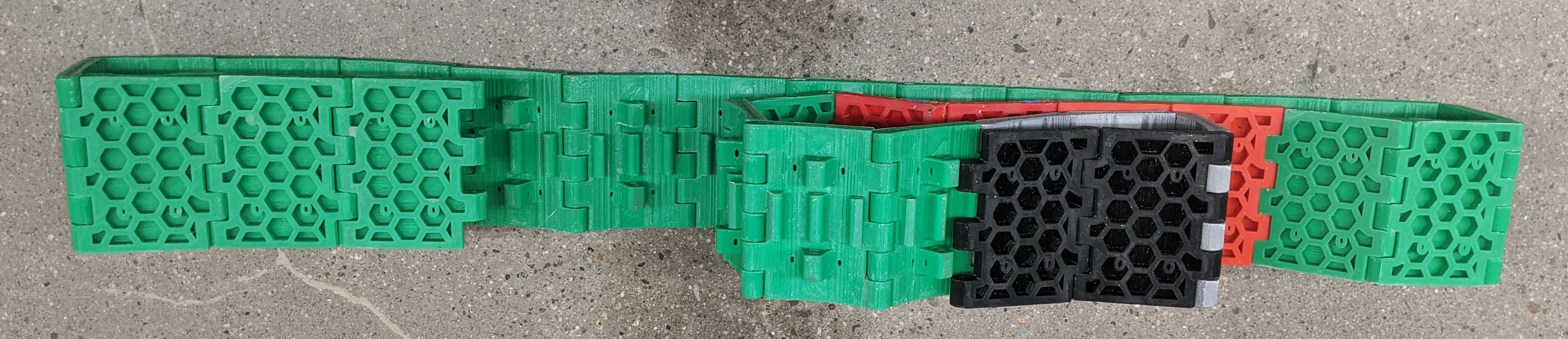

Belts consist of two parts: Thread parts (PLA or ABS) and gripper (TPU) connected with zip ties. Belts employs lattice structure (HoneyComb) in order to optimize the amount of material used (reduce calculated density), while maintaining structure strength.

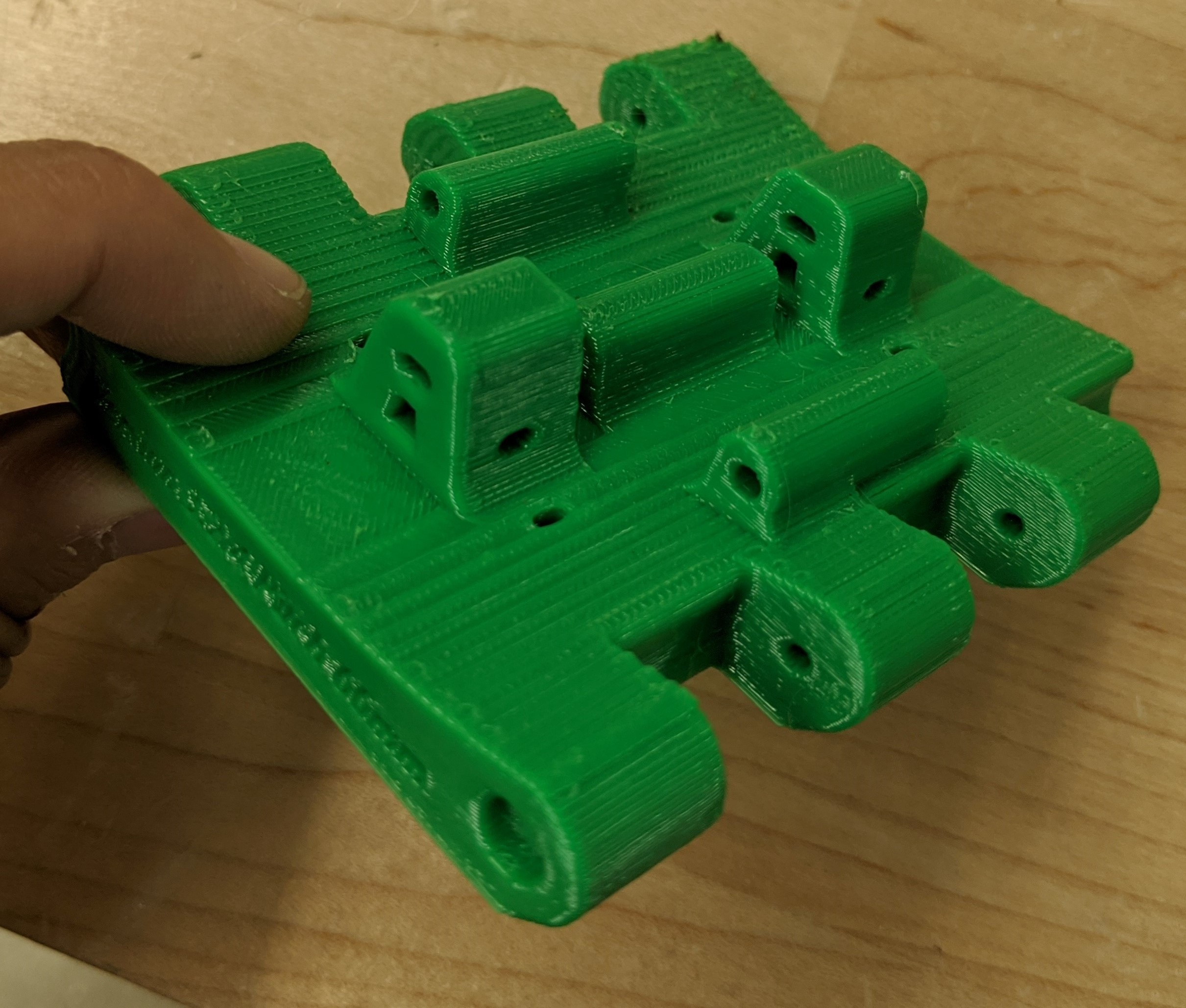

8 filaments spools (MatterHacker) were used as wheels, each of which contains two bearings and attached on a fixed axis.

Entire frames are made of T-slotted aluminum which was used in a class at UCLA and we re-used them since they were supposed to be thrown away after the class ended. We didn't cut the aluminum, but picked size we want from those scraps or adjusted our design correspondingly.

Two 1.5kw e-bicycle motors were powered by 40Ah Lithium-ion battery, which were from a previous thesis project.

Demonstration on north campus

Maximum speed test (About 15mph)

Version 2 belts (in videos) use PLA mostly because of material availability at UCLA Innovation Lab (makerspace), but the new design belts are now printed in ABS for better shock registance.

There is one ongoing upgrade project on this tank to improve the belts.

We also working on a failed 3d print recycle project, and old or damaged belts were melted to a PLA board so that we can laser cut and use for other purposes.

This project is not funded, but using our makerspace is free for all students.

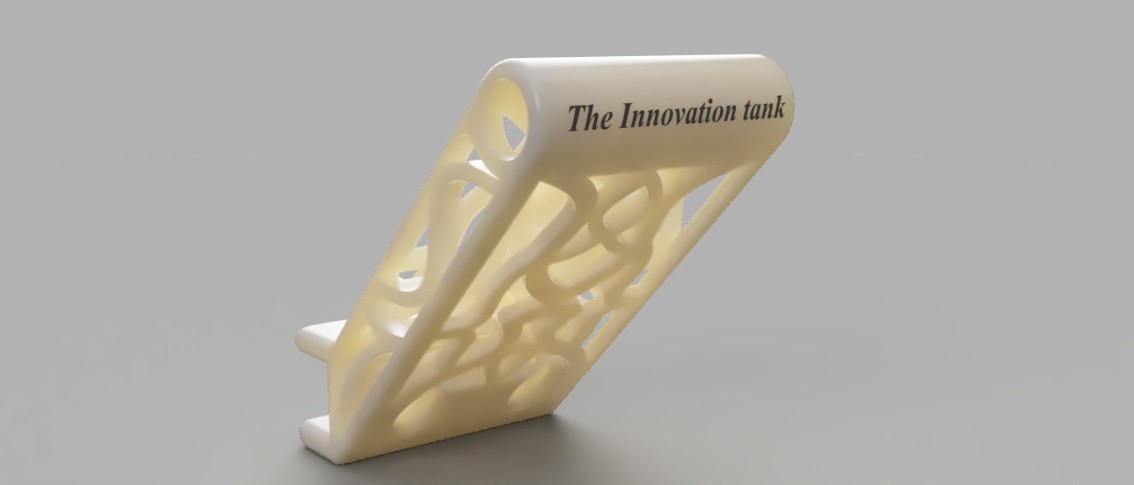

**************Organic Design Throttle Fixture*************

Throttle fixture rendering for our tank. (Black handle in the tank picture)

******************* Version 3, Robust Belt ******************

V3 Belt improved hinge designs which was previously limited due to the size of each belt. Now the belt is thicker and wider, and pitch (belt hinge eye to eye) is 1.5 times larger to reduce number of components. V2 belts only had one tooth per belt, but V3 consists of 3 teeth per belt to spread shear stress due to the motor.

Honeycomb size is increased since the V2 honeycomb trapped small pebbles.

Now made in ABS. 1.5kg for one set of belts

And now we are RECYCLING used belts and other makerspace 3D print waste into beautiful plate for laser cutting. Visit the project for more pictures

https://hackaday.io/project/168768-innovation-pla-plate-recycled-failed-3d-prints

12/5/2019********************************************************************************

STL files and Material selections

Threads:

Material: ABS or Nylon (PLA if you are fine to replace the belt occationally)

Infill: 100%

For the best shock resistance, Nylon is a better choice, but we decided to use PLA for the fisrt versions and ABS for the latest version (which uploaded here). simply because we mostly stock PLA (and recently a lot of ABS too). We didn't want to use up some other precious material just on this project.

We founded that some filament brands were significantly less durable. We recomend Hatchbox and avoid bright or transparent colors which are brittle ususally.

If someone interested in comparison between the brands (PLA), I can make a list next time

Thread grip:

Material: TPU

Infill: 20%

The grip can be attachec on the belts using two zip ties. Infill is 20% to make it squishable a little. Not mandatory to have this grip, but it will protect the belt honeycomb from trapping pebbles and make the tank quieter.

L-joint:

Material: NylonX or (ABS)

Infill: 100%

Used to connect 1 inch t-slotted aluminum in 90deg. it'll be fine to use ABS if the joint is used on where it does not experience torque.

Other Joints:

Material: NylonX (Highly recomended)

Infill: 100%

Any other joints should be printed in Nylon and recommends NylonX, which is nylon reinforced with carbonfiber. (Note most of carbonfiber filament is PLA based and not suitable at all for our purpose)

It's possible to use ABS if you are not riding much or think they are...

Read more » Yusuke Tanaka

Yusuke Tanaka

Mitja Breznik

Mitja Breznik

Russell Munro

Russell Munro

Romain LAPIERRE

Romain LAPIERRE

this is awesome and I love the printed tread implementation, keep up the great work!!!!