-

Kicad Sharp

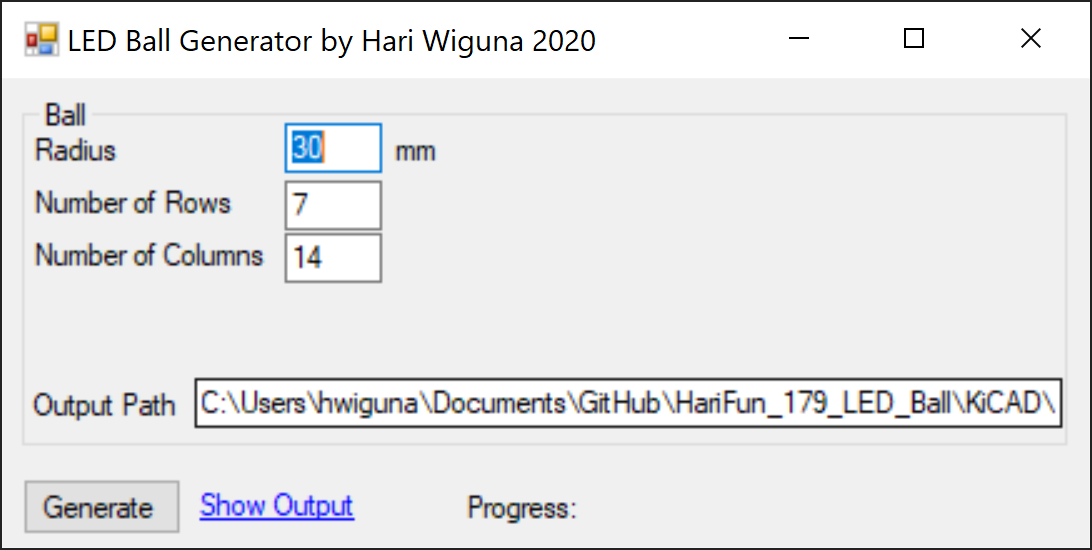

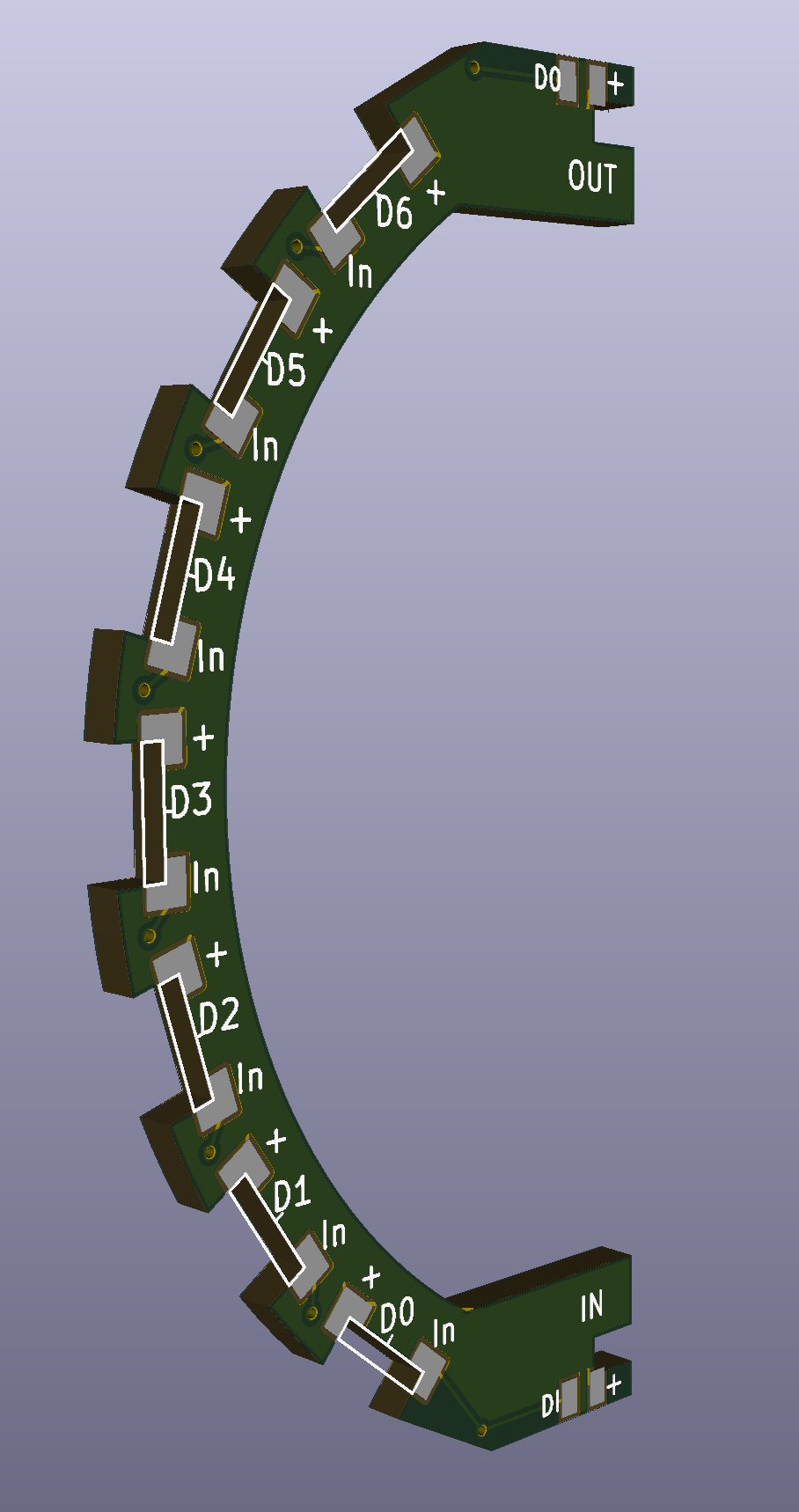

09/07/2020 at 15:24 • 0 commentsI've been working on programmatically creating the PCBs using Kicad Sharp by Uriel Guy.

In theory, any size LED ball could be now created by simply changing the constants in the code. In practice, there are many hurdles that still needs to be ironed out such as copper traces running into pads due to the changing distances between pads as ball radius and number of LEDs are changing.

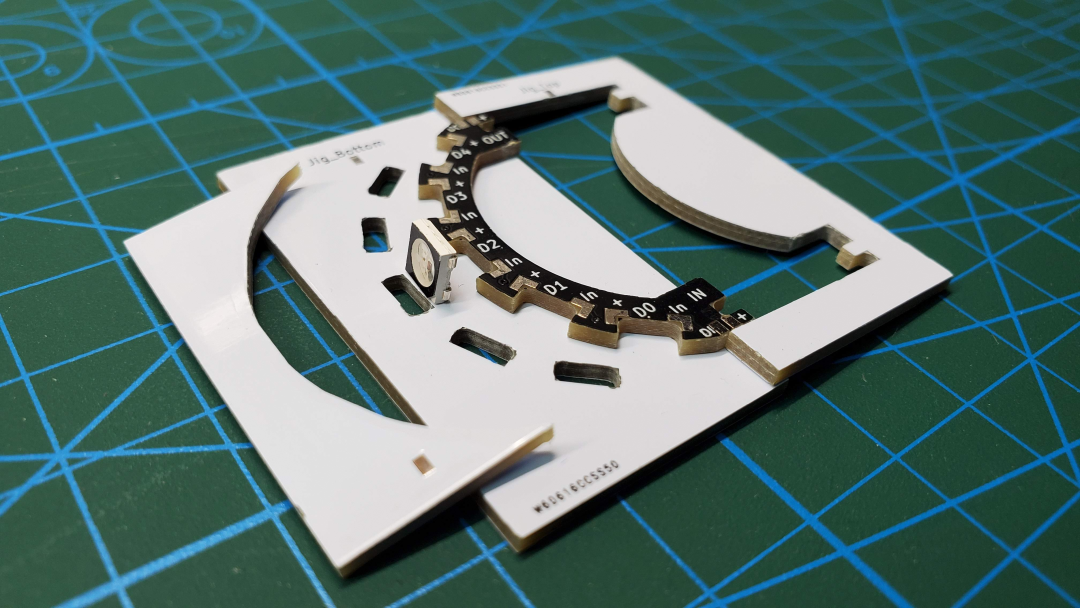

Since the PCBs are created programmatically, it was not that much more work to create jig PCBs that are also dynamically generated based on the LED ball parameters.The idea is to insert the unsoldered LEDs into the holes on the white jig PCB.

Then push the LEDs into black Arc PCB. Hold everything with the other two white PCBs while soldering the top LED pads. Once soldered, remove the Arc and LEDs to solder the other side (without jig).

This batch of PCBs still has lots of fitting issues, so I don't know how well that idea works or if at all.

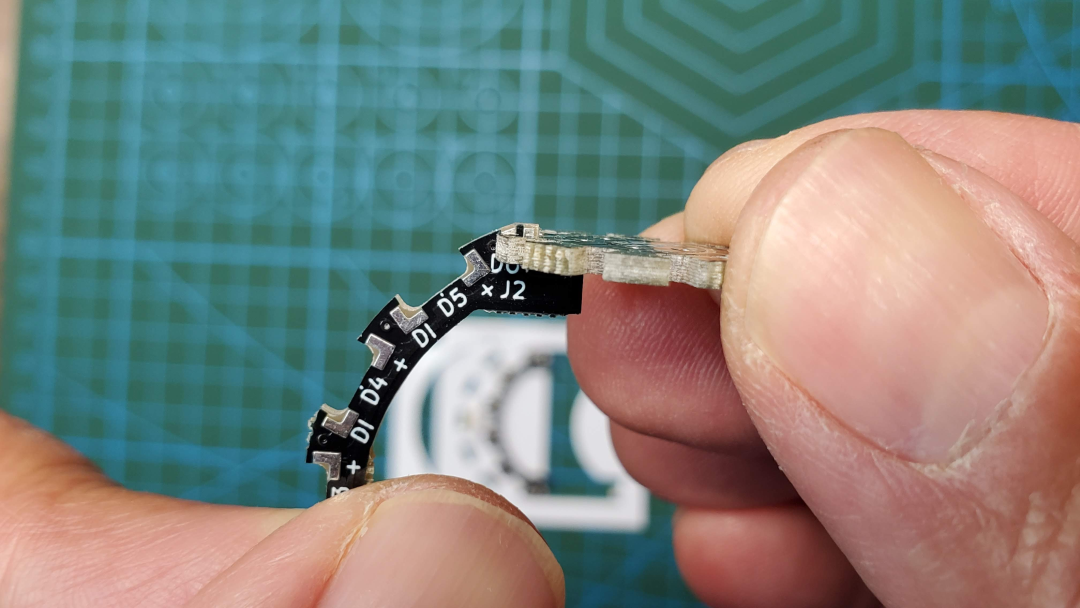

Below is how the old PCBs are notched. It was hard to keep them in place while soldering.

It was very hard to solder because the PCBs can move around in 3D space and had to be held while soldering or they would fall off.

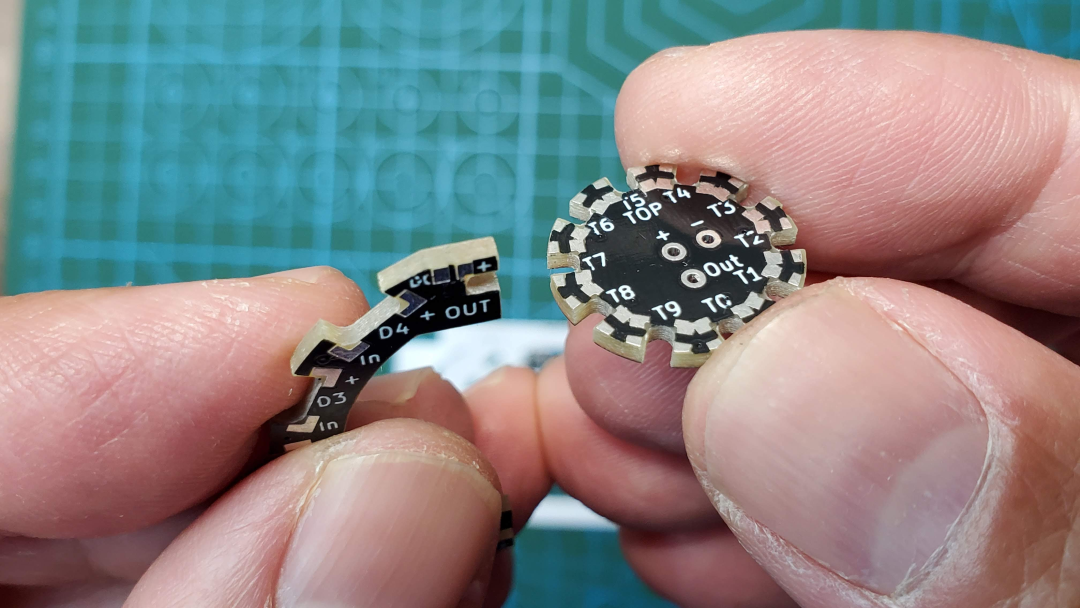

This time, the two pieces are designed to interlock with each other.

Unfortunately, I didn't have the pads quite lined up yet.

I've submitted a new set of PCBs to fix all of the above issues. Hopefully, they fit well and I'd be able to assemble a larger LED ball.

Hari Wiguna

Hari Wiguna