High voltages, like the one in this design are dangerous. It is unsafe for children or users of pacemakers or similar implants.

As noted, the Boost Power Module is the key to the design. It produces a 20,000 volt output from a 3.6 to 6 volt input. While experimenting with how far I can push one, I did manage to overheat it and cause it to internally short out. Luckily, I bought 2 of them. Now I only run the Jacob's Ladder for 10 seconds at a time.

There’s a lot of wire types that can be used for the ladder. I’ve seen the following suggested: stainless steel, zinc-coated steel wire and silver-coated copper wire. The goal is to use something that will resist corrosion (due to heat) while conducting the electricity. I recommend using inexpensive gold-filled wire. It meets all the requirements, looks cool, easy to work with and one only needs to buy 1 ft (30 cm) of it. Cut in half & trim as needed.

Rechargeable LiFePO4 batteries are required due to their high current output and low voltage (as compared to the more common lithium-ion battery (3.2V vs 3.7V)). The original design suggested using AA size batteries. I thought having AA batteries around with different voltages was a bad idea, so I used a larger size.

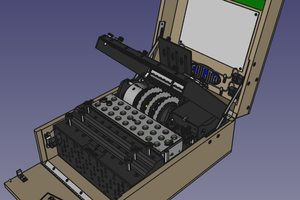

The bottom case has extrusions which hold the components in place. Mounting the battery holder is easy because it just plugs into the top 3D printed case.

In case you’re wondering why I used a 4-position terminal block, you’re not alone. A 3-position would have been fine, but I already designed the case for the 4-position. The conductor in the second position was removed (which took some work). I wanted to make sure the spark wouldn’t cross over to it (even though I doubt it would). See the picture of the inside of the case.

The push button switch is easy to mount because the 3D printed case holds the nut in place. The lock washer that comes with the switch is not used.

The jar is a common jelly type jar with a thin depth lid. It’s only about 0.4” (12 mm) deep with 4 internal prongs (used to grab the jar) spaced 90⁰ from one another. If the lid has visible threads, it’s on the wrong type of jar.

An optional small magnet (any type) can be used to help the spark climb the ladder. The south side should face up.

James Dietz

James Dietz

adriancubas

adriancubas