There are a few problems when it comes to building your own sonar from scratch.

- Get hold of the active element required for sonar: the transducer. Transducer material (usually piezo ceramics) is hard to get in small quantities. Usually they are made to order, and a few hundred dollar for a single batch is pretty common.

- Mechanical design of the transducer. Very little information on this is freely available online. Most companies keep the design process to themselves. And there is some design software available, but that's all commercial as well.

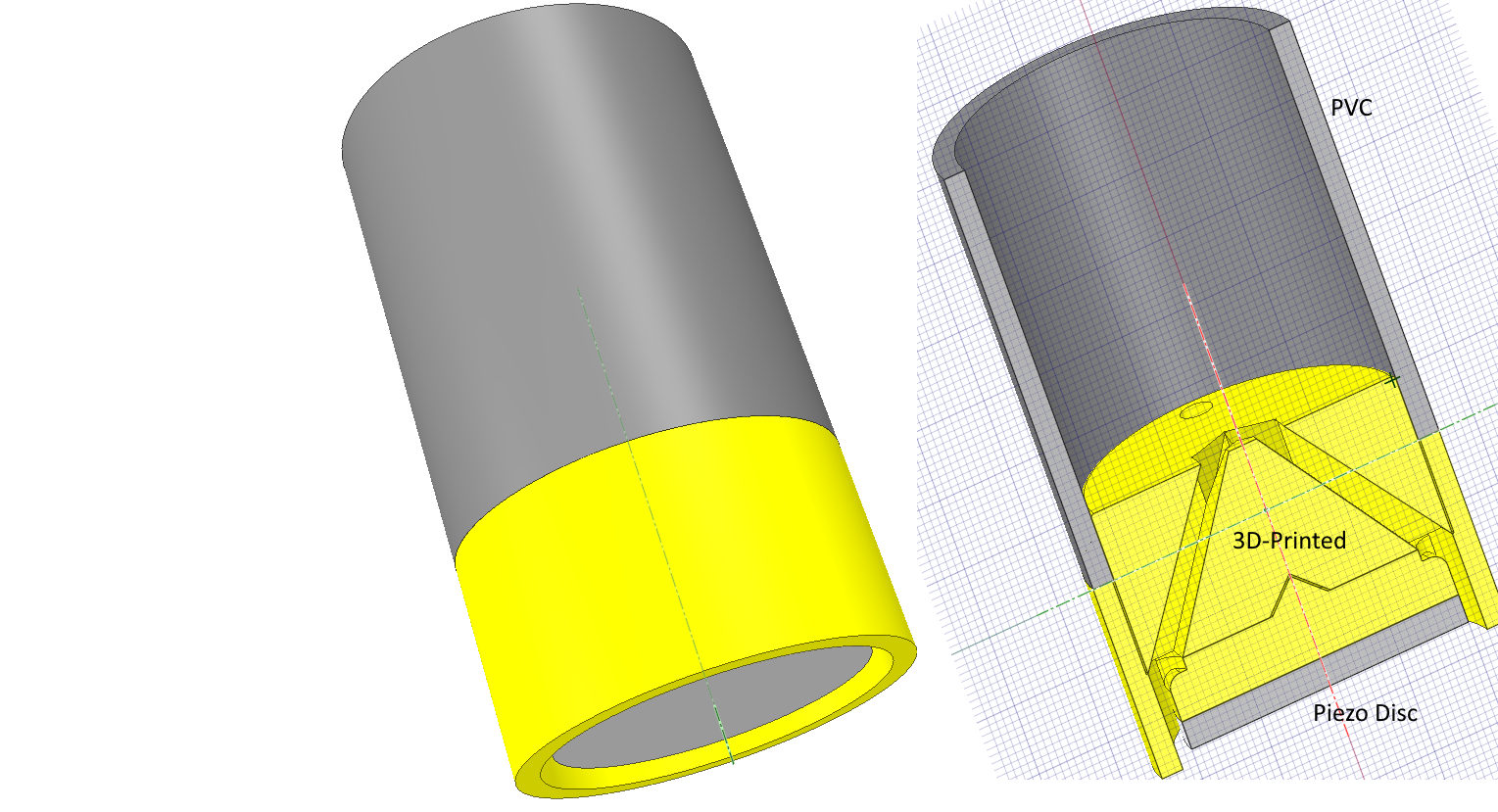

- A watertight housing for transducer and electronics. Not a trivial thing. My experience is that it is very hard to keep water out since it tends to creep through the smallest of holes. Extra complication here is that you will also need some way of connecting the electronics to the outside world.

- The electronics. Although that is not very complicated, it does require some specific components like transformer and tuning coils which are also not as easy to get at the average hobby-electronics store.

Cees Meijer

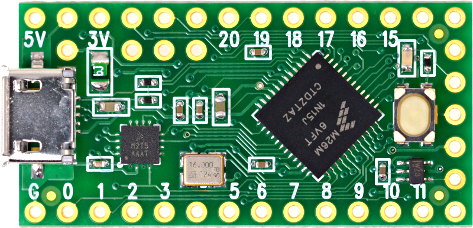

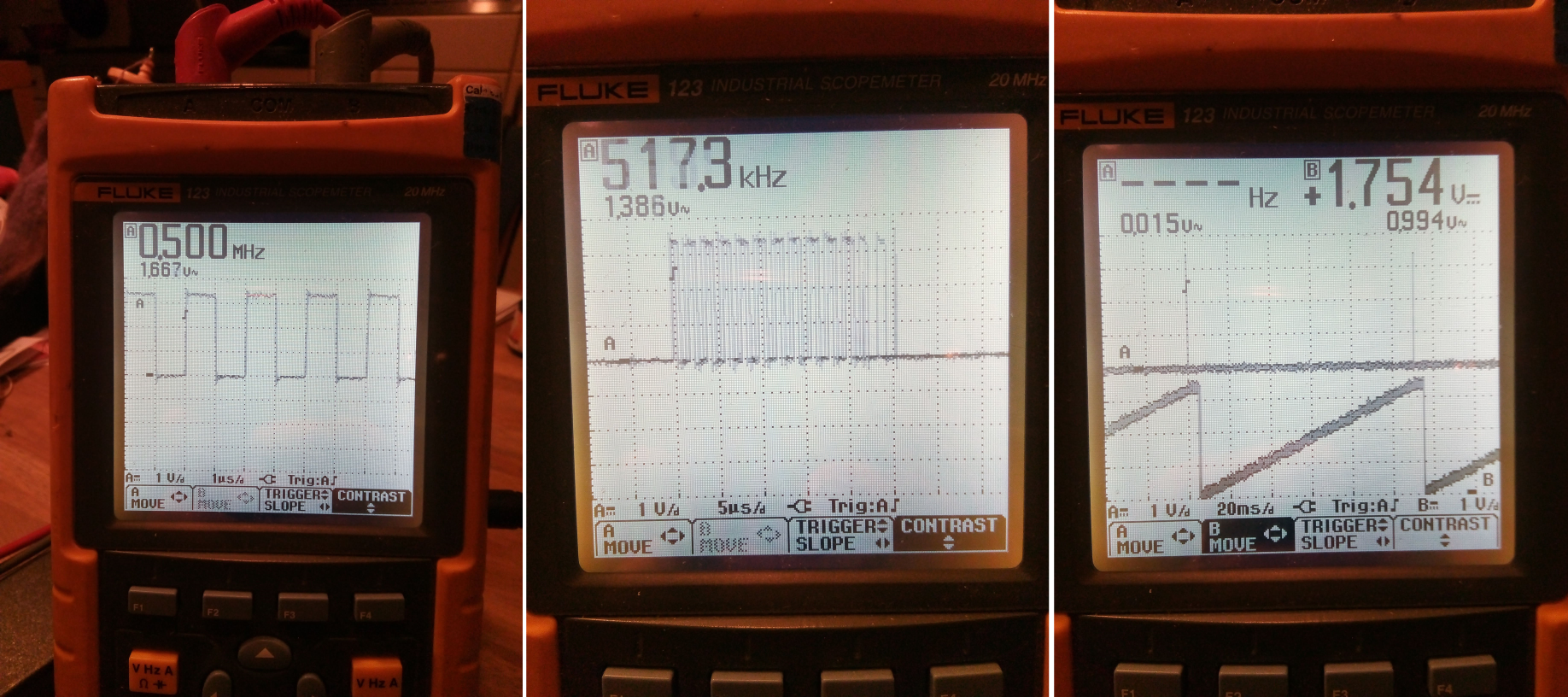

Cees Meijer It looks like even the cheapest Teensy, the TeensyLC (yes,LC for Low Cost) might be sufficient for this task. But will it also be able to generate the transmit pulse and necessary control signals ? I will need a 512kHz burst, and some analogue ramp signal for the Time Variable Gain amplifier. And it turns out that this is not just possible, its also very simple.

It looks like even the cheapest Teensy, the TeensyLC (yes,LC for Low Cost) might be sufficient for this task. But will it also be able to generate the transmit pulse and necessary control signals ? I will need a 512kHz burst, and some analogue ramp signal for the Time Variable Gain amplifier. And it turns out that this is not just possible, its also very simple.

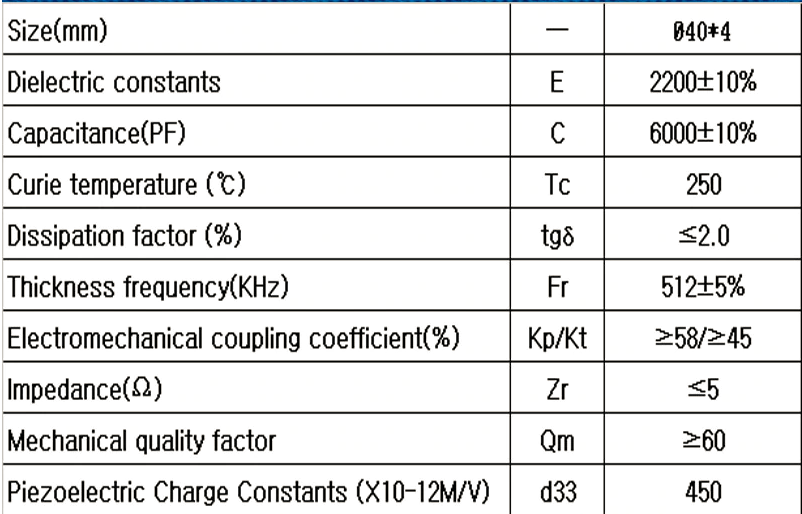

This disc has a 'thickness frequency" of 512 kHz which is a frequency that is commonly used for short / medium range echosounders. Depending on circumstances, ranges of 50 to 100 m should be possible.

This disc has a 'thickness frequency" of 512 kHz which is a frequency that is commonly used for short / medium range echosounders. Depending on circumstances, ranges of 50 to 100 m should be possible.

Hunter Scott

Hunter Scott

Sam Pullman

Sam Pullman

Fascinating stuff. I wonder if you could find out who is supplying parts used inside commercial fish finders and simply order those. After all, they are the right specification already. It might also be possible to hack one. Makes me want to order a transducer and see what I can get out of it.

I've had some luck on Alibaba with finding the manufacturers of a complete object and getting them to sell me a subcomponent. After all, they have it.