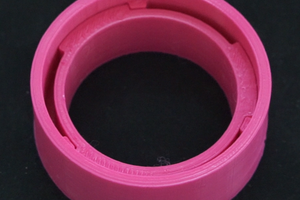

I used a digital capiler to measure the original broken part to be able to reproduce the original as much as possible and use it to support the lamp from the bottom.

I had many tries before getting the final part ready to be used but that's where 3D printing is useful to be able to prototype quickly and iterate thought your design really fast.

PLA filament has been used for this part but you can use ABS for better strength of the part as it used to support the lamp. So far I didn't have any trouble as it's not moving at all but for moving part I would recommend ABS.

I think 3D printing was one of the most convenient solution for this task because I couldn't find the broken part anywhere on the internet other than ...to buy another lamp.

End result was quite impressive. I was able to repair my own house item with just some tools, software and a 3D Printer.

Of course it would have been possible to fix with by making the part yourself with laser cutting wood or CNC but the 3D printing process was pretty straightforward to me.

I give free access to the CAD project file (Fusion 360 is free for hobbist) so everyone can understand how it was designed and/or modify anything on the part itself.

Romain LAPIERRE

Romain LAPIERRE

Yusuke Tanaka

Yusuke Tanaka

ProgressTH

ProgressTH