The firmware is in an external socketed OTP EPROM, so it was easy to unplug and read. Note this is not under the glass, so you can easily change it.

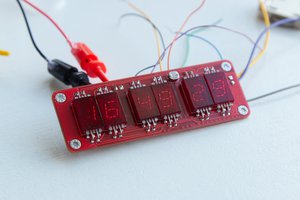

The electronics are under the FVD glass so I had to remove. Not easy, as there are many pins, and it is held-down by sticky rubber pads.

The micro controller is a common 8031 family device.

A quick analysis showed that much of the firmware is character data patterns.

This reduces the amount needing disassembly.

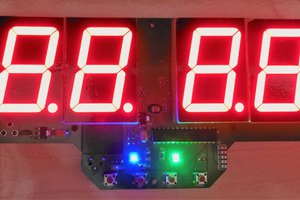

From what I can see, the characters are printed into a pixel buffer, which is output a byte at a time. This allows it to drive two glass modules at a time, with different data if required. This is done by software, there is no DMA involved.

Developing one's own driver hardware and software is possible but hard to justify when there are off the shelf solutions like this already available. One could simply copy the firmware into an 8031 device with on-chip ROM for a more compact solution. Or reprogram the firmware to run an application (such as a clock).

I don't need to do any further investigation, I just present this information for anyone who might be interested.

Keith

Keith

Daniel

Daniel

sjm4306

sjm4306

Victor Chan

Victor Chan

Stephen Holdaway

Stephen Holdaway