[Edit 2021-09-25: Changing approach to include PIC micro-controller. See latest log entry.]

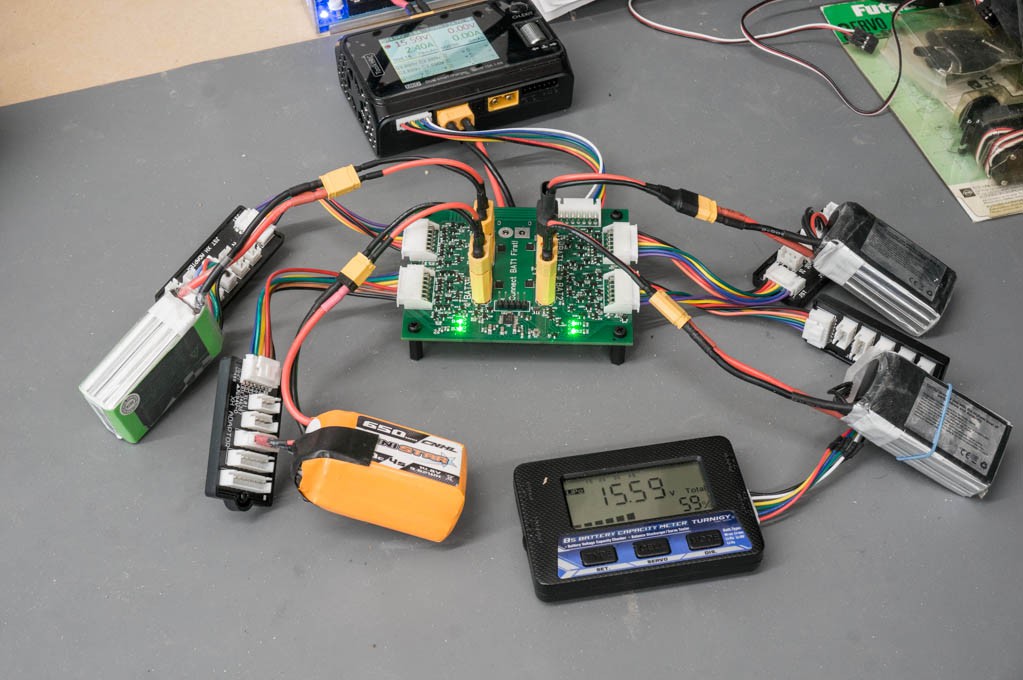

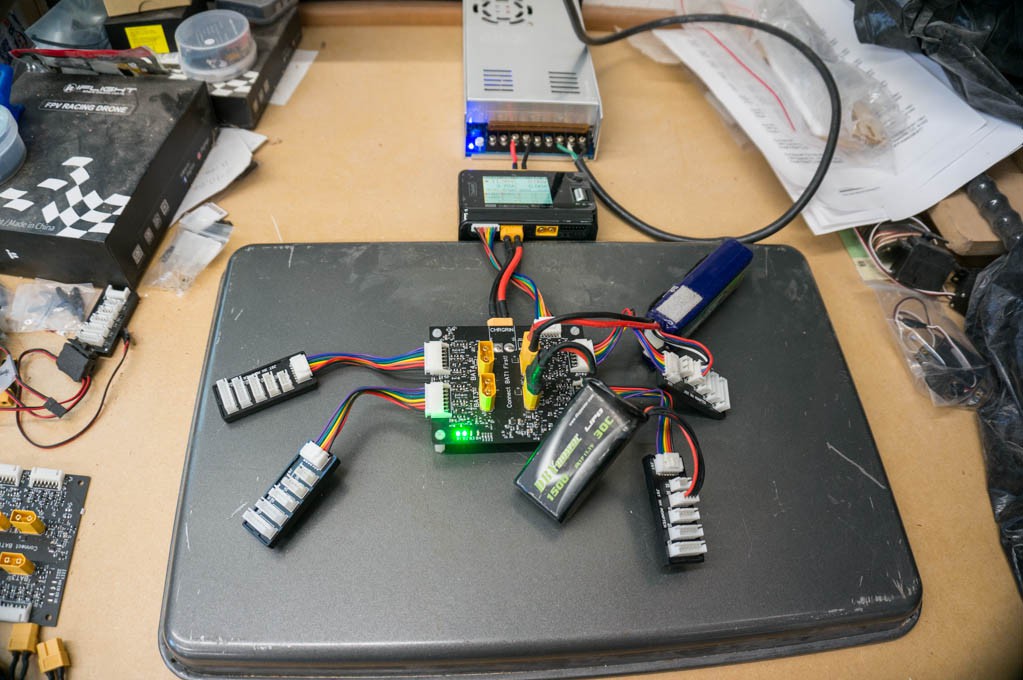

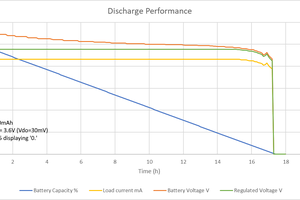

I have accumulated quite a few LiPo and Li-Ion battery packs in the last few years. I have a pretty good 200W battery charger that can charge four batteries simultaneously, but sometimes I would like to charge a few more in parallel to speed up the process. There are parallel battery charging fixtures available from several manufacturers that can do the job. All of them require that the state of charge of the batteries be pretty close before connecting them in parallel to avoid potential catastrophic failures: smoke, fire, explosions. These fixtures include fuses between the batteries which open if too much current flows between the batteries, preventing the catastrophe. One fixture provides a battery checker that displays the battery voltage so that you can ensure that the batteries won't be too far apart in voltage before inserting them into the fixture. All of this relies on the user to know what he is doing...and what's the point? If there is a battery that is discharged deeply, you will have to charge that battery individually anyway since it cannot be connected to the others that are only moderately discharged.

I think there is a better way.

First, a bit of background.

Way back in the last millennium, I was designing battery charger ICs for Linear Technology Corp. I believe that I designed the first commercial Ideal Diode implementation into the LTC1960 and LTC1760. (I may be wrong about that, but if you don't toot your own horn nobody will toot it for you.) It wasn't called an Ideal Diode. There were 5 of these "low forward voltage diodes" on these two chips. It worked beautifully!

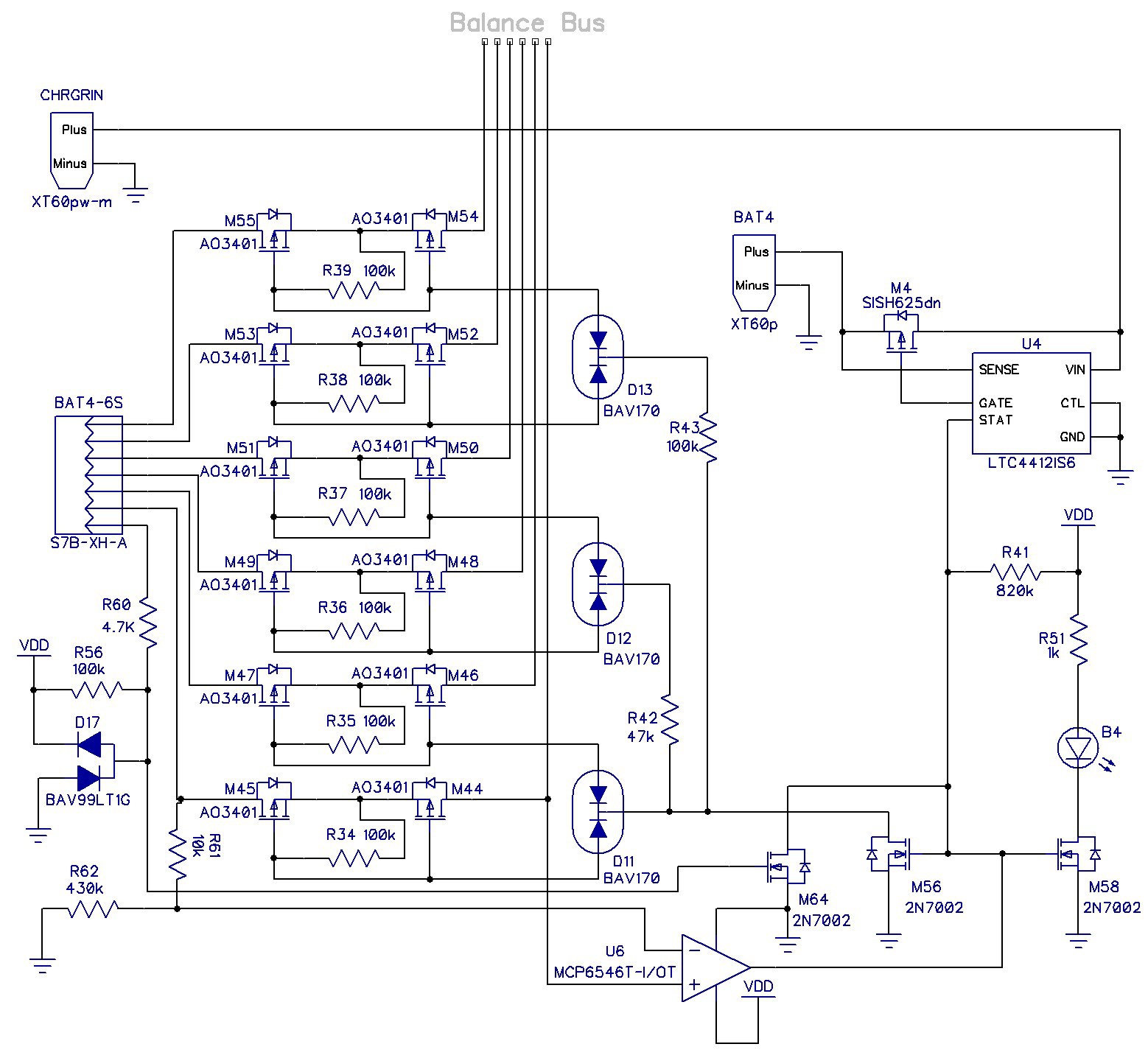

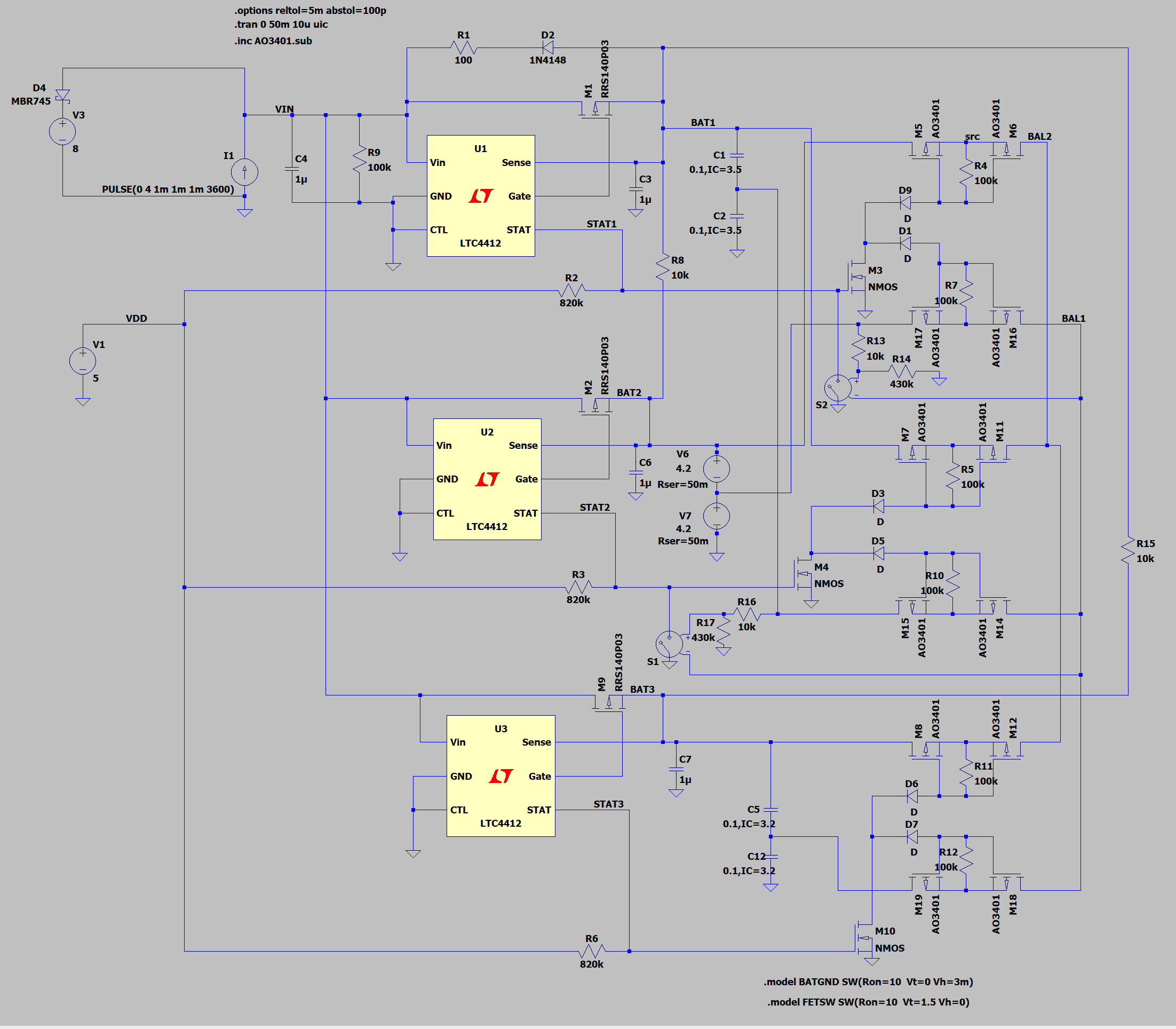

Later, a very capable IC designer working for me turned the concept into the LTC4412 "near" Ideal Diode Power Path Controller as a stand-alone part. The LTC4412 is now listed as an Ideal Diode, and it has been copied by others. The Ideal Diode power path controller is integral to this approach.

[Edit: 2021-07-04 Last week I was reminiscing with that "very capable IC designer" (who is now something of a legend at ADI/LTC) and we decided to see if there were any other commercial implementations of the "Low Loss" diode ORing concept prior to the above mentioned parts. There is a 1999 patent from Boeing that comes pretty close. There are claims made by the Boeing patent that might cover our invention. But neither he nor I was willing to pursue a patent -- we already had more than ten patents each, and the hassle of dealing with the corporate patent lawyers and the US patent office did not appeal to us. In any case, LTC was not sued for any infringement. Besides, Boeing is not really a commercial endeavor and tends to keep its innovations to itself, preferring to sell planes rather than systems or circuitry.]

Problems to Solve:

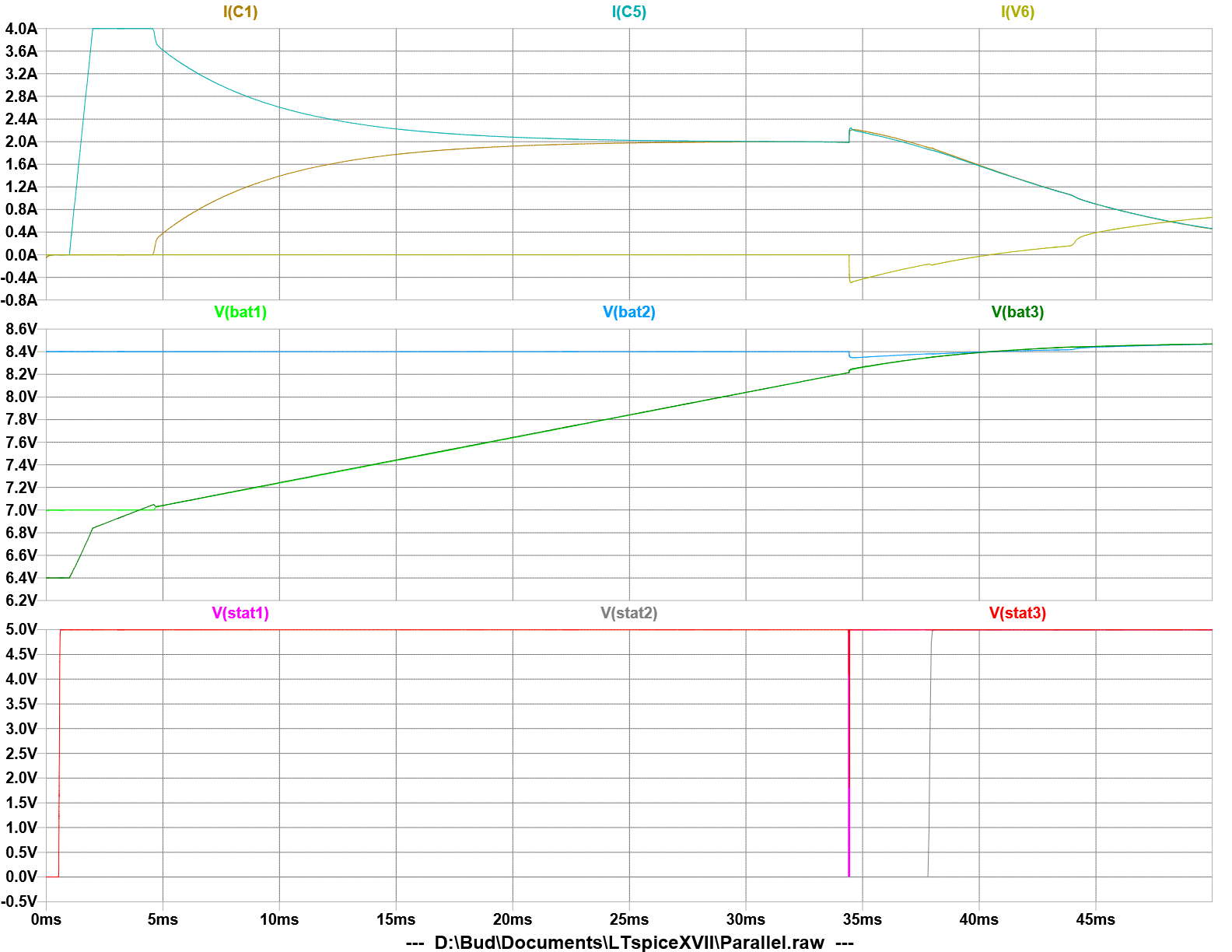

- Mismatched batteries should not charge or discharge each other with high currents.

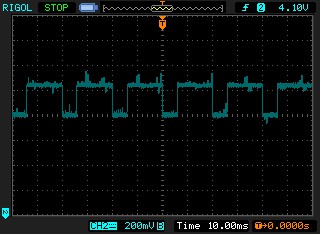

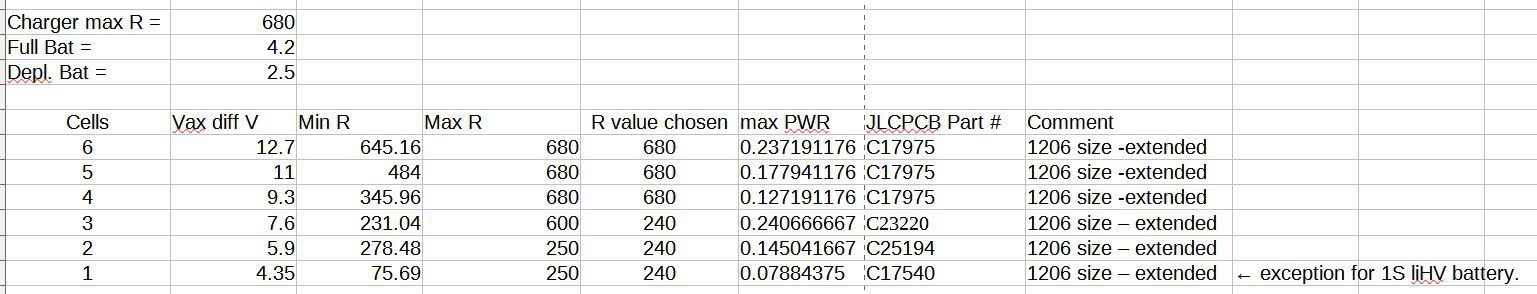

- The charger performs a simple "sanity check' on the connected battery before committing to perform the charging operation. I believe this is just checking voltages at terminals to see if there is a battery connected. If the voltages and impedances aren't within acceptable limits, then the sanity check fails and the charger aborts.

- After the charging begins there is some additional sanity checking. If the impedance on the balance leads is not correct then the charger aborts soon after beginning to charge the battery.

- The charging station must survive a careless user: there must be no requirement to connect batteries or balance leads in any order, swapped balance leads should not destroy components. Dead cells or bad cells should be handled safely.

This parallel charging station must fool the charger into thinking that all is well.

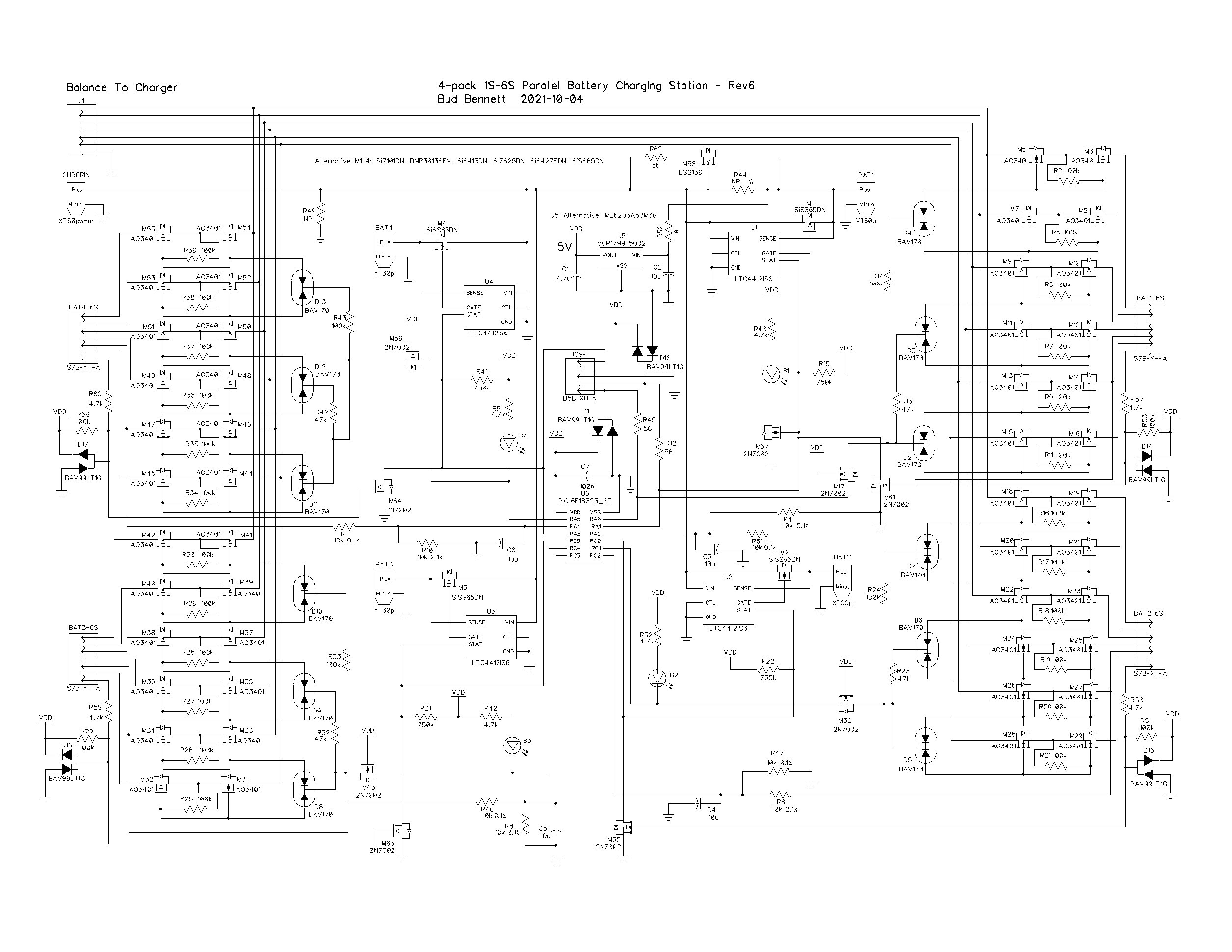

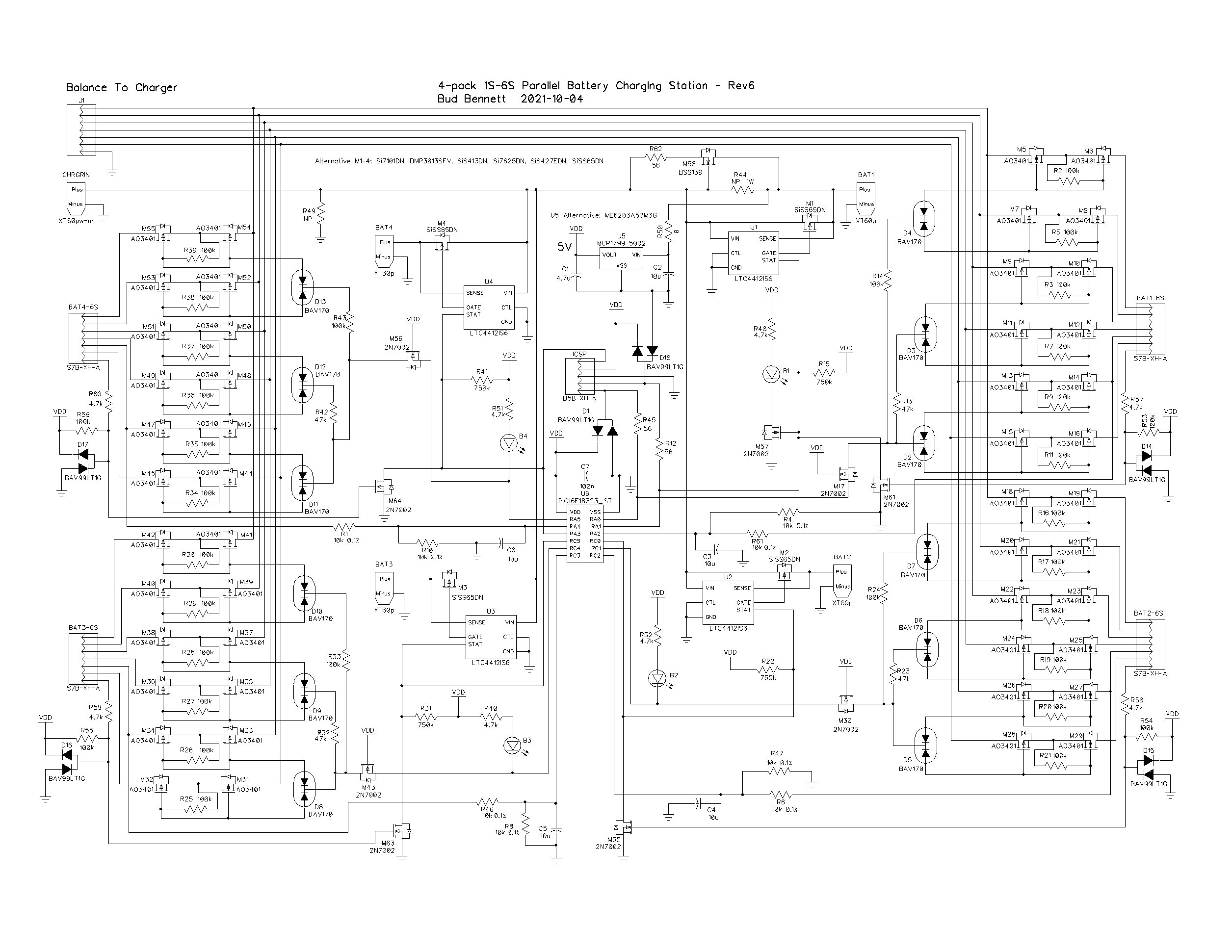

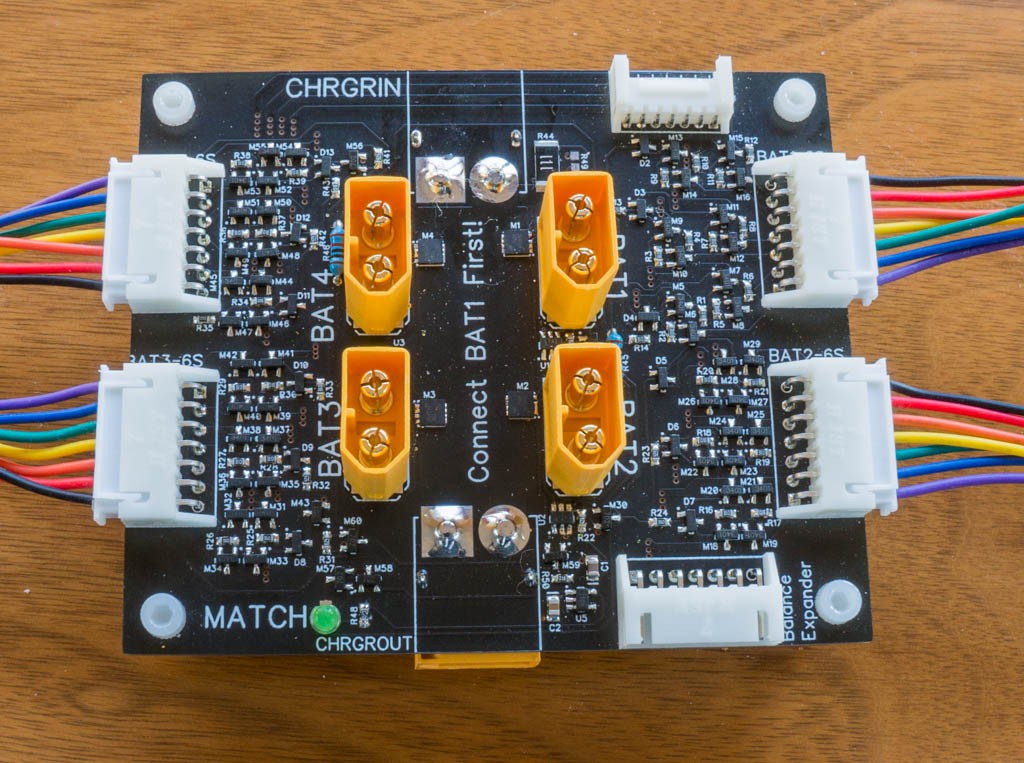

The Schematic to date:

This fixture will charge 1S-6S LiPo, LiFeSO4, Li-Ion, or LiPoHV packs, as long as the cell counts are the same. I'm not sure that it would be a good idea to charge any Nickel-based...

Read more » Bud Bennett

Bud Bennett

George

George

Rory

Rory

Sagar 001

Sagar 001

Hi Bennett, can you share the code to upload to the PIC?